Thin-part flatness shaper

A flatness and shaping machine technology, applied in measuring devices, instruments, etc., can solve the problems of unsatisfactory flatness shaping effect of thin parts, inability to realize automatic detection and shaping, low detection accuracy and detection efficiency, etc., to achieve reliable fixation and shaping. Good effect and high shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

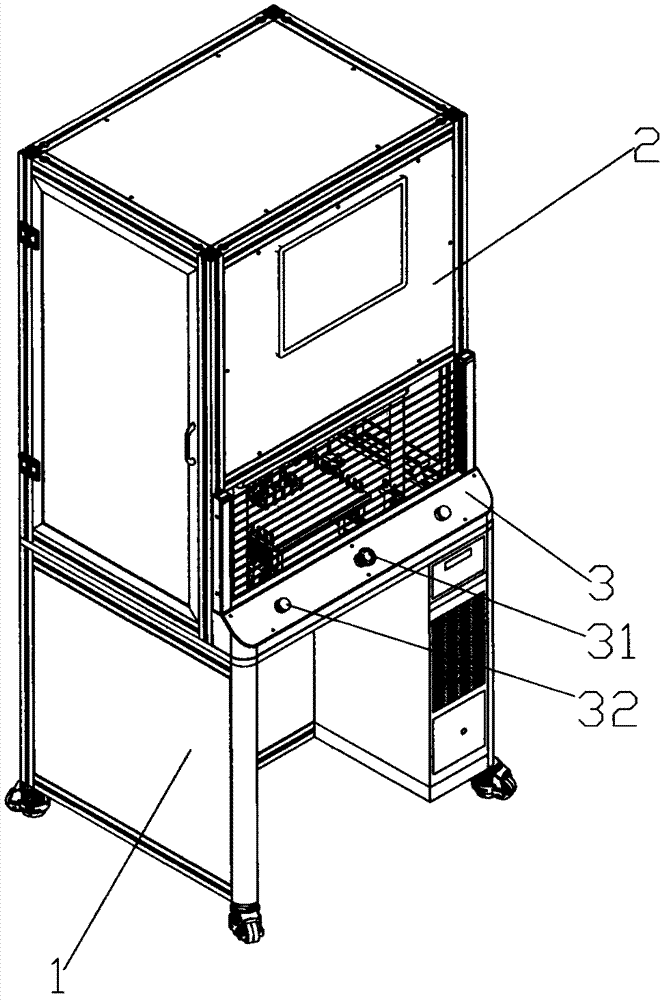

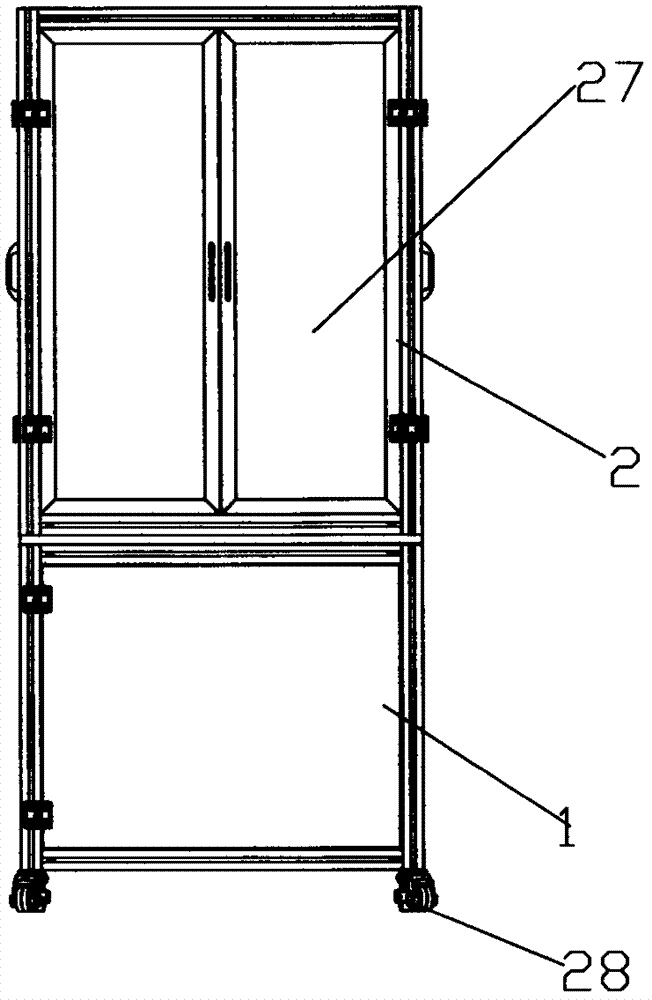

[0024] Such as Figure 1 to Figure 6 As shown, a flatness shaping machine for thin parts includes a frame 1 on which a protective frame 2 and a control box 3 are arranged. Caster wheels 28 can also be set at the bottom of the frame 1, which is convenient for moving the whole machine. The guard frame 2 has a door body 27, the control box 3 is provided with an emergency stop switch 31 and a start switch 32, and the guard frame 2 is provided with a flatness detection and shaping device arranged on the frame 1;

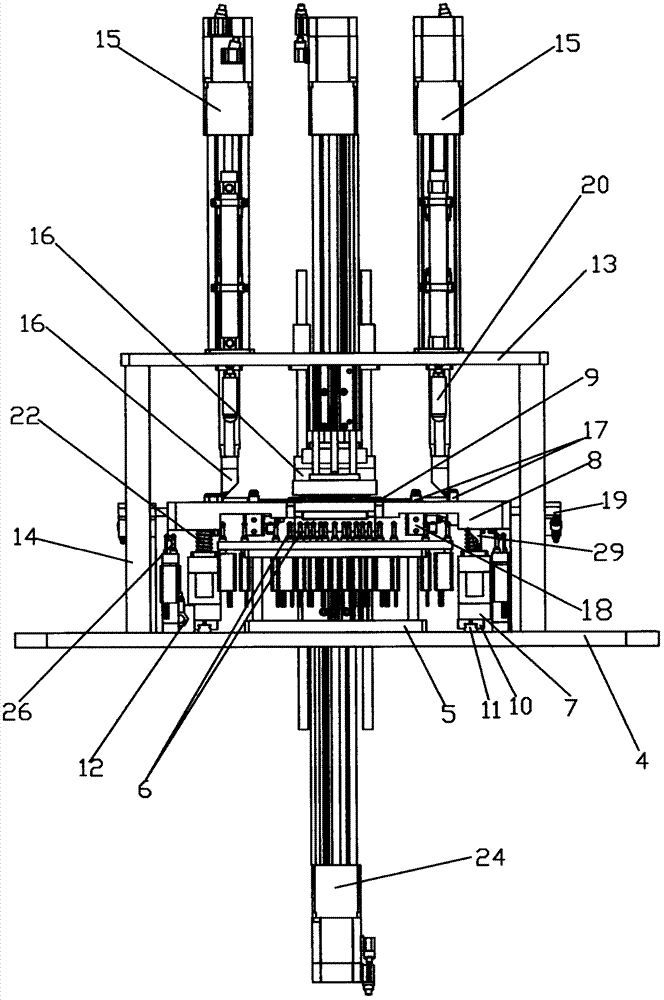

[0025] The flatness detection and shaping device includes a testing mechanism, a thin piece clamping mechanism and a thin piece shaping me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com