Patents

Literature

31results about How to "Guaranteed plastic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

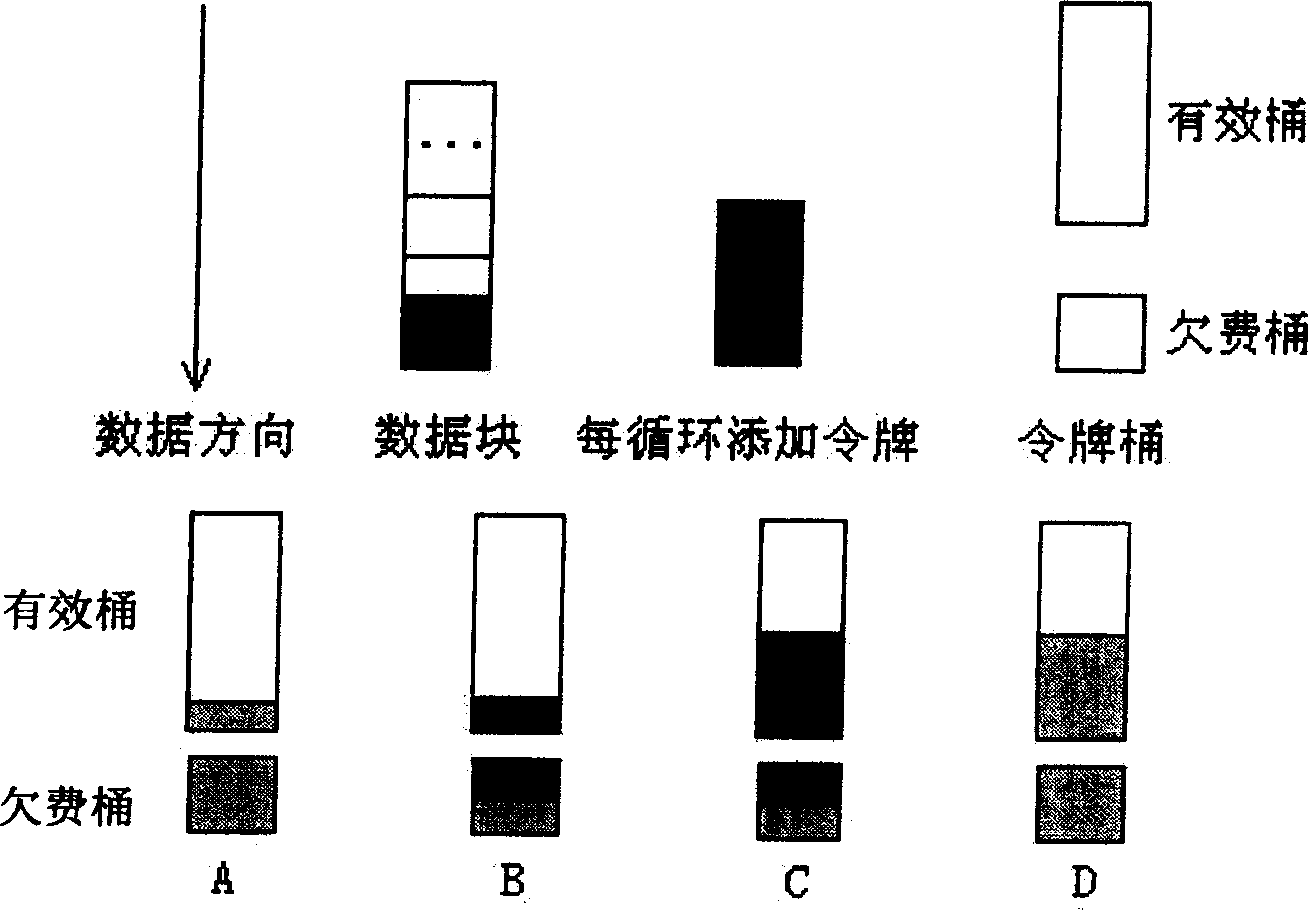

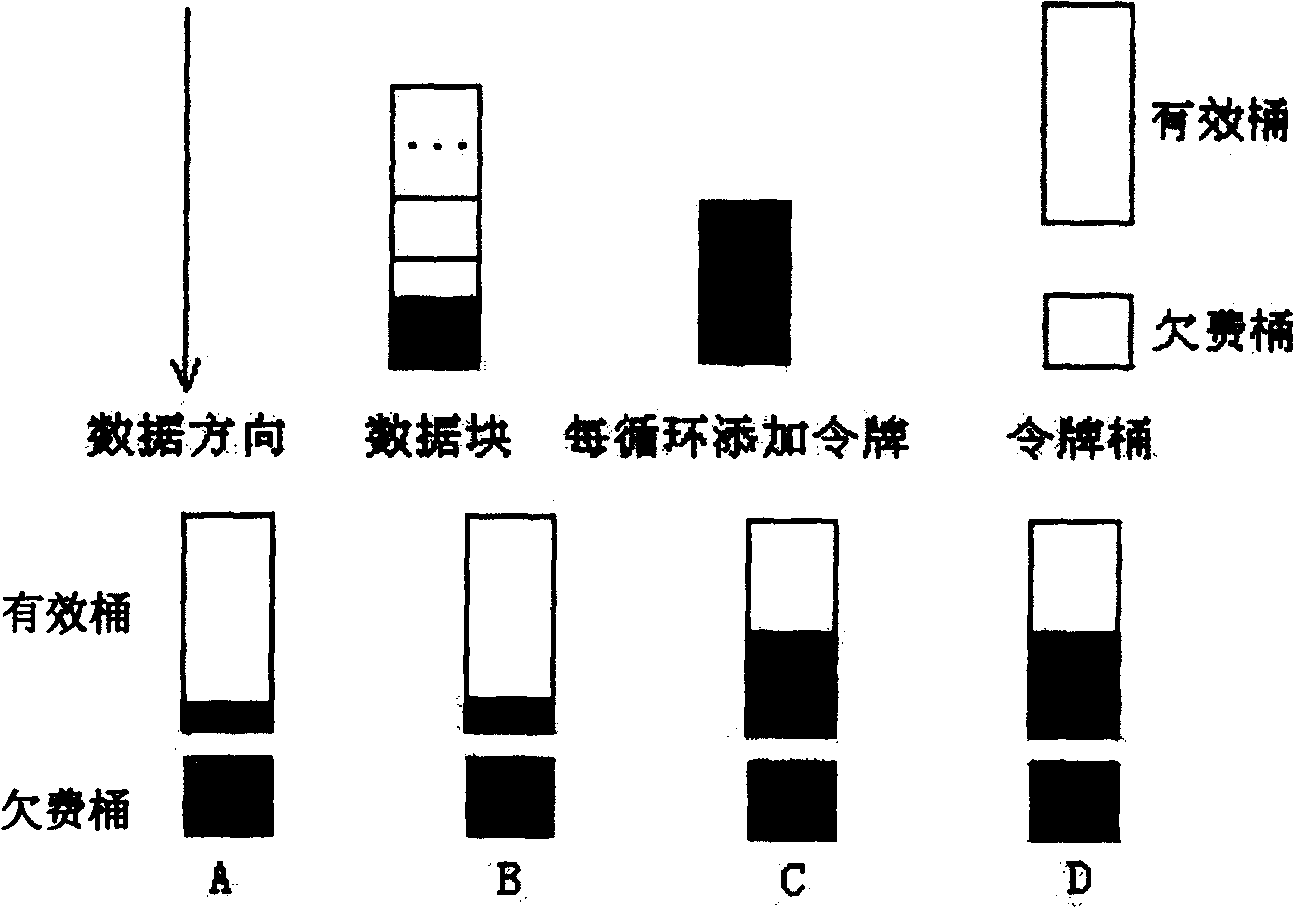

Realizing method of data stream constraint control

ActiveCN1835447AReduce storage spaceImprove pass rateData switching networksData streamConstraint control

The method comprises: constructing a token bucket that includes depth parameter and bandwidth parameter; the depth of the token bucket is sum of the fixing token bucket value and the dynamical token bucket depth value; in term of flow rate allocating to users, the relevant token numbers are added into the token bucket, and meanwhile in term of actual flow rate of users, the token numbers is subtracted from the token bucket; before subtracting the token numbers, it is made illegal that the token numbers is small than the depth value of fixing token bucket; when the token is added at the next time, firstly the depth value of fixing token bucket is filled up, and then the flow rate of users is allowed to pass through; it also can be implemented by adding tokens based on flow rate; the depth value of dynamical token bucket varies along with maximum bandwidth; the depth value of fixing token bucket can be a token numbers corresponding to a length of packet with maximum data length.

Owner:HUAWEI TECH CO LTD

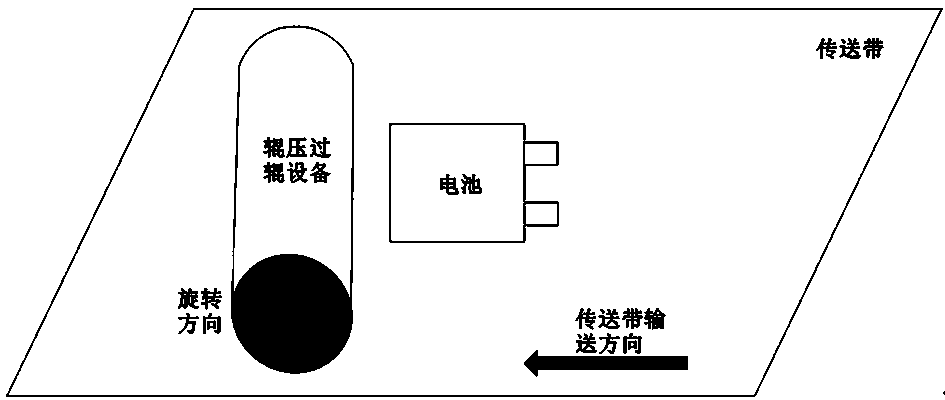

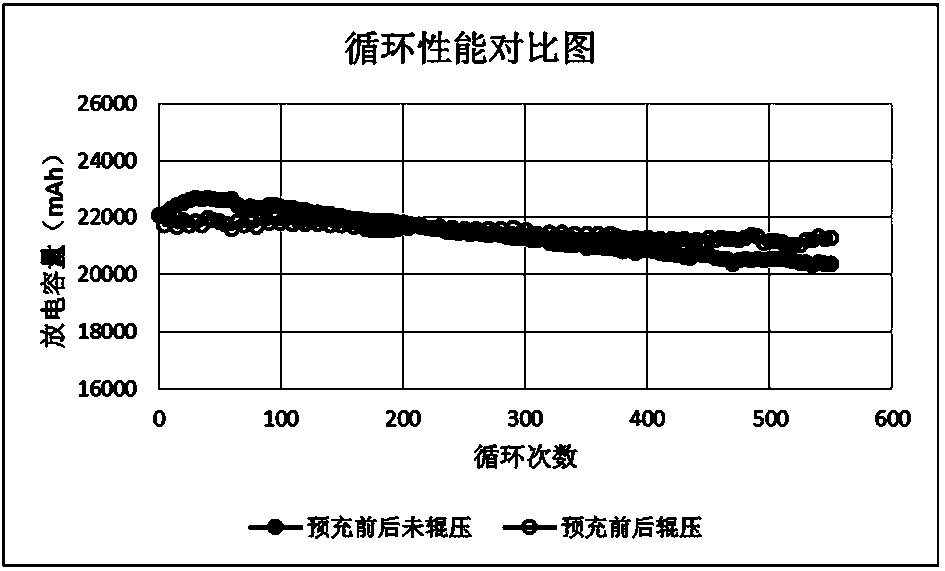

Novel control method for improving lithium ion soft-package laminated battery diaphragm fold

InactiveCN108155424AImprove performanceGuaranteed plastic effectFinal product manufactureSecondary cells charging/dischargingElectrical batteryPre-charge

The invention relates to a novel control method for improving lithium ion soft-package laminated battery diaphragm fold. The problem that the battery performance is influenced due to the fold of the soft-package laminated lithium ion battery diaphragm is solved. The control method comprises the following steps: laying down a battery after liquid injection, thereby ensuring that the electrolyte sufficiently infiltrates a pole piece; and then performing rolling on the lay-down battery, and controlling the pressure and speed of the rolling in the rolling process; pre-charging the battery after the rolling is ended; and performing secondary rolling on the completely pre-charged battery, further shaping the diaphragm, and releasing the gas to finish the secondary package. The contacting interface between a positive / negative pole piece and the diaphragm is better by comparing the lithium ion soft-package laminated battery prepared based on the control method with the battery without performing the rolling shaping, the dead lithium existing in the fold area caused by the diaphragm fold is avoided, thus the capacity of the positive / negative material is sufficiently played, and the batteryperformance is improved.

Owner:JIANGSU FRONT NEW ENERGY +1

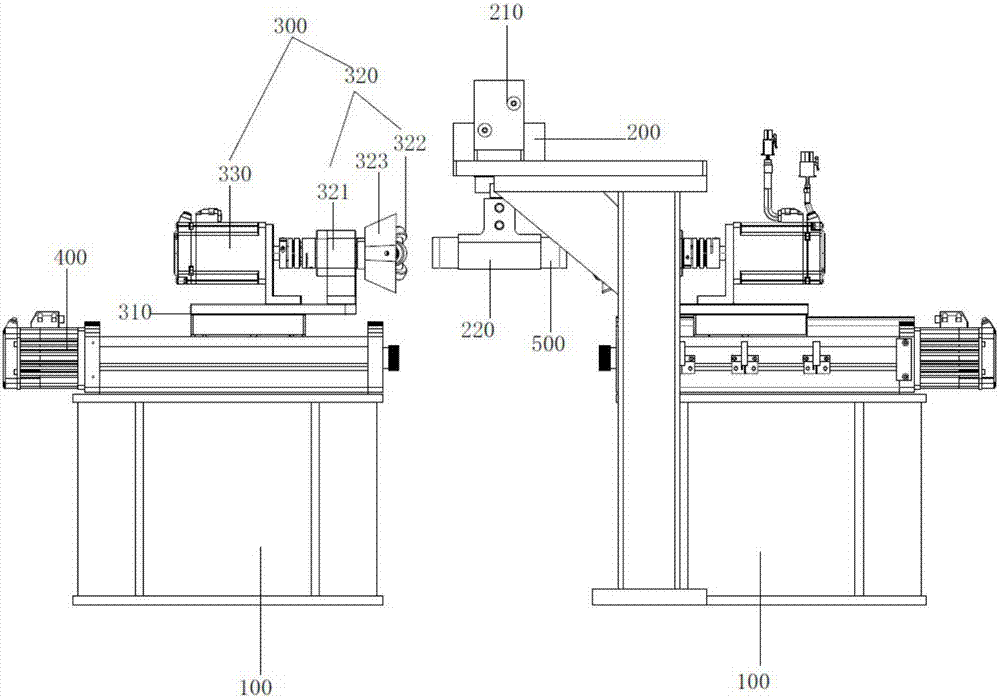

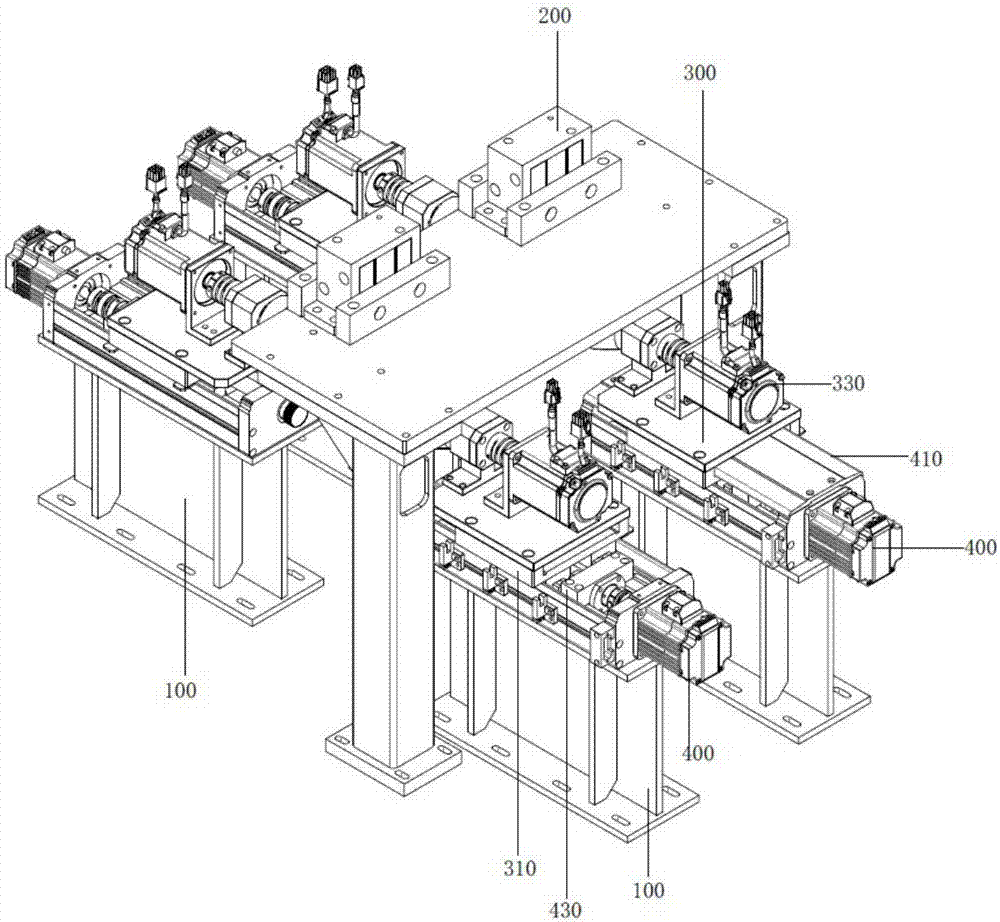

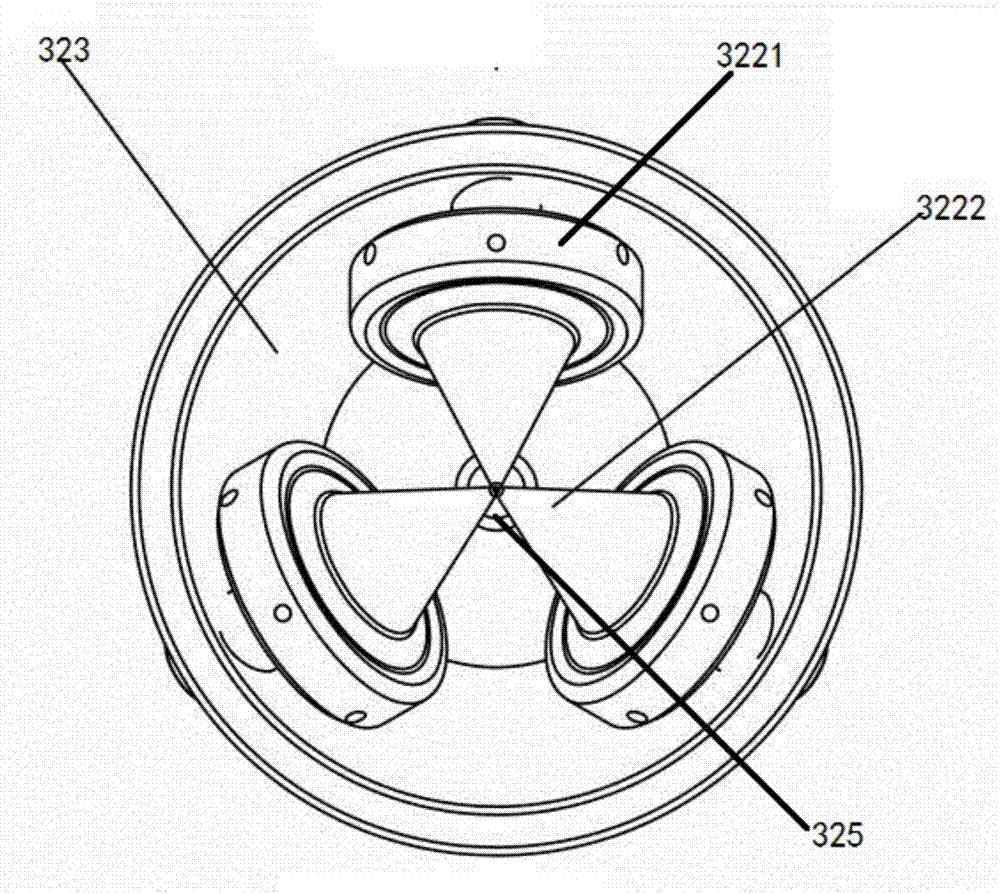

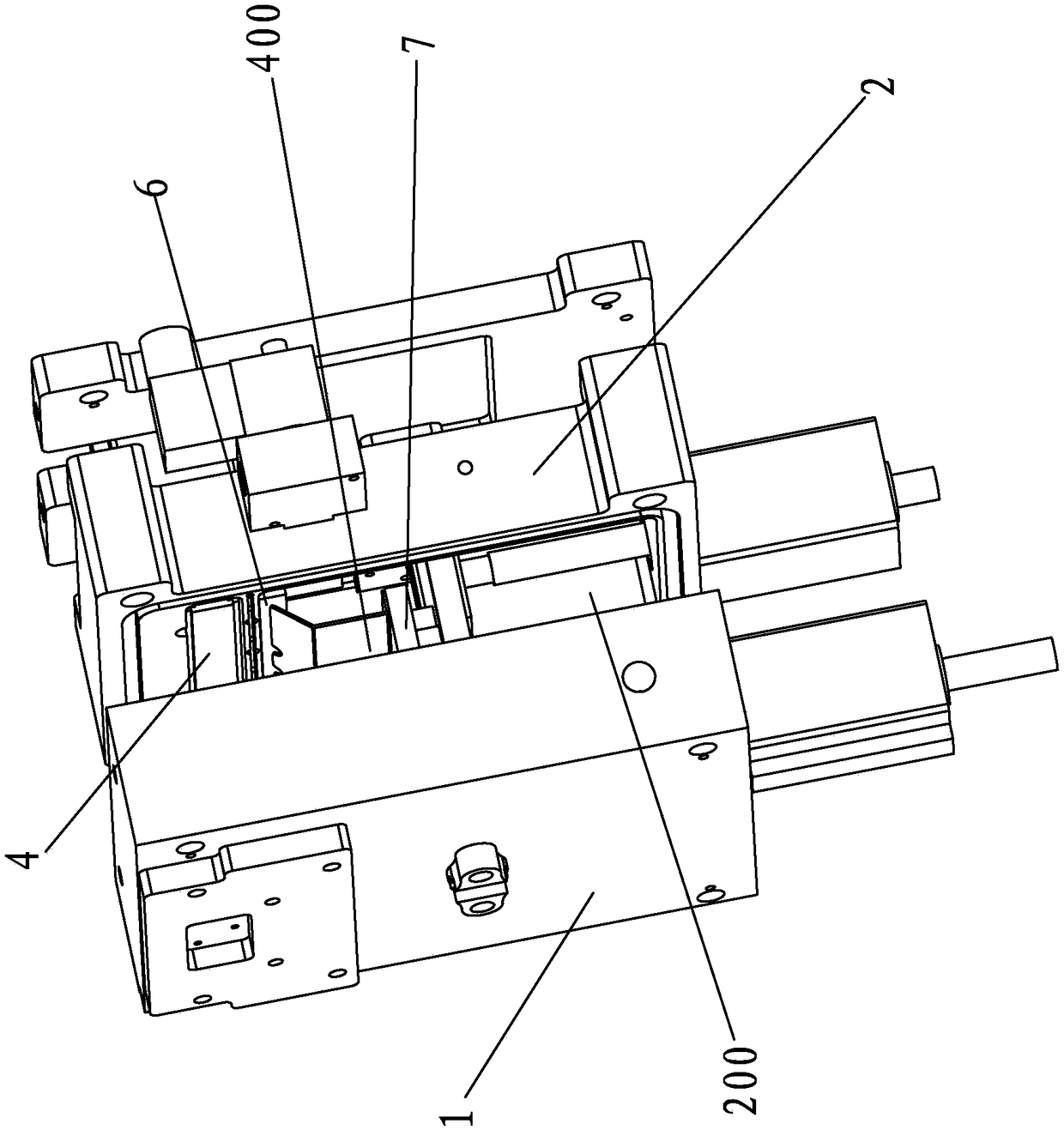

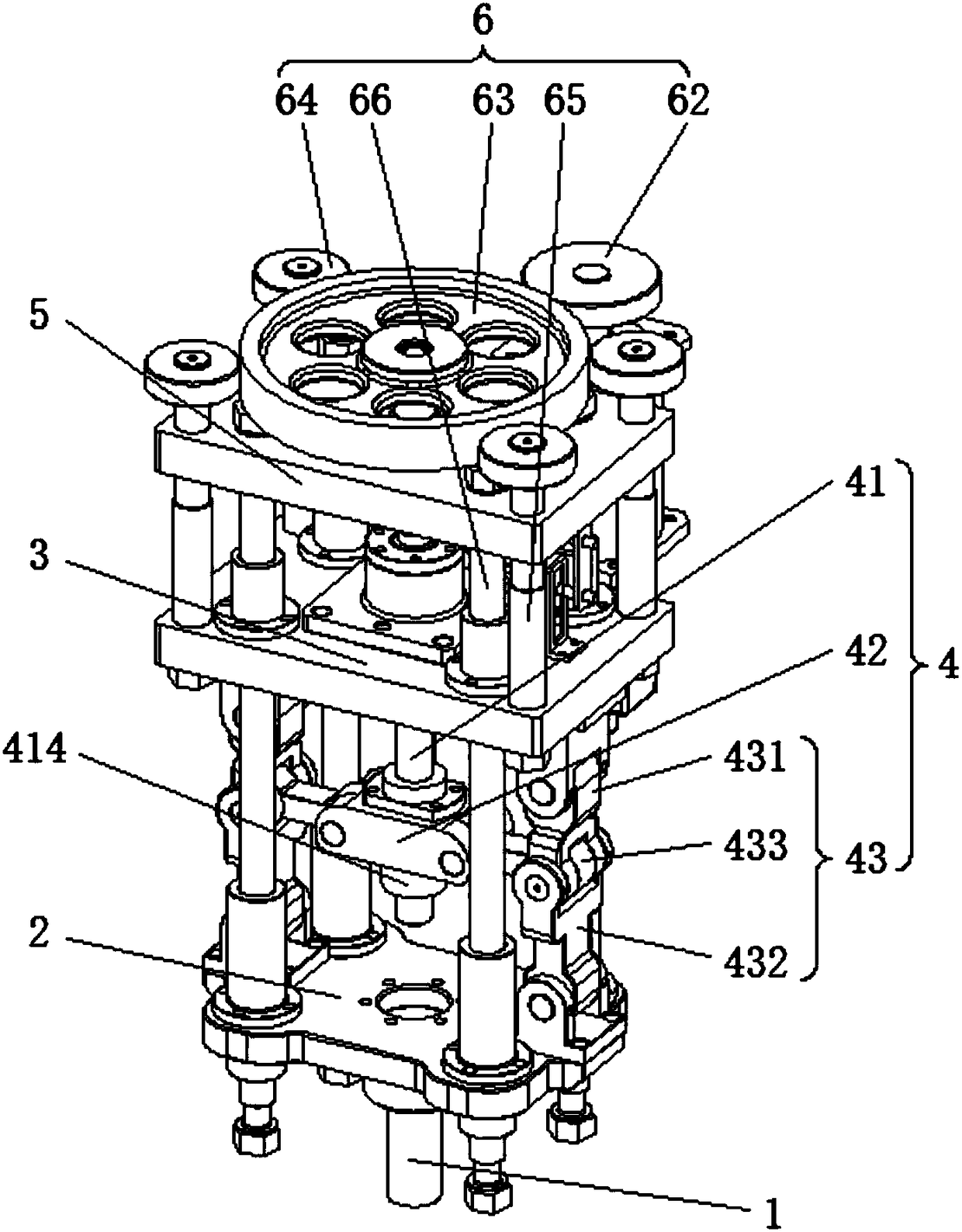

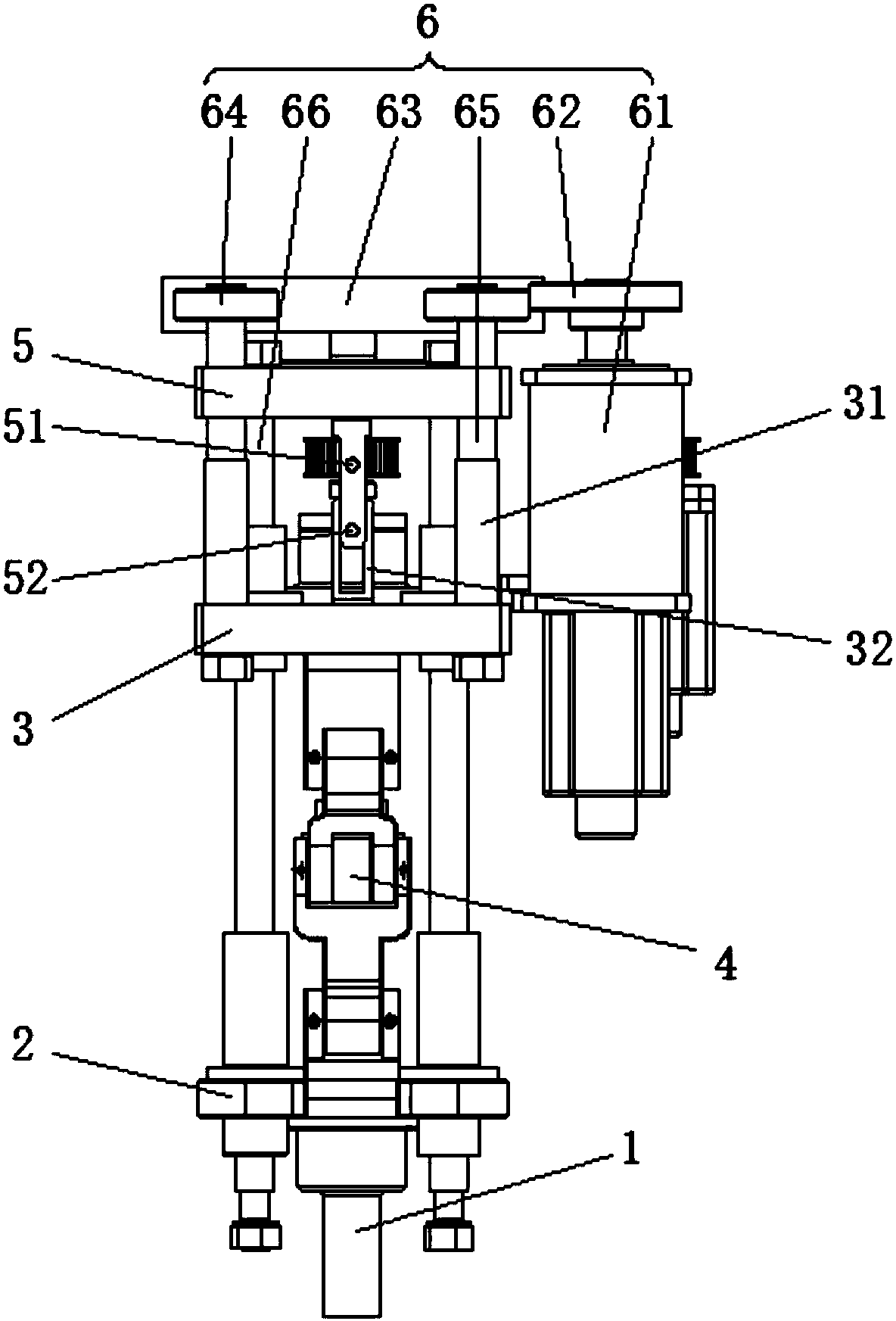

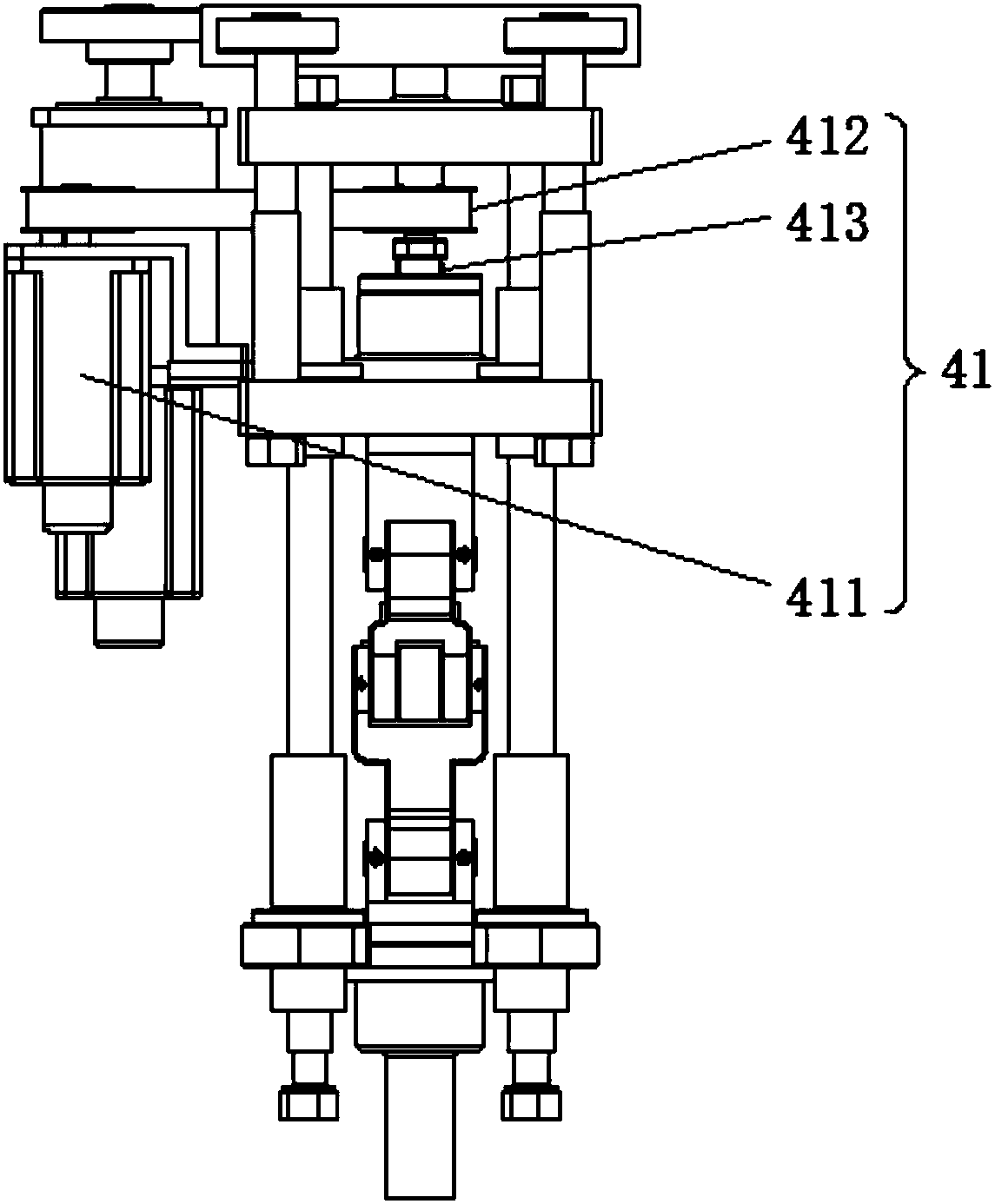

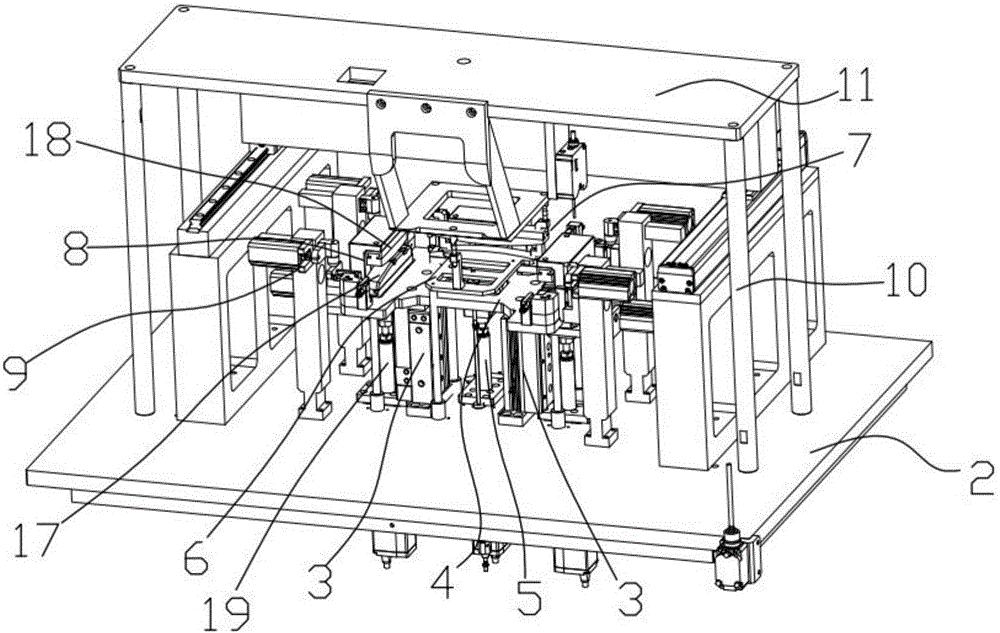

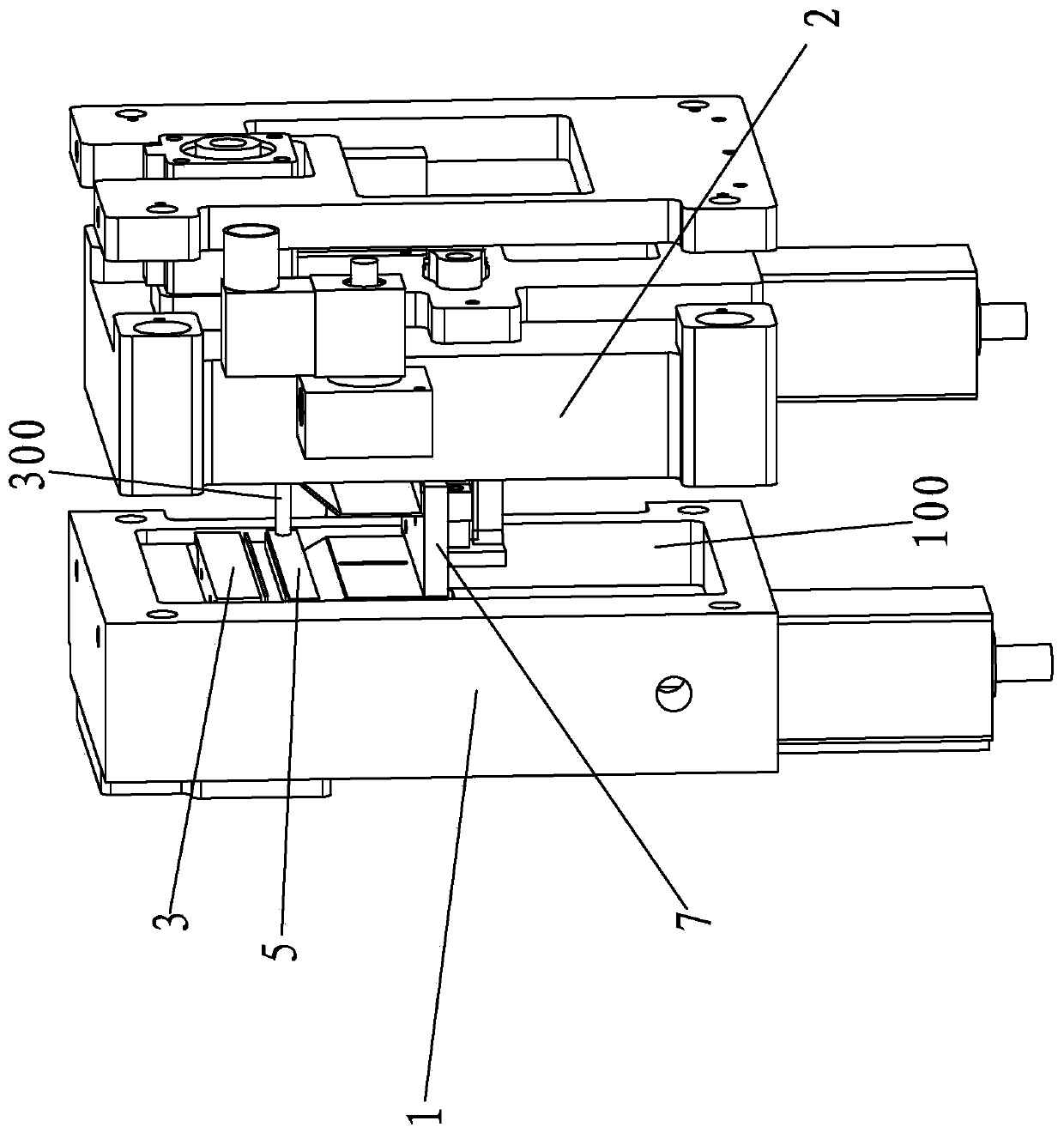

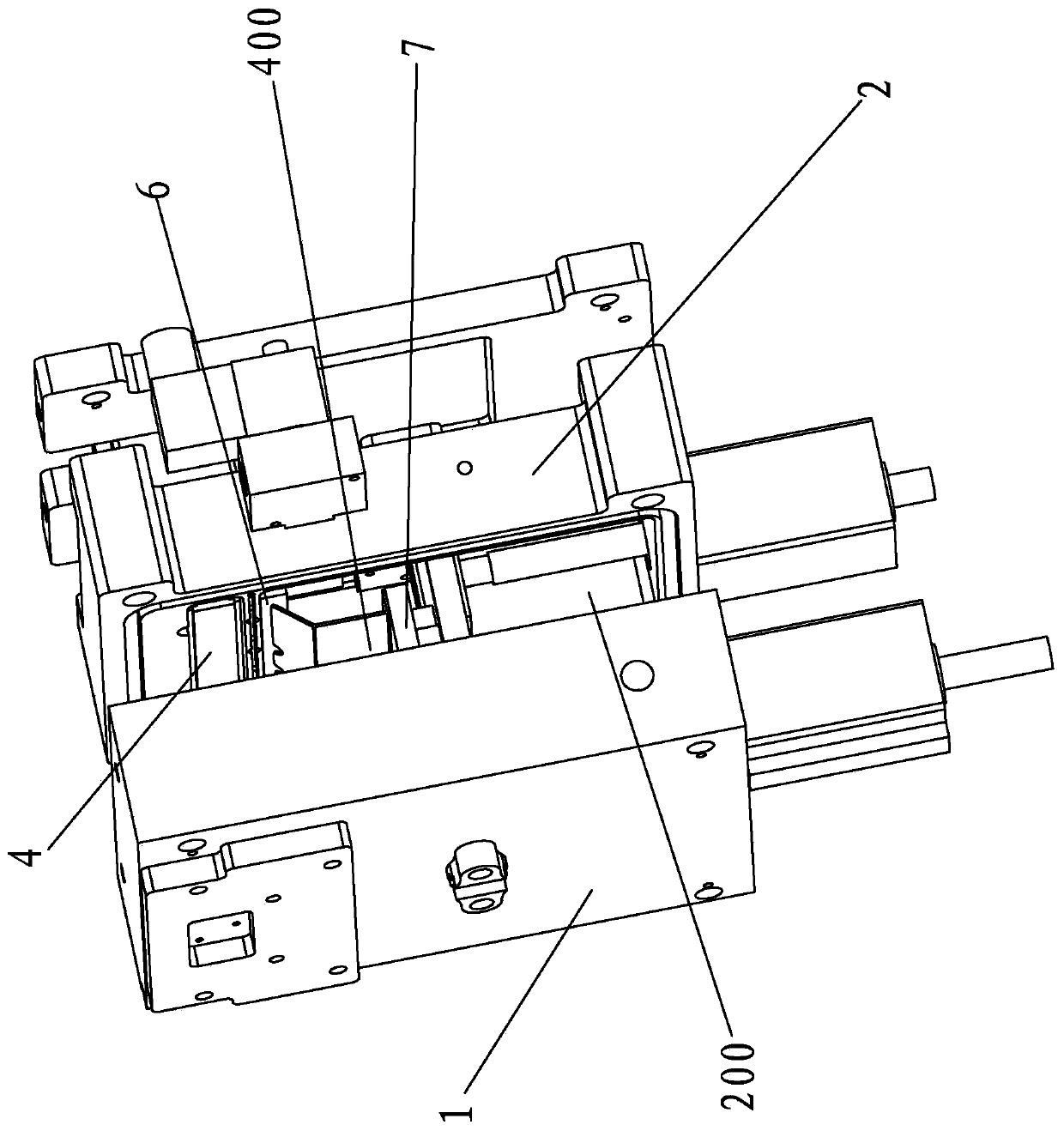

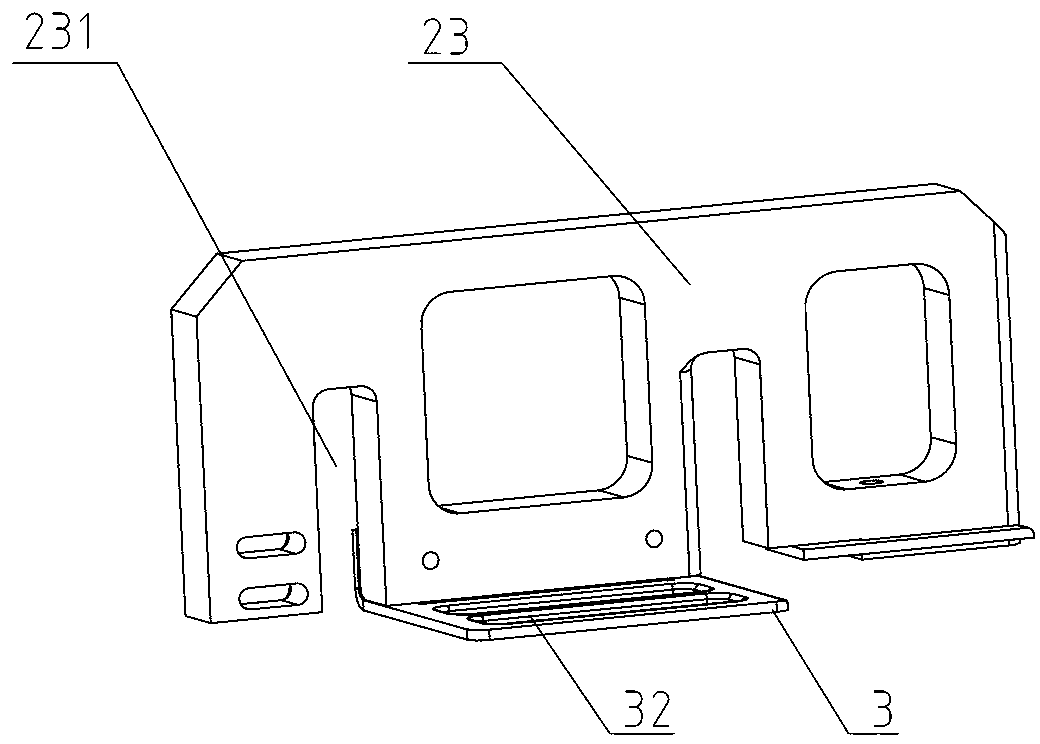

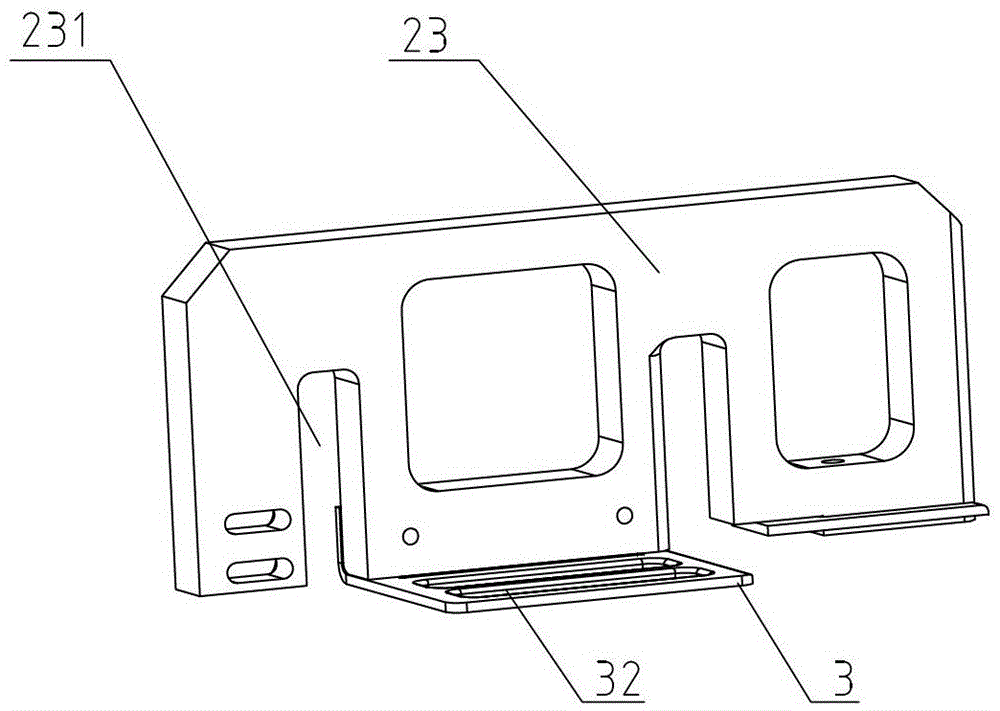

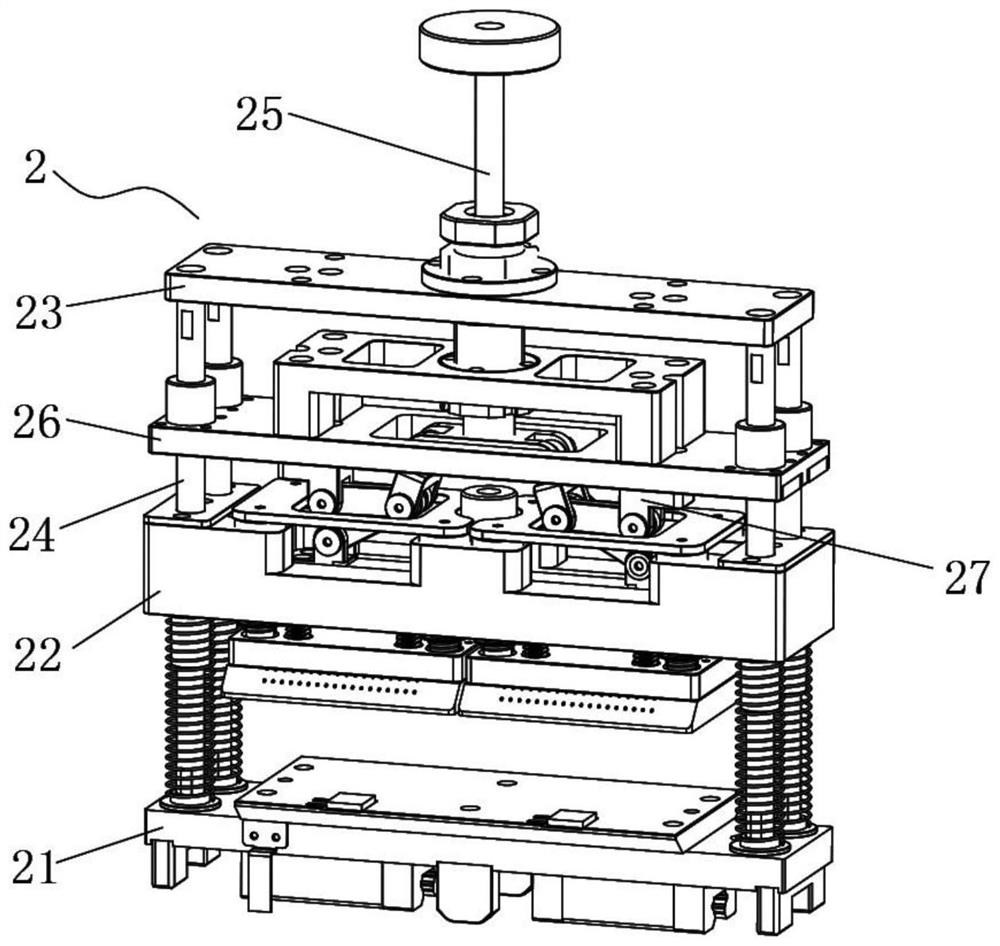

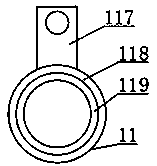

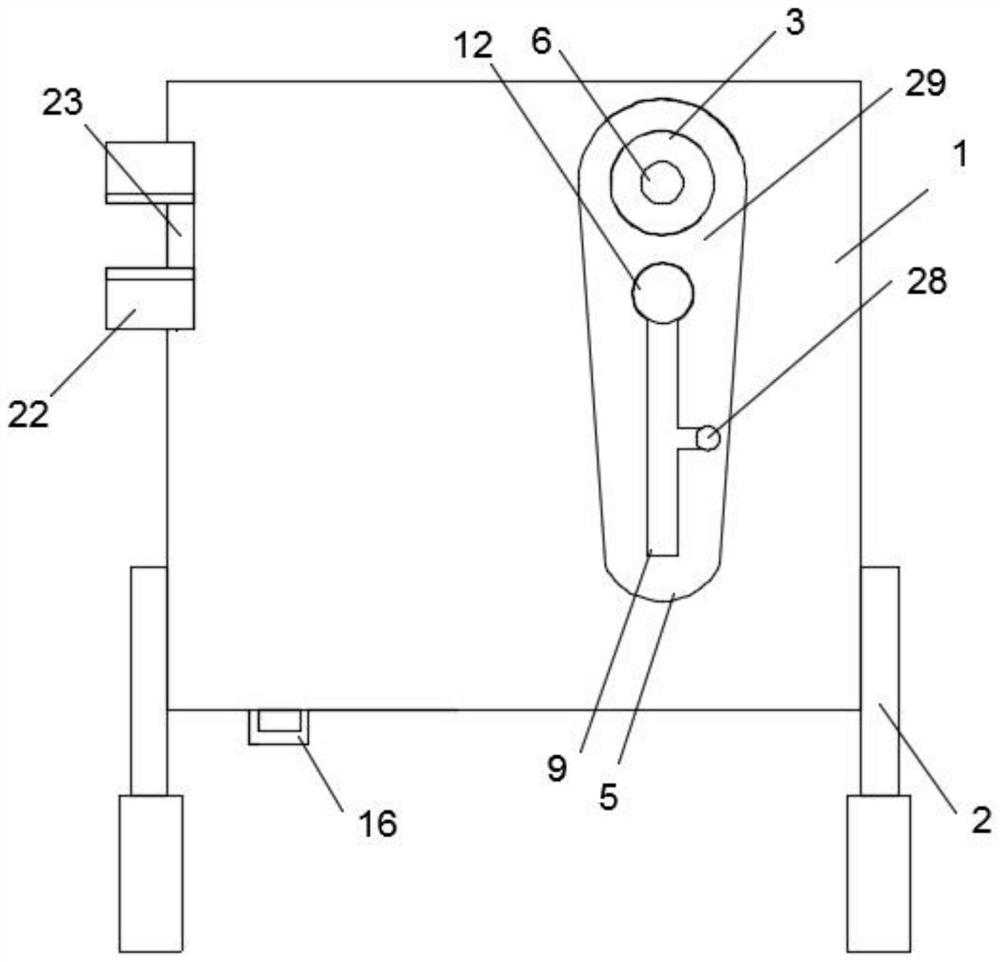

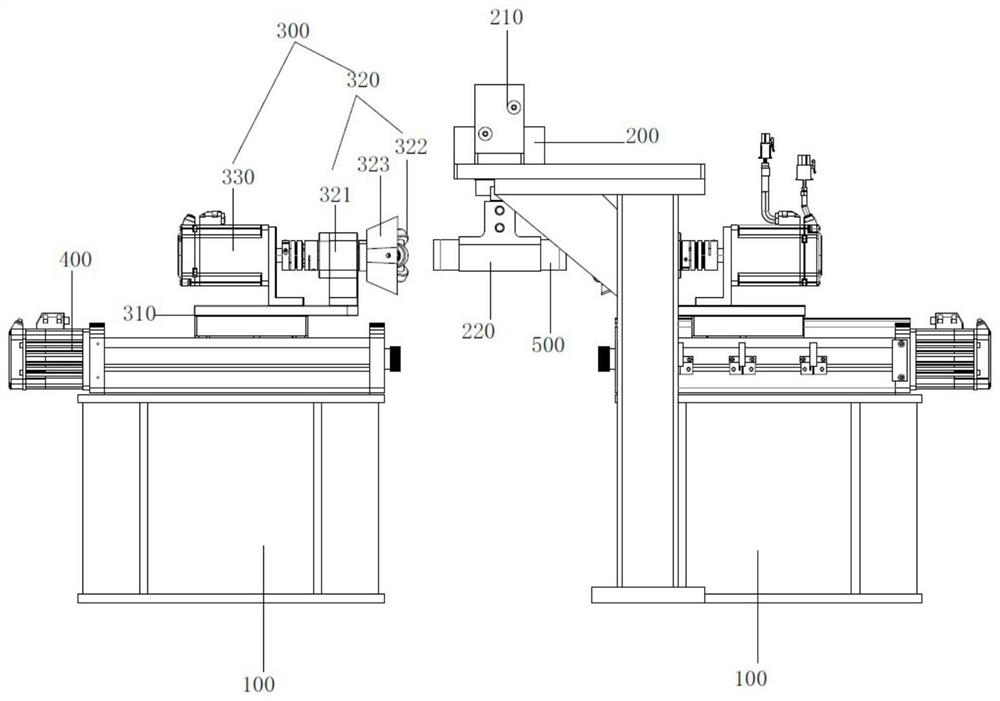

Electric core end face kneading flattening device

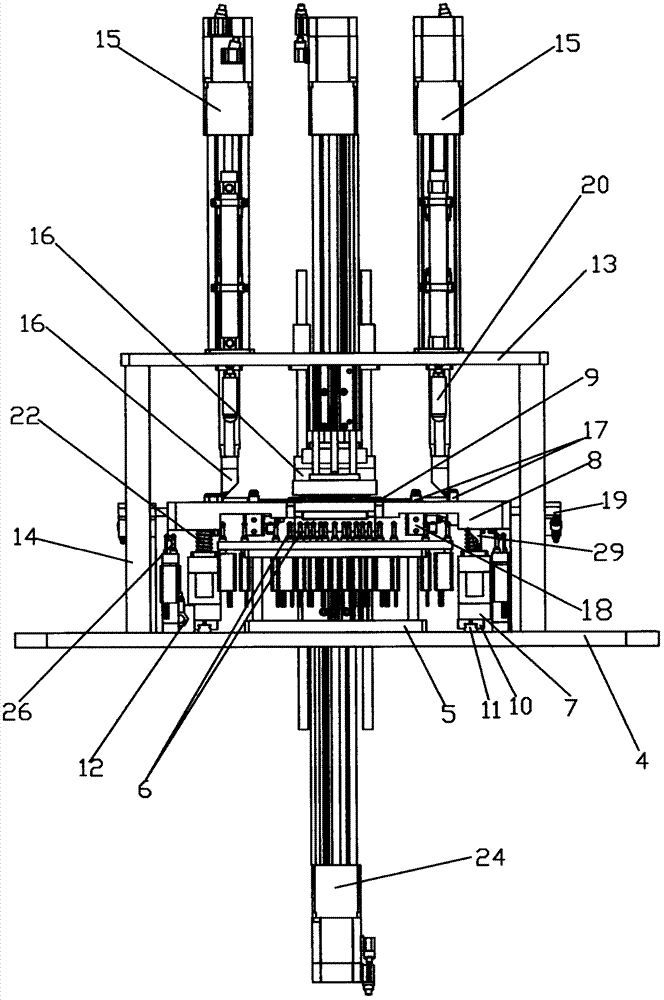

ActiveCN107394248ARealize automatic reversingImprove processing efficiencyAssembling battery machinesFinal product manufactureElectrical and Electronics engineeringEngineering

The present invention provides an electric core end face kneading flattening device, which comprises a frame, an electric core clamping device and a kneading flattening device, the electric core clamping device and the kneading flattening device are correspondingly arranged, the electrical core clamping device is arranged on the frame through a rotating device, the kneading flattening device is installed slidably on the frame, and a sliding seat can move front and back relatively to the kneading flattening device. The electric core clamping device and the kneading flattening device are arranged on the frame, the electric core clamping device is used for fixing and clamping an electric core to match with the kneading flattening device for kneading flattening shaping of end faces of the electric core, meanwhile the electrical core clamping device is arranged on the frame through the rotating device, the rotating device drives the electric core clamping device to rotate so as to realize the automatic reversing of the electric core, the processing efficiency is improved, labor intensity is reduced, clamping error caused by secondary clamping can be avoided, wherein the clamping error can lead to differences in shaping effect of the two end faces of the electric core, and can affect the processing quality.

Owner:WUHAN YIFI LASER EQUIP CO LTD

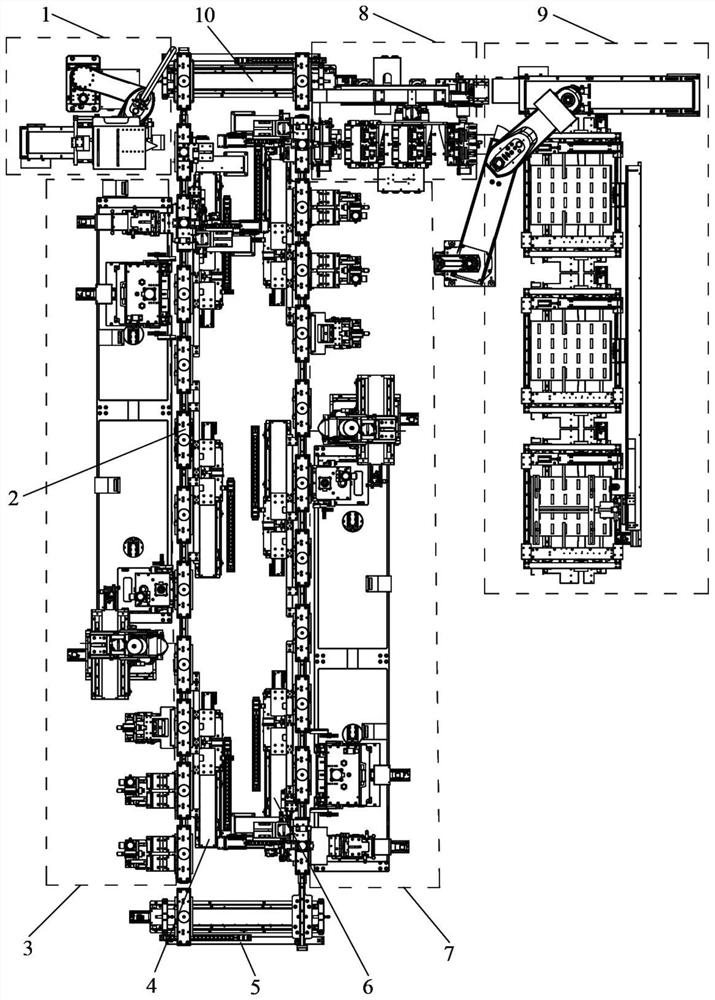

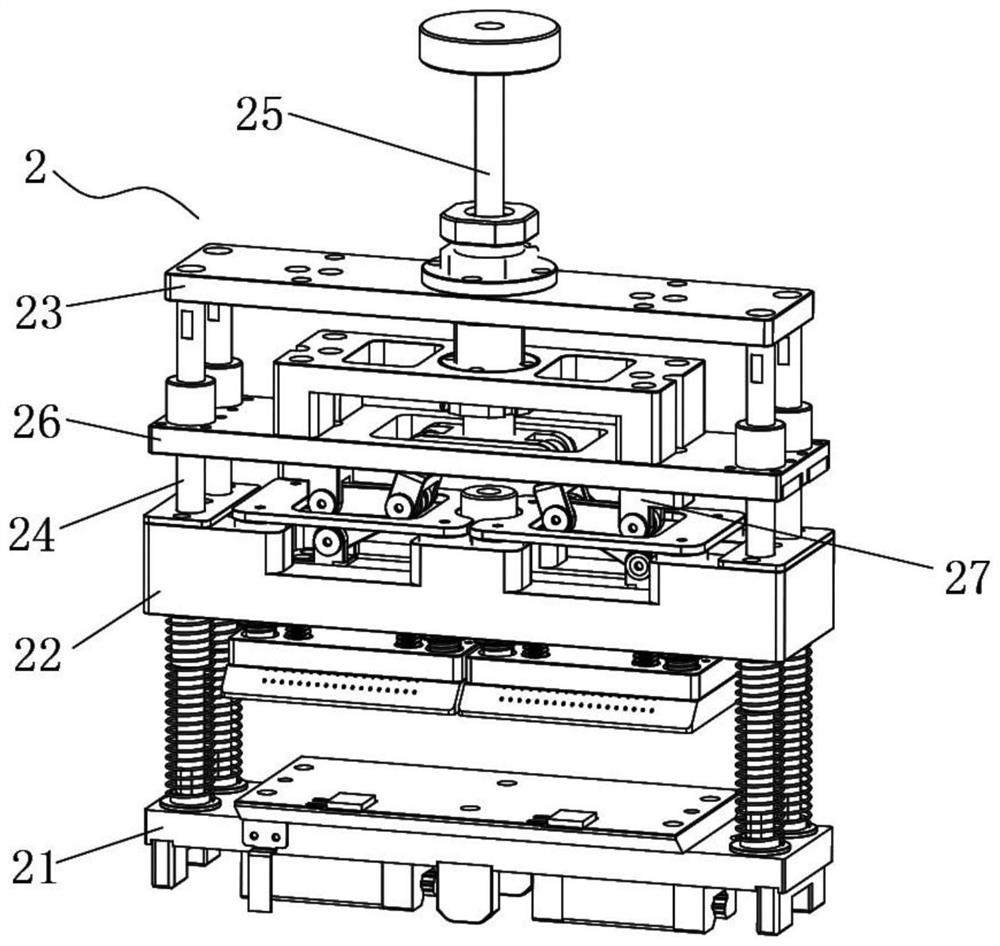

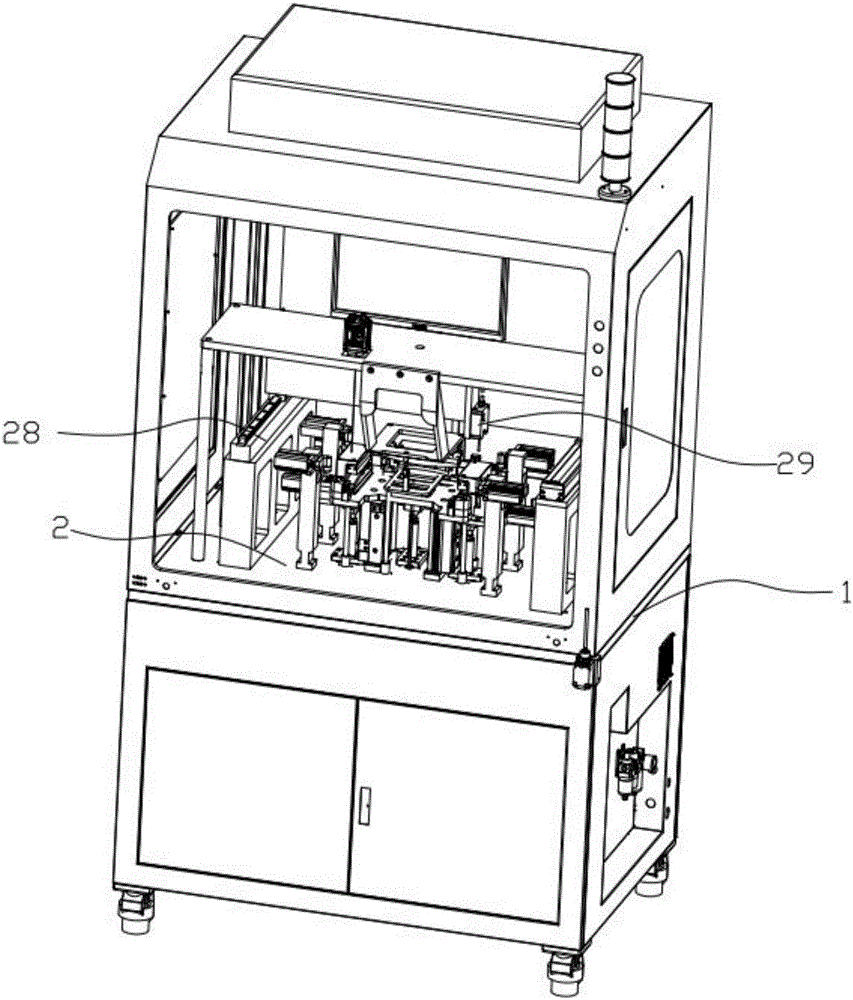

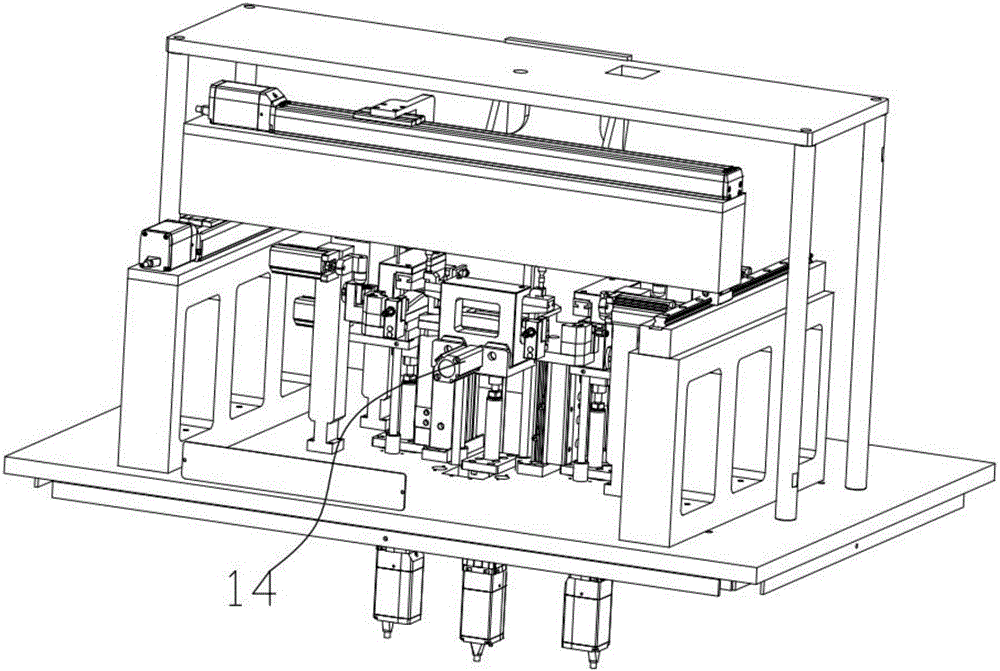

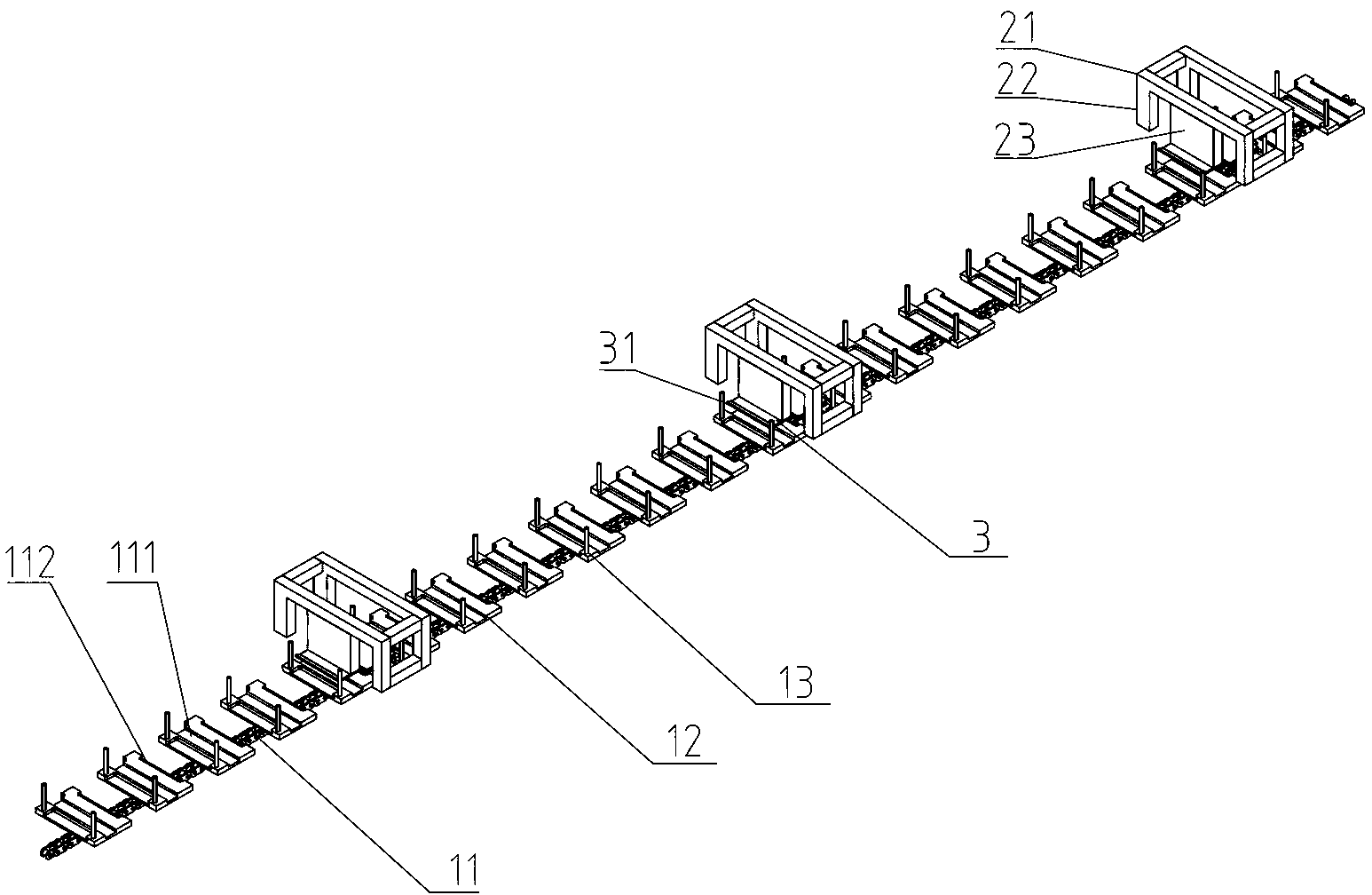

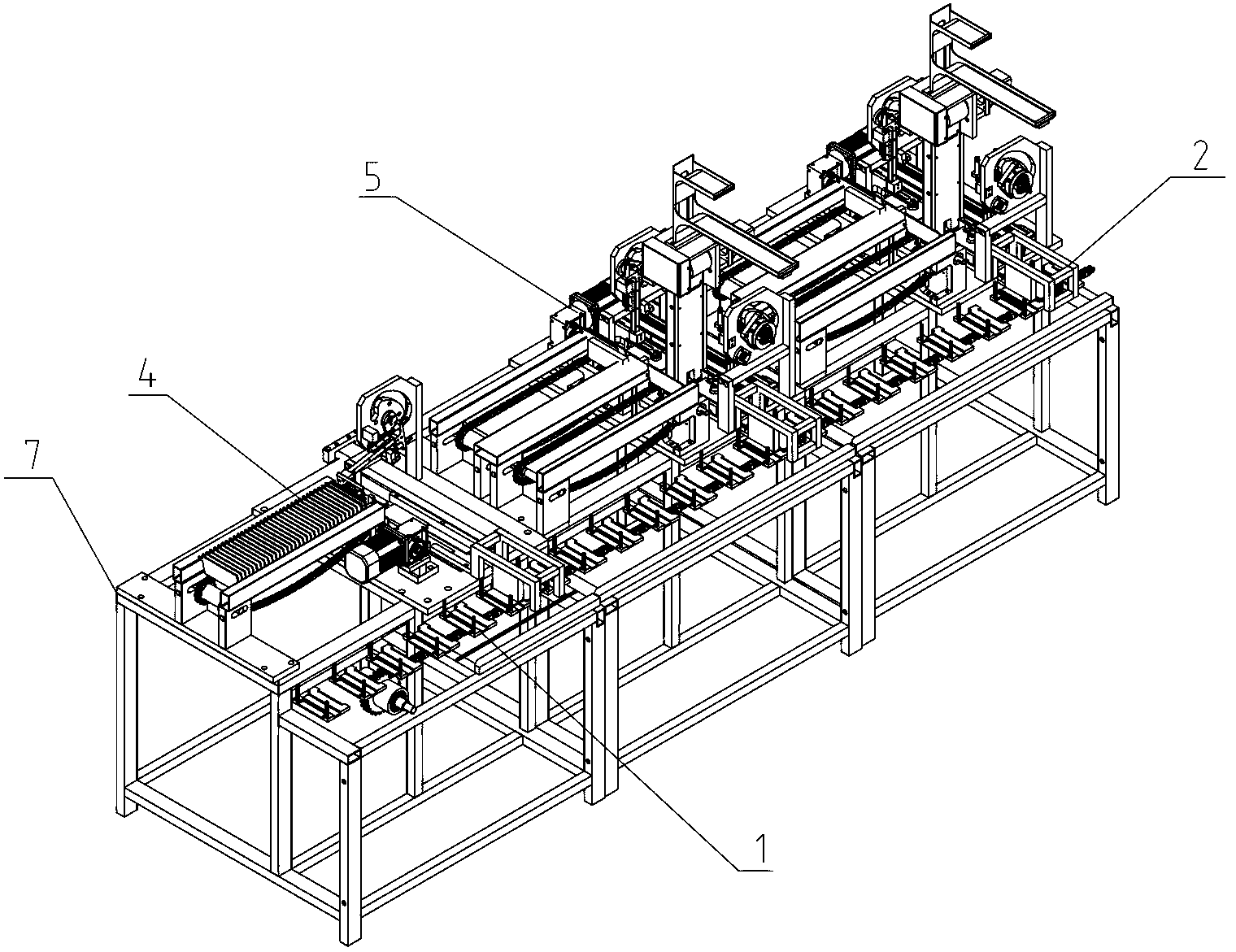

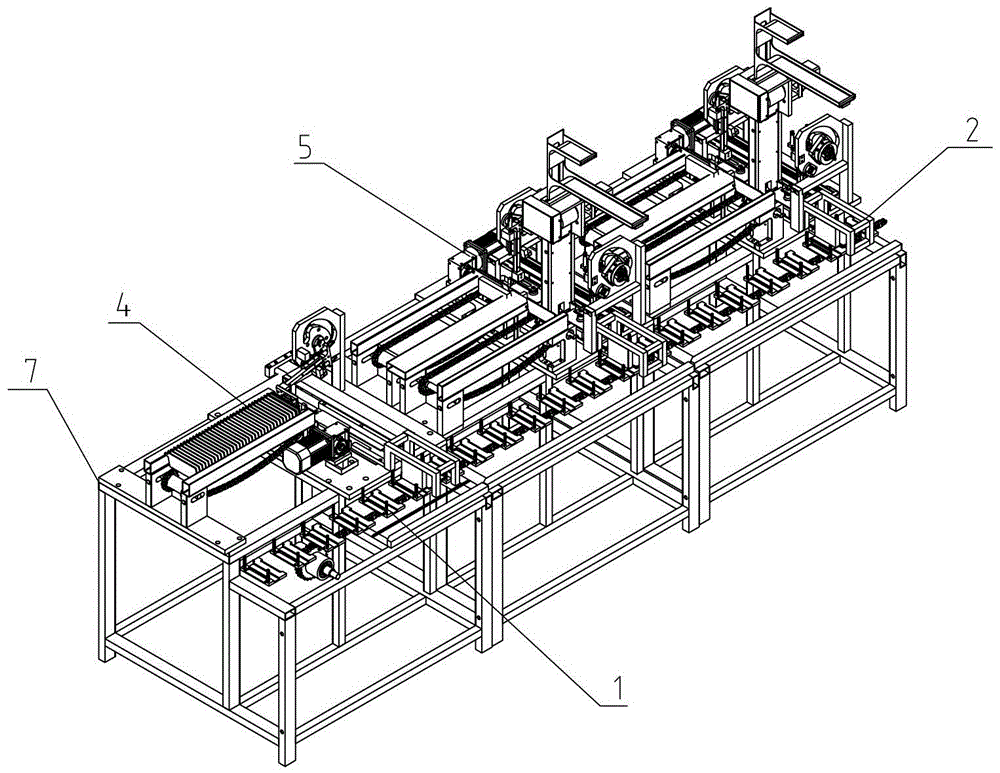

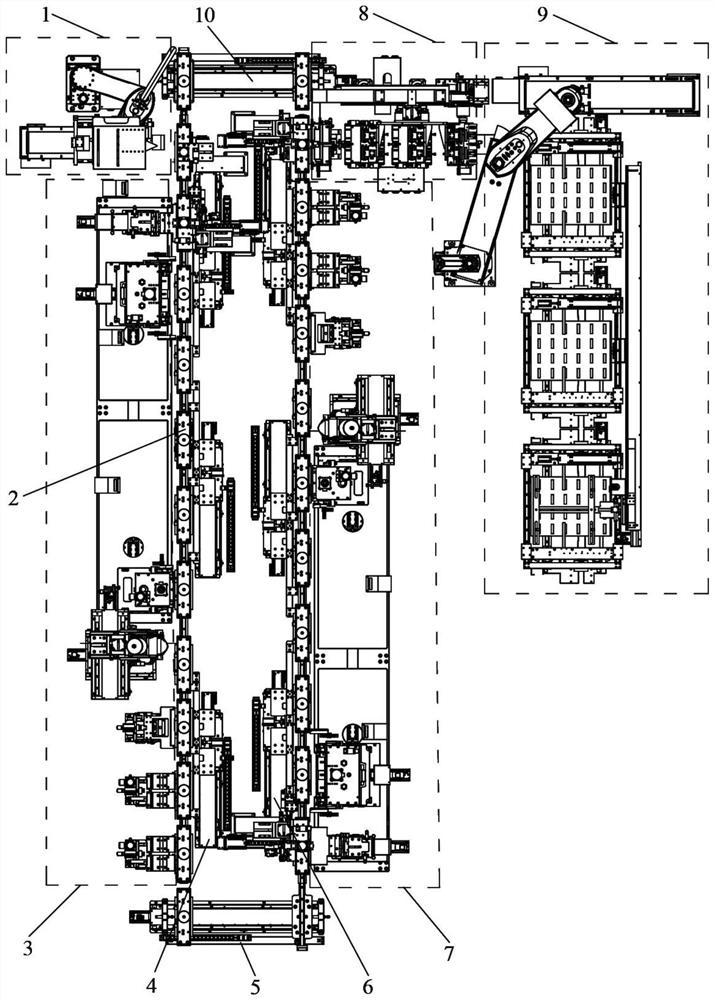

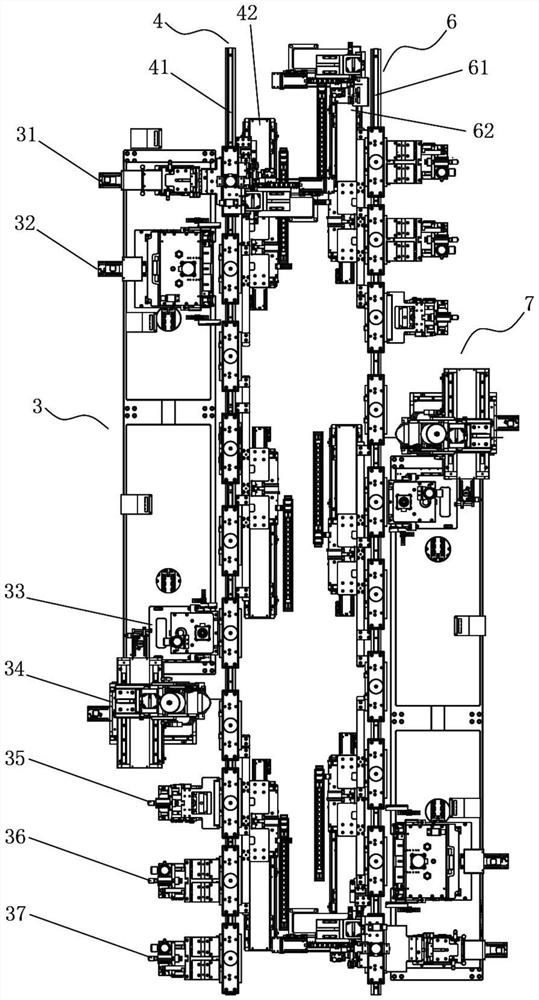

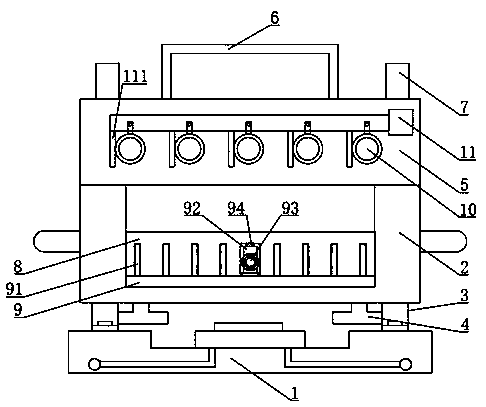

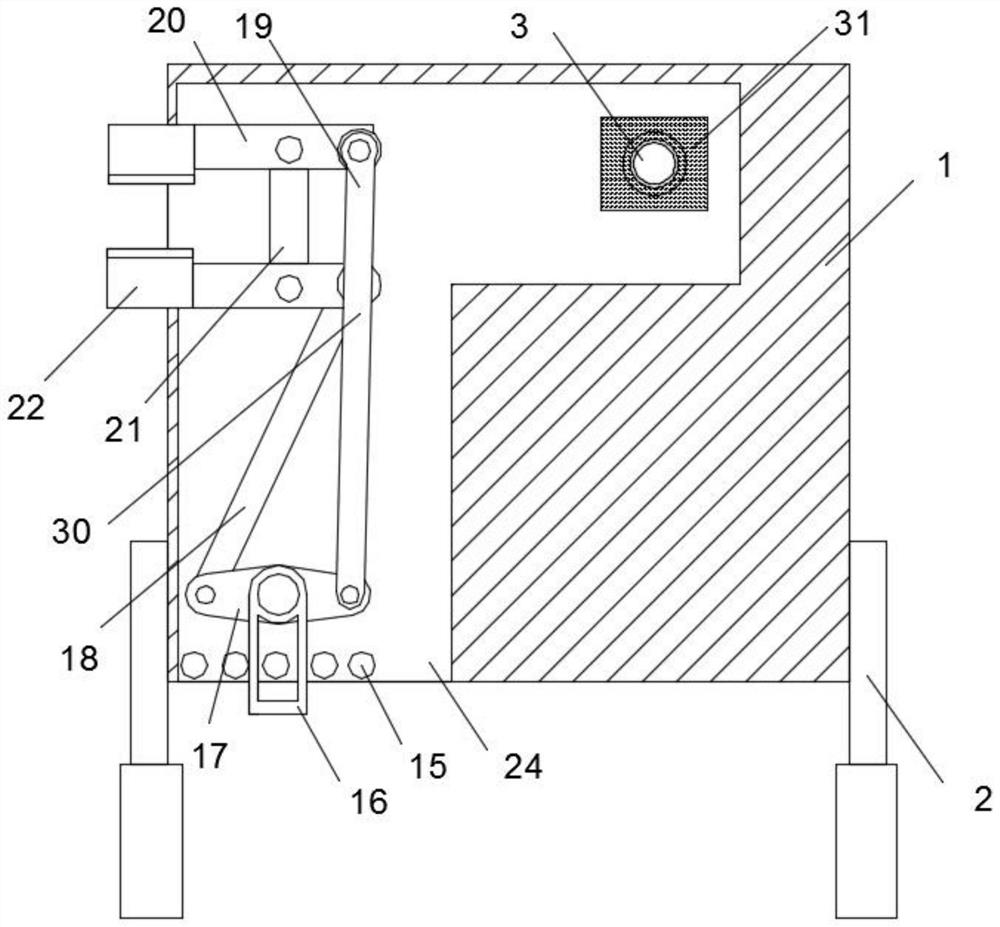

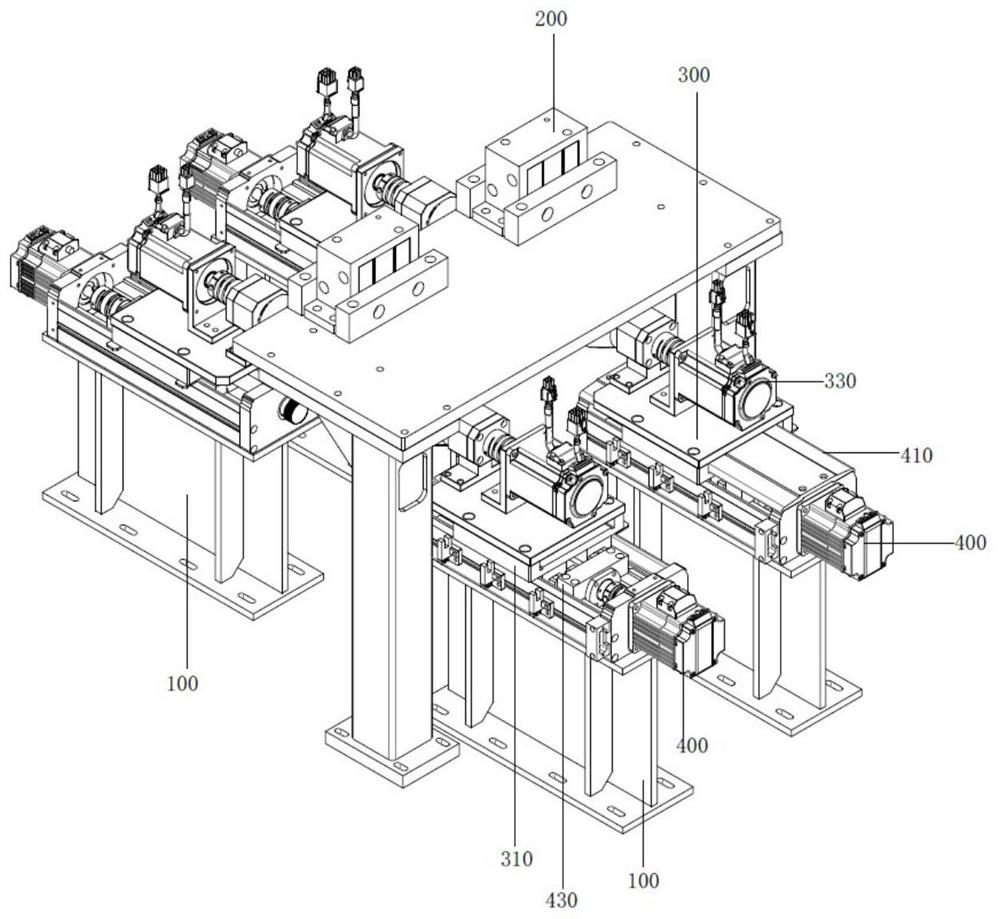

Lithium battery shaping equipment

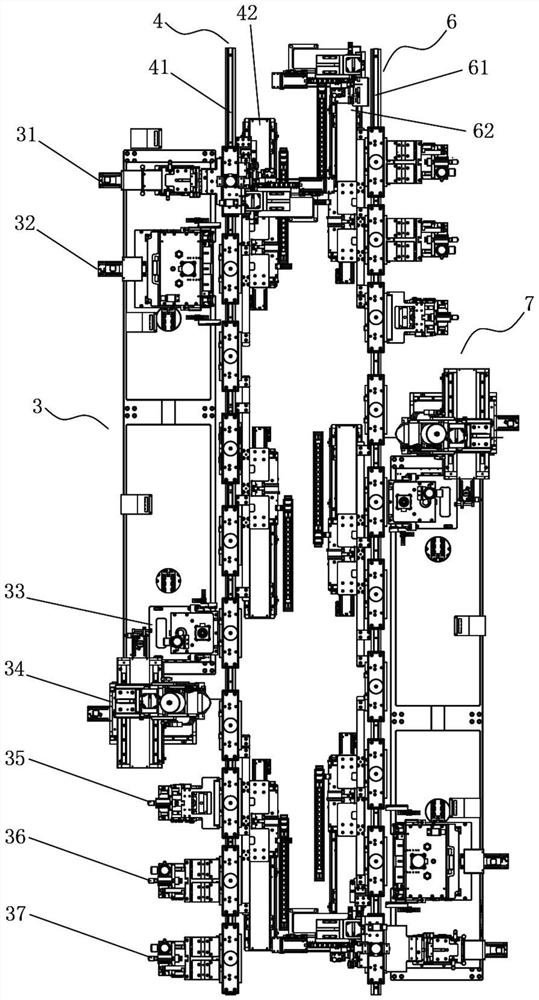

ActiveCN111786027AImprove shaping efficiencyQuality assuranceAssembling battery machinesFinal product manufactureEngineeringTransfer mechanism

The invention provides lithium battery shaping equipment. The lithium battery shaping equipment comprises a feeding mechanism, a left shaping mechanism, a right shaping mechanism, a left conveying mechanism, a right conveying mechanism, a front clamp transfer mechanism, a rear clamp transfer mechanism, a fine shaping mechanism, a discharging mechanism and a plurality of battery cell clamps, wherein the left conveying mechanism and the right conveying mechanism are distributed in parallel left and right; the front clamp transfer mechanism is connected to the front ends of the left conveying mechanism and the right conveying mechanism, the rear clamp transfer mechanism is connected to the rear ends of the left conveying mechanism and the right conveying mechanism, and the battery cell clampsare circularly conveyed on the left conveying mechanism, the rear clamp transfer mechanism, the right conveying mechanism and the front clamp transfer mechanism. The feeding mechanism and the left shaping mechanism are arranged on the left side of the left conveying mechanism from front to back. The full-automatic battery cell shaping machine has the beneficial effects that the automation of eachshaping process of a battery cell is realized, the production efficiency is improved, and the production stability can be ensured.

Owner:东莞市爱康智能技术有限公司

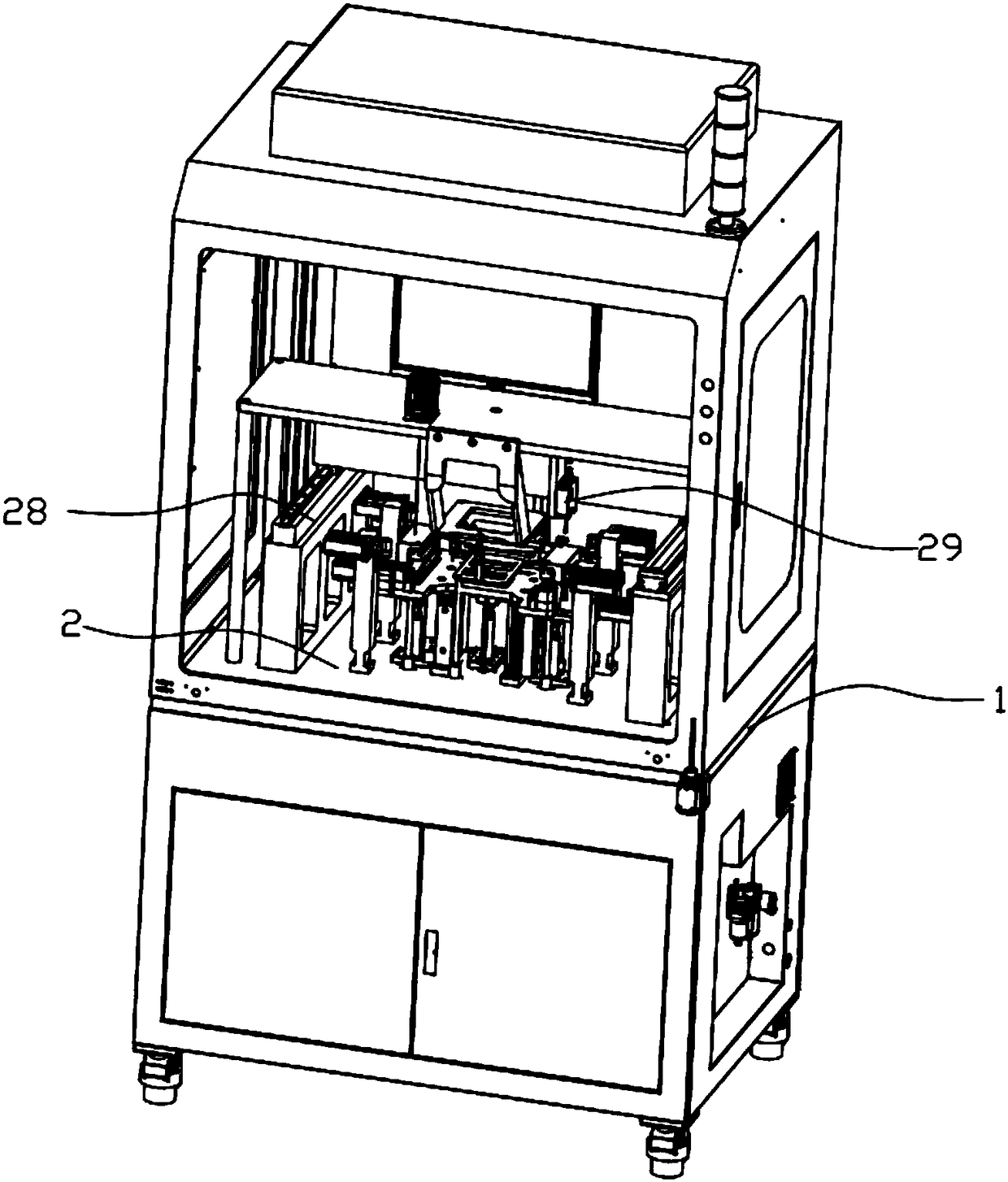

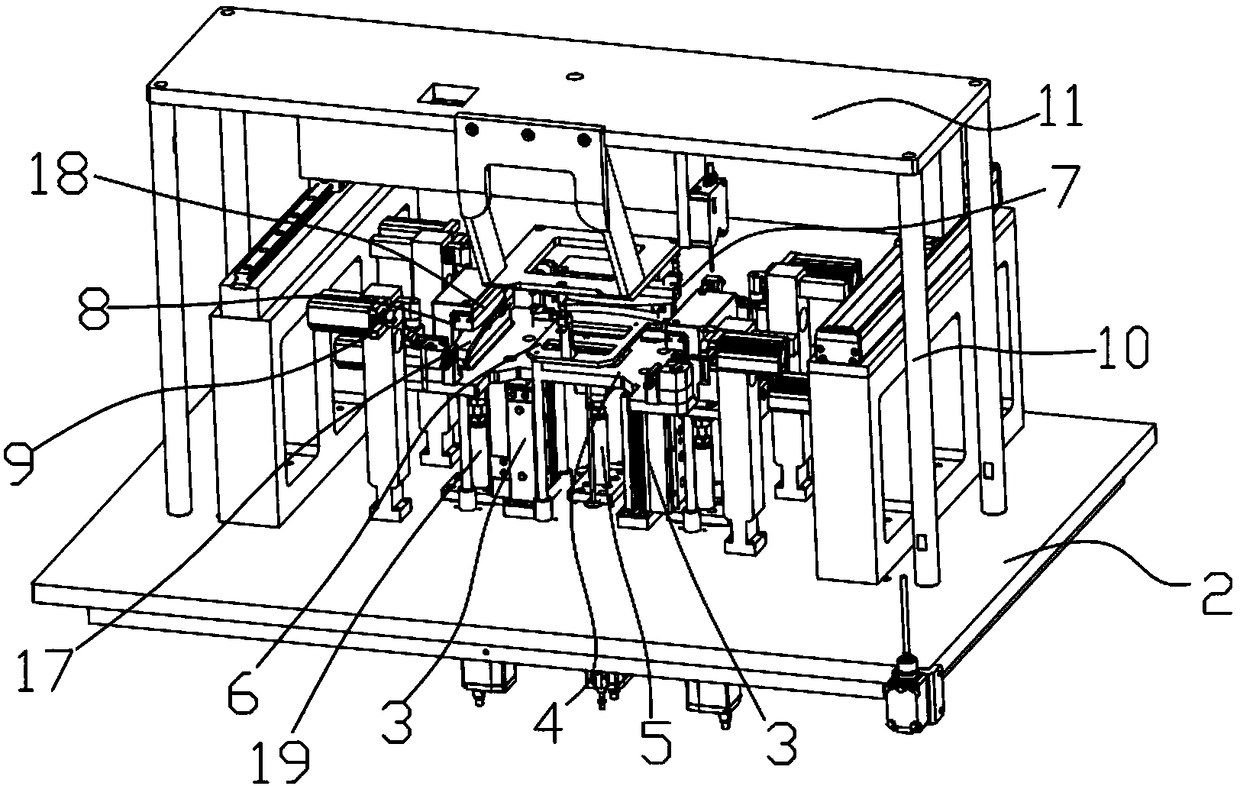

Thin-part flatness shaper

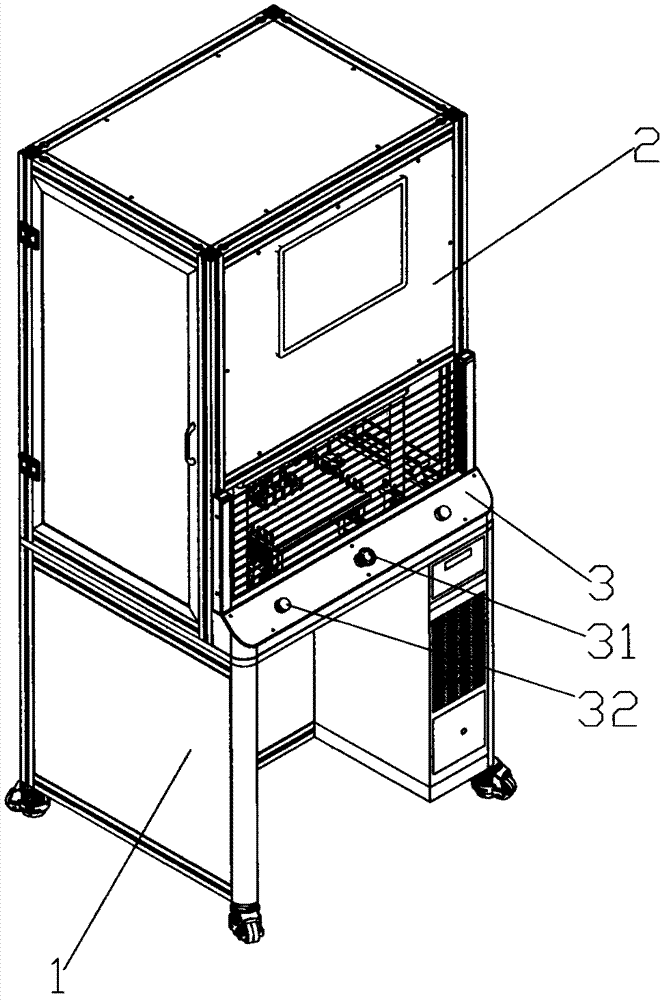

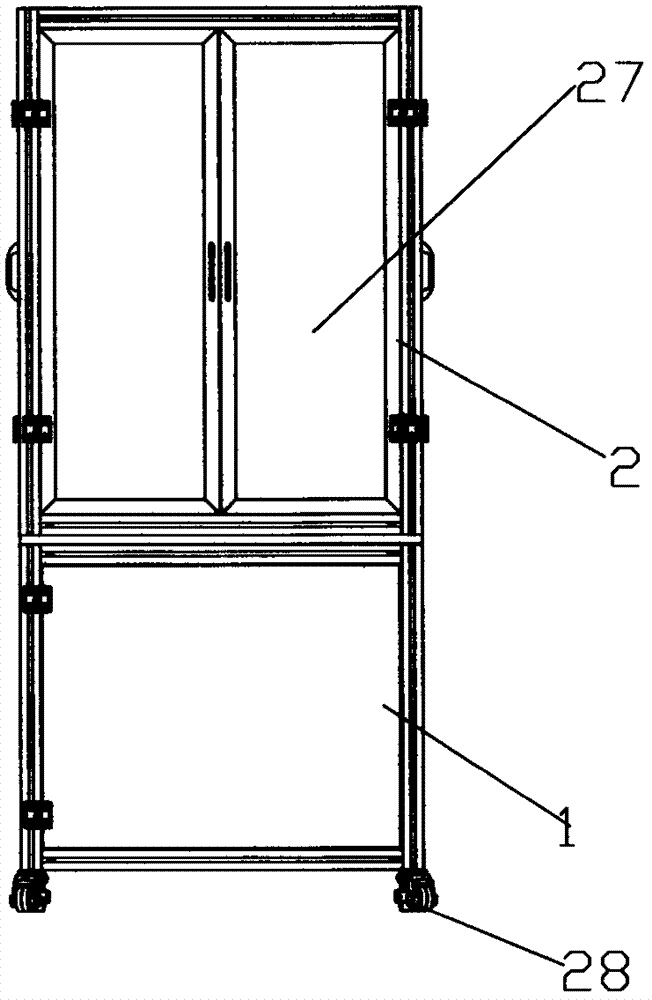

InactiveCN104742387AImprove detection accuracyEasy to fixMeasurement devicesEmergency Stop SwitchEngineering

The invention discloses a thin-part flatness shaper which comprises a rack. A protecting frame and a control box are arranged on the rack, the protecting frame is provided with a door body, the control box is provided with an emergency stop switch and a start switch, and a flatness detection shaping device is arranged in the protecting frame and comprises a testing mechanism, a thin-part clamping mechanism and a thin-part shaping mechanism which are arranged on a base; the testing mechanism comprises a testing pedestal and a flatness detection probe; the thin-part clamping mechanism comprises a thin-part clamping pedestal and a thin-part clamping plate, the thin-part clamping plate is provided with a clamping cavity, a thin-part is arranged in the clamping cavity, the base is provided with a power mechanism, and due to the power mechanism, the thin-part clamping mechanism can move forwards and backwards by virtue of a slide rail and a slide block cooperating with each other; and the thin-part shaping mechanism comprises a shaping fixed plate and a shaping assembly, and the shaping assembly comprises a shaping cylinder and a shaping press head. The thin-part flatness shaper is simple in structure, the precision and efficiency of detection on thin-part flatness are relatively high, and the shaping effect on thin-part flatness is relatively good.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

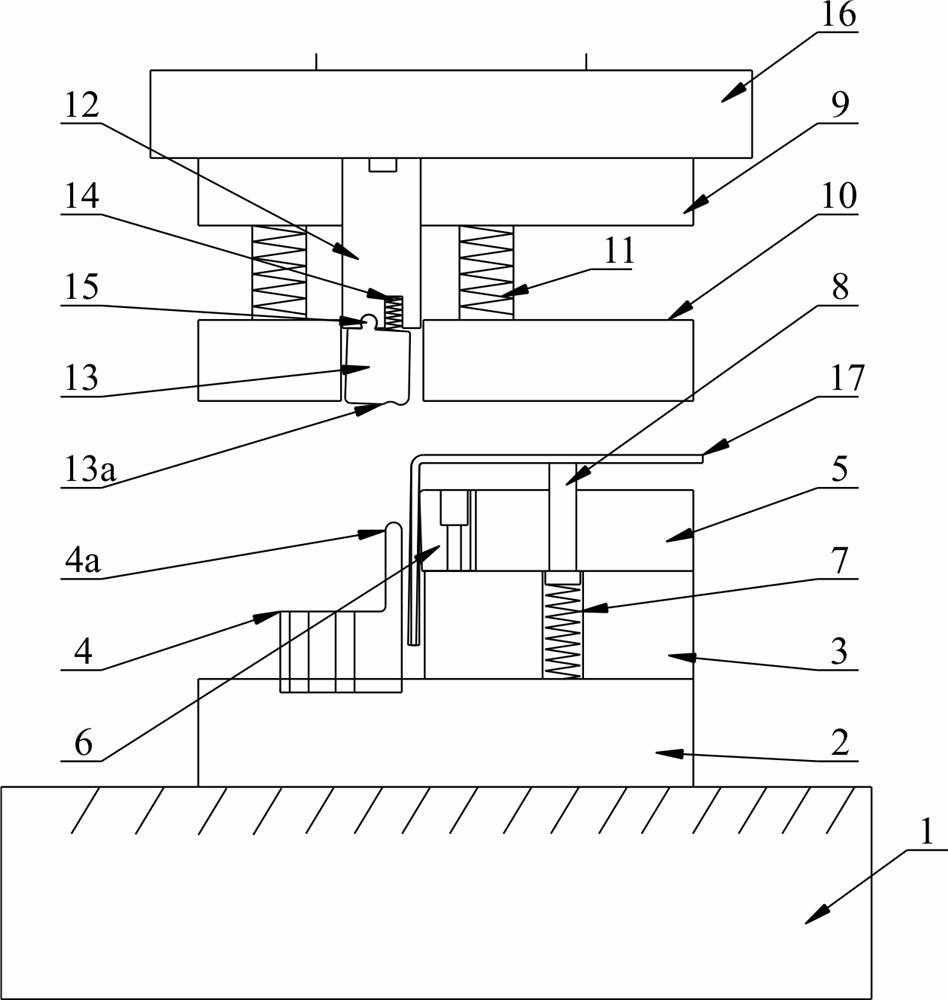

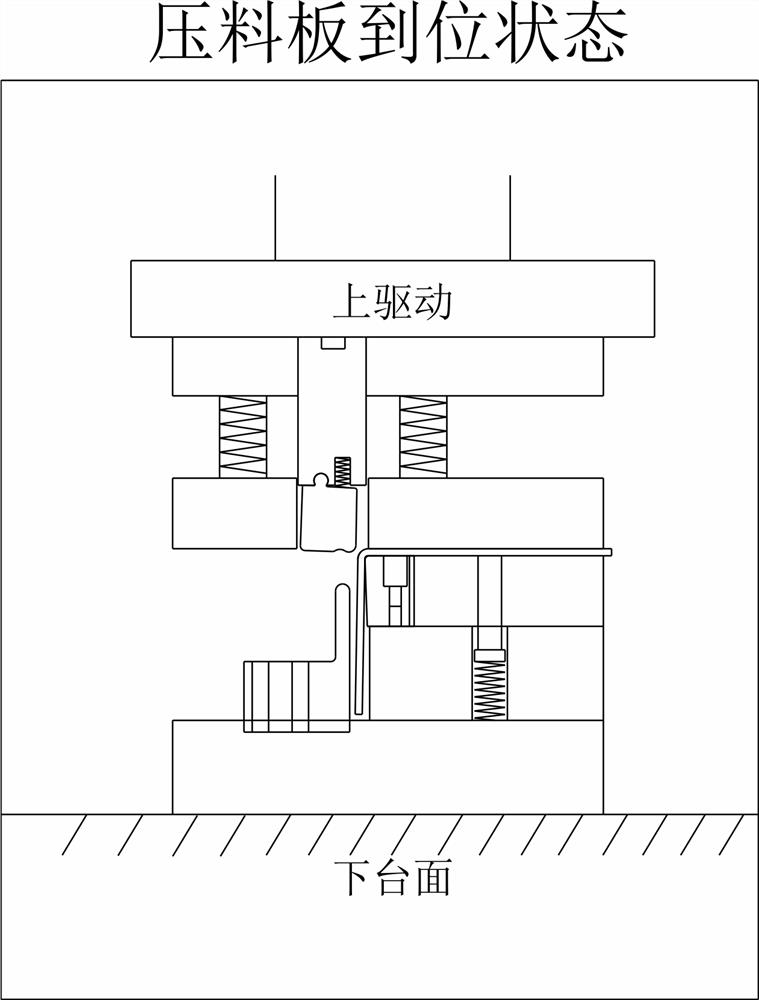

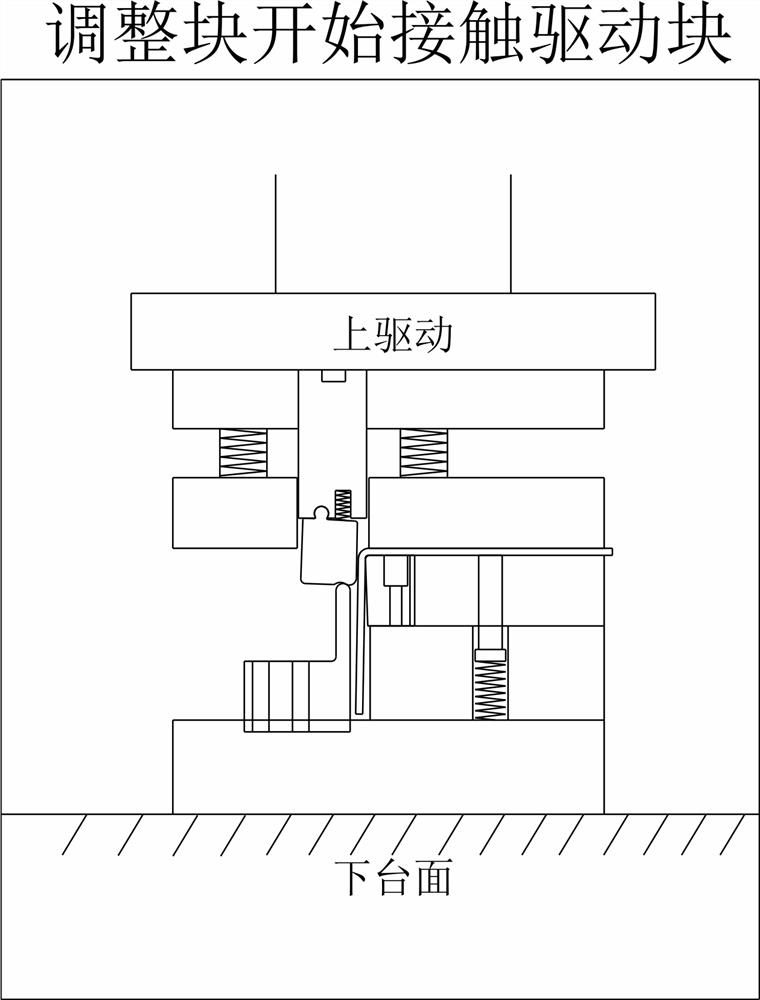

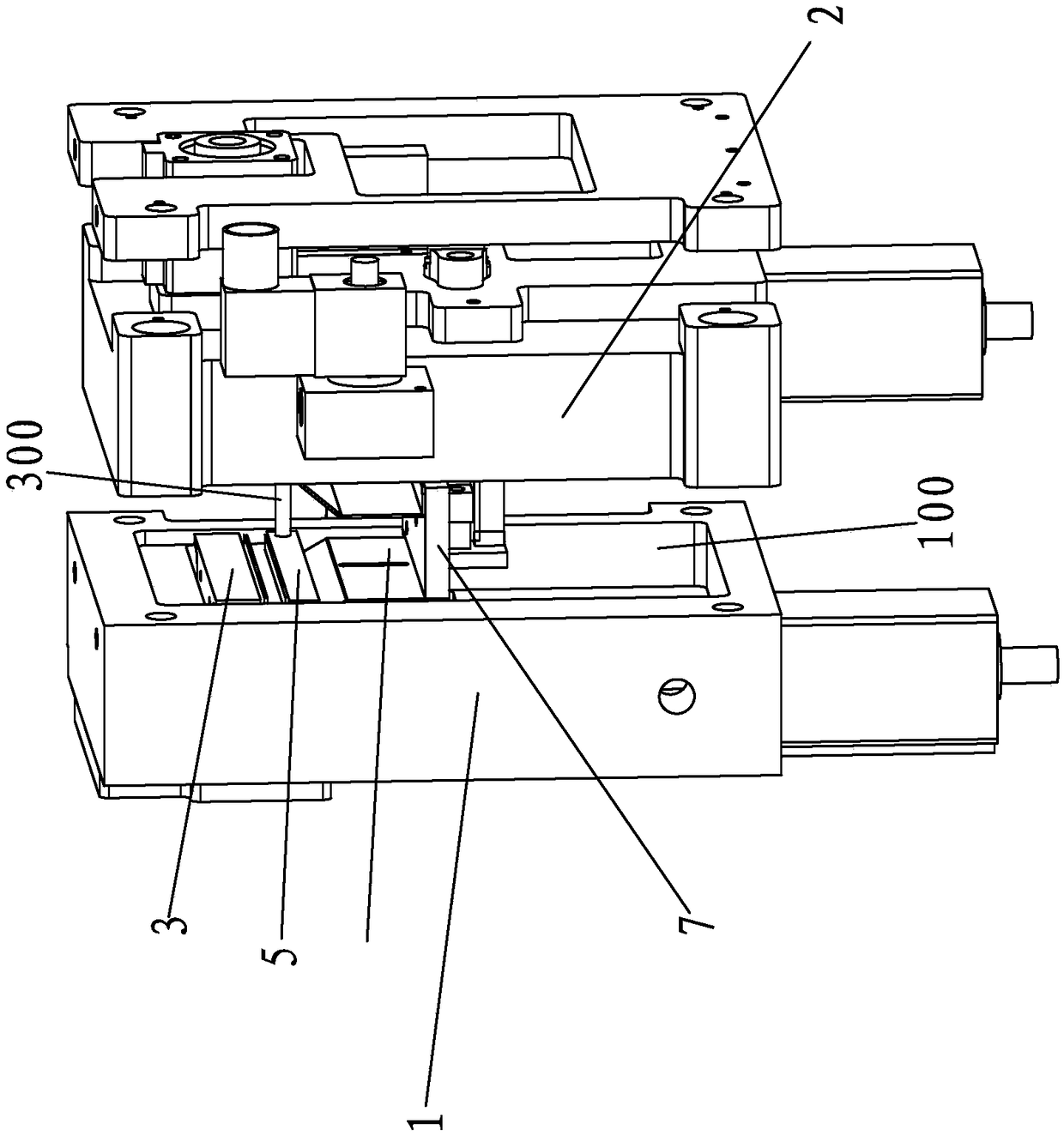

Quick adjusting device for bending springback of stamping die

The invention discloses a quick adjusting device for bending springback of a stamping die. The quick adjusting device for bending springback of the stamping die comprises a lower table top assembly and an upper punch assembly, wherein the lower table top assembly comprises a lower die plate installed on a lower table top, a lower die adjusting block and an adjusting driving block; the adjusting driving block is arranged beside the lower die adjusting block; the upper punch assembly comprises a material pressing plate and a bending assembly which are installed at an upper drive bottom; the material pressing plate is connected to the upper drive bottom through a spring; the bending assembly comprises an adjusting fixing base; a channel allowing the adjusting fixing base to penetrate through is formed in the material pressing plate; the bottom of the adjusting fixing base is connected with a bending adjusting block jointly matched with the adjusting drive block and the lower die adjusting block; the side face of the bending adjusting block is a bending molded surface; the top face of the bending adjusting block is hinged to the bottom of the adjusting fixing base through a rotating shaft; and the bending adjusting block abuts against the bending adjusting block from the bottom through the adjusting driving block to drive the bending adjusting block to rotate so as to extrude a product. According to the quick adjusting device for bending springback of the stamping die provided by the invention, the springback amount of a stamped part can be controlled more effectively and accurately.

Owner:JIANGSU SCHUERHOLZ PRECISION METAL FORMING CO LTD

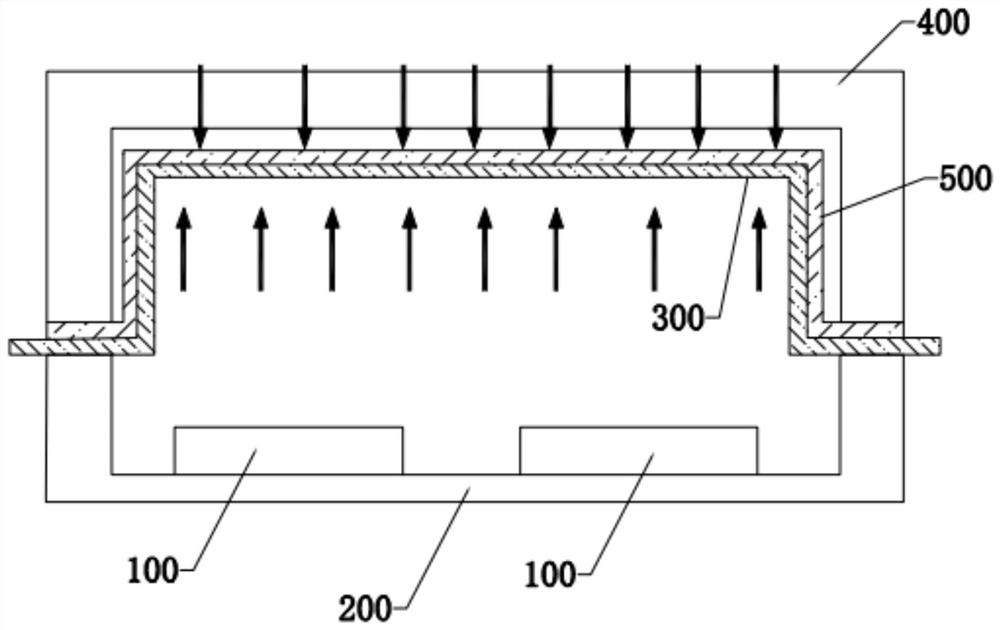

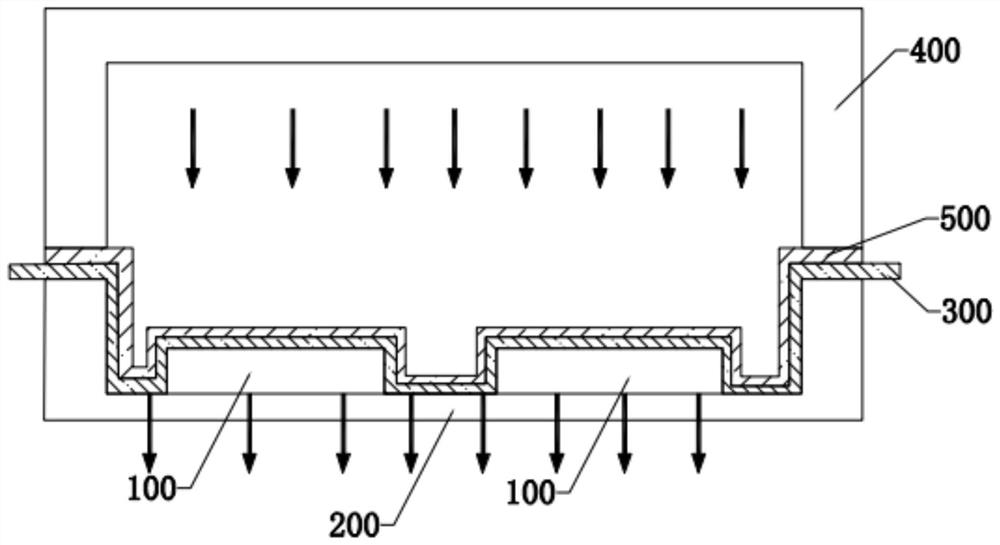

Tea leaf packing process

ActiveCN108382672APreservation effectImprove freshnessPackaging by pressurising/gasifyingPacking procedureEngineering

The invention discloses a tea leaf packing process. The tea leaf packing process includes a pre-treatment procedure and a packing procedure. The packing procedure is implemented through the followingsteps that (1) packing bags fall; (2) die closing is performed, and the tea leaf packing bags on a shaping cavity are completely contained in an airtight cavity; (3) primary vacuumizing is performed on the airtight cavity of the step (2); (4) sealing is performed, specifically, hot-pressing sealing is performed on the primarily vacuumized packing bags in the airtight cavity; (5) secondary vacuumizing on the airtight cavity is started; (6) primary vacuum breaking is performed on the airtight cavity; (7) upper shaping treatment is performed in the airtight cavity; (8) lower shaping treatment isperformed in the airtight cavity; (9) tertiary vacuumizing is performed on the airtight cavity; (10) secondary vacuum breaking is performed on the airtight cavity; and (11) die opening is performed, shaped packing bags on the shaping cavity are taken out, and then tea leaf packing is finished. Compared with the prior art, by means of the tea leaf packing process, the fresh-keeping effect of tea leaves in the bags is good, no tea leaf piece residue exists, six-side shaping is achieved, and therefore the advantages of good packing and shaping effects, attractive packing and many procedures are achieved.

Owner:安溪县钱盛自动化设备有限公司

Electric servo shaping arber press

PendingCN108127951AEnhanced stamping strengthExempt power sourcePress ramMetal working apparatusEngineeringEnergy consumption

The invention relates to an electric servo shaping arber press, wherein comprises a flushing pressure head, a first basal plate, a second basal plate, and a connecting rod structure. Fitted between the first basal plate and the second basal plate, the connecting rod structure includes a lifting device, an intermediate connector, and a connecting rod component symmetrically arranged on both sides of the intermediate connector; the connecting rod component comprises an upper connecting rod, a lower connecting rod, and a bearing connecting rod; one end of the upper connecting rod is rotatably connected with one end of the lower connecting rod and one end of the bearing connecting rod through a rotary shaft; the other end of the upper connecting rod is rotatably connected with the second basalplate, the other end of the lower connecting rod is rotatably connected with the first basal plate, and the other end of the bearing connecting rod is rotatably connected with the intermediate connector; the intermediate connector is matched with the lifting device, and longitudinally moves driven by the lifting device; the flushing pressure head is fixedly arranged on the first basal plate, andthe first basal plate longitudinally moves driven by the connecting rod structure. The electric shaping arber press utilizes the connecting rod structure to greatly improve the stamping force so as tosave the energy consumption.

Owner:CHANGZHOU GIAN TECH

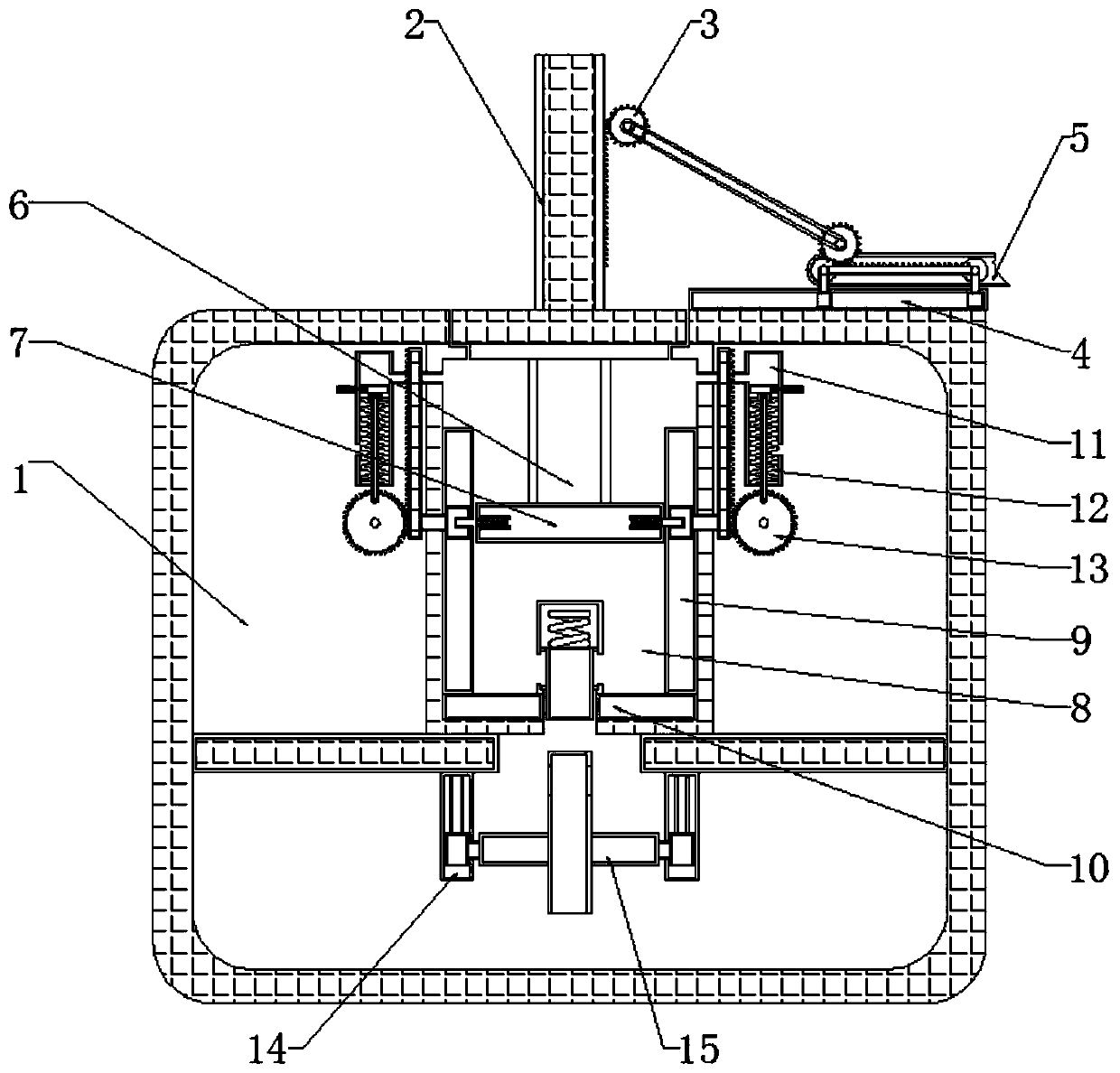

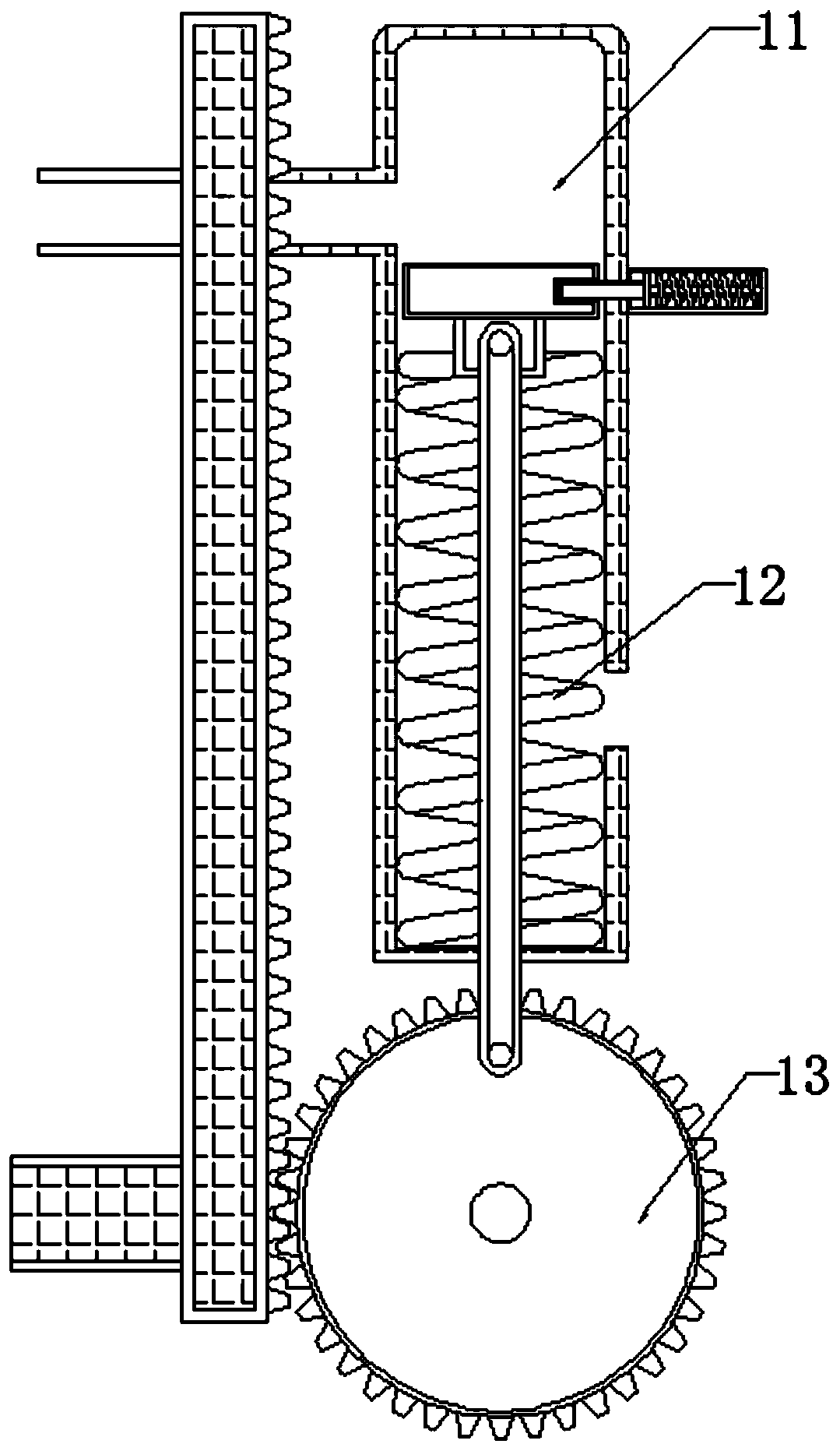

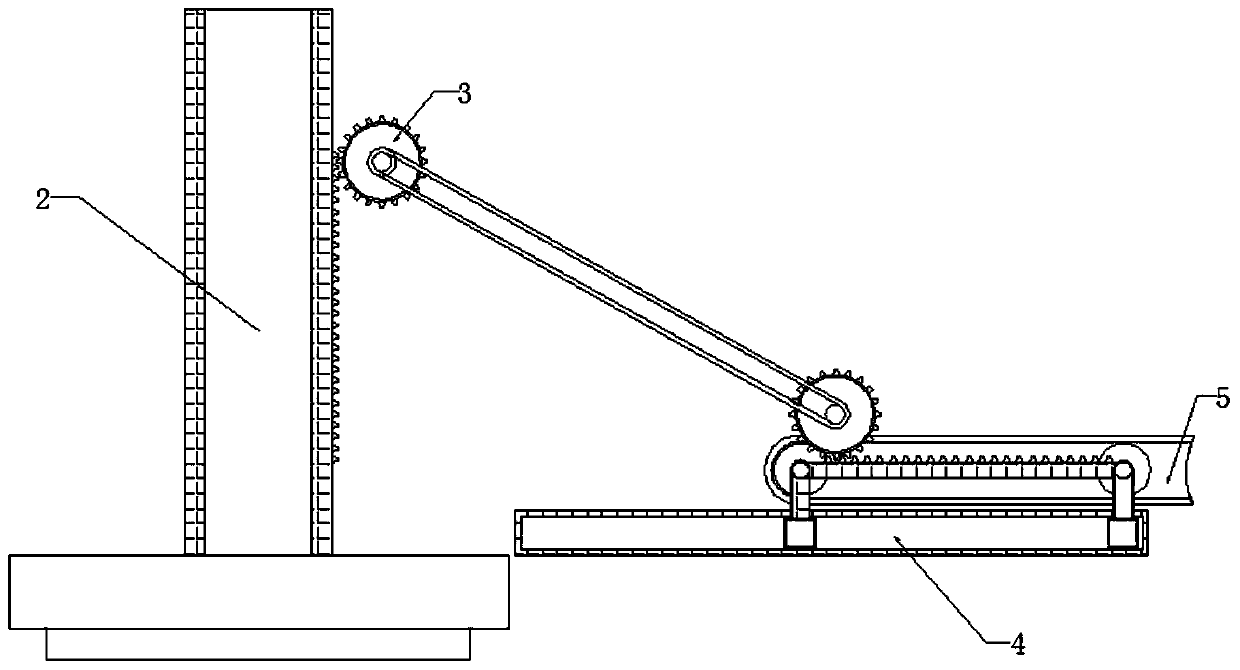

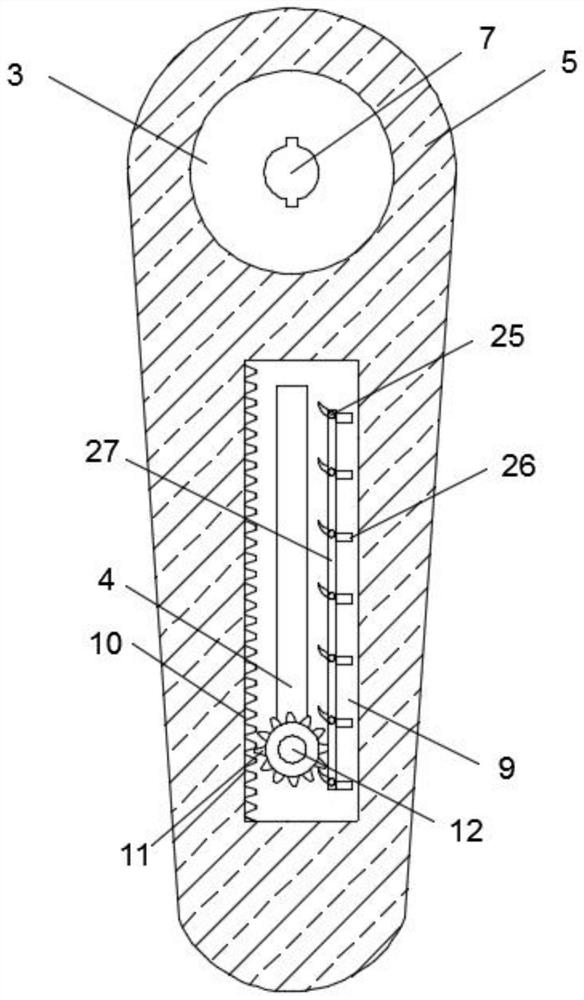

Device for increasing injection pressure through melting temperature pressurization

The invention relates to the technical field of die machining, and discloses a device for increasing the injection pressure through melting temperature pressurization. The device comprises an injection molding machine. The upper portion of the exterior of the injection molding machine is movably connected with a movable cover, the right side of the movable cover is movably connected with conveyingwheel, the upper portion of the injection molding machine is fixedly connected with a fixed sliding rail, the upper portion of the fixed sliding rail is movably connected with a conveying belt, the lower portion of the movable cover is movably connected with a hydraulic rod, the lower portion of the hydraulic rod is movably connected with an injection molding plate, and the interior of the injection molding machine is movably connected with a plastic melting box. Power sliding blocks are reset under the effects of reset springs 12, thus, power wheels are driven to continuously rotate in a reciprocating manner, the power wheels are engaged with racks on the outer sides of movable sliding blocks, through rotation of the power wheels, pressure is continuously provided for the injection molding plate, the pressure during plastic output is guaranteed, thus, the effect of continuously increasing the pressure for plastic output is achieved, and the effect of plastic output is guaranteed.

Owner:万小英

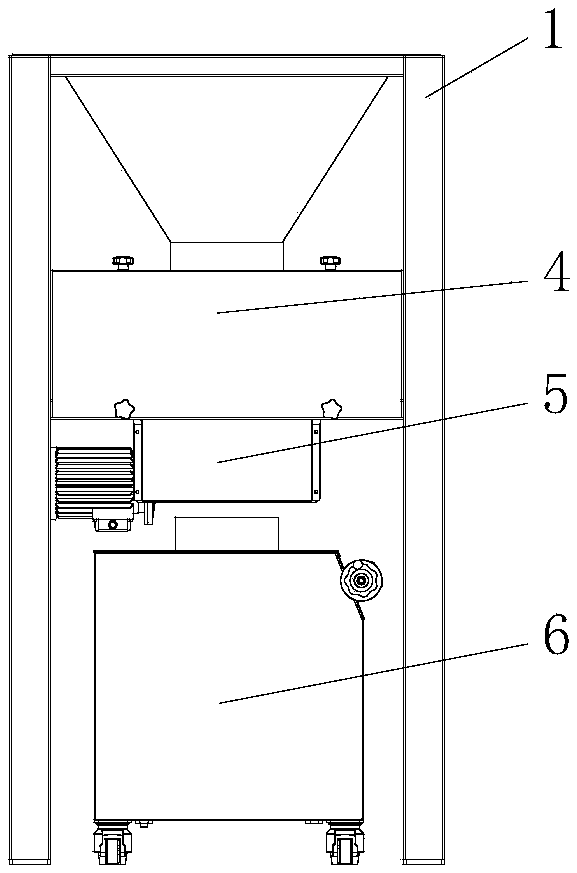

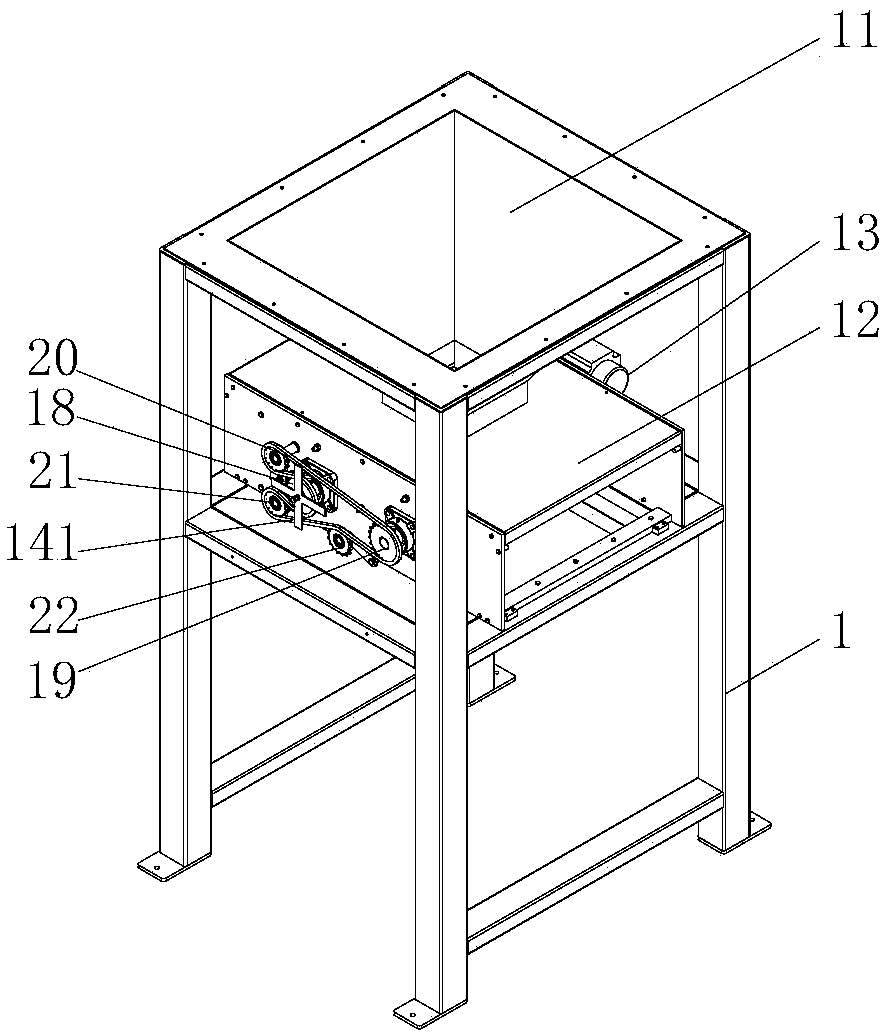

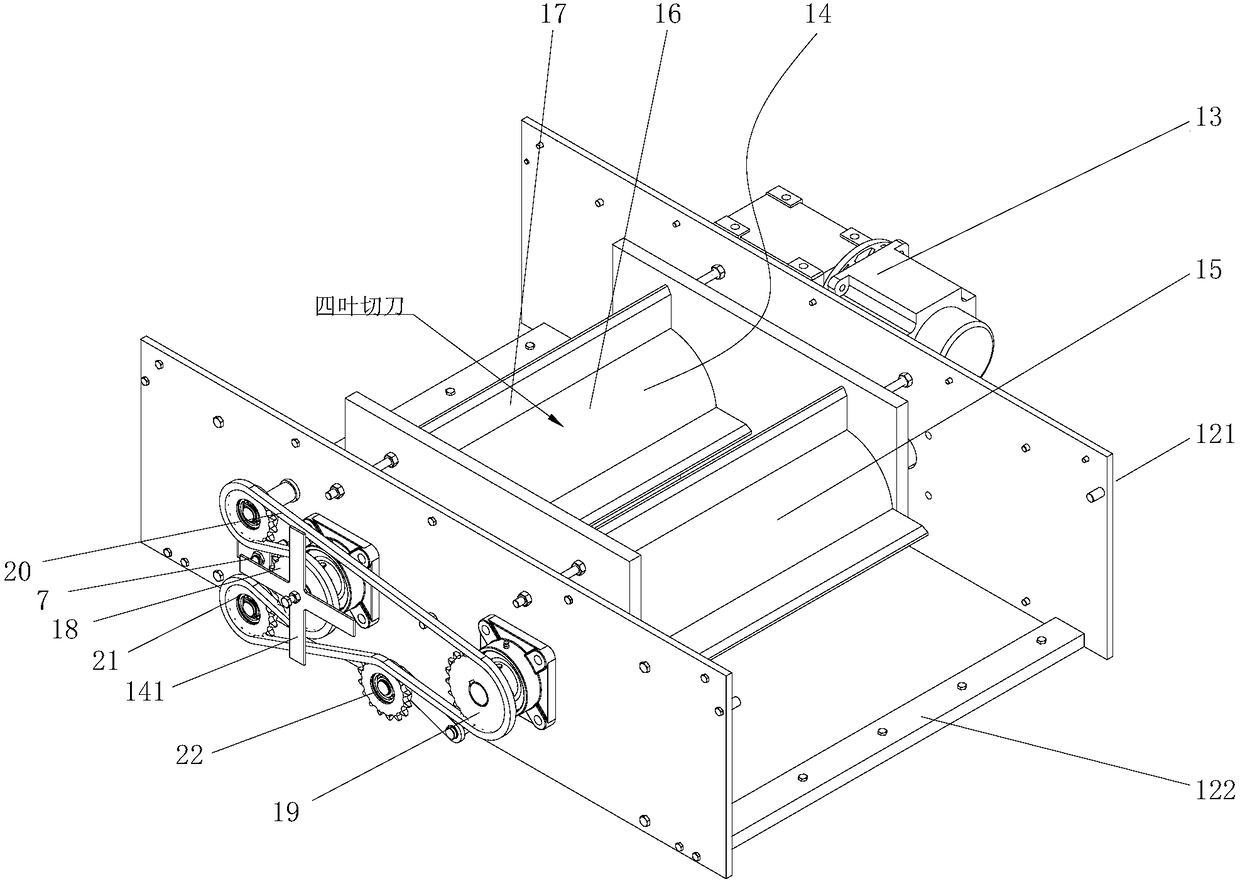

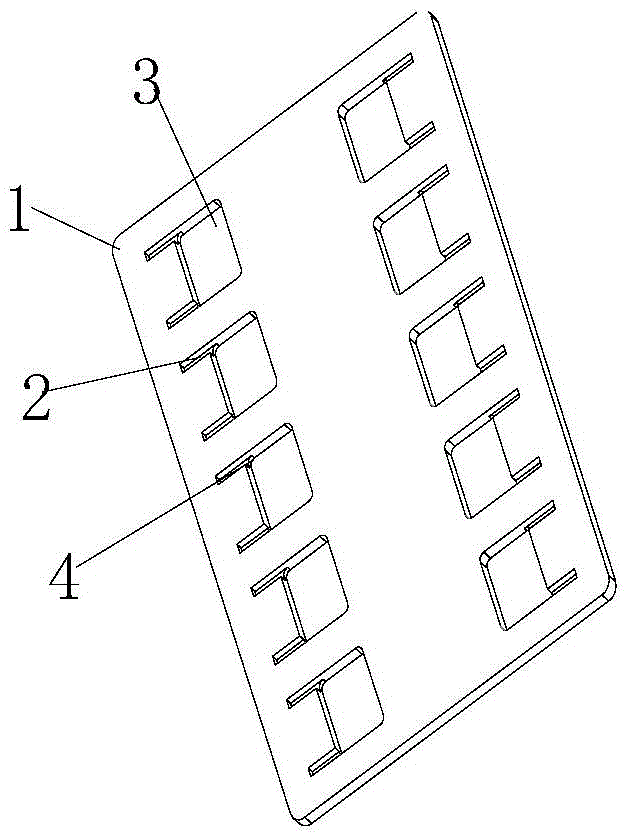

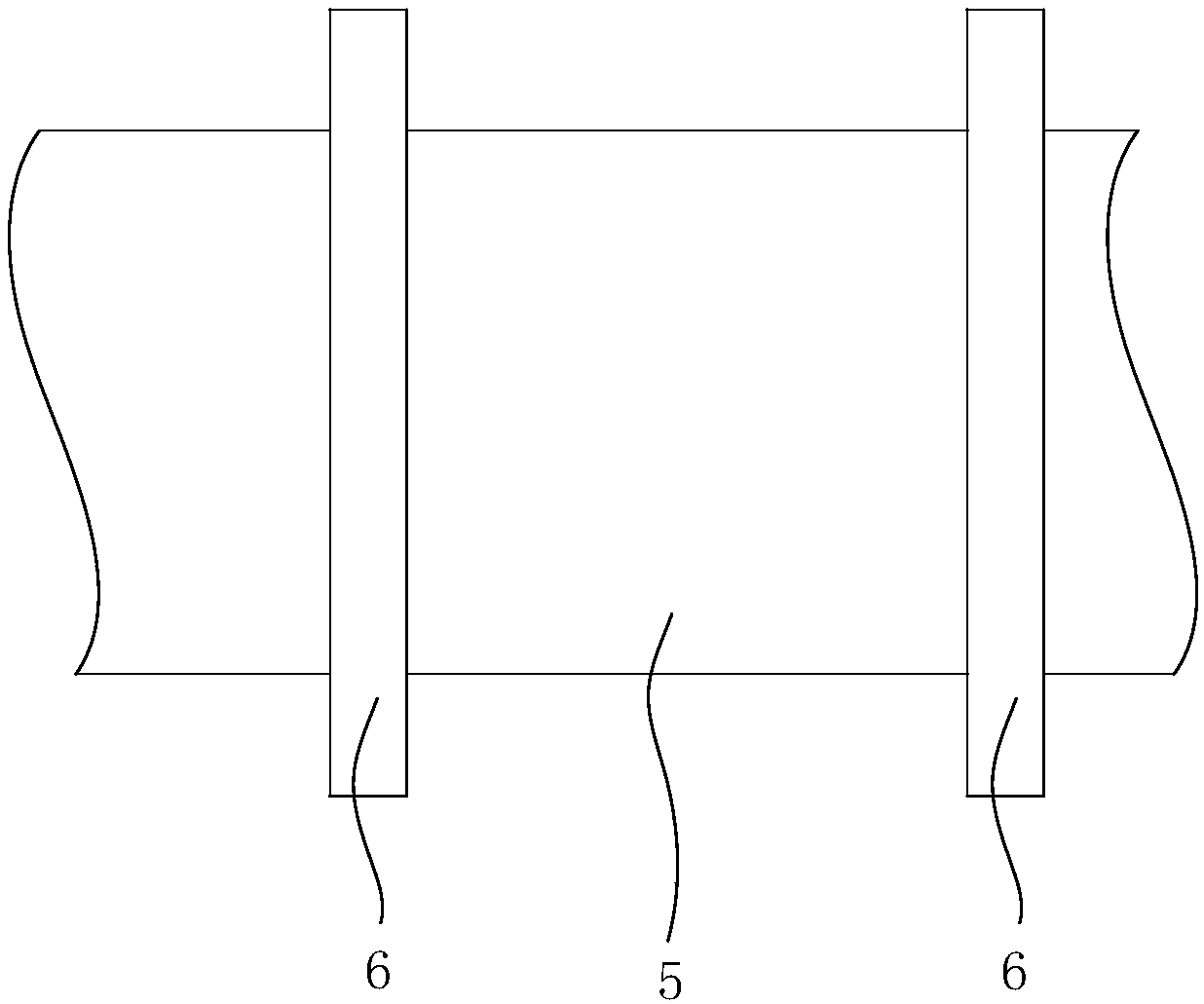

Automatic discharging, dough-pressing and shaping machine

PendingCN108497007AGuaranteed plastic effectEasy to eatDough-sheeters/rolling-machines/rolling-pinsDough shaping and dividing combinationEngineeringDrive motor

The invention discloses an automatic discharging, dough-pressing and shaping machine. The automatic discharging, dough-pressing and shaping machine comprises a discharging mechanism, a sheet-pressingmechanism and a shaping mechanism arranged from top to bottom, wherein a uniformly stirred dough material is lifted to a discharging hopper, the dough material passes through between a driving rollercutter and a driven roller cutter, the driving roller cutter is driven by a drive motor and cooperates with cutting blades arranged in one-to-one correspondence to roll and cut the dough material intoa certain quantity of small pieces to be discharged to the sheet-pressing mechanism, the sheet-pressing mechanism adopts two hexagonal sheet-pressing rollers, a driving sheet-pressing roller and a driven sheet-pressing roller rotate in opposite directions under the transmission of a sheet-pressing motor, and the blocky dough material is pressed into sheets and delivered to the shaping mechanism;the shaping mechanism controls the size of discharged materials by adjusting the gap size between the driving roller and an adjusting roller by virtue of a synchronous adjusting mechanism, the drivingroller adopts rolling bars which are easy to receive the materials, the dough materials are preliminarily pressed by the adjusting roller and the driving roller, and then a shaping roller cooperateswith the adjusting roller to perform secondary pressing and discharge dough sheets. The automatic discharging, dough-pressing and shaping machine realizes production automation in shaping the dough materials into dough sheets used for processing in a production process of bread.

Owner:龙海市安得马富机械有限公司

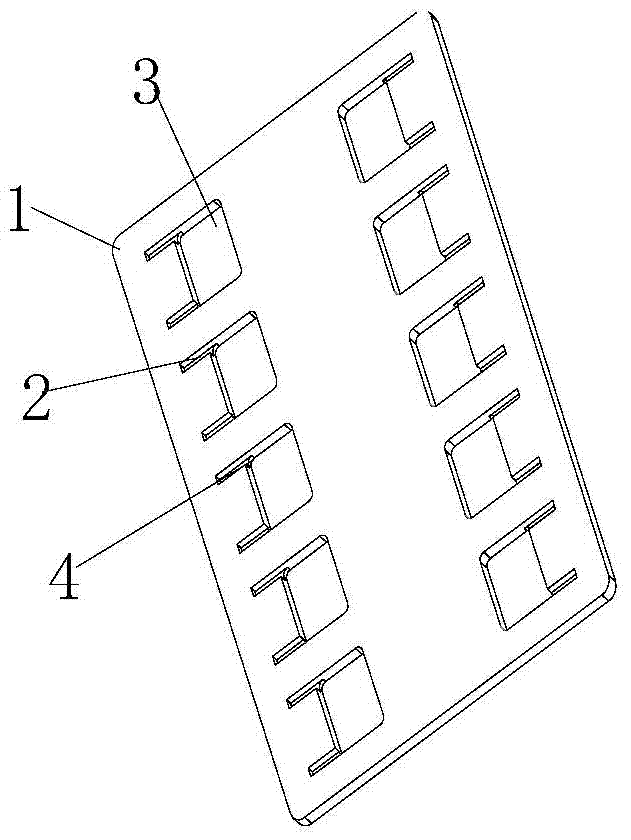

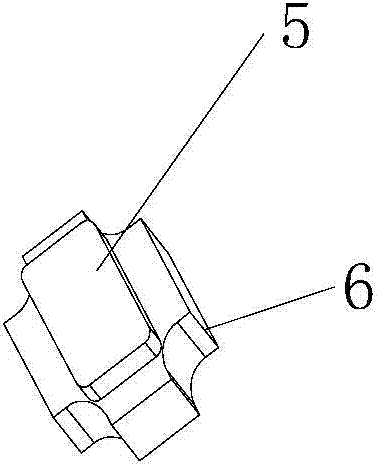

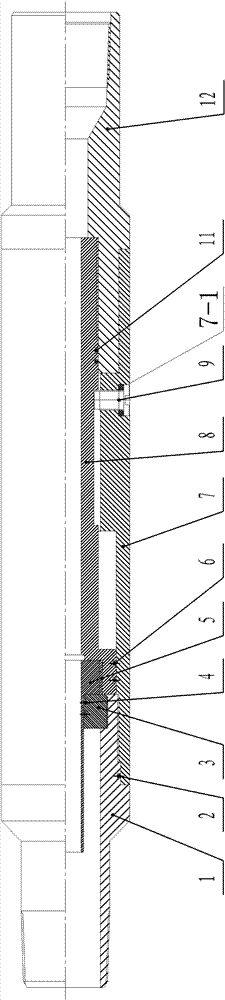

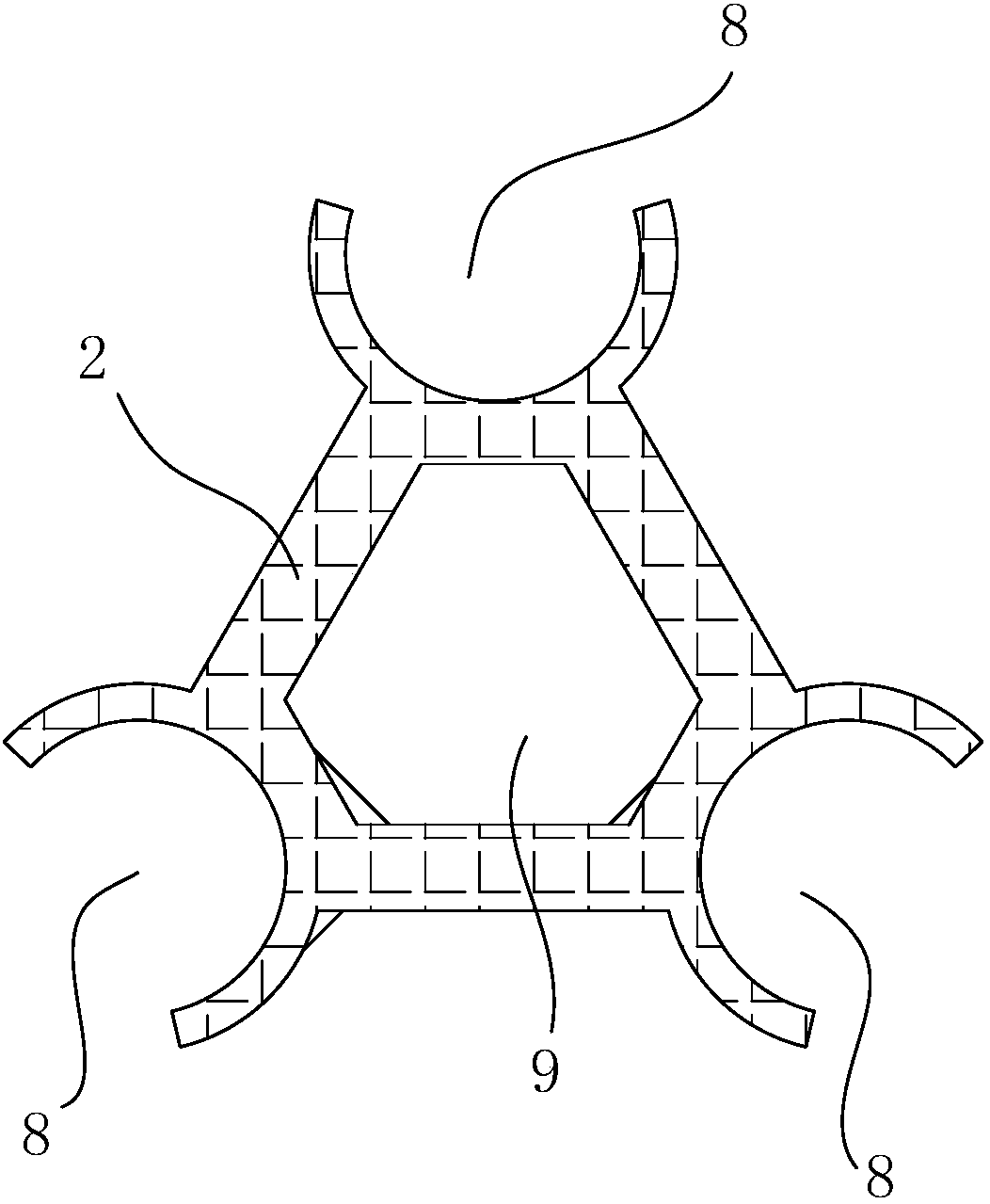

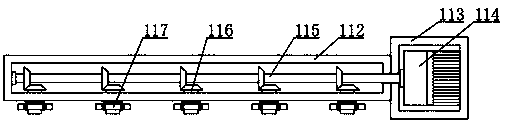

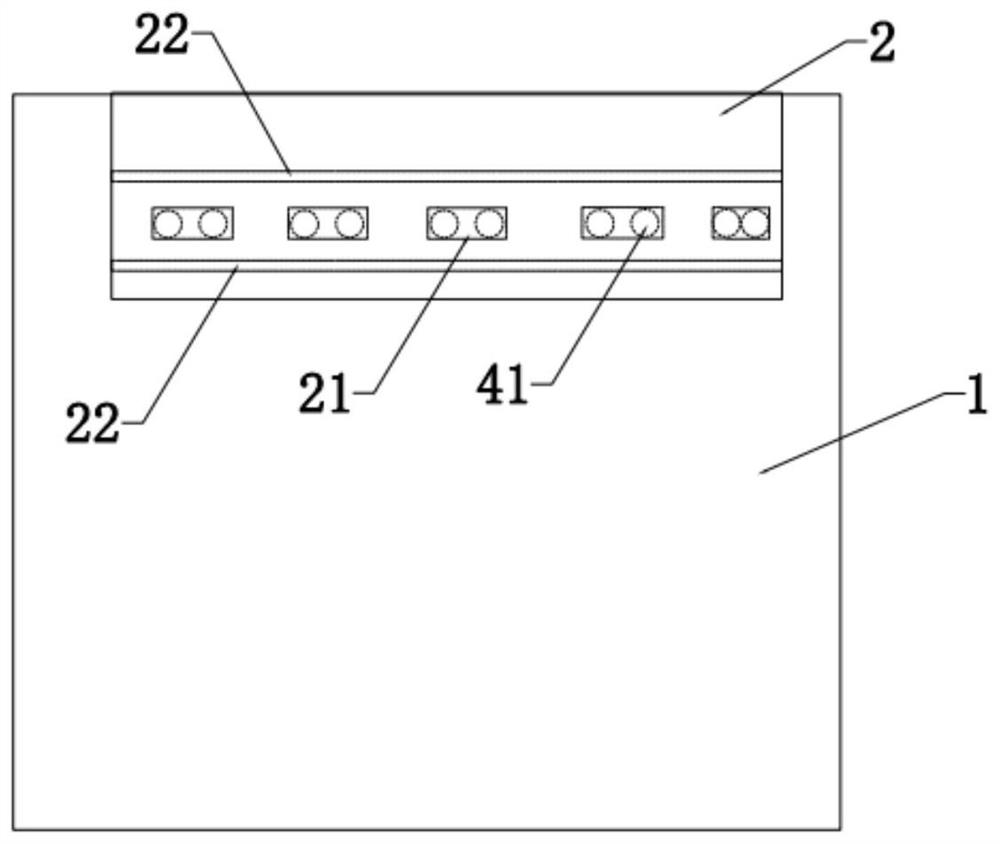

Tool and technology for shaping loudspeaker voice coil

ActiveCN103596115AAvoid secondary deformationQuality assuranceElectrical transducersEngineeringBlock match

The invention belongs to the field of loudspeakers, and particularly relates to a tool and technology for shaping a loudspeaker voice coil. The tool for shaping the loudspeaker voice coil comprises a tool substrate and is characterized in that containing holes holding the loudspeaker voice coil are evenly formed in the tool substrate; the portion, at one side of each containing hole, of the tool substrate is provided with a lead groove used for holding one lead of the voice coil; the tool for shaping the loudspeaker voice coil further comprises ejection blocks matched with the containing holes; each ejection block comprises an ejection body and a holding portion; each ejection body and the corresponding holding portion are integrally arranged; the outer diameter of each ejection body is larger than the outer diameter of the voice coil and smaller than the inner diameter of each containing hole; the shaping technology of heating is conducted on the loudspeaker voice coil. According to the tool and technology for shaping the loudspeaker voice coil, the uniformity of the size of the voice coil can be effectively guaranteed and the stability of the quality of a loudspeaker is guaranteed.

Owner:BESTAR HLDG

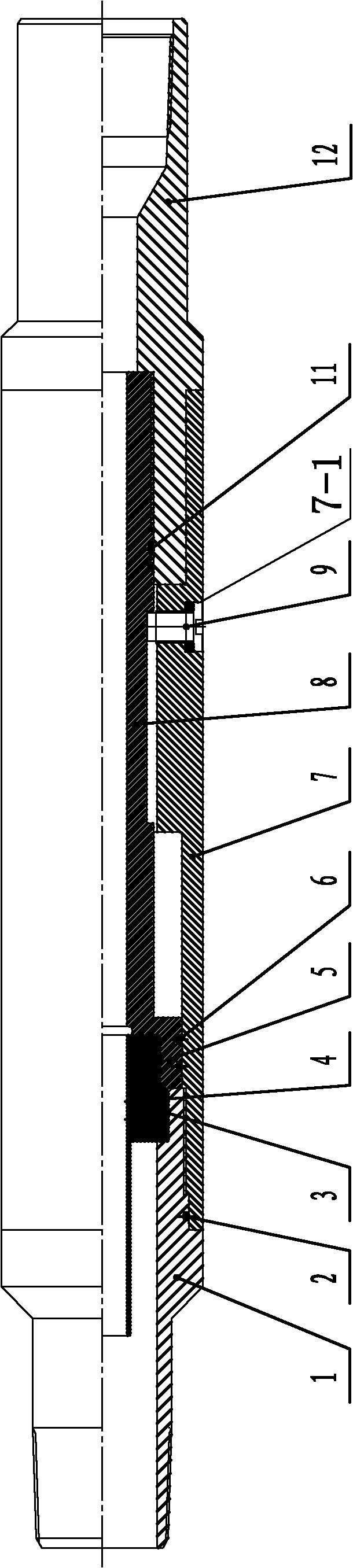

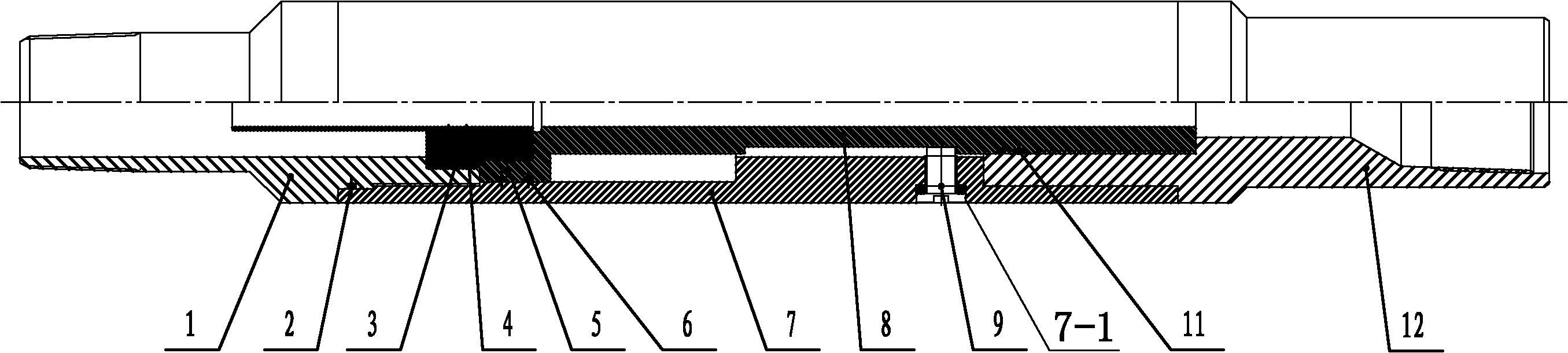

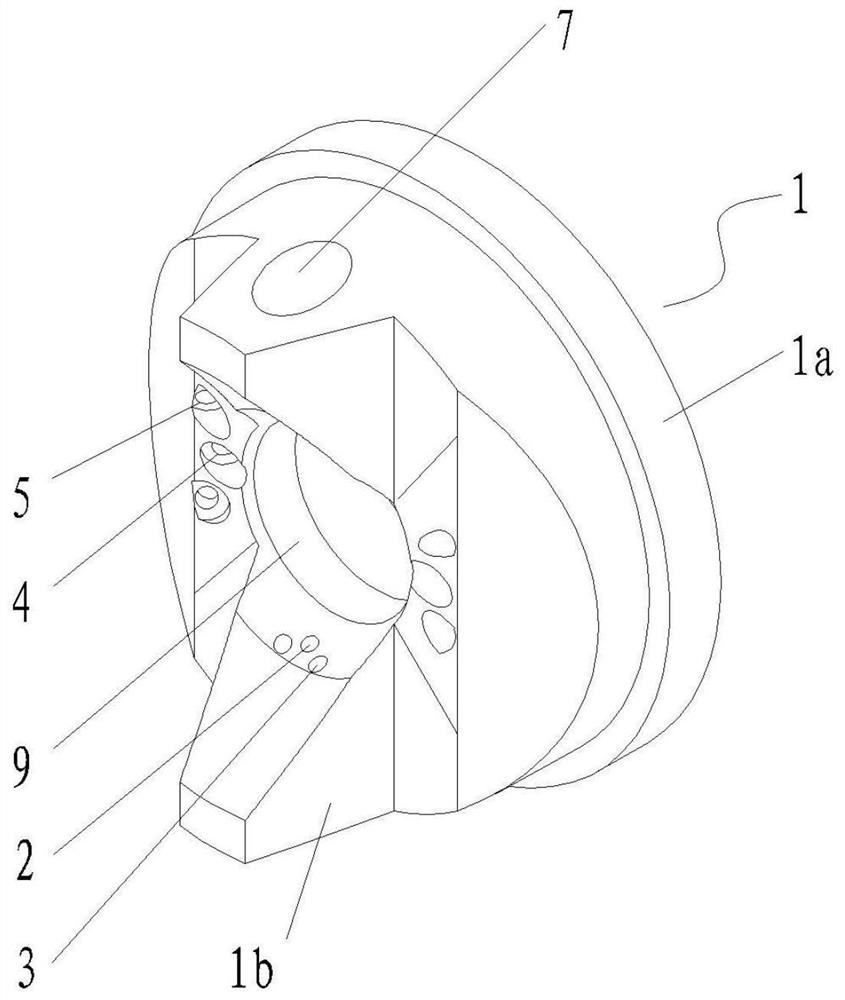

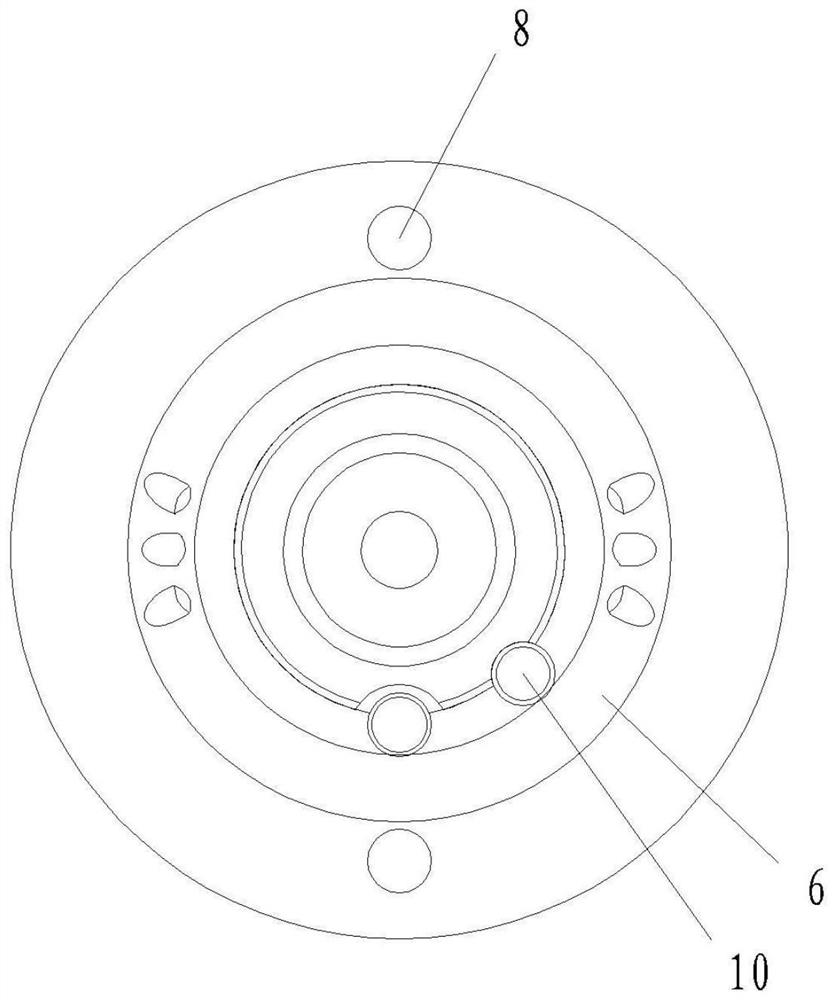

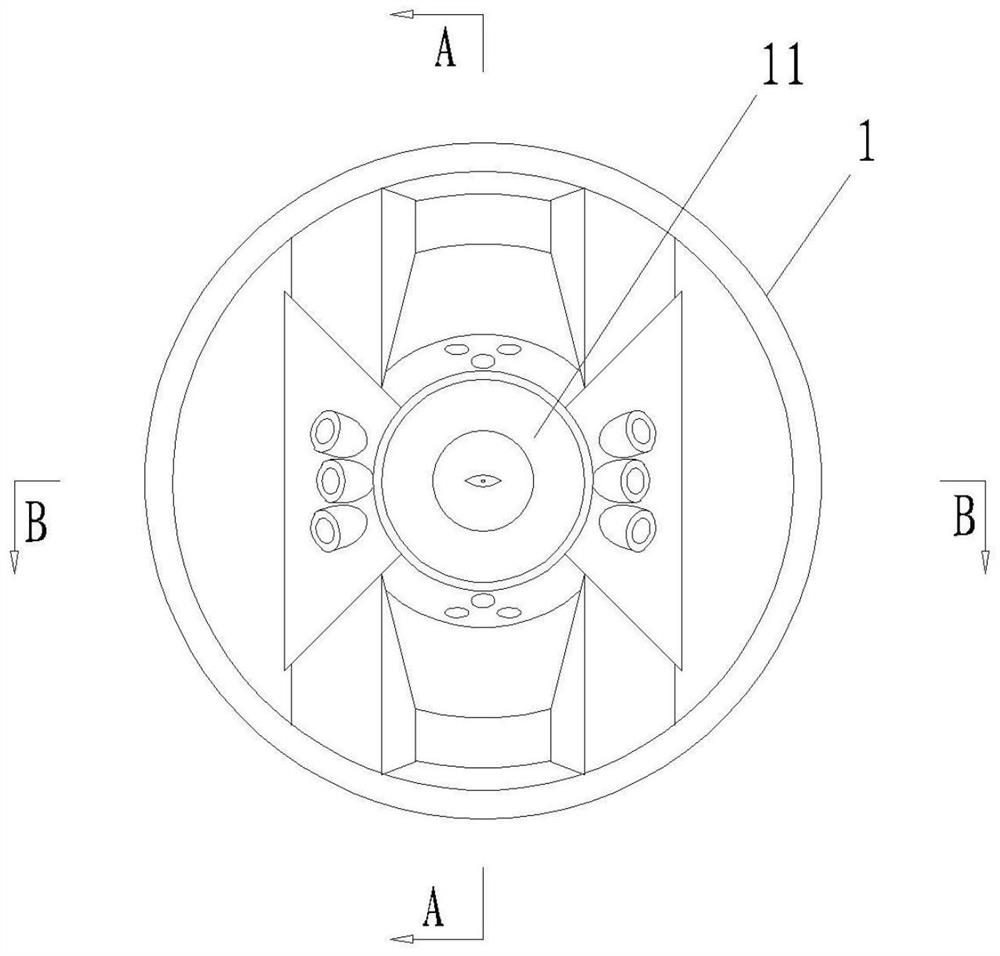

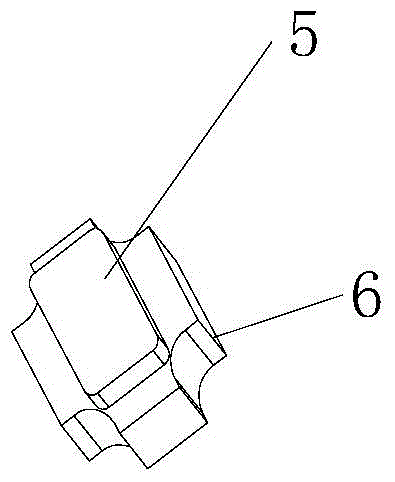

Rotating nipple for hydraulic shaping

The invention discloses a rotating nipple for hydraulic shaping and relates to a rotating nipple, solving the problems that the shaping orientation of a power motor is uncertain, and the power motor has failure and is damaged under the action of hydraulic pressure and a reactive torque. In the invention, a steering rod is inserted in a rotating sleeve, and a positioning hole is arranged on the rotating sleeve; a positioning pin is inserted in the positioning hole and used for positioning the steering rod and the rotating sleeve; the lower end of an upper joint is inserted in the rotating sleeve as well as sleeved at the upper end of the steering rod; the upper part of a lower joint is inserted at the lower end of the rotating sleeve, and the upper end surface of the lower joint is in contact with the lower end surface of the steering rod; a guide block is arranged on the lower part of the steering rod, and a stop block is arranged below the guide block; and the upper end of the stop block is in contact with the guide block. The rotating nipple replaces the traditional hydraulic motor, achieves the purpose of omnibearing shaping and guarantees the shaping effect.

Owner:DAQING OILFIELD CO LTD

Intelligent measuring repair device

ActiveCN106424211APrevent slight displacementGuaranteed plastic effectMetal-working feeding devicesMetal working apparatusComputer engineeringRestoration device

The invention provides an intelligent measuring repair device. The device comprises a machine shell, a work table is arranged on the machine shell, a supporting mechanism, a shaping mechanism and positioning mechanisms are arranged on the work table, the shaping mechanism comprises two supporting blocks, a bearing mechanism is arranged on the supporting blocks, and comprises a bottom plate, a first air cylinder is arranged on the lower portion of the bottom plate and penetrates the centre of the bottom plate to be arranged on a carrying plate in a pushed manner, the two sides of the bottom plate are provided with a first shaping portion used for shaping and two second shaping portions symmetrically arranged on the two sides of the bottom plate, and the four positioning mechanisms are arranged on the four corners of the bottom plate. According to the repair device, a computer back shell is placed on the carrying plate, the carrying plate is pulled to the shaping mechanism through a lead screw, and is clamped between the shaping head and the bearing head, the vertical position of the computer back shell is fixed through the first air cylinder on the lower portion, the four corners of the computer back shell are fixed through the positioning mechanisms, meanwhile, through a limiting mechanism, the computer back shell is limited, fine displacement of the back shell during shaping is prevented, and the shaping effect is ensured.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

A tea packaging process

ActiveCN108382672BPreservation effectImprove freshnessPackaging by pressurising/gasifyingPacking procedureEngineering

The invention discloses a tea leaf packing process. The tea leaf packing process includes a pre-treatment procedure and a packing procedure. The packing procedure is implemented through the followingsteps that (1) packing bags fall; (2) die closing is performed, and the tea leaf packing bags on a shaping cavity are completely contained in an airtight cavity; (3) primary vacuumizing is performed on the airtight cavity of the step (2); (4) sealing is performed, specifically, hot-pressing sealing is performed on the primarily vacuumized packing bags in the airtight cavity; (5) secondary vacuumizing on the airtight cavity is started; (6) primary vacuum breaking is performed on the airtight cavity; (7) upper shaping treatment is performed in the airtight cavity; (8) lower shaping treatment isperformed in the airtight cavity; (9) tertiary vacuumizing is performed on the airtight cavity; (10) secondary vacuum breaking is performed on the airtight cavity; and (11) die opening is performed, shaped packing bags on the shaping cavity are taken out, and then tea leaf packing is finished. Compared with the prior art, by means of the tea leaf packing process, the fresh-keeping effect of tea leaves in the bags is good, no tea leaf piece residue exists, six-side shaping is achieved, and therefore the advantages of good packing and shaping effects, attractive packing and many procedures are achieved.

Owner:安溪县钱盛自动化设备有限公司

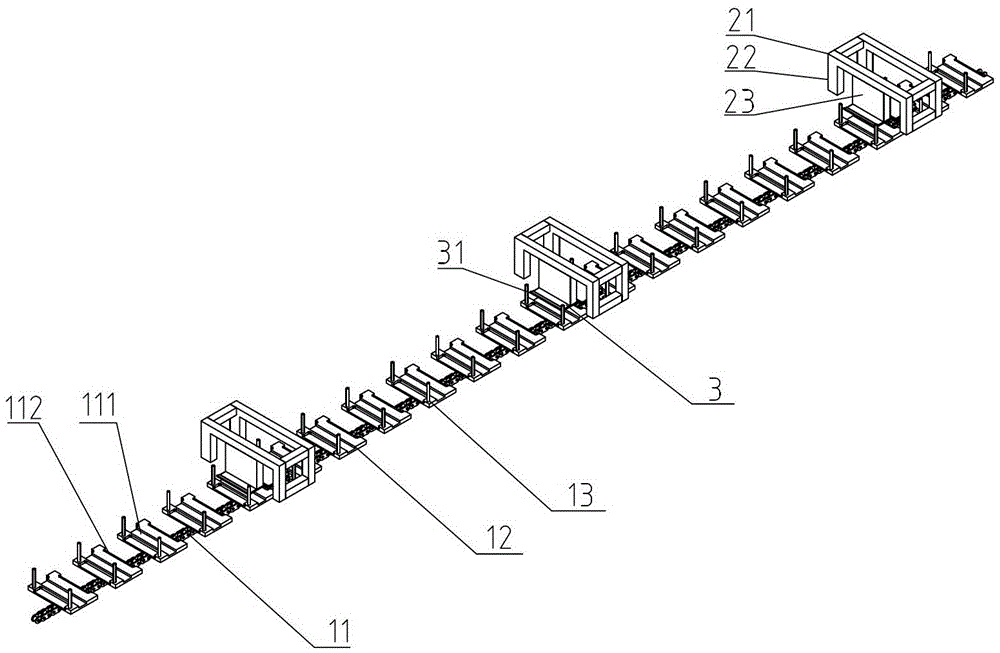

Laminating mechanism of storage battery wrapping and laminating machine

ActiveCN103311564AIncrease productivityGuaranteed contactFinal product manufactureSecondary cells manufactureMechanical engineering

The invention discloses a laminating mechanism of a storage battery wrapping and laminating machine and relates to storage battery automatic production equipment. The conventional storage battery wrapping and laminating machine is low in laminating efficiency. The laminating mechanism disclosed by the invention comprises a conveying device and a plurality of carrying plates, wherein the carrying plates are arranged above the conveying device at intervals, are fixed above the conveying device through a fixing frame and are gradually heightened along the conveying direction of the conveying device; a push rod is arranged on the conveying device; the height of the push rod is greater than that of each carrying plate; when the conveying device runs, the push rod scraps polar plates on the carrying plates into the conveying device, and the polar plates are laminated on the conveying device layer by layer; base plates and wrapping polar plates of a base plate transferring device and a wrapping device are simultaneously transferred to the carrying plates of the fixing frame; in a running process of the conveying device, the polar plates on the carrying plates are continuously scraped into the conveying device; the polar plates are laminated on the conveying device to form plate groups and then are conveyed by the conveying device; and the plate groups can be continuously formed, so that the production efficiency is high.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

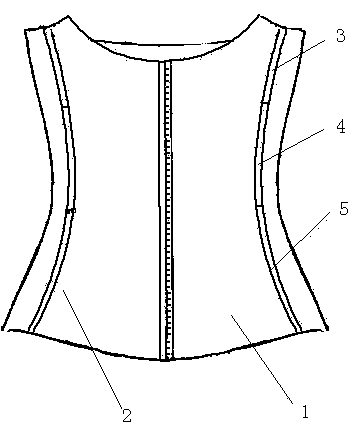

Waist belt capable of alleviating pressure on front abdomen

The invention discloses a waist belt capable of alleviating pressure on front abdomen. The waist belt comprises a clothes body (1); and adjusting hooks are arranged on the edges of joint parts of the clothes body (1). The waist belt is characterized in that: the two sides of the front part of the clothes body (1) are provided main steel bone pipes (2) respectively; each main steel bone pipe (2) is composed of an upper segment (3), a middle segment (4) and a lower segment (5), wherein the length of the upper segment (3) is shorter than that of the middle segment (4), and the length of the middle segment (4) is shorter than that of the lower segment (5); and steel bone is arranged in the upper segments (3) and the lower segments (5). The waist belt is simple in structure, and skillful in design, and is capable of alleviating pressure on human body front abdomen.

Owner:DALIAN SUNLAURA IND

A stacking mechanism of a battery pack sheet stacking machine

ActiveCN103311564BIncrease productivityGuaranteed contactFinal product manufactureSecondary cells manufactureEngineeringBattery pack

The invention discloses a stacking mechanism of a battery pack sheet stacking machine, which relates to automatic battery production equipment. The stacking efficiency of the existing battery pack sheet stacker is low; the stacking mechanism of the invention comprises a conveying device and a plurality of pallets , the pallets are arranged above the conveying device at intervals, the pallet is fixed above the conveying device by the fixing frame and gradually increases along the conveying direction of the conveying device, and the conveying device is provided with a push rod, and the height of the push rod is higher than the height of the pallet , When the conveying device moves, the push rod scrapes the pole plate on the pallet into the conveying device and the pole plate is stacked on the conveying device; During the operation of the conveying device, the pole plates on the pallet are continuously scraped into the conveying device, and the pole plates are stacked on the conveying device into pole groups and sent out by the conveying device, which can continuously form pole groups with high production efficiency.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

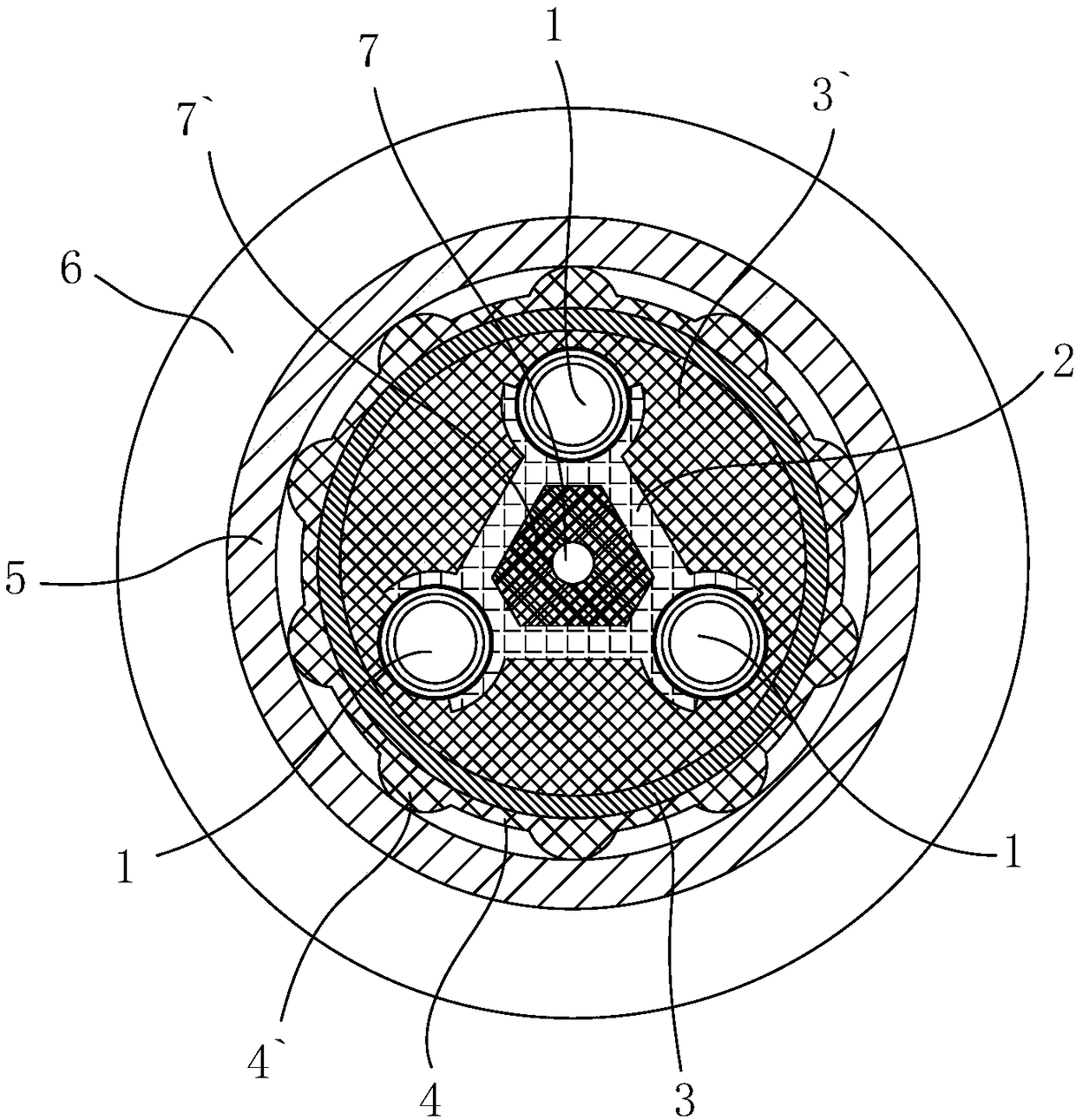

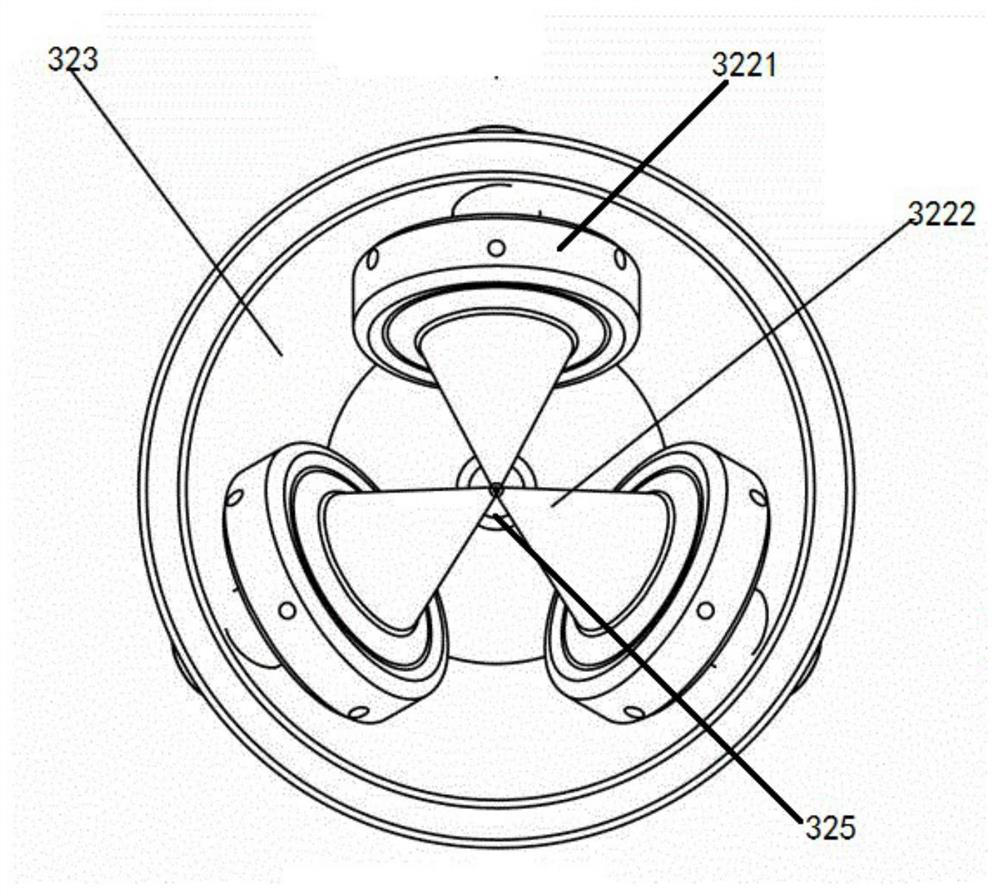

Atomization air cap

PendingCN112742619AImprove atomization effectAdjustable spray widthLiquid spraying apparatusHigh pressure gasPhysics

The invention discloses an atomization air cap which comprises a cap body, a mounting cavity used for mounting a nozzle is formed in the cap body, atomizing holes are formed in the cap body, and the atomizing holes are used for guiding high-pressure gas to be sprayed out and to intersect with the spraying direction of the nozzle to form secondary atomization. According to the atomization air cap, the atomization holes are used for guiding the high-pressure gas to be sprayed out to intersect with a certain point of a spraying path of the nozzle, fluid sprayed out of the nozzle is impacted by the high-pressure gas at the intersection to achieve secondary atomization, the structure can be used in cooperation with the conventional nozzle, the atomization effect of the nozzle is improved, and the spraying efficiency is improved.

Owner:CHONGQING CHANGJIANG COATING EQUIP

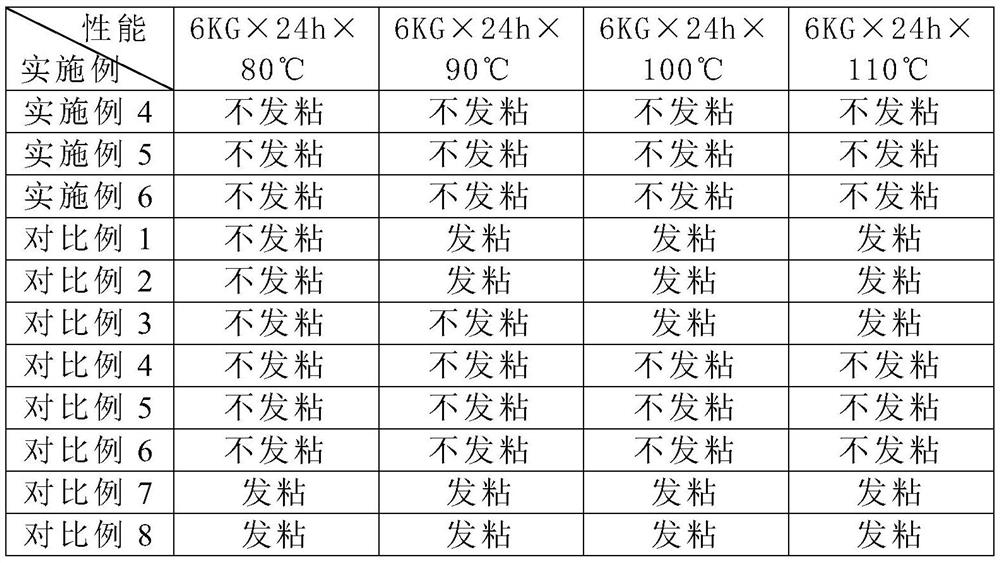

A kind of high anti-adhesive coating material and high heat-resistant anti-adhesive PVC products

ActiveCN111073424BGuaranteed plastic effectExcellent anti-sticking and high temperature resistanceFireproof paintsWax coatingsPolymer sciencePlasticizer

The invention relates to a high anti-adhesion coating material and a high heat-resistant anti-adhesion PVC product, belonging to the technical field of polymer materials. The high anti-adhesive coating material for PVC of the present invention includes the following components in parts by weight: 0.3-0.6 parts of acrylate copolymer, 0.2-0.3 parts of water-soluble polyurethane, 0.05-0.2 parts of wax emulsion, fluorine-silicon modified nano 0.2 to 0.4 parts of particles, 0.2 to 0.4 parts of polyacrylamide, 0.15 to 0.3 parts of polyethylene glycol, and 0.4 to 1 part of solvent; the high anti-adhesive coating material of the present invention can effectively inhibit growth when applied to soft PVC products. The plasticizer migrates, and the coated PVC product does not blister or peel.

Owner:NINGBO JINGMEI SCI & TECH CO LTD

Rotating nipple for hydraulic shaping

The invention discloses a rotating nipple for hydraulic shaping and relates to a rotating nipple, solving the problems that the shaping orientation of a power motor is uncertain, and the power motor has failure and is damaged under the action of hydraulic pressure and a reactive torque. In the invention, a steering rod is inserted in a rotating sleeve, and a positioning hole is arranged on the rotating sleeve; a positioning pin is inserted in the positioning hole and used for positioning the steering rod and the rotating sleeve; the lower end of an upper joint is inserted in the rotating sleeve as well as sleeved at the upper end of the steering rod; the upper part of a lower joint is inserted at the lower end of the rotating sleeve, and the upper end surface of the lower joint is in contact with the lower end surface of the steering rod; a guide block is arranged on the lower part of the steering rod, and a stop block is arranged below the guide block; and the upper end of the stop block is in contact with the guide block. The rotating nipple replaces the traditional hydraulic motor, achieves the purpose of omnibearing shaping and guarantees the shaping effect.

Owner:DAQING OILFIELD CO LTD

Loudspeaker voice coil shaping tooling and shaping process

ActiveCN103596115BAvoid secondary deformationQuality assuranceElectrical transducersEngineeringBlock match

Owner:BESTAR HLDG

A lithium battery shaping device

ActiveCN111786027BImprove shaping efficiencyQuality assuranceAssembling battery machinesFinal product manufactureEngineeringTransfer mechanism

The invention provides a lithium battery shaping device, comprising a feeding mechanism, a left shaping mechanism, a right shaping mechanism, a left transport mechanism, a right transport mechanism, a front clamp transfer mechanism, a rear clamp transfer mechanism, a fine shaping mechanism, a blanking mechanism and several The left transport mechanism and the right transport mechanism are arranged side by side, the front clamp transfer mechanism is connected to the front end of the left transport mechanism and the right transport mechanism, and the rear clamp transfer mechanism is connected to the back end of the left transport mechanism and the right transport mechanism. The core fixture is circulated on the left transport mechanism, the rear fixture transfer mechanism, the right transport mechanism and the front fixture transfer mechanism; the feeding mechanism and the left shaping mechanism are set on the left side of the left transport mechanism from front to back, and the fine shaping mechanism and the right shaping mechanism The mechanism is set on the right side of the right transport mechanism from front to back, and the blanking mechanism is set on the side of the fine shaping mechanism. sex.

Owner:东莞市爱康智能技术有限公司

Processing equipment for sheath-free wires

InactiveCN108877997AImprove stress resistanceImprove fire resistanceApparatus for feeding conductors/cablesInsulated cablesWire rodProcess equipment

The invention relates to processing equipment for cable wires, aiming at providing new processing equipment for sheath-free wires by adapting to changes in product structure. The processing equipmentcomprises a bracket extrusion device and a wire core drawing device; the wire core drawing device comprises a metal wire feeding unit, the discharging port of the metal wire feeding unit is engaged with the feeding port of the metal wire straightening unit, and the discharging port of the metal wire straightening unit is engaged with the feeding port of the wire drawing unit; the wire drawing unitcomprises two drawing rolls arranged on the box in a rotating arrangement, the roll lengths of the two drawing rolls are horizontally and spaced apart, shaping grooves are disposed around the surfaceof the wire drawing roller, and the plurality of shaping grooves are spaced apart from each other along the longitudinal direction of the wire drawing roller. The processed cable has excellent pressure resistance, fire resistance, wear resistance, high temperature resistance and the like.

Owner:SICHUAN XINDONGFANG CABLE GROUP

Shaping jig for powder metallurgy

The invention belongs to the technical field of shaping jigs and discloses a shaping jig for powder metallurgy. The shaping jig comprises a heating base mechanism, a first jig body, a powder filling opening, a second jig body, a handle and a positioning shaft, wherein the powder filling opening is formed in the bottom of the first jig body; a first shaping plate matched with a second shaping plateis movably arranged at the bottom of the cavity of the first jig body; radiating holes are uniformly formed in the outer wall of the front side of the second jig body; and matching radiating hole sealing mechanisms are arranged at the radiating holes. According to the shaping jig, the radiating hole sealing mechanisms are arranged, when the radiating holes need to be opened, a servo motor is started to rotate anticlockwise, the servo motor drives a rotary rod to rotate, the rotary rod drives a plurality of groups of movable rods to synchronously rotate in the same direction through matching of a driving bevel gear and a driven bevel gear to further drive a support block and a sealing separation blade to rotate anticlockwise to open the radiating hole for heat dissipation, manual operationis not adopted, and the using potential safety hazard is reduced while greatly saving labor force.

Owner:吴中区甪直奥顿自动化设备厂

Weldment hydraulic shaping device

InactiveCN112337999AImprove shape qualityImprove applicabilityMetal-working feeding devicesPositioning devicesClassical mechanicsStructural engineering

The invention discloses a weldment hydraulic shaping device, and particularly relates to the technical field of weldment shaping machining. The weldment hydraulic shaping device comprises an operationpanel, a first hydraulic rotating motor, a second hydraulic rotating motor and armrests, wherein the armrests are symmetrically and fixedly installed on the two sides of the operation panel. According to the weldment hydraulic shaping device provided by the invention, through the arrangement of a correcting assembly, the first hydraulic rotating motor is started to drive a matching cam to rotatein a reciprocating mode, a pushing shaft is made to bend a horizontal weldment around a matching cylinder, and weldments with different sizes can be clamped and shaped, so that applicability is high,operation is conducted conveniently, and the shaping quality of the weldment is good; and through the arrangement of a limiting assembly, when a transmission long plate moves forwards, a transmissionshort plate moves backwards, clamping blocks at the end parts of connecting plates clamp inwards, otherwise, the clamping blocks loosen outwards, so that a correction machine clamps and protects the qualified part of the weldment while shaping the deformed part of the weldment, secondary deformation of the qualified part of the weldment is prevented, and the shaping effect of the weldment is ensured.

Owner:苏州市华振机械电器有限公司

Partition disc assembly and plastic uptake method

The invention belongs to the technical field of plastic uptake, and discloses a partition disc assembly and a plastic uptake method. The partition disc assembly comprises a partition disc film, an upper clamping plate and a lower clamping plate. The partition disc film is made of a flexible high-temperature-resistant material and is provided with a first side face and a second side face which are oppositely arranged; the upper clamping plate is arranged on the first side face and is parallel to the length or width direction of the partition disc film; the lower clamping plate is arranged on the second side face and is opposite to the upper clamping plate; the partition disc film is clamped between the upper clamping plate and the lower clamping plate; and the partition disc assembly can be flexibly adjusted according to the size of the spare area of a plastic uptake machine base plate, the plastic uptake effect of a plastic uptake base material can be guaranteed while plastic uptake material consumption is reduced, and the plastic uptake production flexibility is improved. The partition disc assembly is used in the plastic uptake method, when the whole plastic uptake machine base plate cannot be fully filled with the plastic uptake base material, plastic uptake work can be conducted on plastic uptake equipment with a small number of plastic uptake materials, the plastic uptake work efficiency is improved, and the plastic uptake work cost is reduced.

Owner:成都欧派智能家居有限公司

An intelligent measuring and repairing device

ActiveCN106424211BLarge displacementGuaranteed plastic effectMetal-working feeding devicesMetal working apparatusRestoration deviceComputer engineering

The invention provides an intelligent measuring repair device. The device comprises a machine shell, a work table is arranged on the machine shell, a supporting mechanism, a shaping mechanism and positioning mechanisms are arranged on the work table, the shaping mechanism comprises two supporting blocks, a bearing mechanism is arranged on the supporting blocks, and comprises a bottom plate, a first air cylinder is arranged on the lower portion of the bottom plate and penetrates the centre of the bottom plate to be arranged on a carrying plate in a pushed manner, the two sides of the bottom plate are provided with a first shaping portion used for shaping and two second shaping portions symmetrically arranged on the two sides of the bottom plate, and the four positioning mechanisms are arranged on the four corners of the bottom plate. According to the repair device, a computer back shell is placed on the carrying plate, the carrying plate is pulled to the shaping mechanism through a lead screw, and is clamped between the shaping head and the bearing head, the vertical position of the computer back shell is fixed through the first air cylinder on the lower portion, the four corners of the computer back shell are fixed through the positioning mechanisms, meanwhile, through a limiting mechanism, the computer back shell is limited, fine displacement of the back shell during shaping is prevented, and the shaping effect is ensured.

Owner:SUZHOU KANGHONG INTELLIGENT EQUIP CO LTD

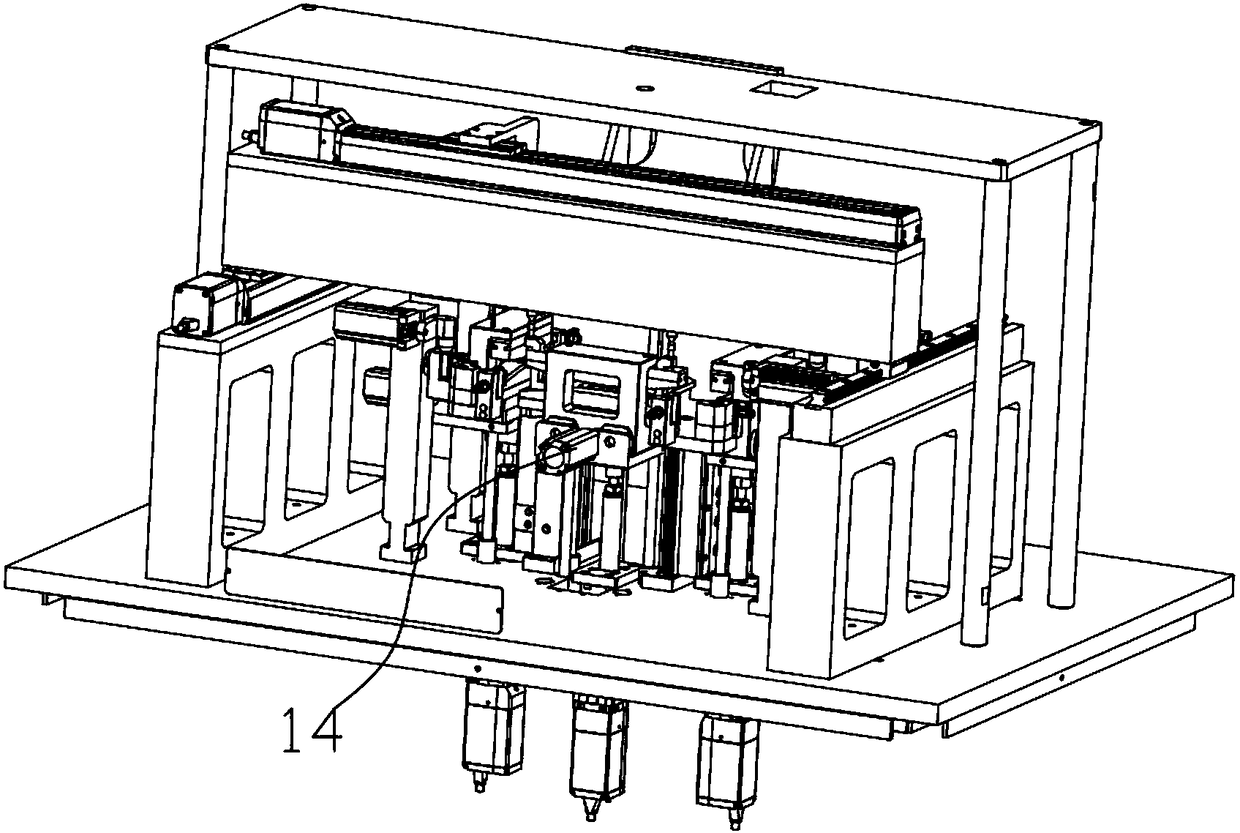

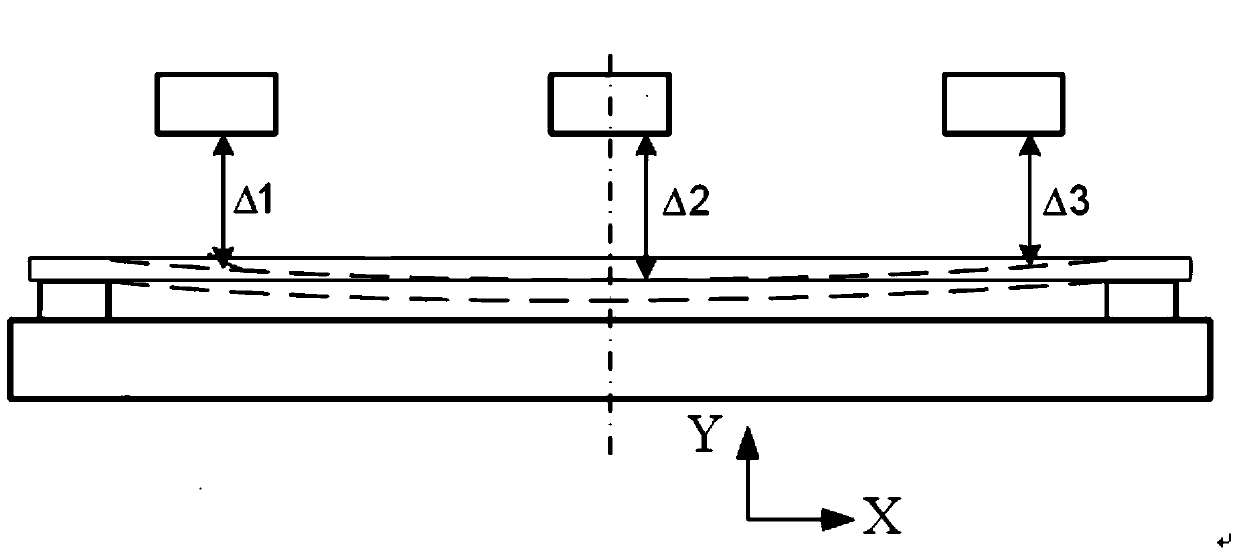

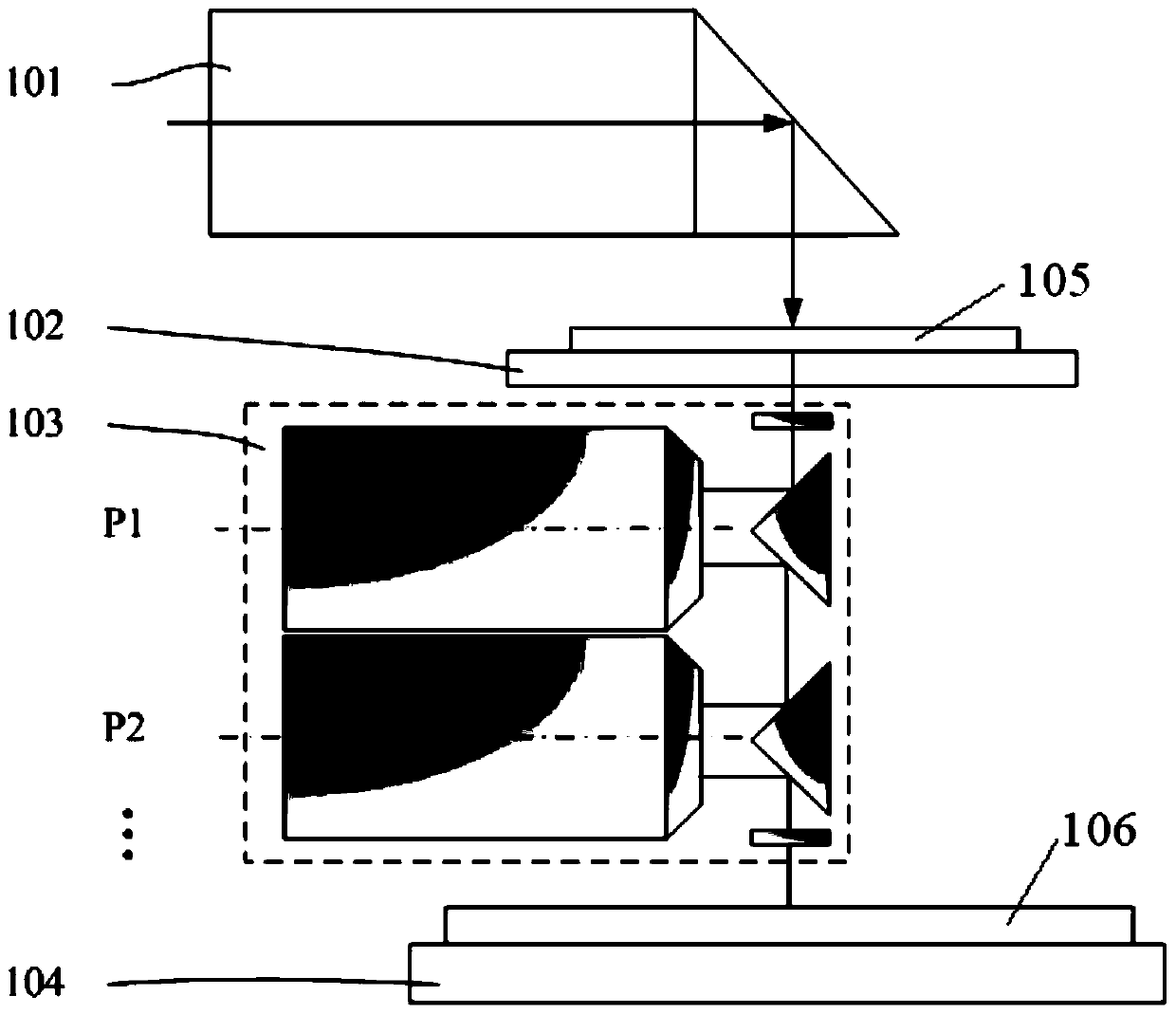

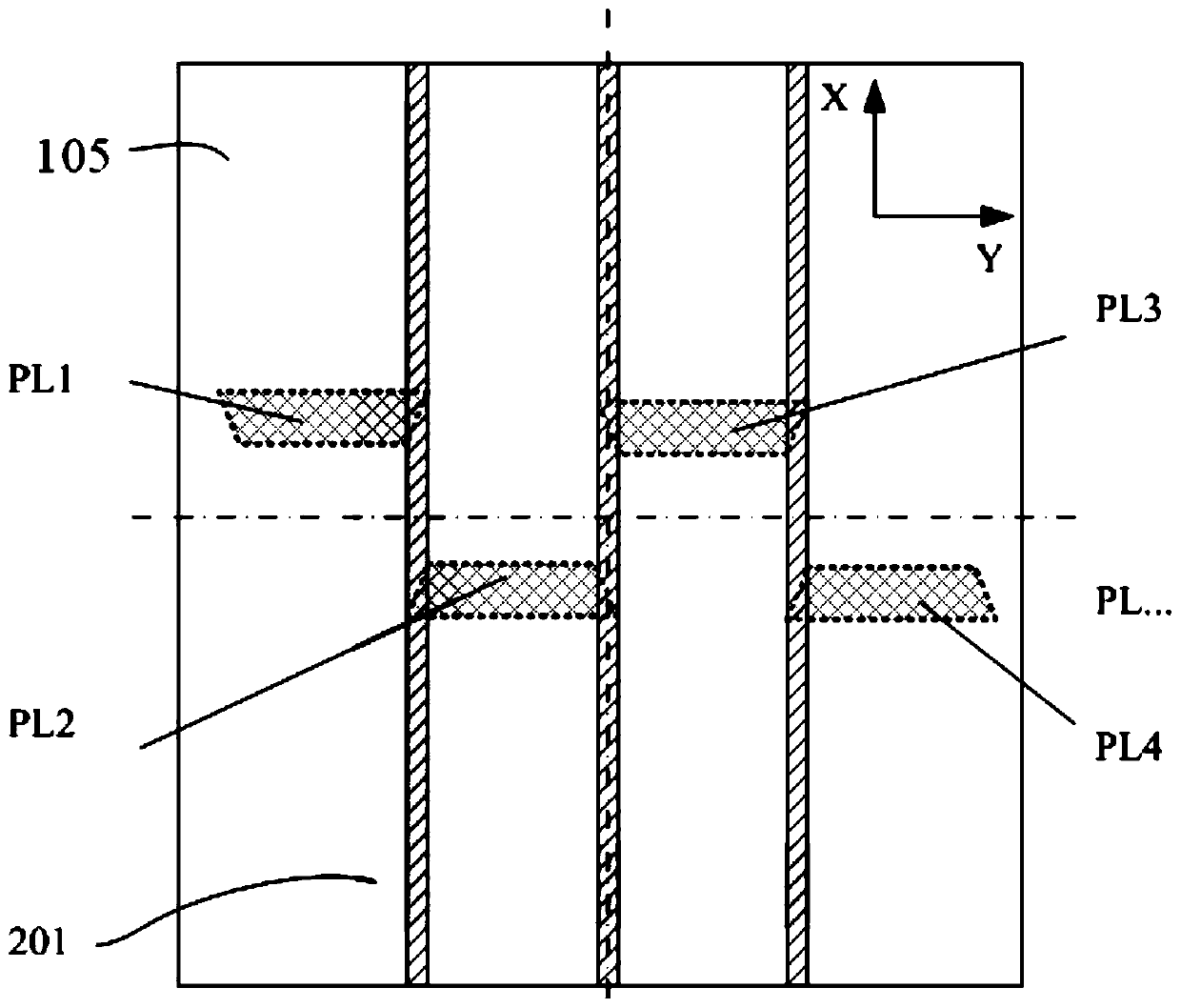

A large mask reshaping device and method

ActiveCN104570592BGuaranteed plastic effectSolving Image Quality IssuesPhotomechanical exposure apparatusMicrolithography exposure apparatusCycle controlMeasurement device

The invention provides a device and method for shaping a large mask plate. The device comprises a large mask plate, a plate bearing bench, multiple vertical lifting mechanisms and multiple measurement devices. The large mask plate is fixed to the plate bearing bench. The measurement devices are used for feeding the measured large mask plate position signal back to the corresponding vertical lifting device. The vertical lifting device adjusts a vertical position of the large mask plate according to the feedback signal. The device utilizes the vertical lifting mechanisms and the multiple measurement devices to shape the large mask plate so that real-time close-cycle control of large mask plate vertical deflection is realized, large mask plate shaping effects are effectively guaranteed and the problem of poor imaging quality caused by large mask plate self-weight deformation is solved. The device has a simple structure and is convenient for operation.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

A device for flattening the end face of a cell

ActiveCN107394248BRealize kneading and shapingRealize automatic shapingAssembling battery machinesFinal product manufactureControl theoryMechanical engineering

The invention provides a device for kneading and flattening the end face of a battery cell, which includes a frame, a battery cell clamping device and a kneading and flattening device. On the frame, the kneading and flattening device is slidably installed on the frame, and can move back and forth relative to the kneading and flattening device. In the present invention, the cell clamping device and the kneading device are arranged on the frame, and the cell clamping device is used to realize the fixed clamping of the cell, and the kneading device is used to realize the kneading and shaping of the end face of the cell; at the same time, In the present invention, the battery cell clamping device is installed on the frame through the slewing device, and the slewing device is used to drive the battery cell clamping device to rotate, so as to realize the automatic reversing of the battery cell, which can not only improve the processing efficiency, reduce labor intensity, but also avoid The clamping error caused by the secondary clamping is eliminated, resulting in differences in the shaping effects of the two end faces of the battery cell, which affects its processing quality.

Owner:WUHAN YIFI LASER EQUIP CO LTD

Realizing method of data stream constraint control

ActiveCN100426738CReduce storage spaceImprove pass rateData switching networksData streamConstraint control

The method comprises: constructing a token bucket that includes depth parameter and bandwidth parameter; the depth of the token bucket is sum of the fixing token bucket value and the dynamical token bucket depth value; in term of flow rate allocating to users, the relevant token numbers are added into the token bucket, and meanwhile in term of actual flow rate of users, the token numbers is subtracted from the token bucket; before subtracting the token numbers, it is made illegal that the token numbers is small than the depth value of fixing token bucket; when the token is added at the next time, firstly the depth value of fixing token bucket is filled up, and then the flow rate of users is allowed to pass through; it also can be implemented by adding tokens based on flow rate; the depth value of dynamical token bucket varies along with maximum bandwidth; the depth value of fixing token bucket can be a token numbers corresponding to a length of packet with maximum data length.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com