A kind of high anti-adhesive coating material and high heat-resistant anti-adhesive PVC products

A coating material, high anti-stick technology, applied in the field of high anti-stick coating materials and high heat-resistant and anti-stick PVC products, can solve the problems of product performance deterioration, abnormal noise, environmental pollution, etc., and achieve excellent anti-stick resistance. High temperature performance, guaranteed plastic effect, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

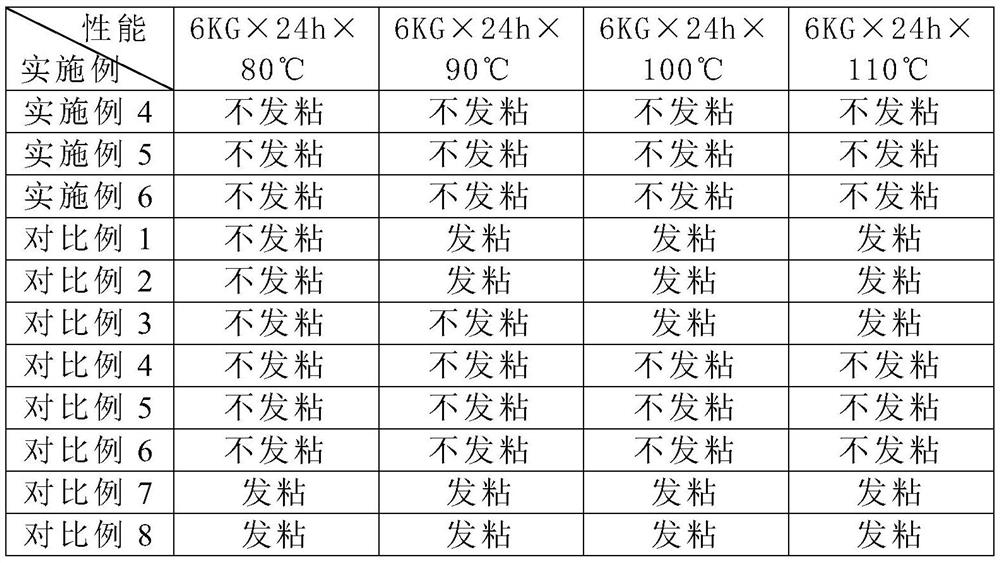

Examples

Embodiment 1

[0061] The components of the high anti-adhesive coating material used for PVC in this embodiment are: 0.6 parts of acrylate copolymer, 0.2 parts of water-soluble polyurethane, 0.1 part of wax emulsion, 0.3 part of fluorosilicon modified silicon dioxide, polyacrylamide 0.2 parts, polyethylene glycol 0.2 parts, ethanol 0.6 parts.

[0062] Among them, the preparation method of fluorine-silicon modified nanoparticles is to prepare the following raw material components in weight percentage: 67% ethanol, 23% ammonia water, 2% nano silicon dioxide, 6% tetraethyl orthosilicate, perfluorodecyl Triethoxysilane 1.3%, hexadecyltrimethoxysilane 0.7%; mix ethanol and nanoparticles evenly, add ammonia water slowly, disperse evenly, then slowly add tetraethyl orthosilicate, perfluorodecyl triethyl 50% of oxysilane and hexadecyltrimethoxysilane, stirred for 6 hours, then added the remaining perfluorodecyltriethoxysilane, and continued to stir for 6 hours; after that, filtered and washed, the c...

Embodiment 2

[0064] The components of the high anti-adhesive coating material used for PVC in this embodiment are: 0.4 part of acrylate copolymer, 0.3 part of water-soluble polyurethane, 0.2 part of wax emulsion, 0.2 part of fluorosilicon modified calcium carbonate, 0.4 part of polyacrylamide , 0.3 parts of polyethylene glycol, and 0.5 parts of ethylene glycol.

[0065] Among them, the preparation method of fluorine-silicon modified nanoparticles is to prepare the following raw material components in weight percentage: 70% ethanol, 22% ammonia water, 15% nano-calcium carbonate, 5% tetraethyl orthosilicate, perfluorodecyltri Chlorosilane 1.3%, Hexadecyltriethoxysilane 0.7%;

[0066] Mix ethanol and nano-calcium carbonate evenly, then slowly add ammonia water, disperse evenly, then slowly add tetraethyl orthosilicate, 40% of perfluorodecyl trichlorosilane and hexadecyl triethoxysilane, and stir for 4 hours , and then add the remaining perfluorodecyltrichlorosilane, and continue to stir for ...

Embodiment 3

[0068] The components of the high anti-adhesive coating material used for PVC in this embodiment are: 0.5 part of acrylate copolymer, 0.2 part of water-soluble polyurethane, 0.2 part of wax emulsion, 0.4 part of fluorosilicone modified montmorillonite, polyacrylamide 0.3 parts, polyethylene glycol 0.2 parts, isopropanol 0.7 parts.

[0069] Among them, the preparation method of fluorine-silicon modified nanoparticles is to prepare the following raw material components in weight percentage: 62% ethanol, 28% ammonia water, 2% nano-montmorillonite, 7% tetraethyl orthosilicate, perfluorodecyl Triethoxysilane 2%, hexadecyl trimethoxysilane 1%; mix ethanol and nano-montmorillonite evenly, add ammonia water slowly, disperse evenly, then slowly add tetraethyl orthosilicate, perfluorodecyl 60% of triethoxysilane and hexadecyltrimethoxysilane were stirred for 7 hours, then the remaining perfluorodecyltriethoxysilane was added, and the stirring was continued for 7 hours; then filtered and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com