A large mask reshaping device and method

A technology of shaping device and large mask, which is applied in photoplate making process exposure device, photoplate making process of pattern surface, microlithography exposure equipment, etc., to achieve the effect of convenient operation, simple structure and solving the problem of imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

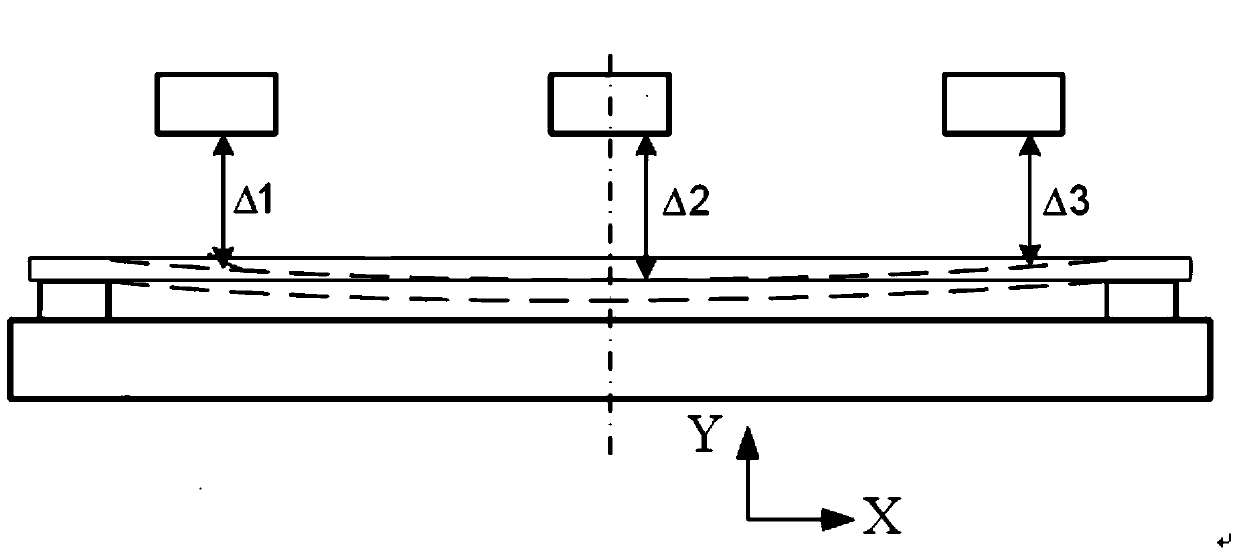

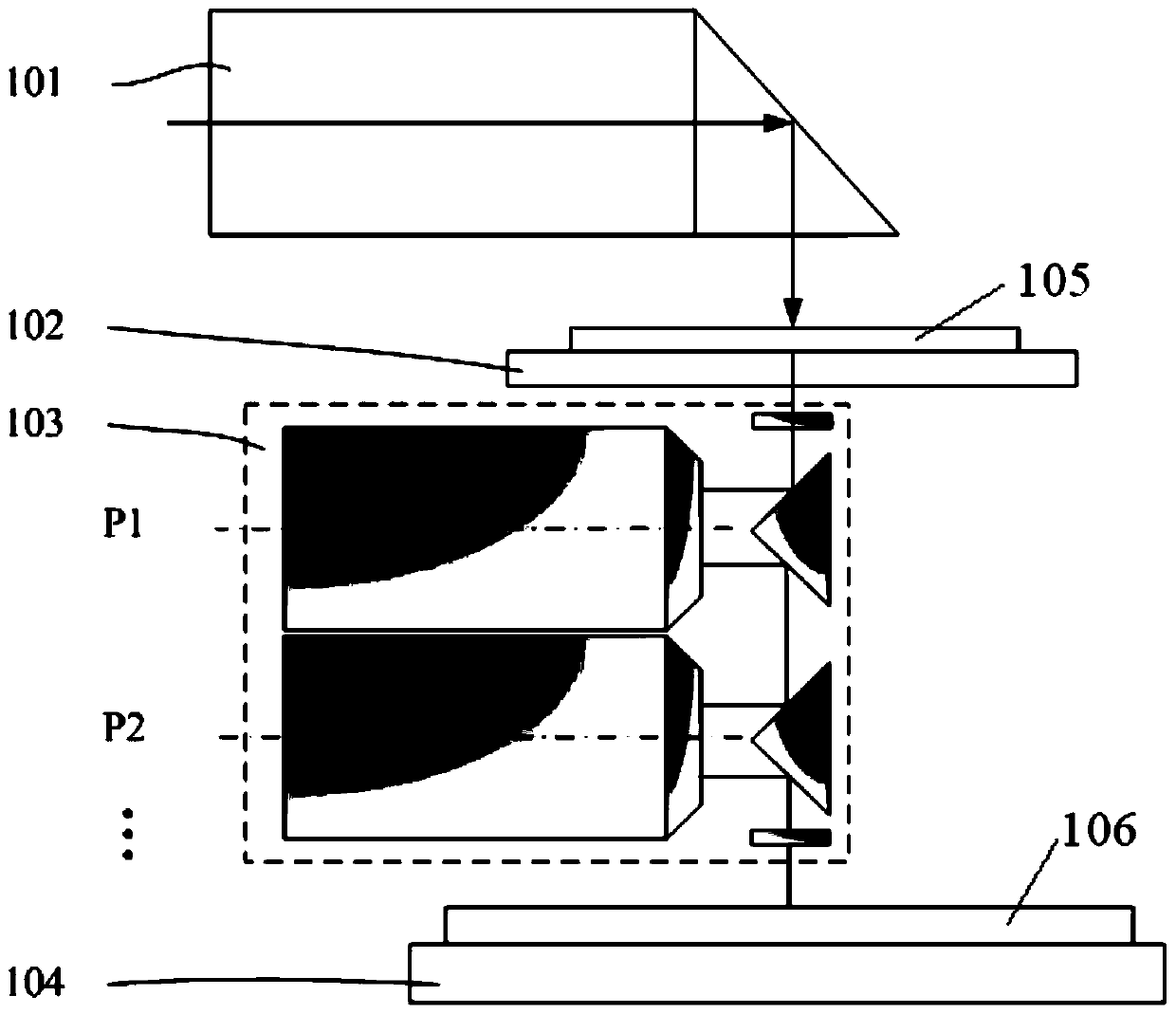

[0069] like Figure 4 and 5 As shown, the present invention provides a large reticle shaping device, the X direction is the scanning direction, and the Y direction is the non-scanning direction. Several groups of measuring devices 301; wherein,

[0070] The large reticle 304 is fixed on the stage 303 by vacuum adsorption;

[0071] The vertical lifting mechanism 302 and the measuring device 301 are arranged vertically opposite to the large reticle 304 respectively, and have a certain gap with the upper surface of the large reticle 304, and are horizontally arranged near the field of view of the objective lens;

[0072] Specifically, the vertical lifting mechanism 302 and the measuring device 301 are respectively arranged on the first side (upper side in the figure) of the large reticle 304, and each set of vertical lifting mechanisms 302 corresponds to a set of measuring devices 301, the measuring device 301 is arranged adjacent to the corresponding vertical lifting mechanis...

Embodiment 2

[0104] In Embodiment 1, the measuring device is arranged in conjunction with the vertical lifting mechanism (that is, a set of vertical lifting mechanisms is equipped with a set of measuring devices), and is arranged above the large reticle (Mask). The measuring device is arranged near the vertical lifting mechanism to complete the measurement of the vertical position of the large reticle (Mask), and feed back the measured position signal to the vertical lifting mechanism, so that the vertical lifting mechanism can adjust the vertical position of the large mask in real time. The amount of deformation effectively guarantees the shaping effect of the shaping device. Realize the closed-loop control of the vertical deformation of the large reticle.

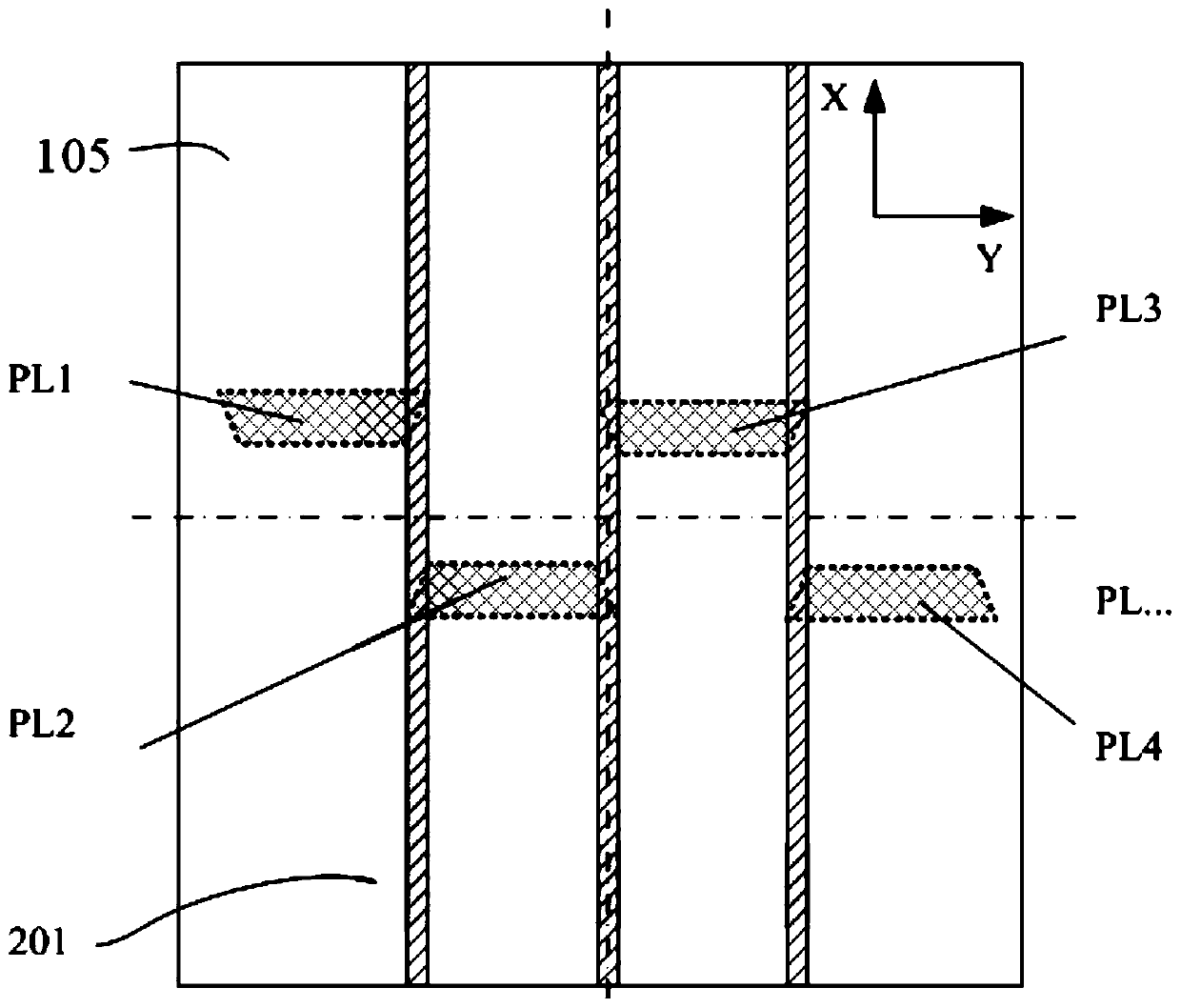

[0105] like Figure 11 and 12As shown, since the deformation of the large reticle 704 (Mask) in the vertical direction is basically the same as the deformation along the X direction, only one set of measuring devices 701 can be arra...

Embodiment 3

[0110] Embodiment 3 differs from the mask of Embodiment 2 in that, as Figure 13 and 14 As shown, three sets of measuring devices arranged at intervals in the Y direction are arranged under the large reticle, that is to say, the vertical lifting mechanism 901 is arranged vertically opposite to the first side of the large reticle 904;

[0111] Three sets of measuring devices 903 are arranged vertically opposite to each other on the second side of the large reticle 904 (lower in the figure), and are connected to a measuring device base 904;

[0112] The vertical lifting mechanism 901 and the same group of measuring devices 903 in the same position in the non-scanning direction are matched with each other.

[0113] In this embodiment, one set of measuring devices 903 and three sets of vertical lifting mechanisms 901 are arranged at intervals in the X direction, and three sets of measuring devices 903 and three sets of vertical lifting mechanisms 901 are arranged at intervals in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com