Novel control method for improving lithium ion soft-package laminated battery diaphragm fold

A battery separator and control method technology, applied in secondary batteries, battery pack parts, secondary battery charging/discharging, etc. problem, to achieve a good interface effect, ensure performance, and ensure the effect of no wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0028] See figure 1 with figure 2 , a novel control method for improving the wrinkle of lithium-ion pouch laminated battery diaphragm, comprising the following steps:

[0029] Step 1: Put the battery aside after filling it. After liquid injection and side sealing, the battery is placed at a high temperature of 45°C for 24 hours, and then transferred to normal temperature for 24 hours to ensure sufficient wetting of the pole pieces.

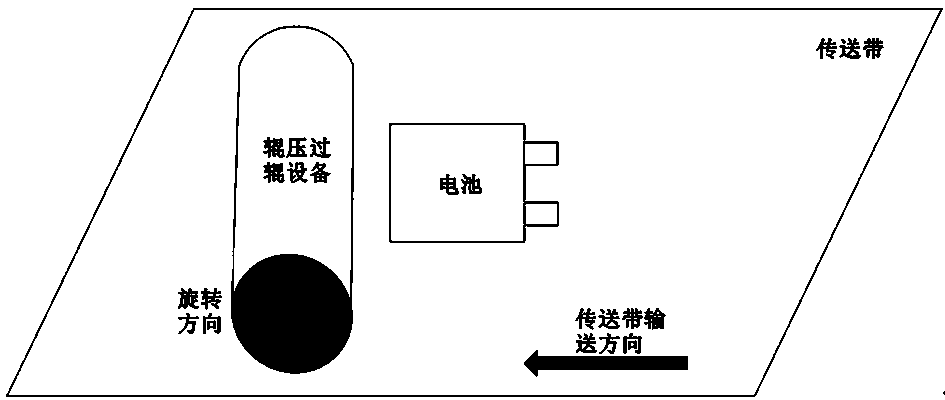

[0030] Step 2: Roll pressing before battery pre-charging. Use the transmission method to roll the shelved battery, adjust the pressure and speed of the rolling process, the pressure is 0.05MPa, and the rolling speed is 1m / s. When the battery is placed, the bottom is parallel to the pressing roller. For details, refer to figure 1 shown;

[0031] Step 3: Then pre-charge the rolled battery. The pre-charging process is consistent with the pre-charging process of industrially produced lithium-ion batteries. The pre-charging rate is 0.01C, 0.05C, 0...

Embodiment 2)

[0035] Step 1: Put the battery aside after filling it. After liquid injection and side sealing, the battery is placed at a high temperature of 45°C for 36 hours, and then transferred to room temperature for 12 hours to ensure sufficient wetting of the pole pieces.

[0036] Step 2: Roll pressing before battery pre-charging. Use the transmission method to roll the shelved battery, adjust the pressure and speed of the rolling process, the pressure is 0.3MPa, and the rolling speed is 2 m / s. When the battery is placed, the bottom is parallel to the pressure roller. Specifically refer to figure 1 shown;

[0037] Step 3: Then pre-charge the rolled battery. The pre-charging process is consistent with the pre-charging process of industrially produced lithium-ion batteries. The pre-charging rate is 0.01C, 0.05C, 0.1C, 0.2C;

[0038] Step 4: During the prefilling process, some gas will be generated due to the formation of the SEI film. The diaphragm is further shaped and exhausted by ...

Embodiment 3)

[0041] Step 1: Put the battery aside after filling it. After liquid injection and side sealing, the battery is placed at a high temperature of 45°C for 36 hours, and then transferred to room temperature for 24 hours to ensure sufficient wetting of the pole pieces.

[0042] Step 2: Roll pressing before battery pre-charging. Use the transmission method to roll the shelved battery, adjust the pressure and speed of the rolling during the rolling process, the pressure is 0.1MPa, and the rolling speed is 2 m / s. When the battery is placed, the bottom is parallel to the pressing roller. Specifically refer to figure 1 shown;

[0043] Step 3: Then pre-charge the rolled battery. The pre-charging process is consistent with the pre-charging process of industrially produced lithium-ion batteries. The pre-charging rate is 0.01C, 0.05C, 0.1C, 0.2C;

[0044] Step 4: During the prefilling process, some gas will be generated due to the formation of the SEI film. The diaphragm is further shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com