Patents

Literature

169results about How to "Effective exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Respiratory mask

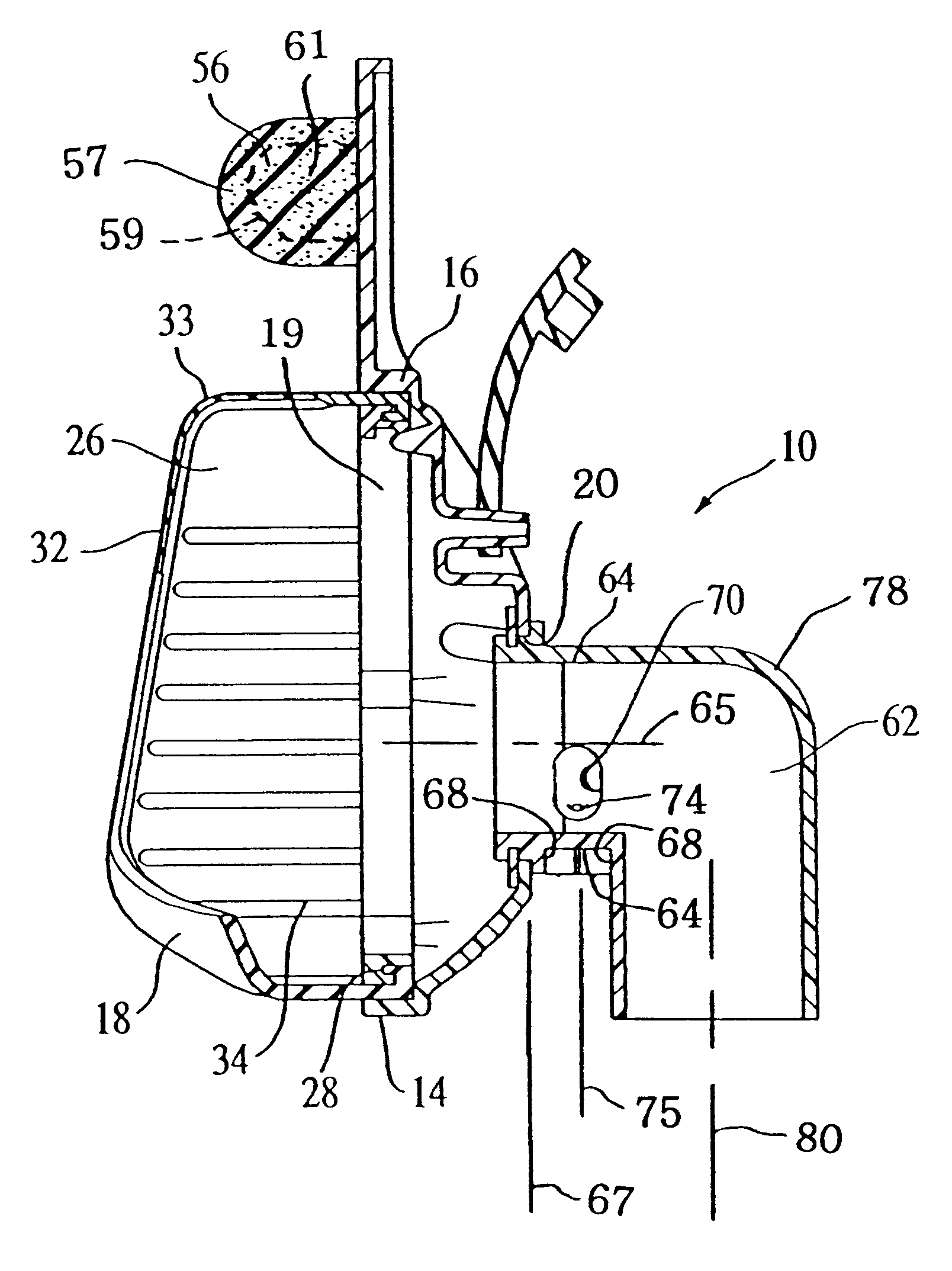

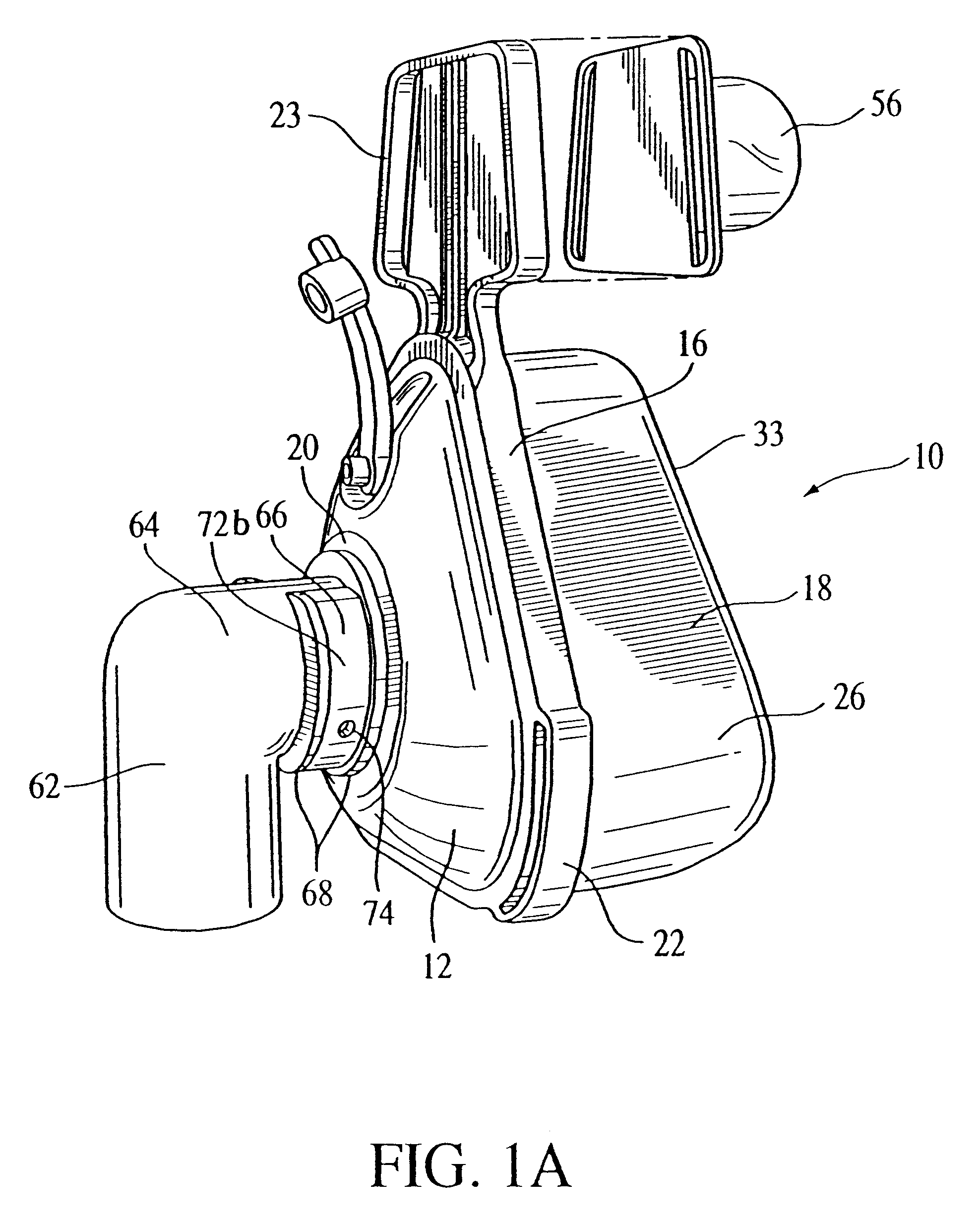

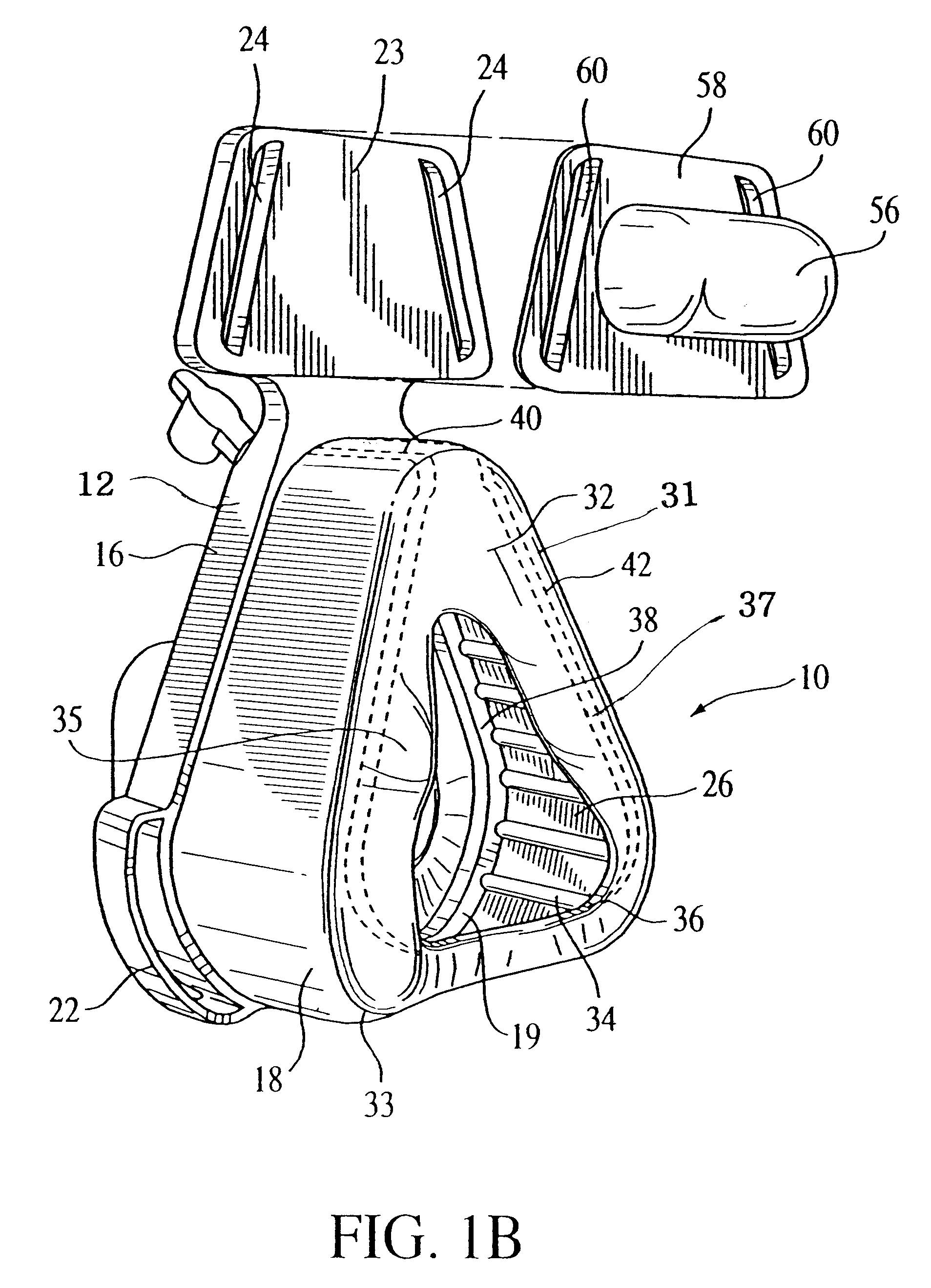

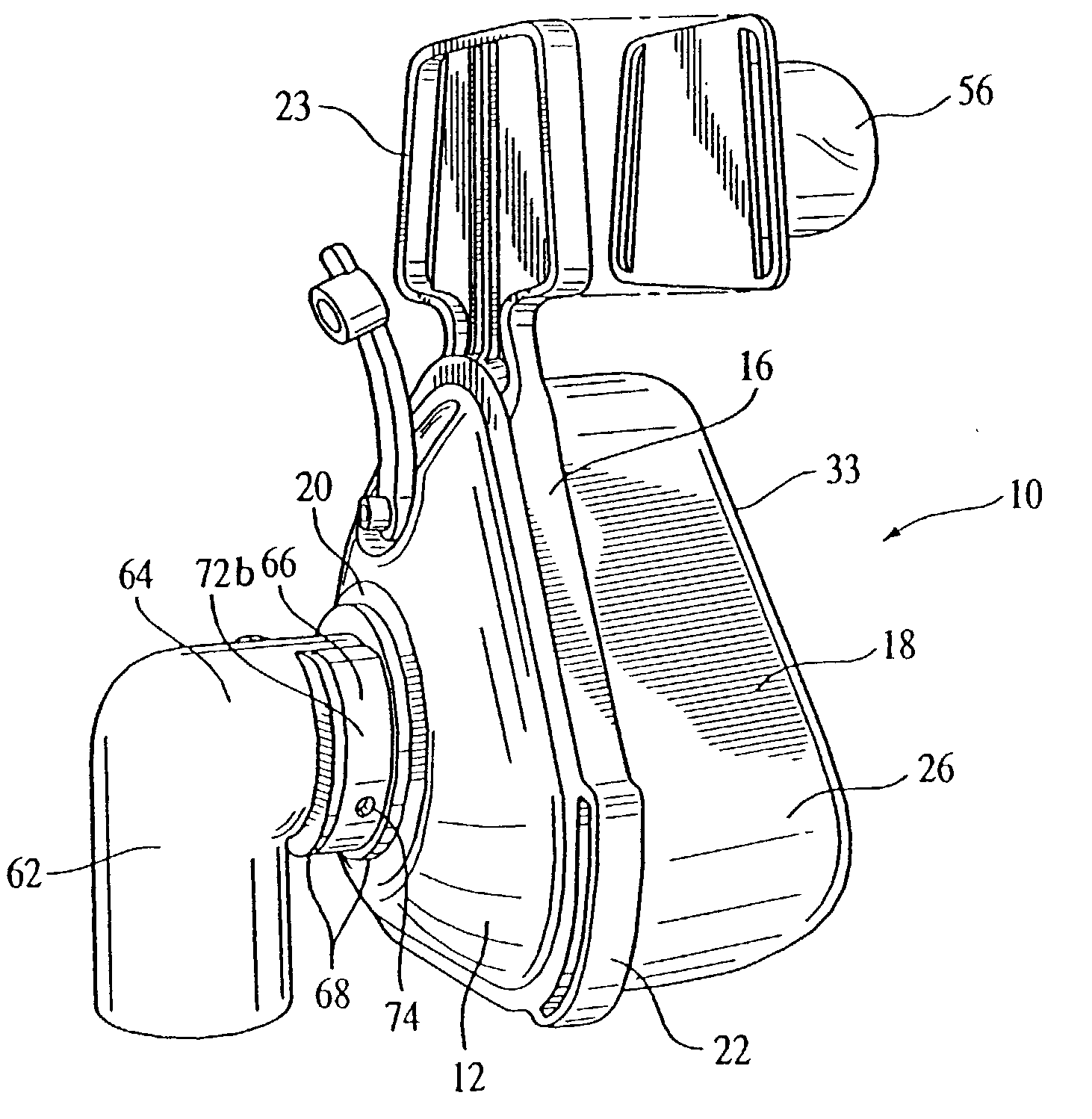

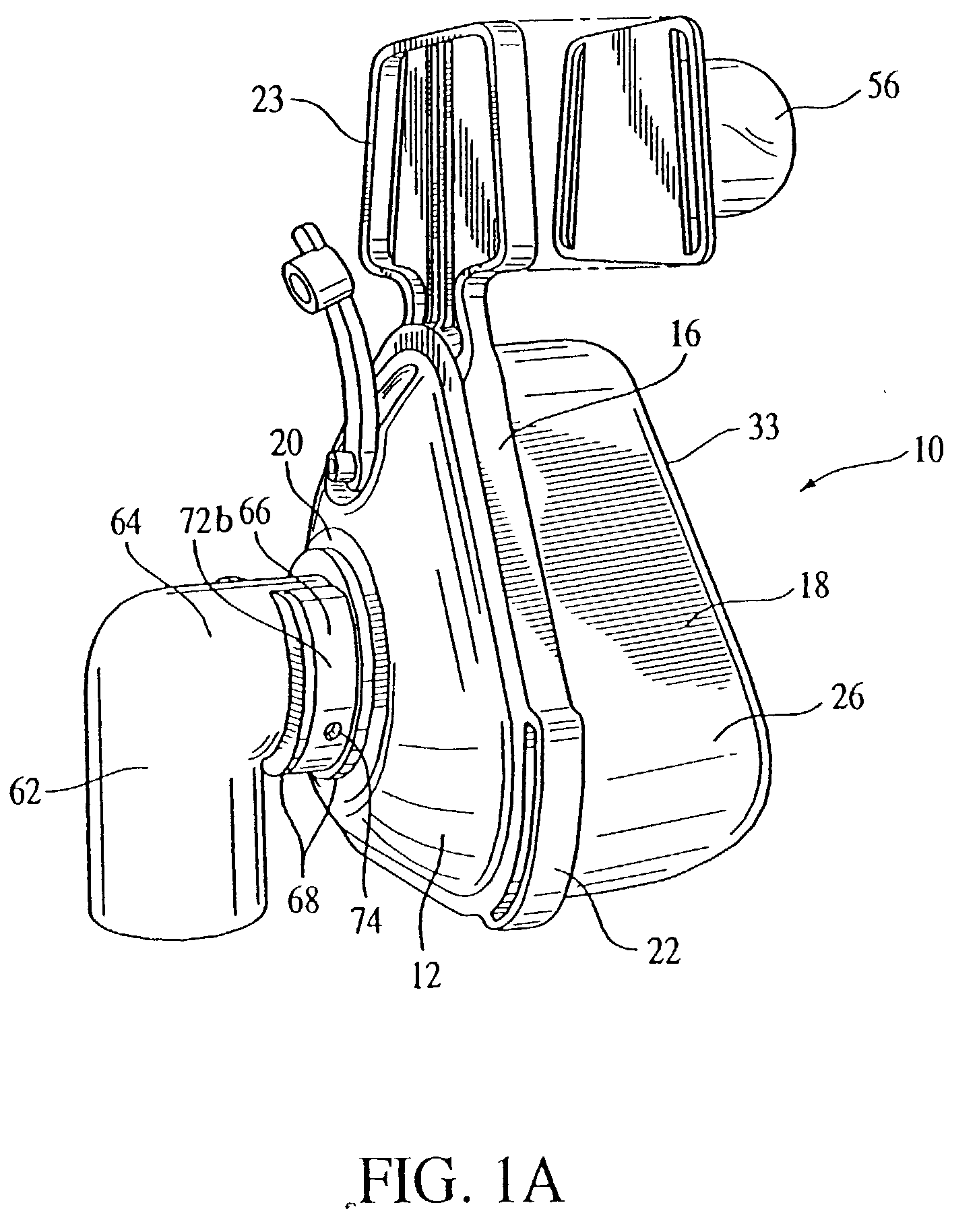

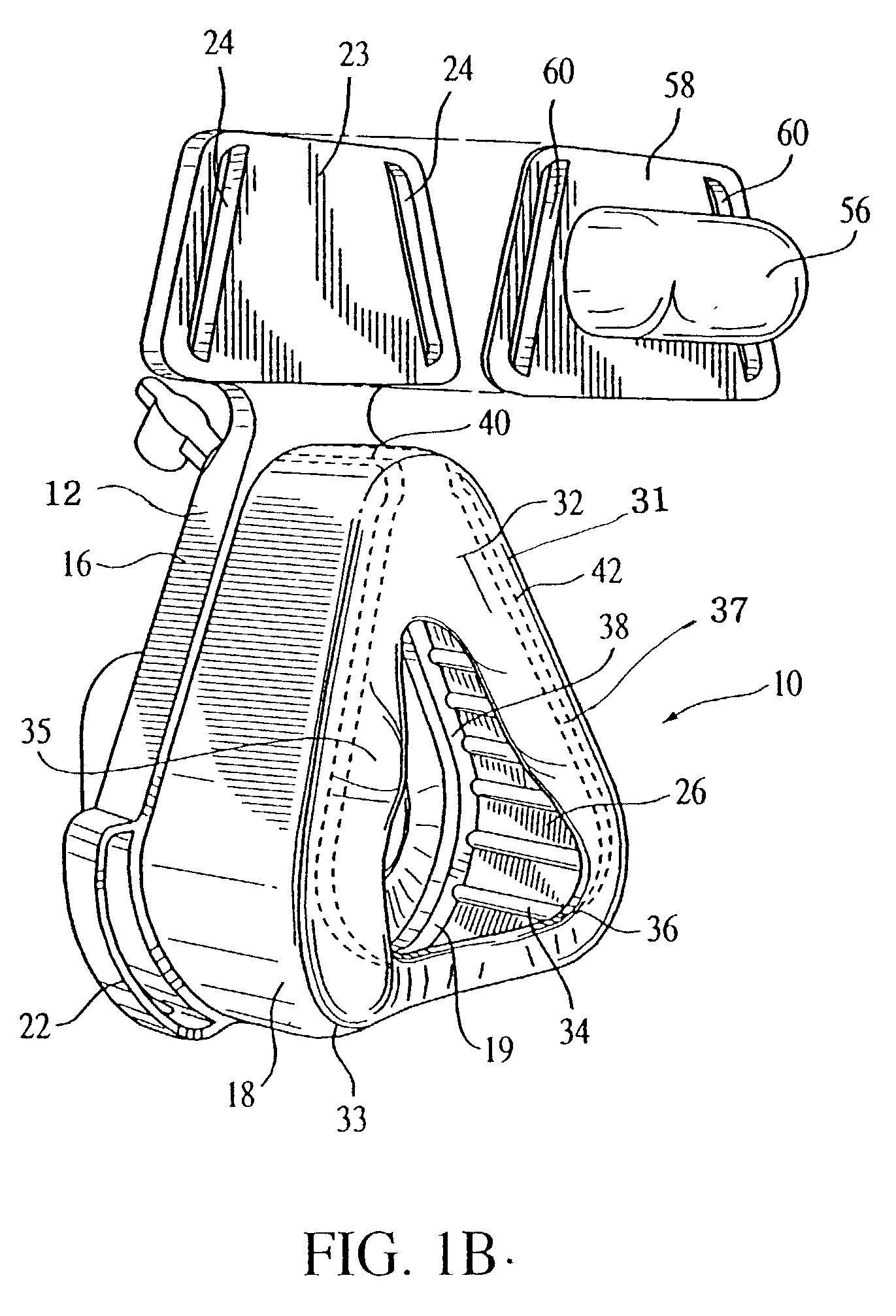

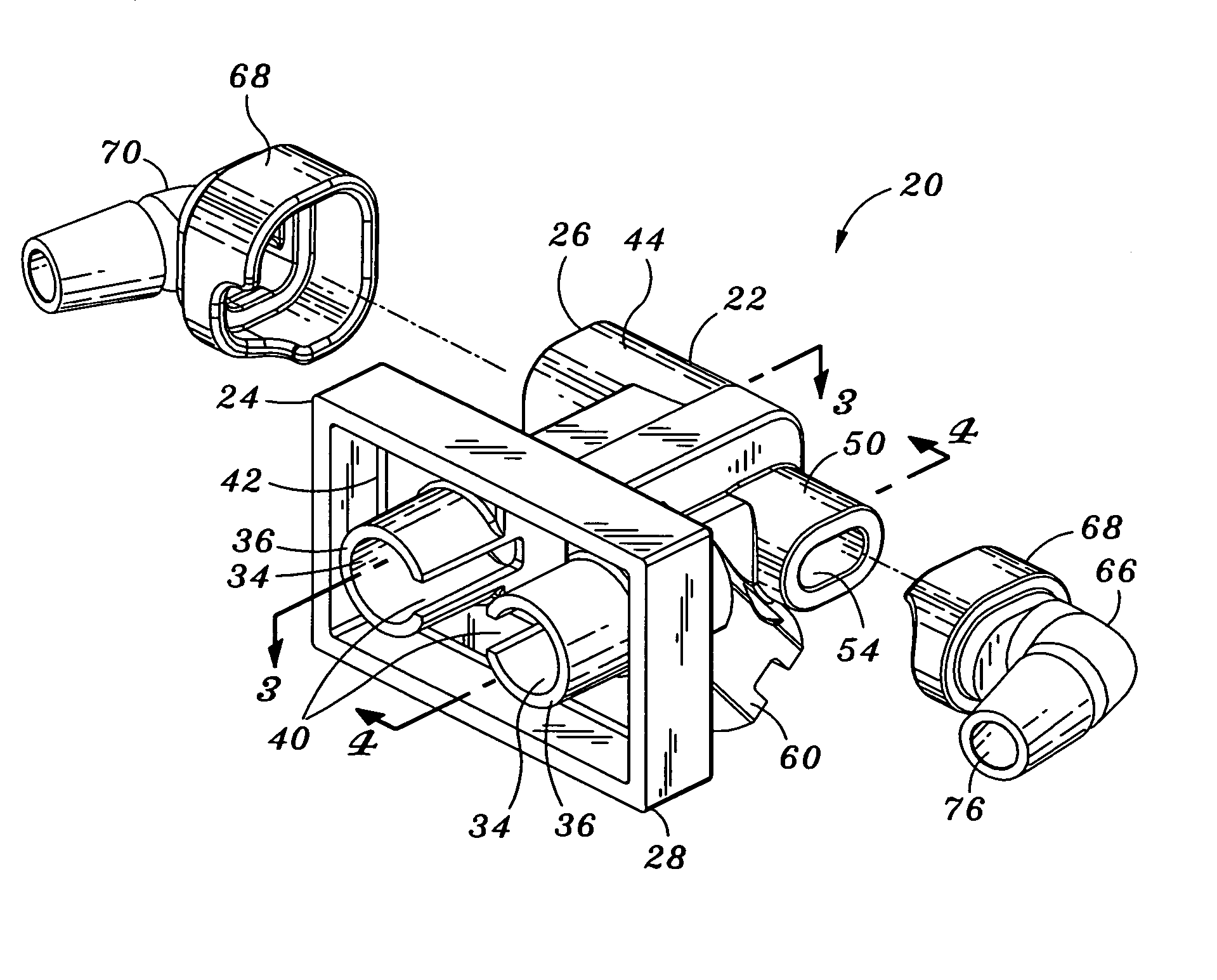

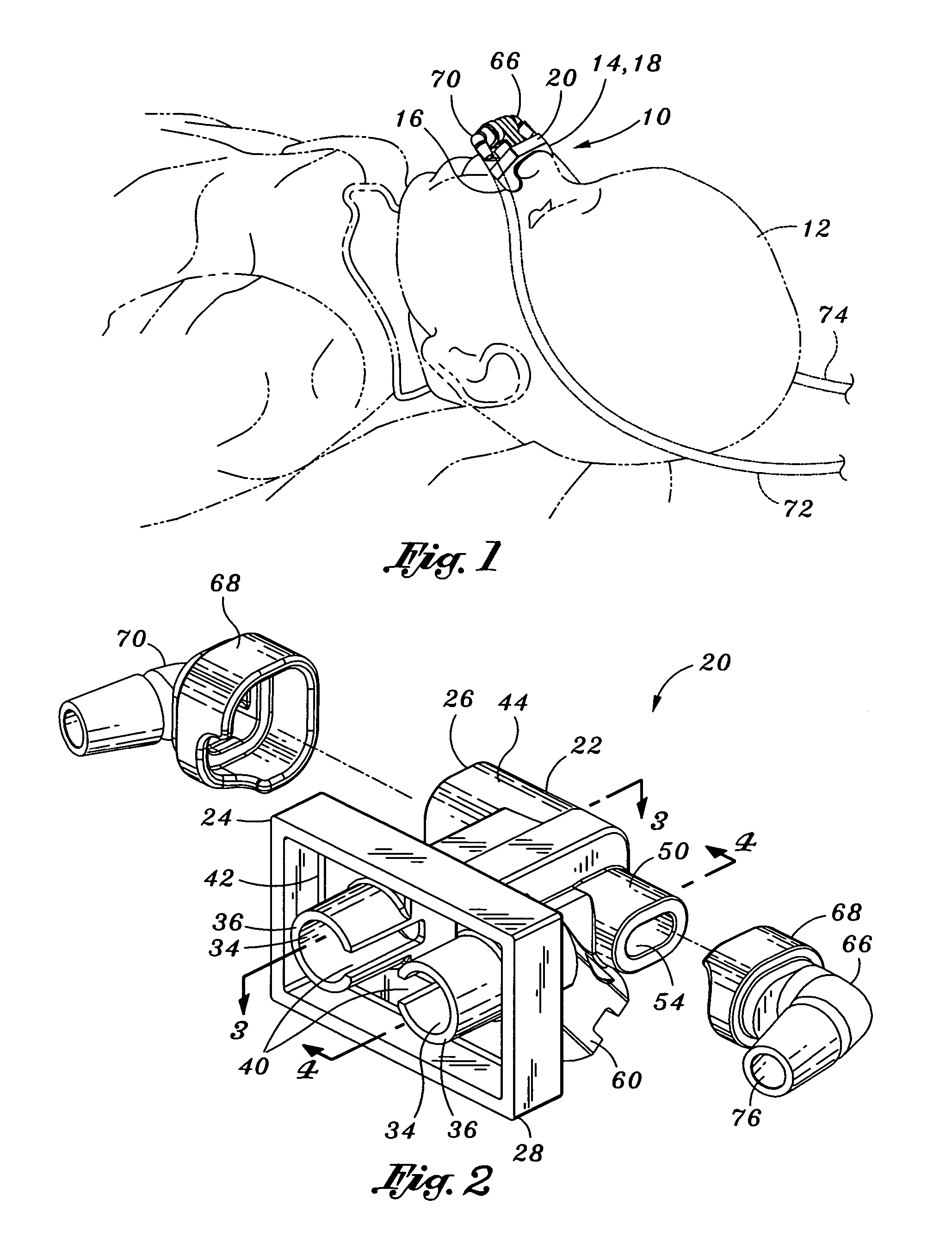

InactiveUS6467483B1Improve comfortReduce noise levelRespiratory masksBreathing masksCushionRespiratory mask

A respiratory mask having a flexible, mask seal portion for engagement with the face of a user, a gel forehead cushion and a rotatable elbow coupling having integral exhaust ports. The mask seal portion has a thin section which permits the mask to more easily adapt to the contour of the face of the user. The gel forehead cushion provides increased compliancy and resiliency to better adapt to multiple user physical profiles. The elbow coupling includes tapered through holes in a polycarbonate arc piece to provide a quiet passage of gas through the holes.

Owner:RIC INVESTMENTS LLC

Respiratory mask

InactiveUS20030019496A1Improve comfortReduce noise levelBreathing filtersRespiratory masksPhysical medicine and rehabilitationEngineering

A respiratory mask having a flexible, mask seal portion for engagement with the face of a user, a gel forehead cushion and a rotatable elbow coupling having integral exhaust ports. The mask seal portion has a thin section which permits the mask to more easily adapt to the contour of the face of the user. The gel forehead cushion provides increased compliancy and resiliency to better adapt to multiple user physical profiles. The elbow coupling includes tapered through holes in a polycarbonate arc piece to provide a quiet passage of gas through the holes.

Owner:RIC INVESTMENTS LLC

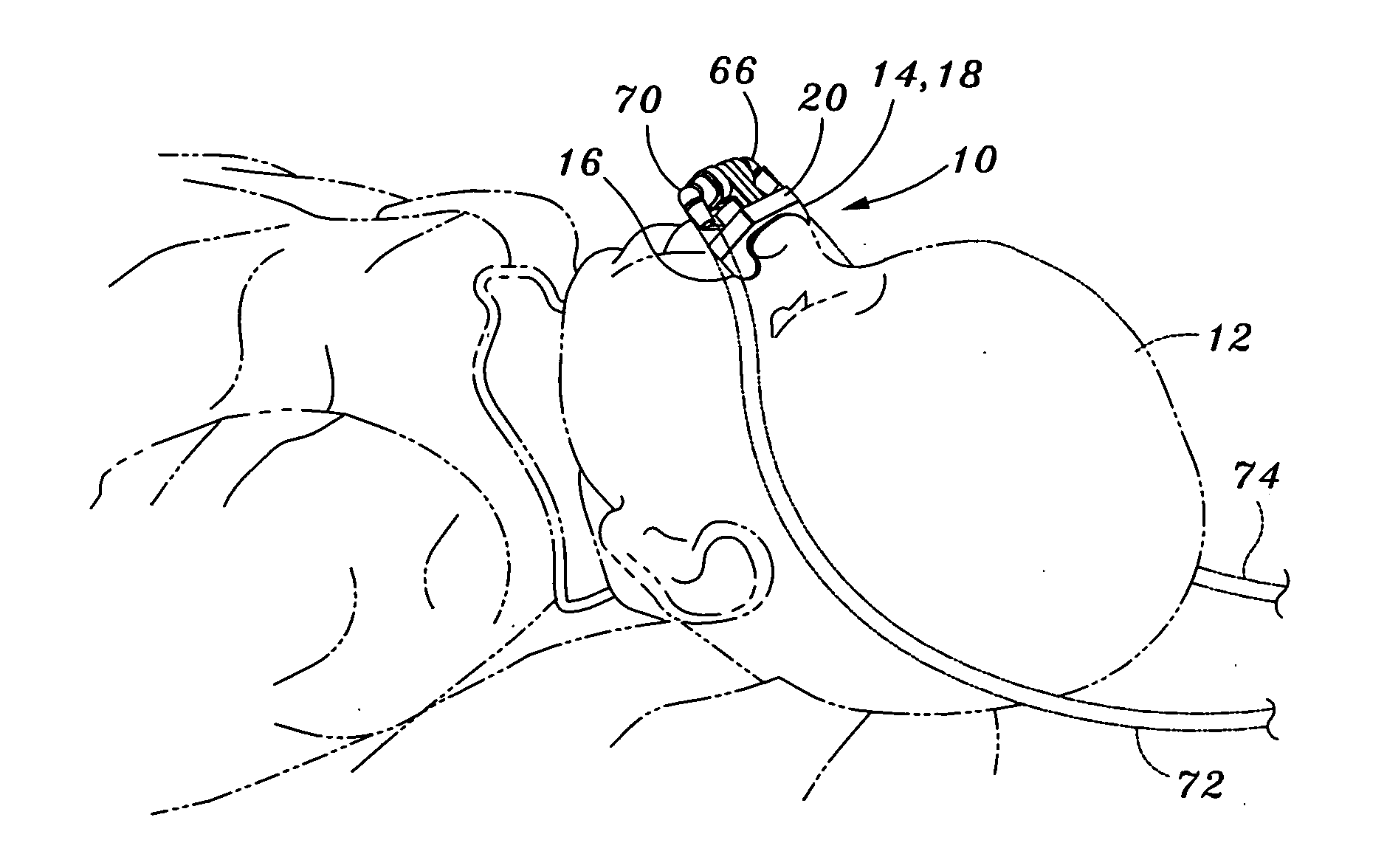

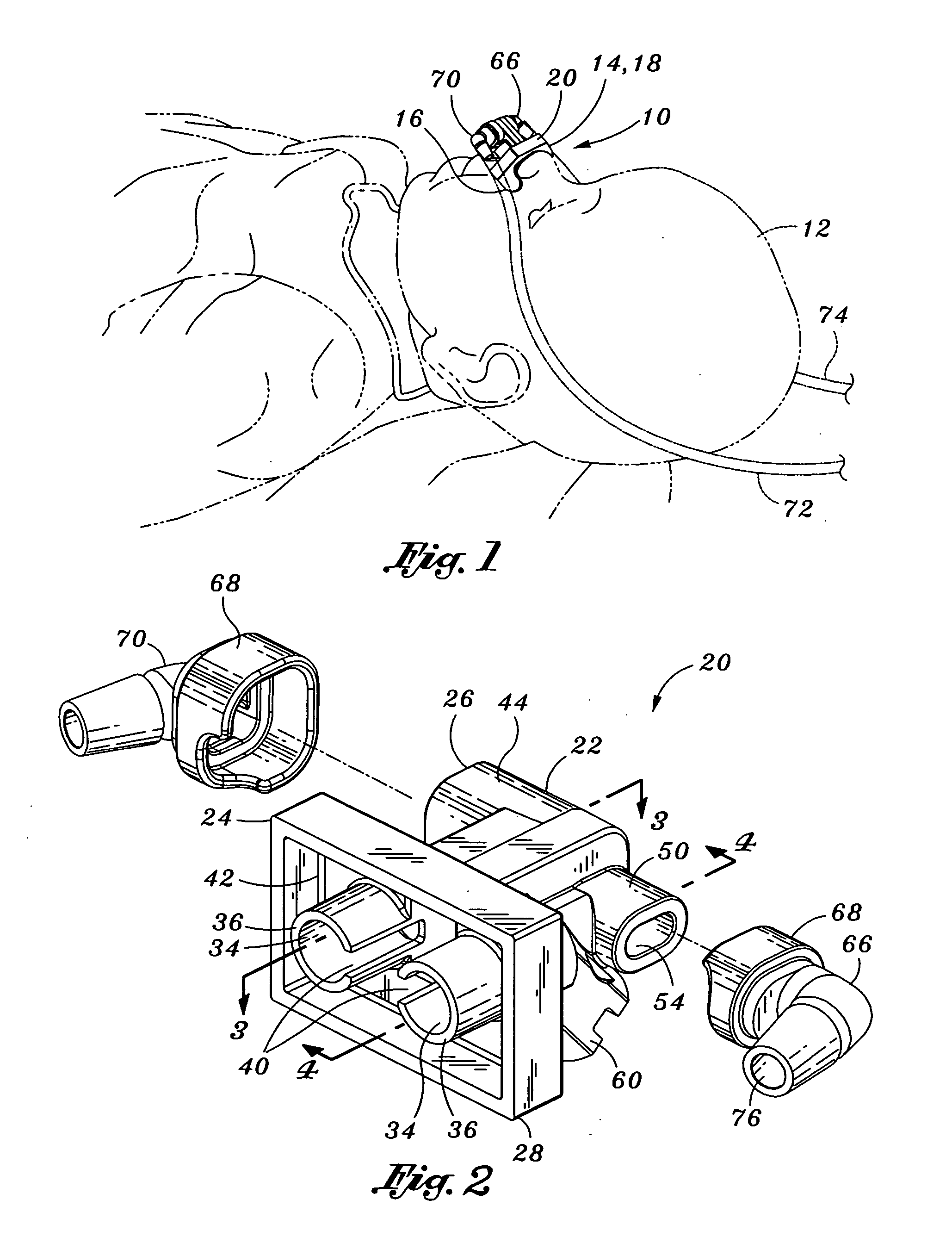

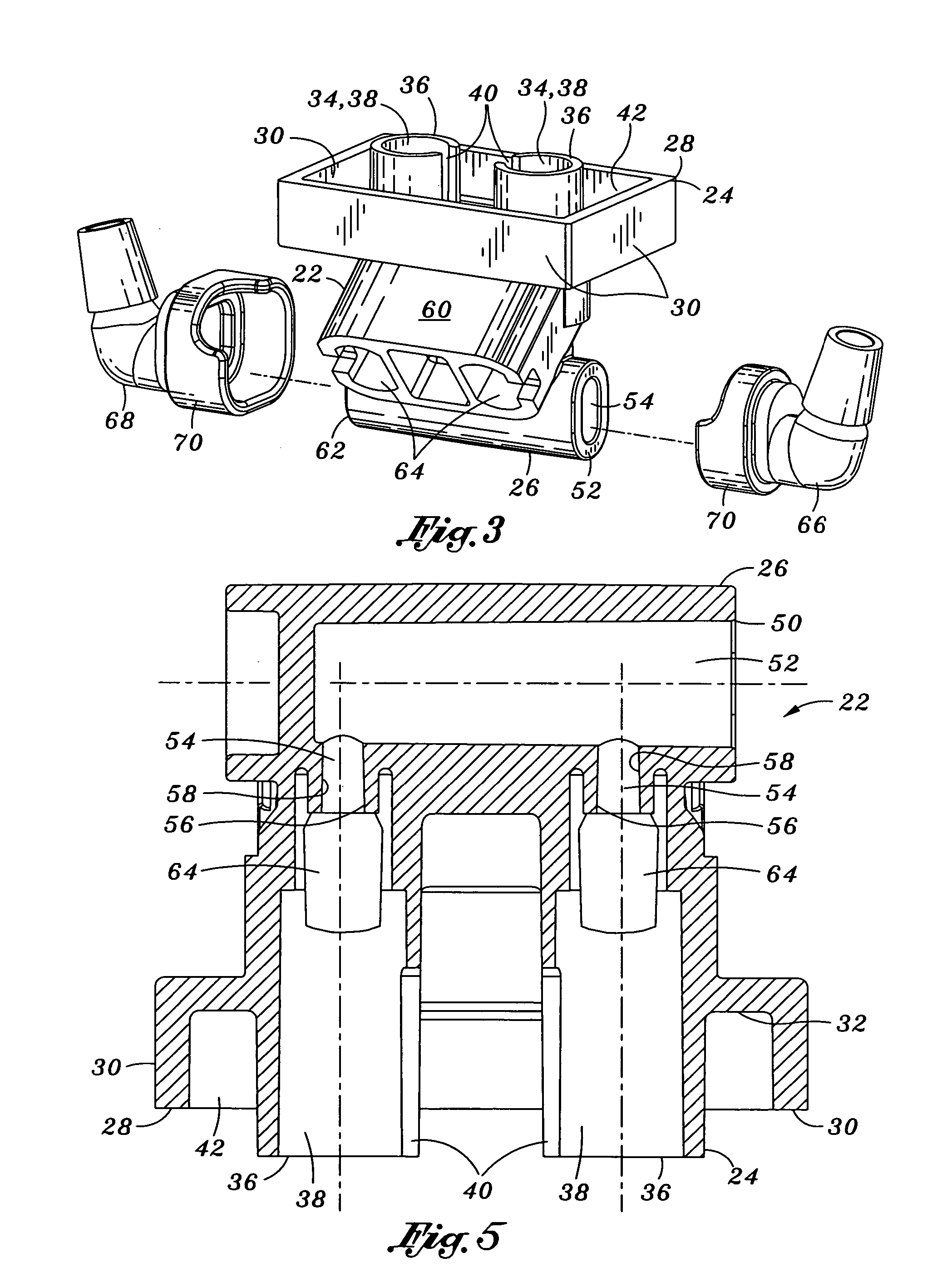

Venturi geometry design for flow-generator patient circuit

ActiveUS20070074724A1Risk minimizationReduce gas pressureRespiratorsFire rescueIntensive care medicineBreathing process

Provided is a universal interface adapted for providing continuous positive airway pressure to a patient when the interface is used with a standard ventilator. The interface is configured to operate at a supply pressure no greater than about 120 centimeters of H2O in order to deliver pressure to the patient of up to about 15 cm of H2O at a flow rate of up to about 12 liters / minute. The universal interface may comprise an interface body having a space pair of breathing passageways intersecting a corresponding of supply passageways. Each one of the breathing passageways is comprised of a patient passageway and an exhalation passageway. Each one of the supply passageways includes a jet venturi having a taper portion. Each one of the exhalation passageways includes a taper portion which tapers outwardly along a direction from the patient passageway toward the exhalation passageway.

Owner:VYAIRE MEDICAL 211 INC

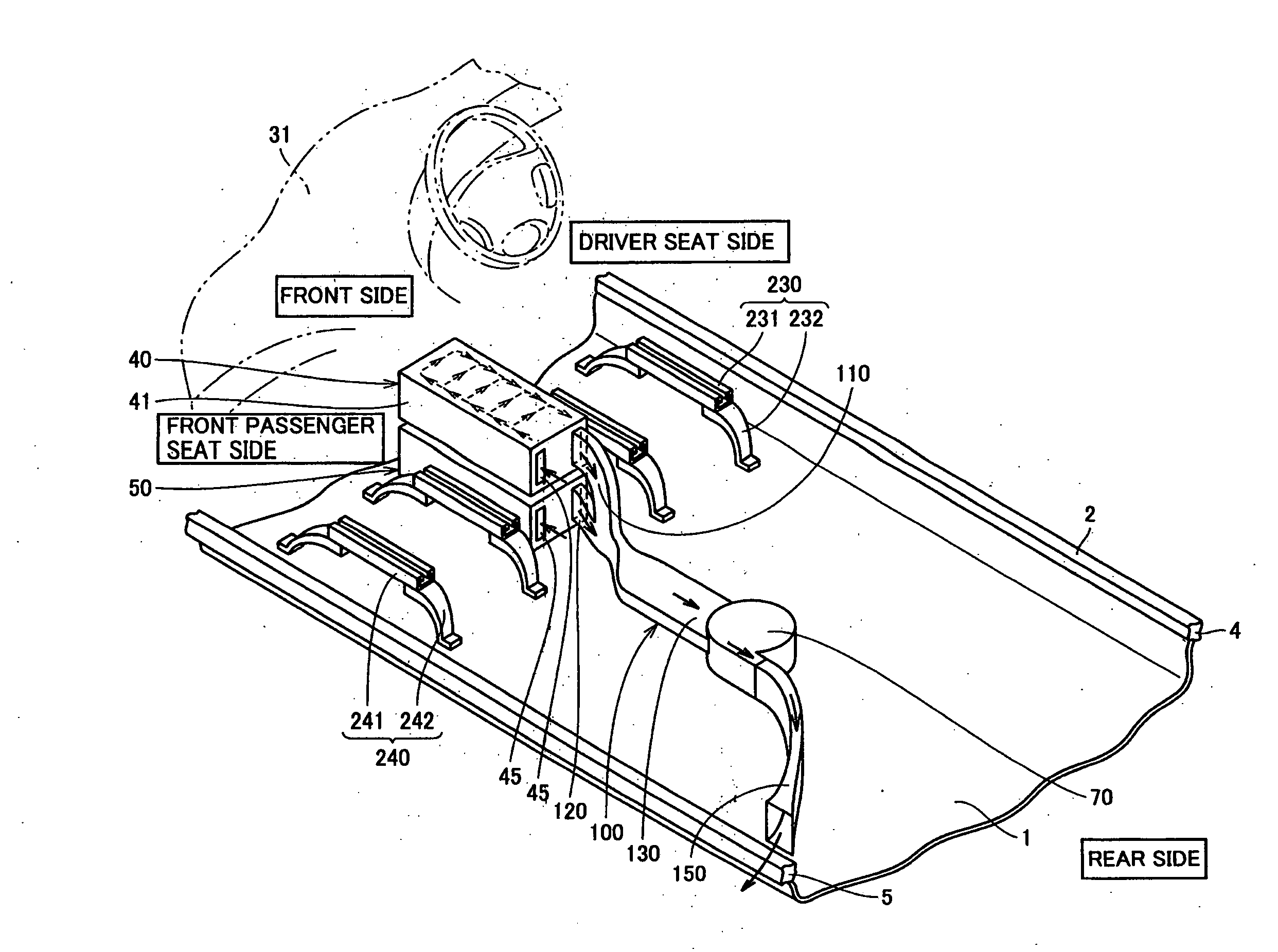

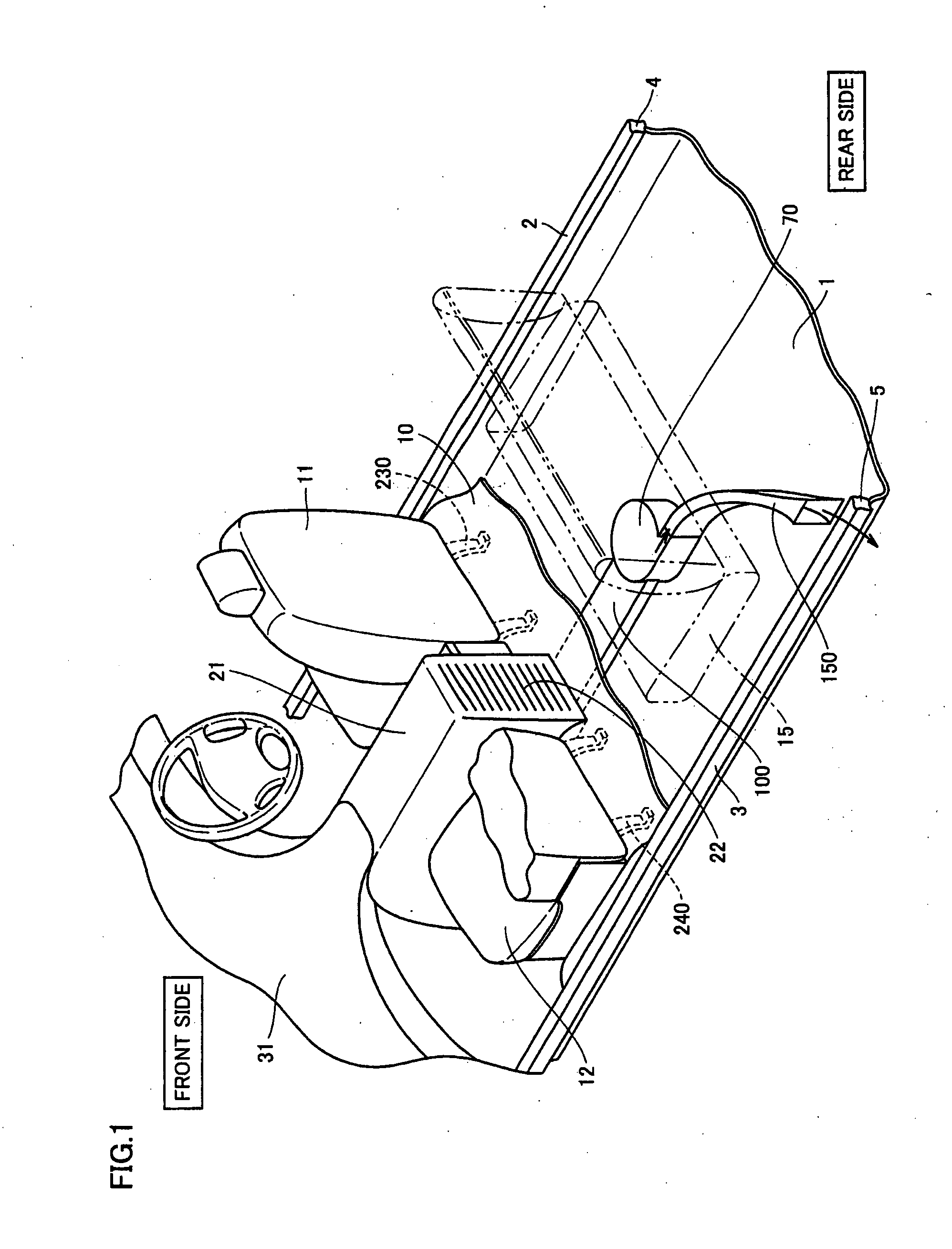

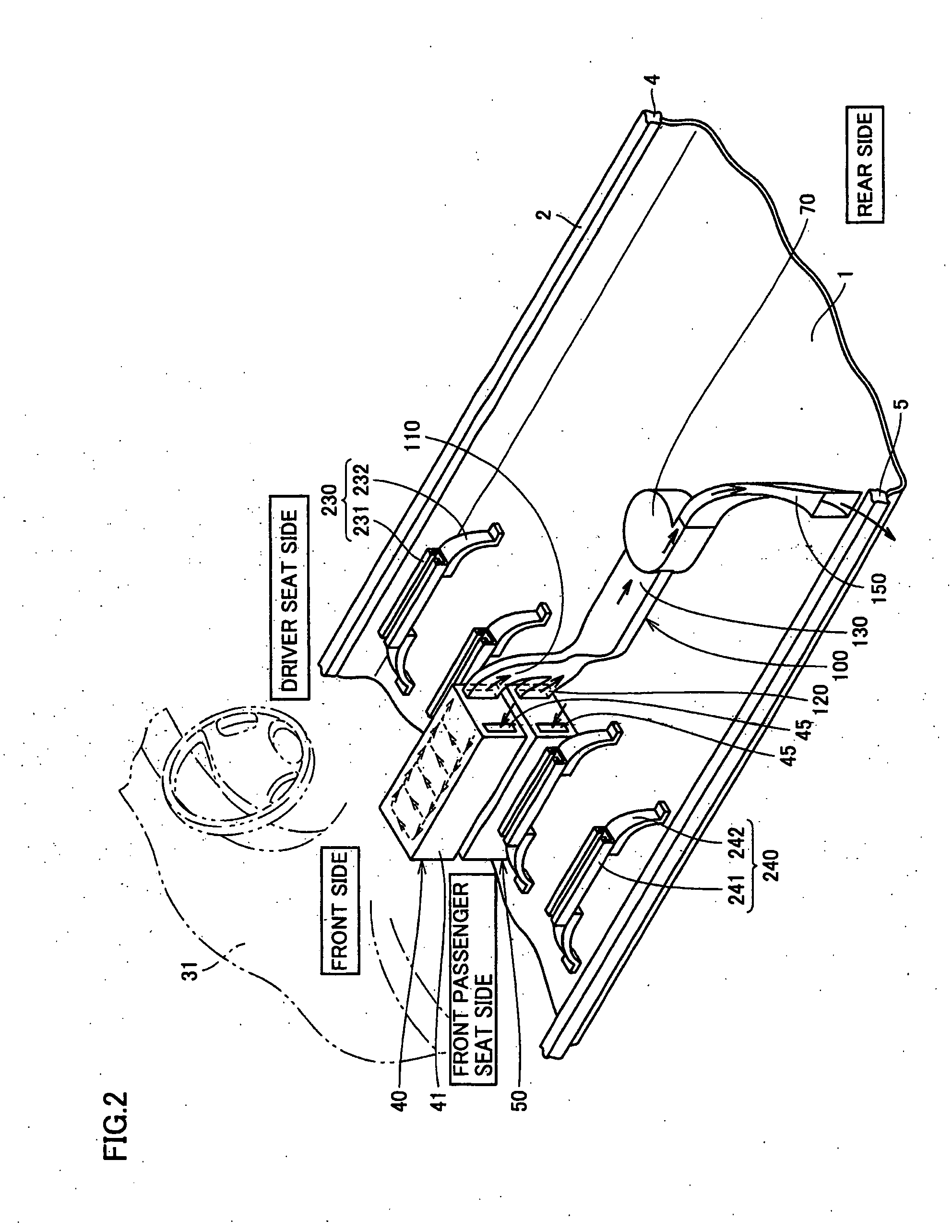

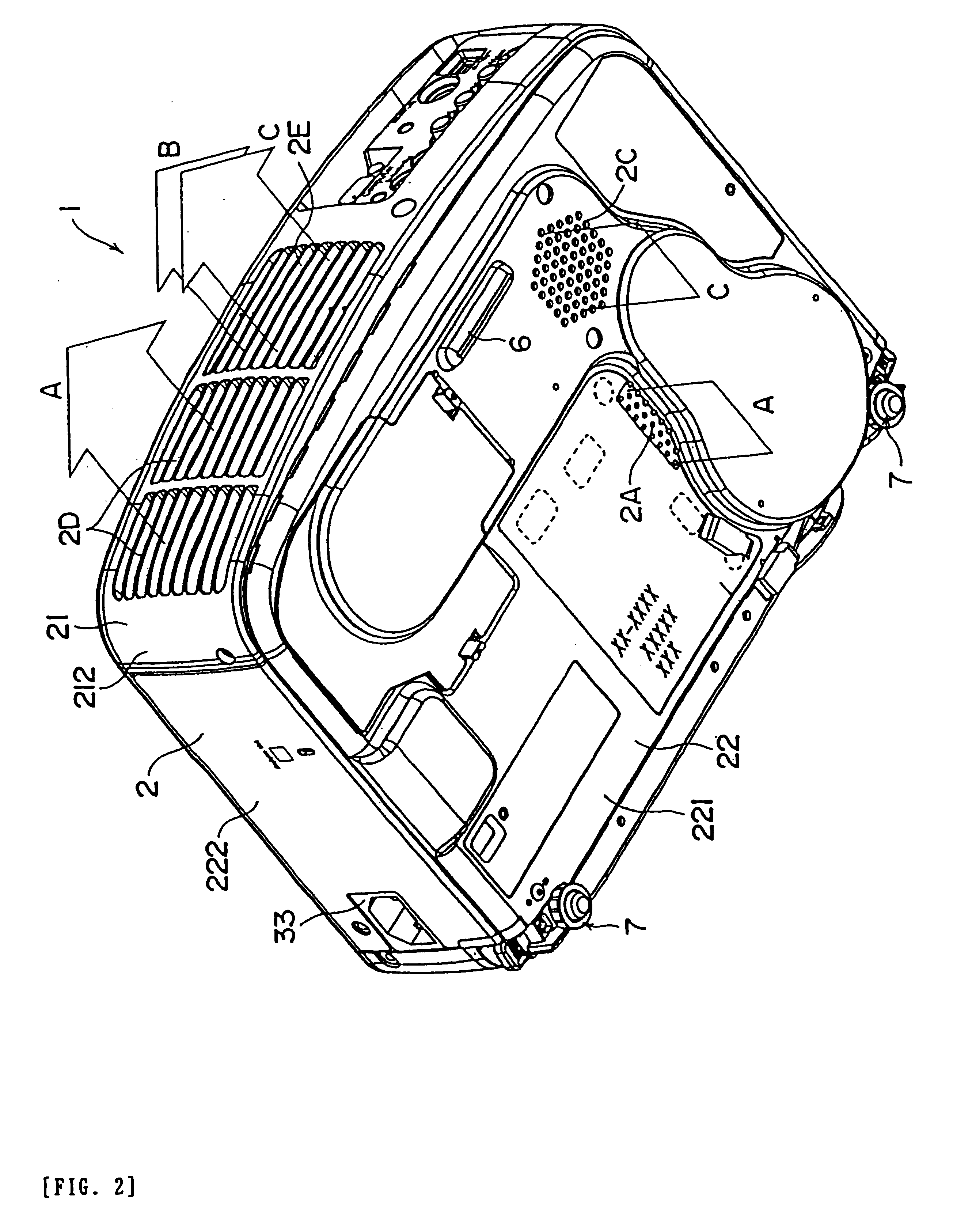

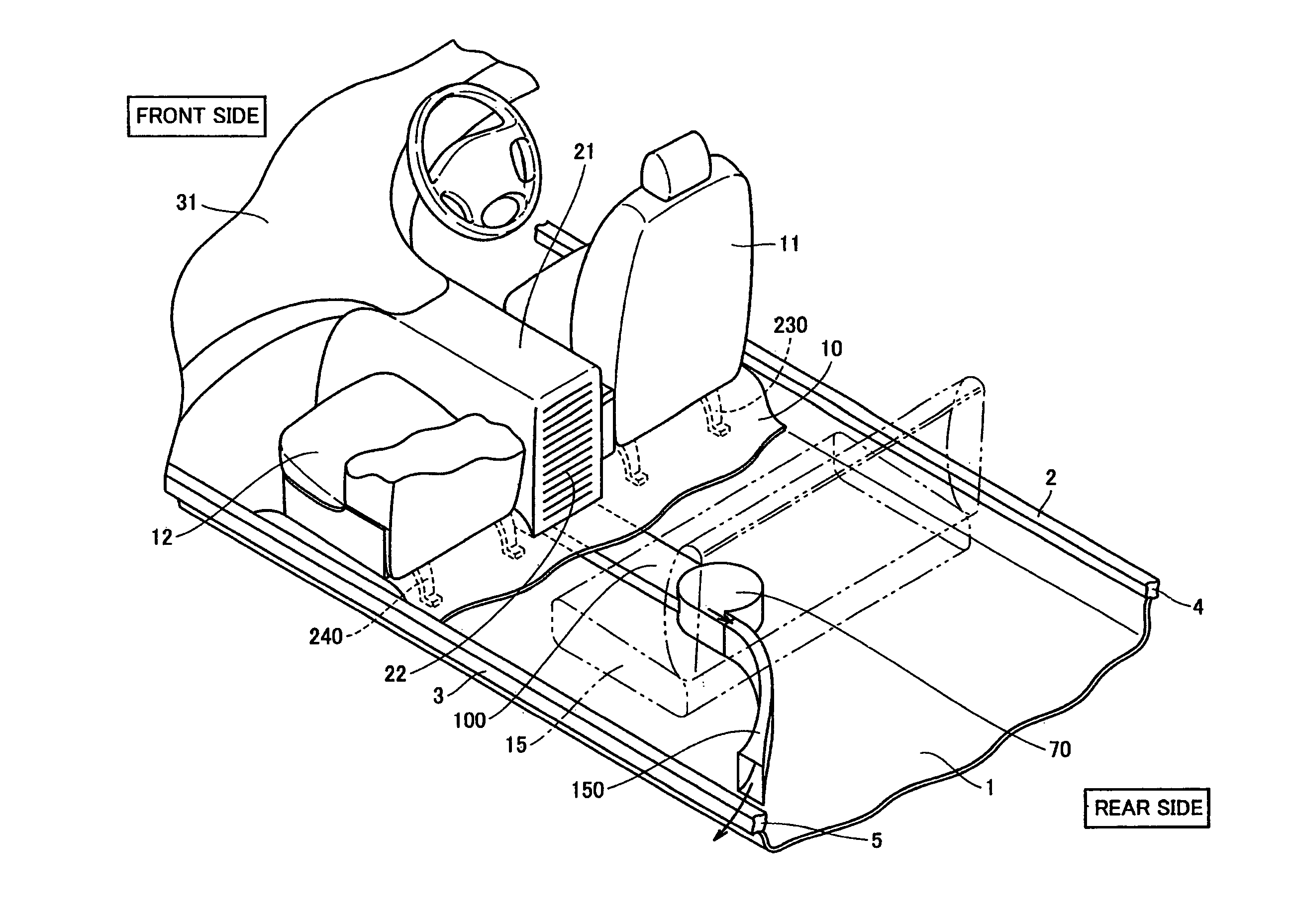

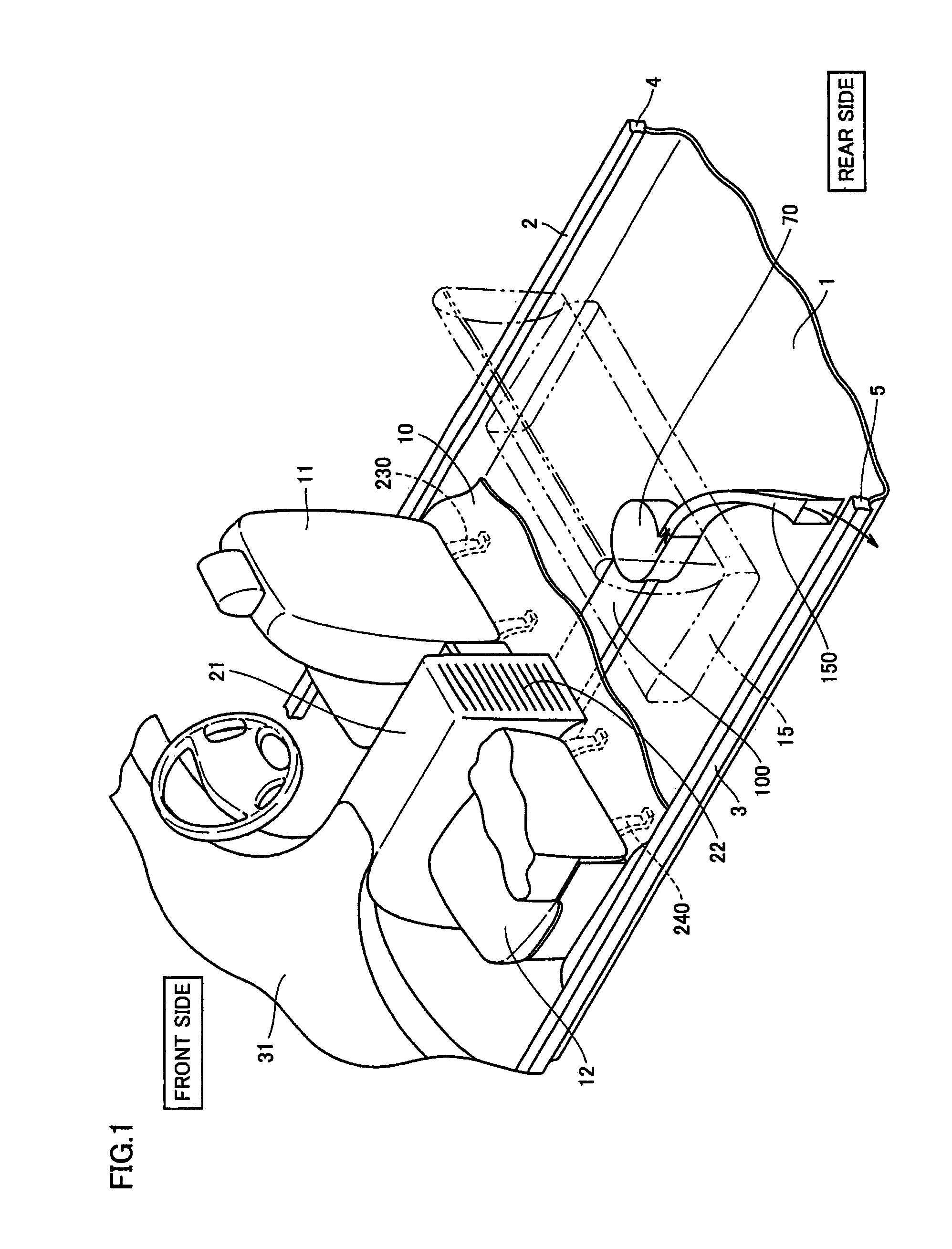

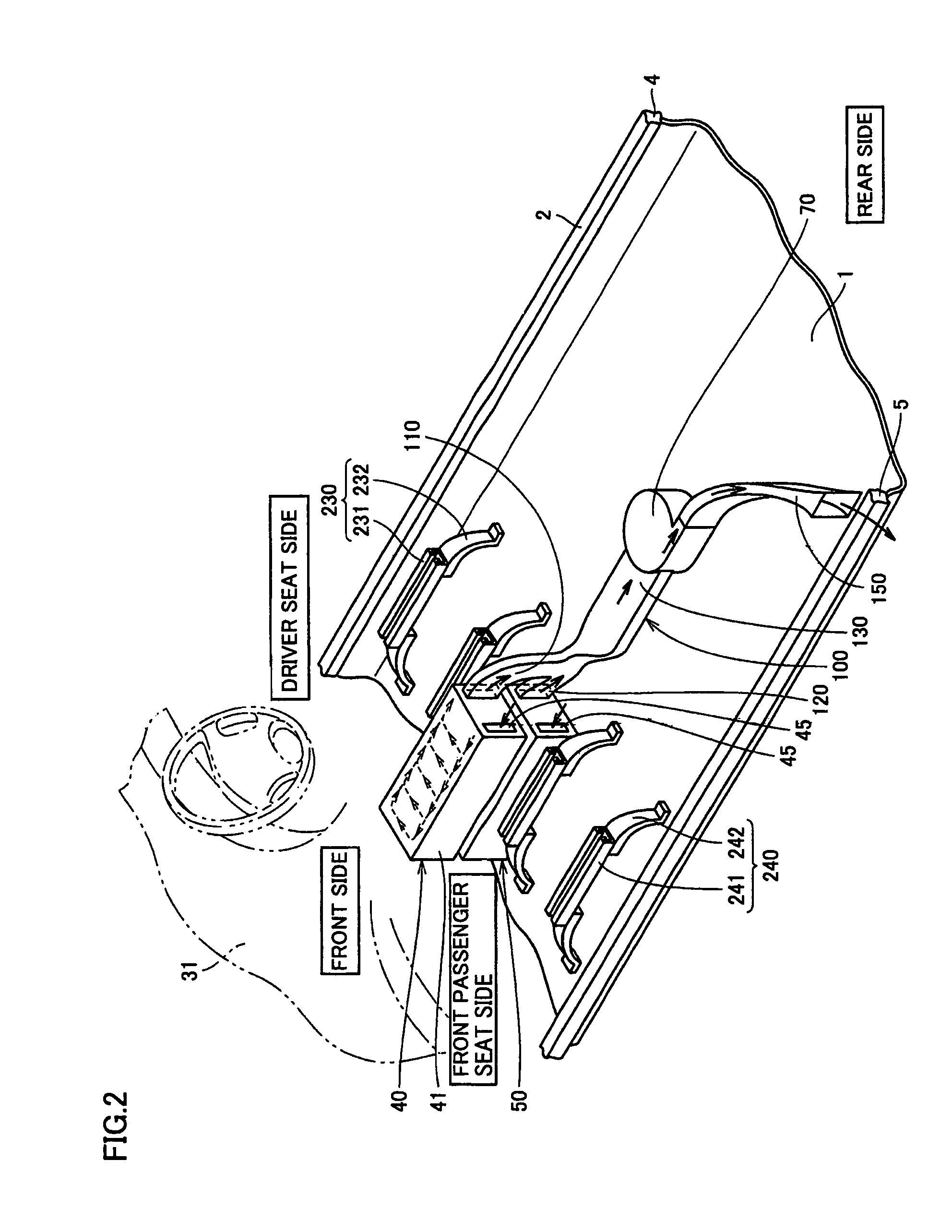

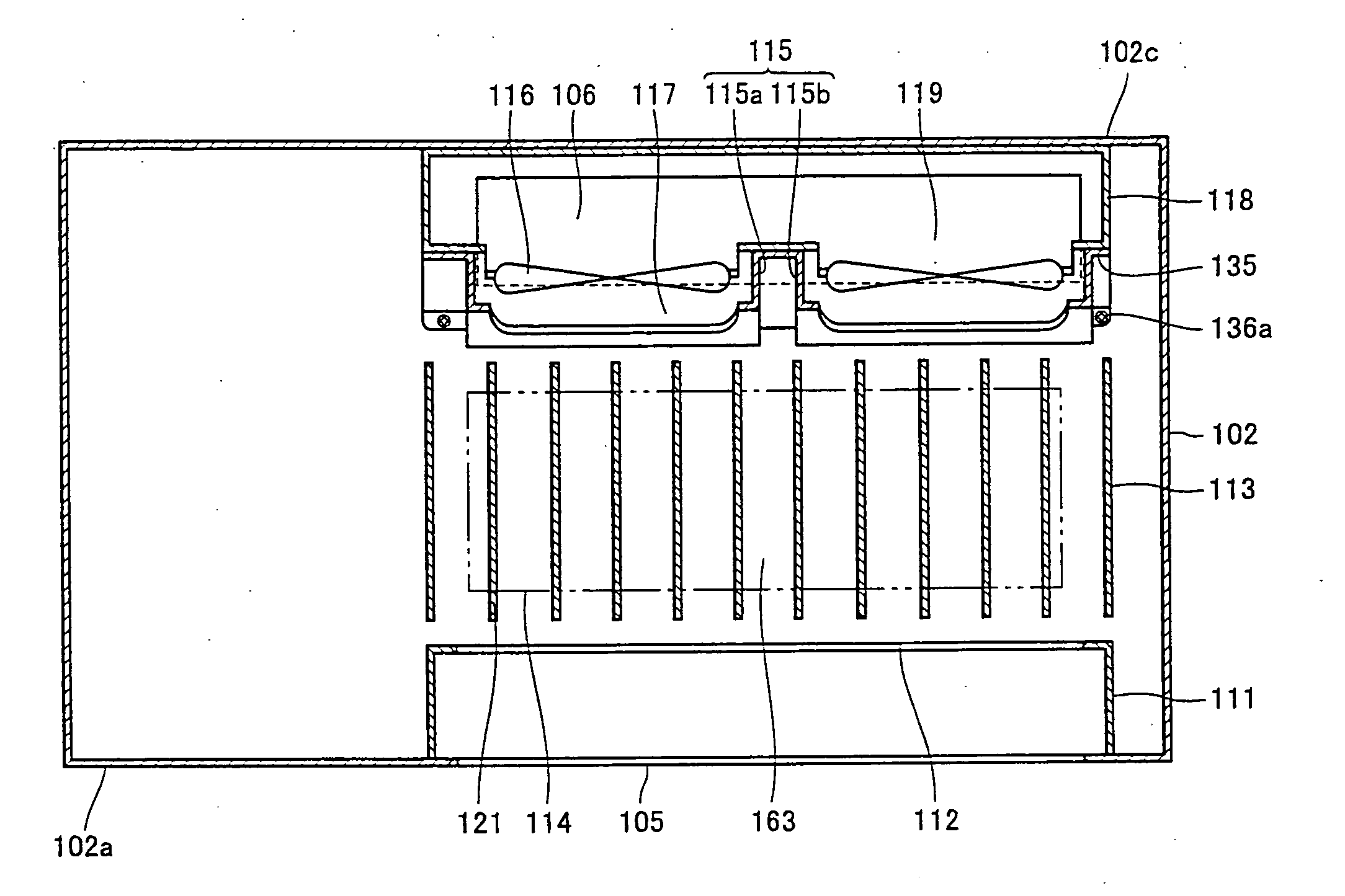

Vehicle-mounted battery cooling structure

ActiveUS20100089675A1Effective exhaustIncrease resistanceElectric propulsion mountingElectric/fluid circuitElectrical and Electronics engineeringCooling medium

Owner:TOYOTA JIDOSHA KK +1

Hydrogen gas generator

InactiveUS20060185242A1Avoid environmental pollutionIncrease profitPhysical/chemical process catalystsReactant parameters controlFuel tankHydrogen fuel cell

Disclosed is a self-regulating hydrogen gas generator for a hydrogen fuel cell. The self-regulating hydrogen gas generator includes a fuel tank, defining an inner space having a designated volume, provided with a hydrogen outlet communicating the inner space, a fuel solution, containing a hydrogen storing material, stored in the fuel tank, and a catalyst contacting the fuel solution for generating hydrogen gas, wherein the catalyst fills a catalytic reactor, provided with a closed portion for interrupting the contact between the catalyst and the fuel solution, and an opened portion contacting the fuel solution, so that the generation and interruption of hydrogen gas are actively regulated based on the increase and decrease of the pressure of the fuel tank.

Owner:TEMCO

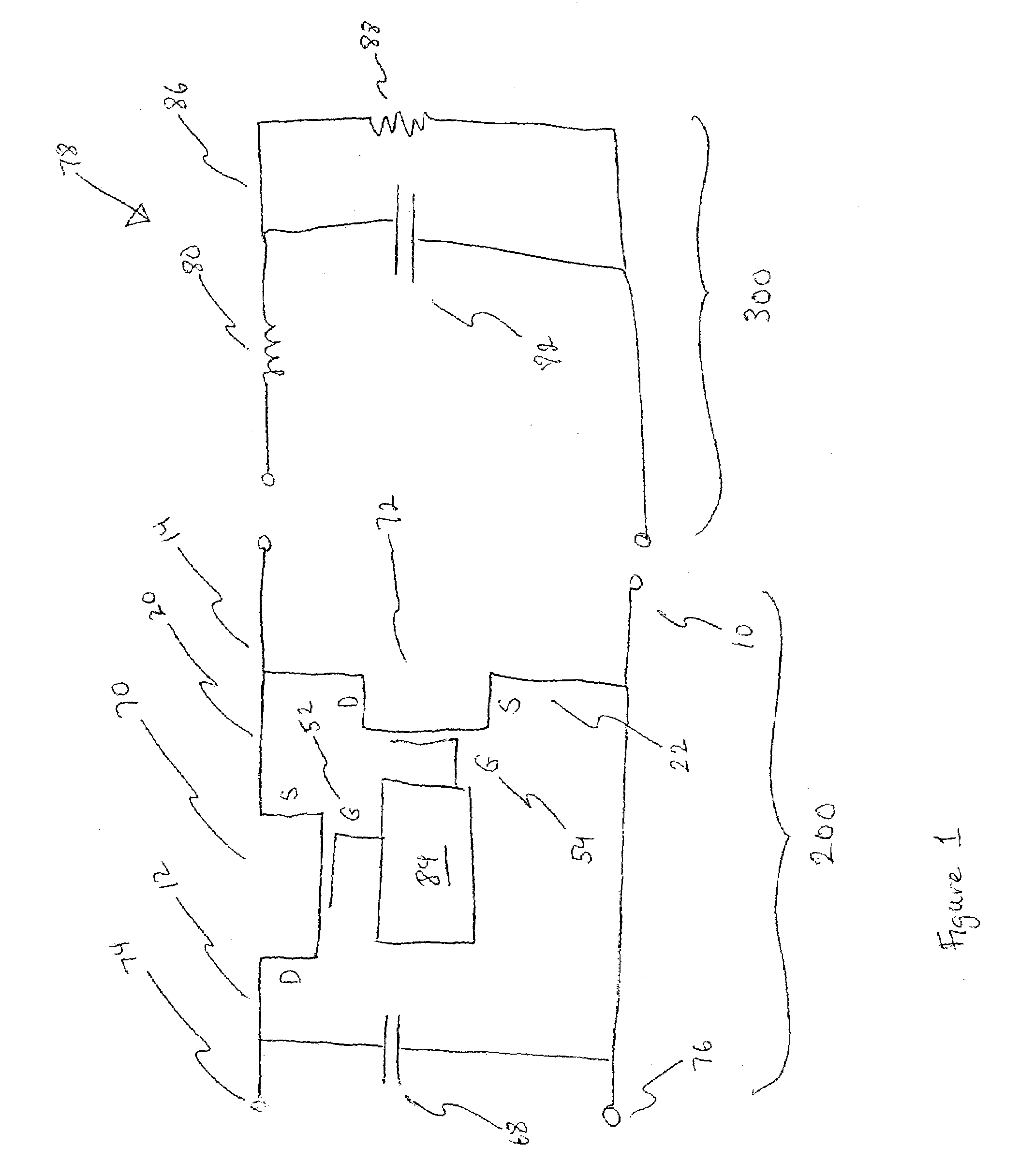

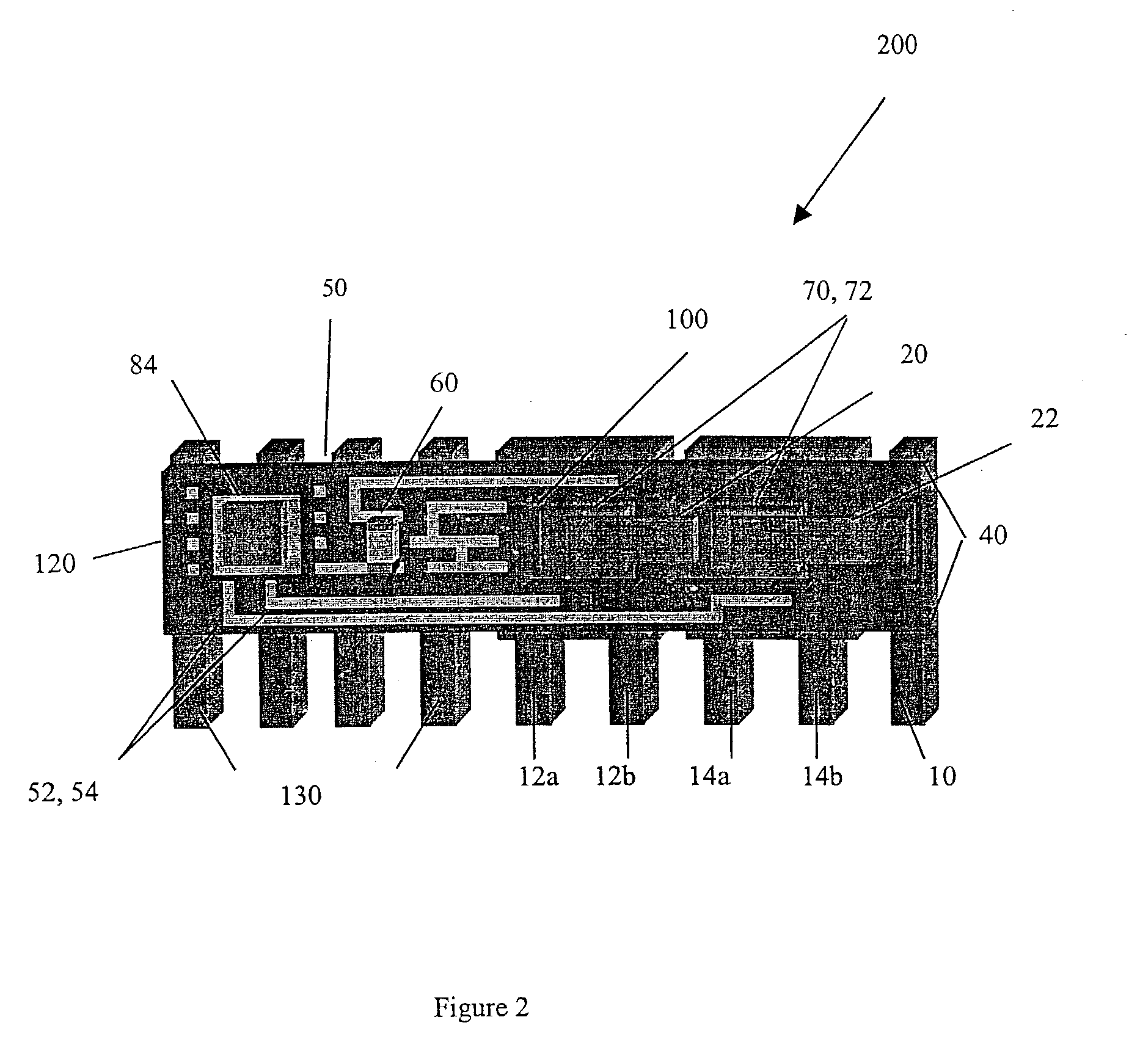

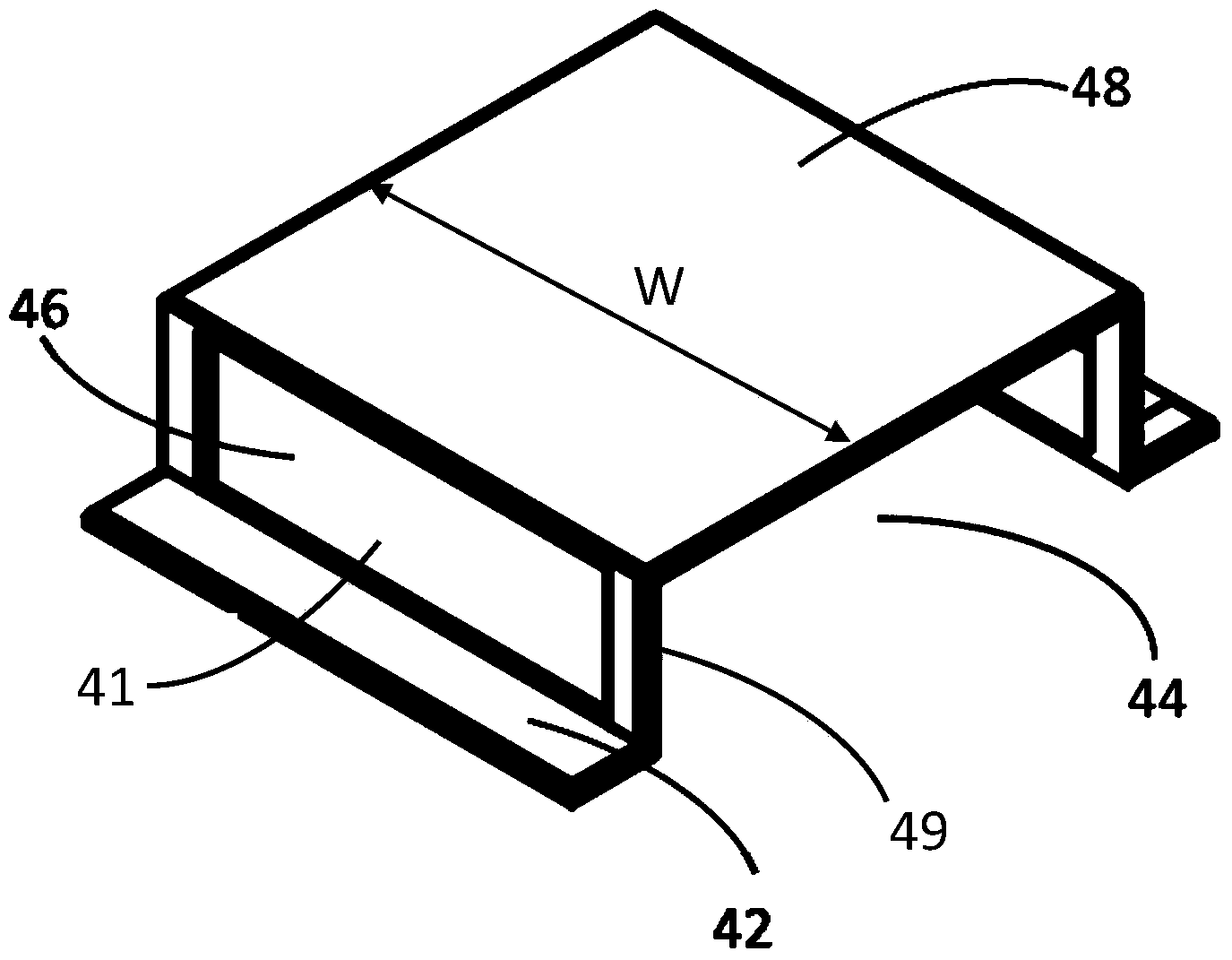

Packaging system for power supplies

InactiveUS6943455B1Firmly connectedLower resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceLow voltage

A packaging system for a high current, low voltage power supply. The power supply uses two bare die field effect transistors whose input and output electrodes are solder attached to low resistance, high current posts in the package. An associated controller chip is mounted to a rigid circuit board, and the circuit board is mechanically attached to the posts. The circuit board thereby gives physical rigidity to the package, but carries no high currents. The use of low resistance, high current posts reduces the heat generated, improving the long term reliability.

Owner:PWER BRIDGE

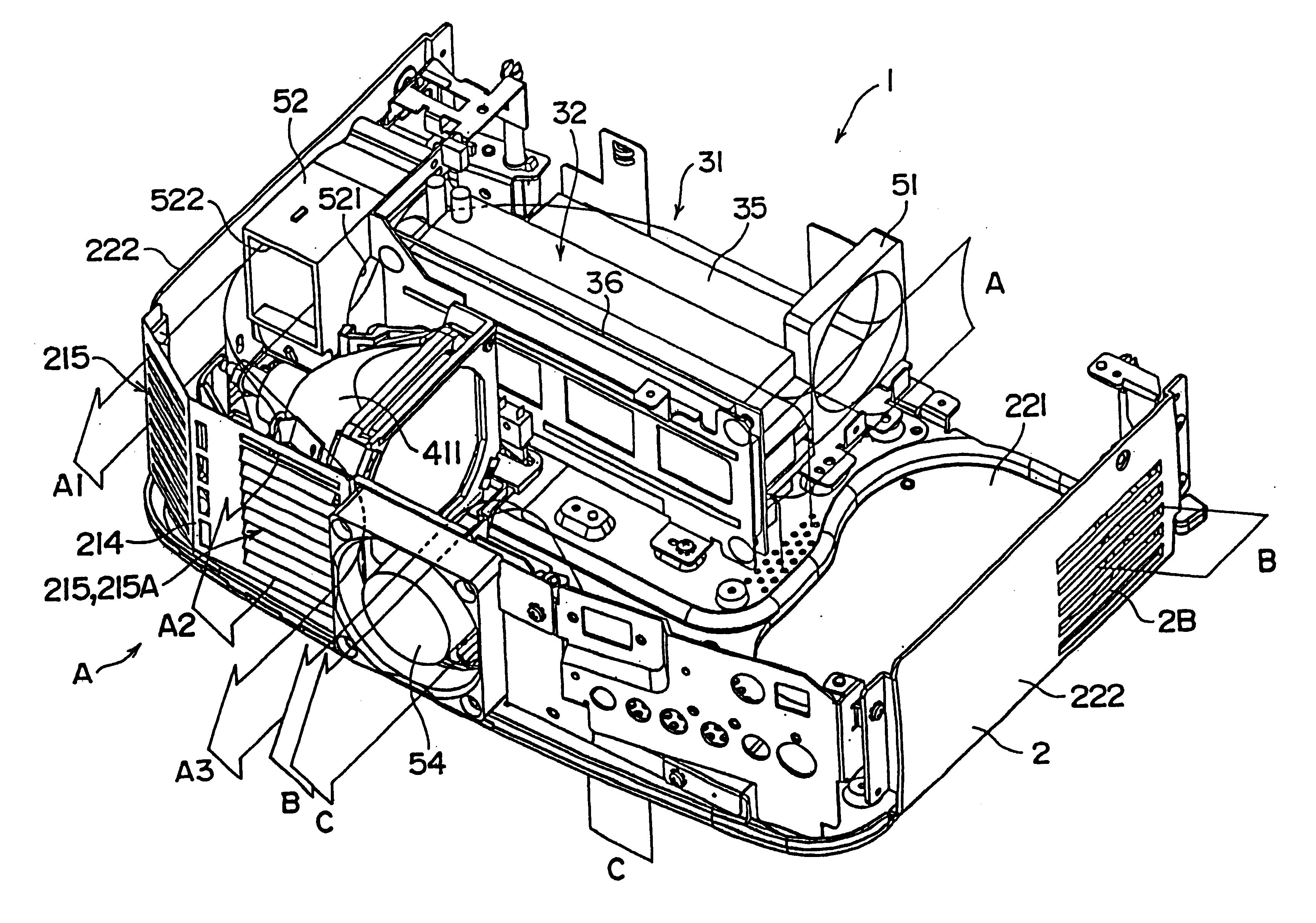

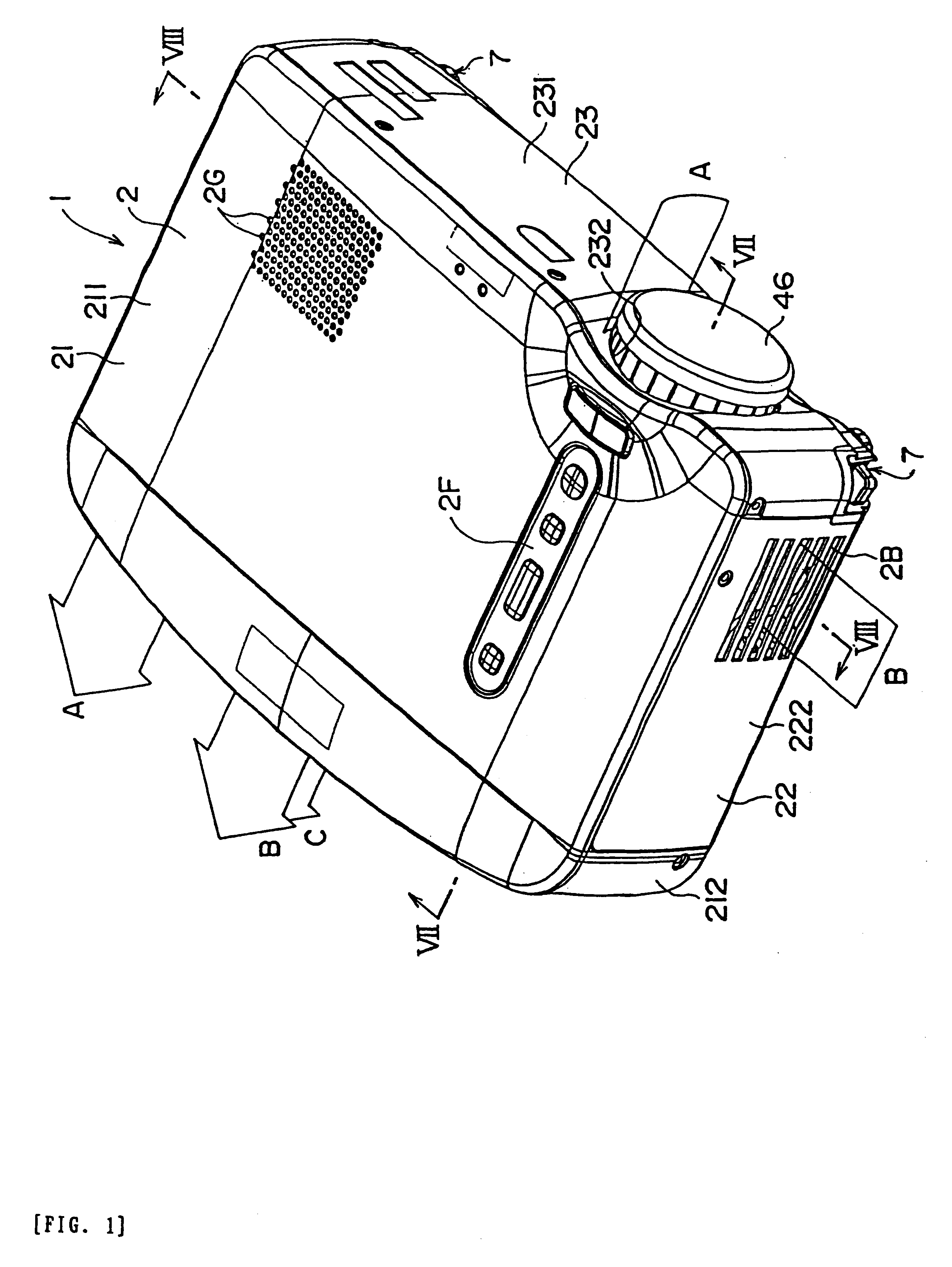

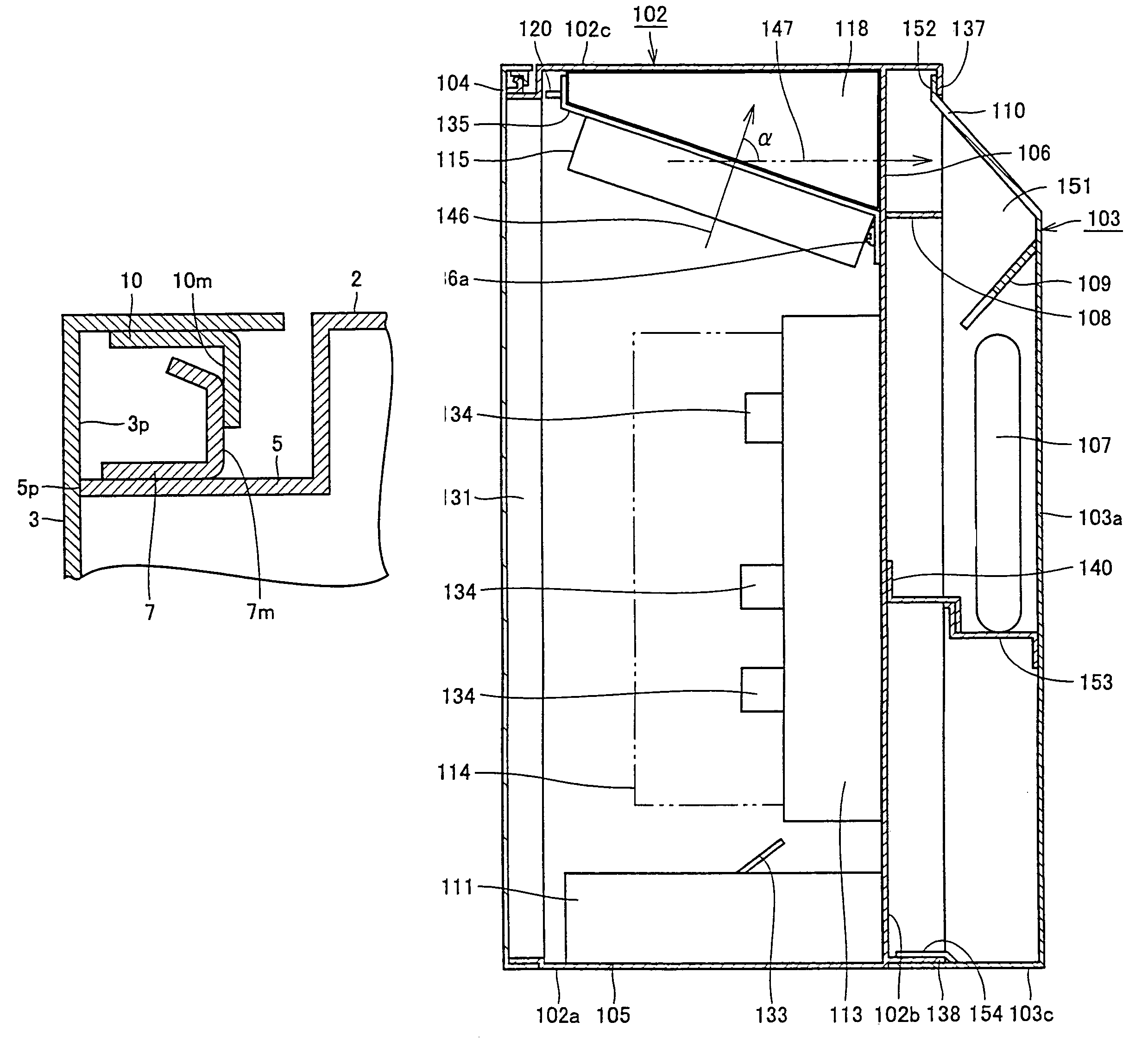

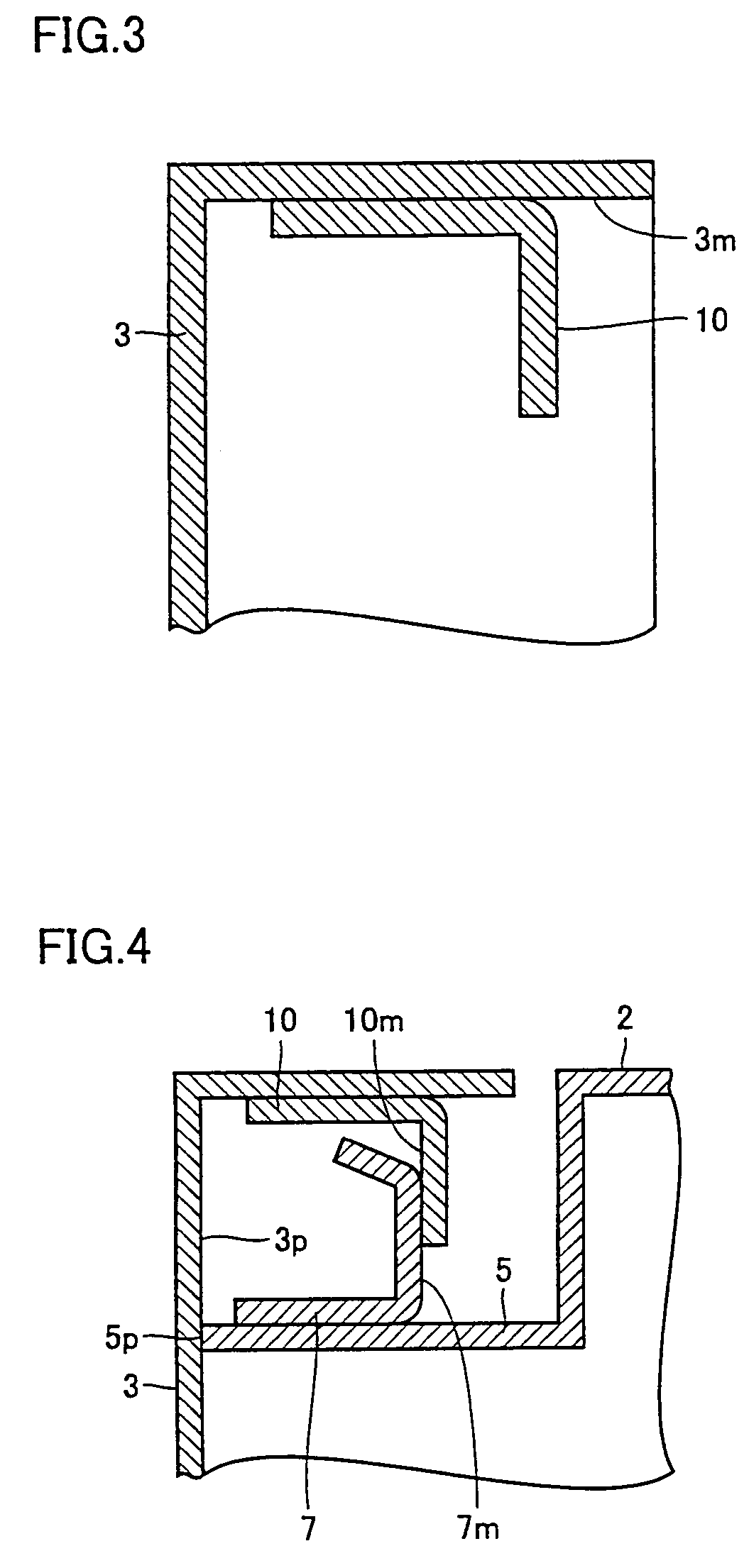

Projector

InactiveUS6558004B2Improve noiseIncrease in sizeTelevision system detailsProjectorsEngineeringAtmospheric pressure

Owner:SEIKO EPSON CORP

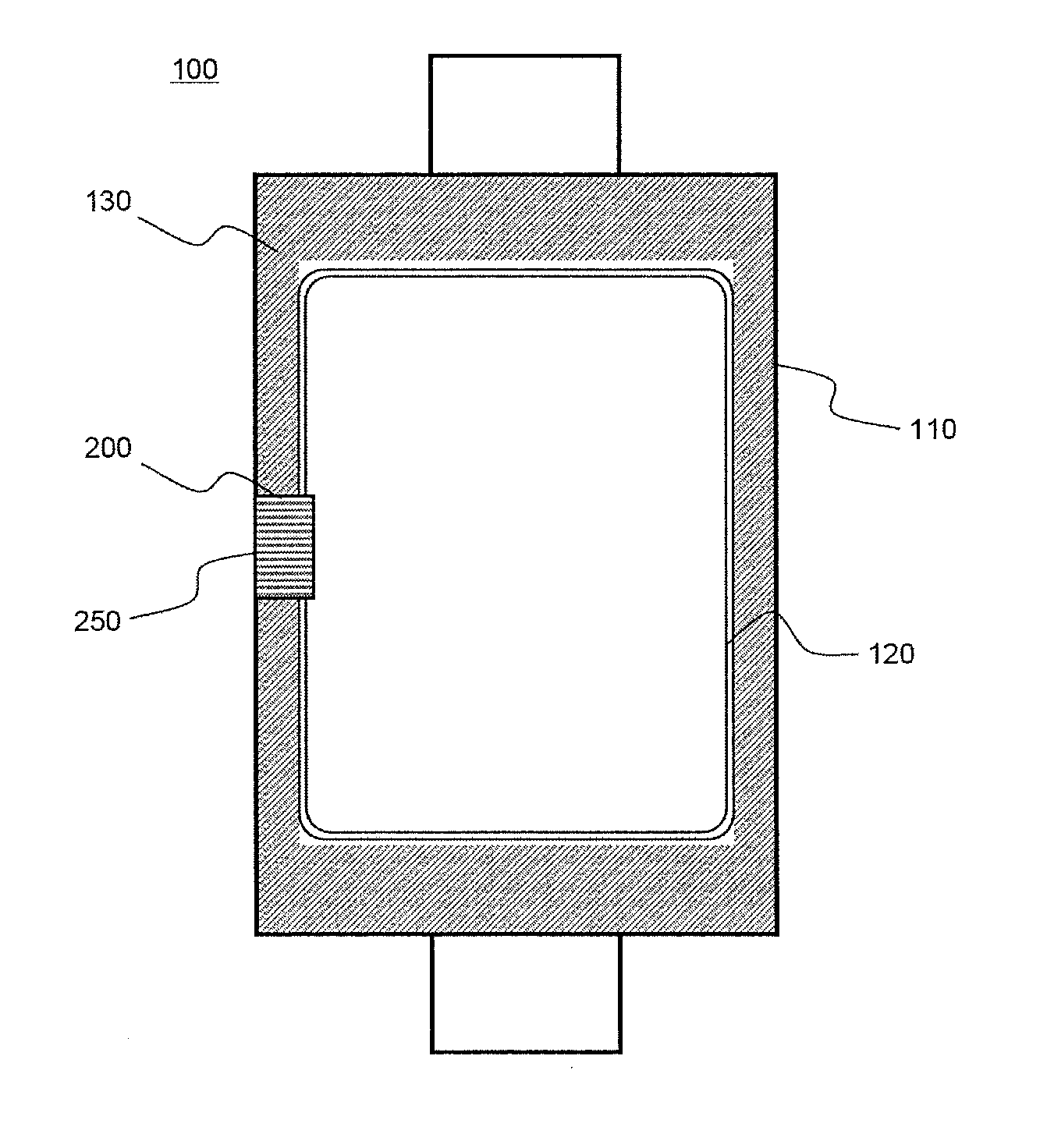

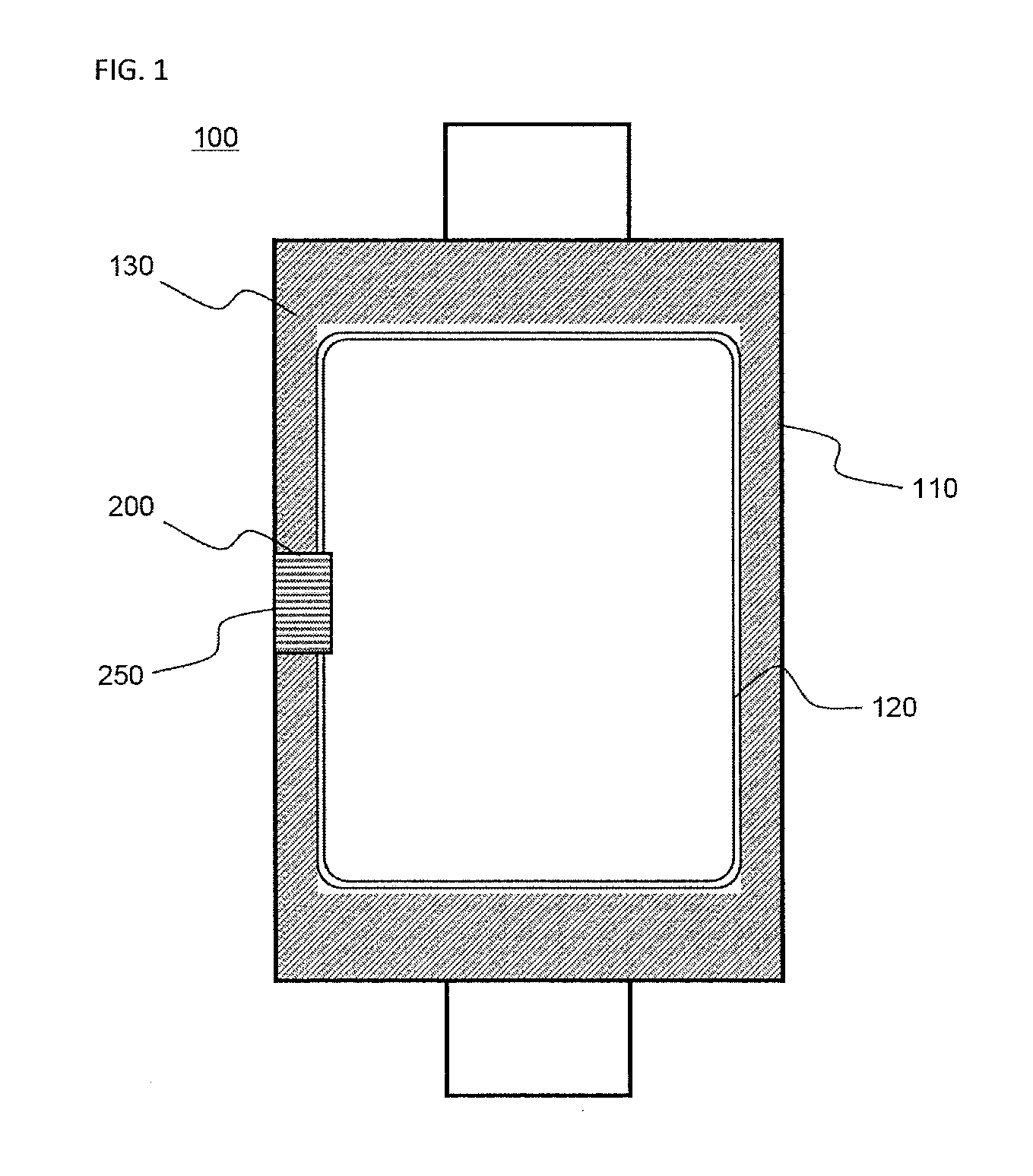

Lithium ion battery and battery pack

ActiveCN104319360AImprove securityEffective exhaustFinal product manufactureLi-accumulatorsEngineeringLithium-ion battery

The invention discloses a lithium ion battery. The lithium ion battery comprises a battery casing, a battery top cap mounted on the battery casing and a pressure relief valve arranged on the battery casing and / or the battery top cap and further comprises a safeguard device, wherein the safeguard device is arranged on the battery casing and / or the battery top cap and fixed corresponding to the pressure relief valve; the safeguard device comprises a baffle plate corresponding to the pressure relief valve, a side wall and an air channel structure; the side wall extends towards the battery casing or the battery top cap from the baffle plate and is connected with the battery casing or the battery top cap; the air channel structure is formed on the side wall. Through the forming of the air channel structure on the side wall, the baffle plate and the air channel structure form relatively separating design, solid spark particles can be effectively blocked by the baffle plate, air can be efficiently discharged through the side air channel structure, and the safety performance of the lithium ion battery is improved.

Owner:DONGGUAN AMPEREX TECH +1

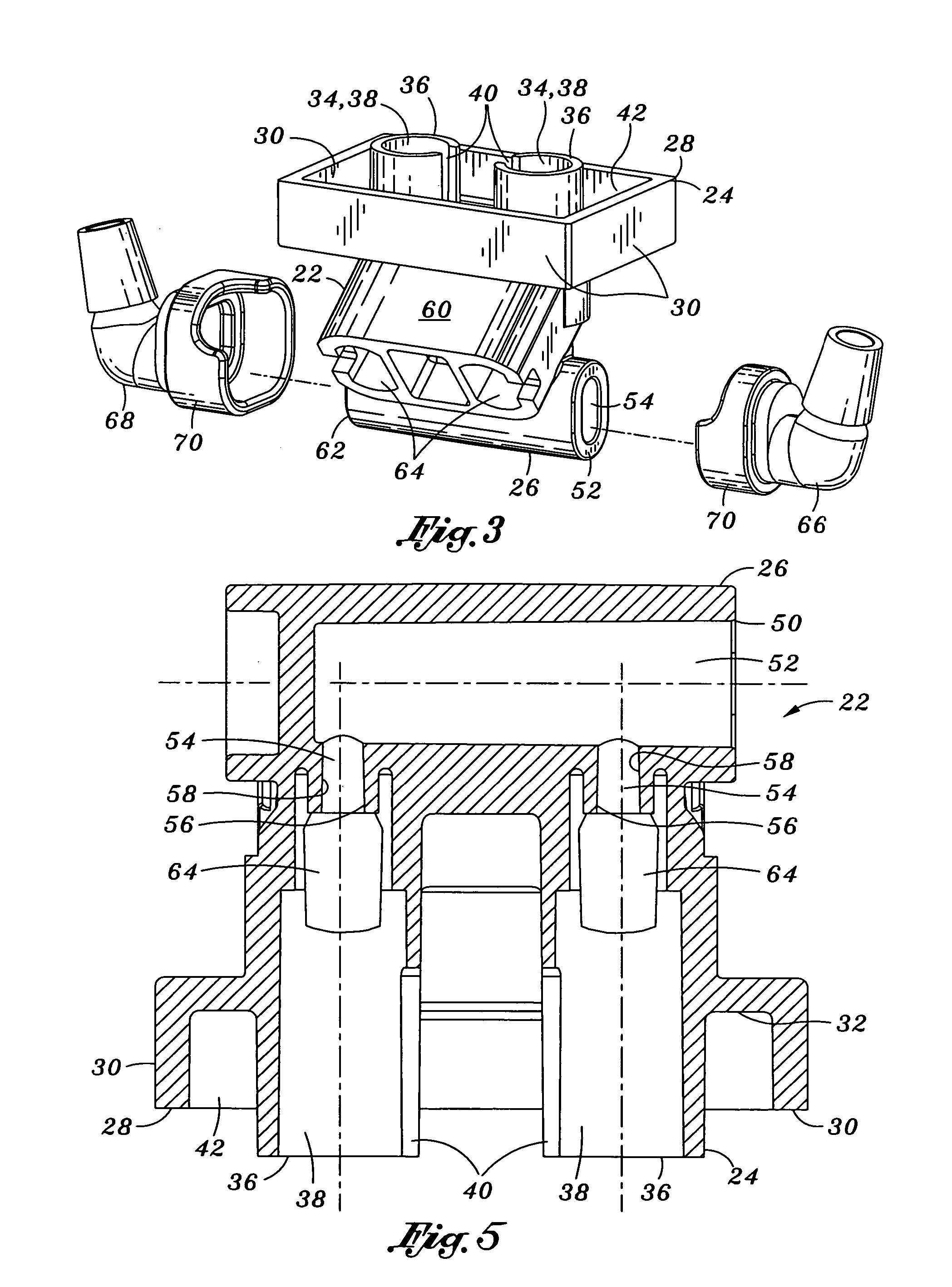

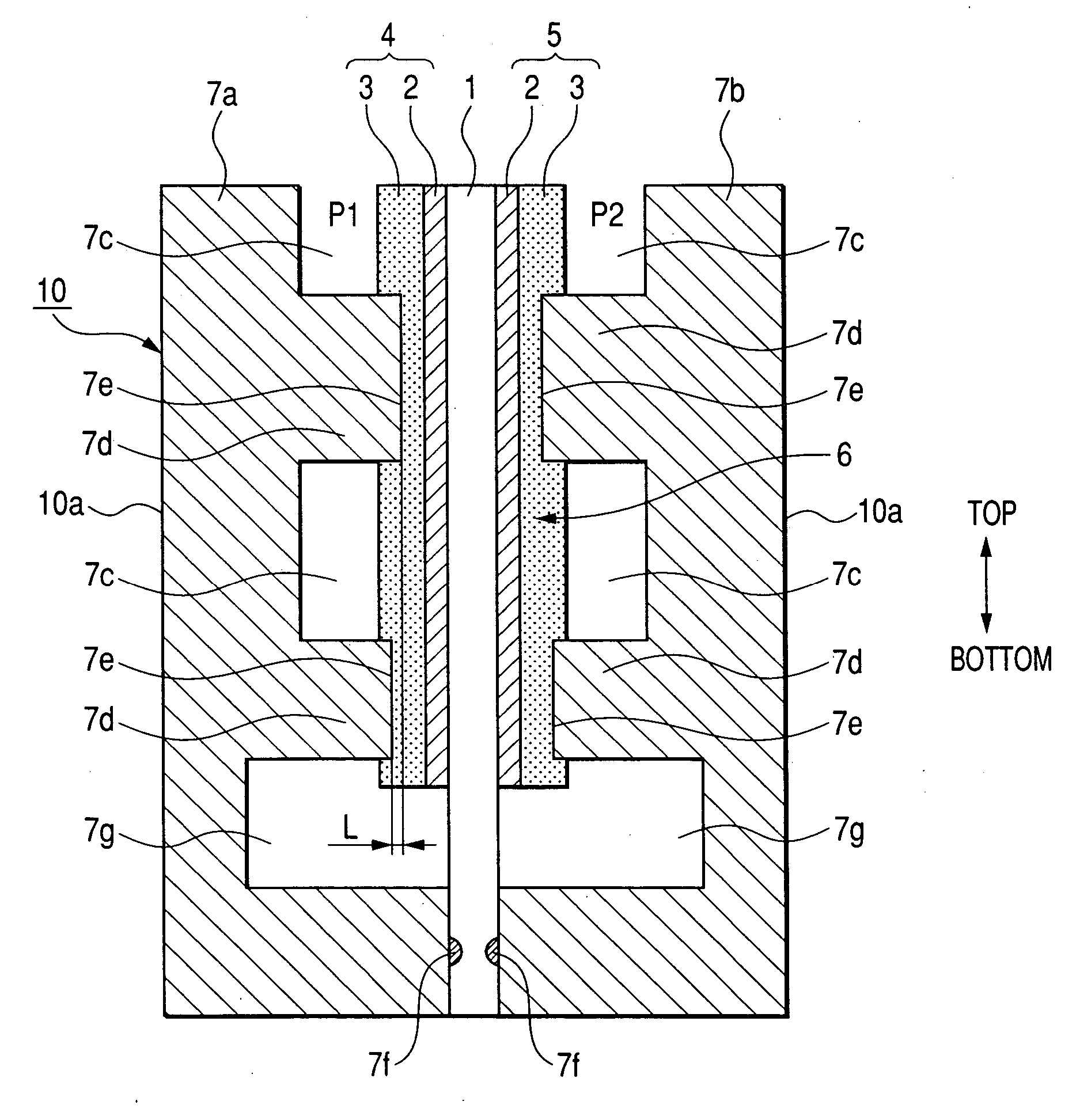

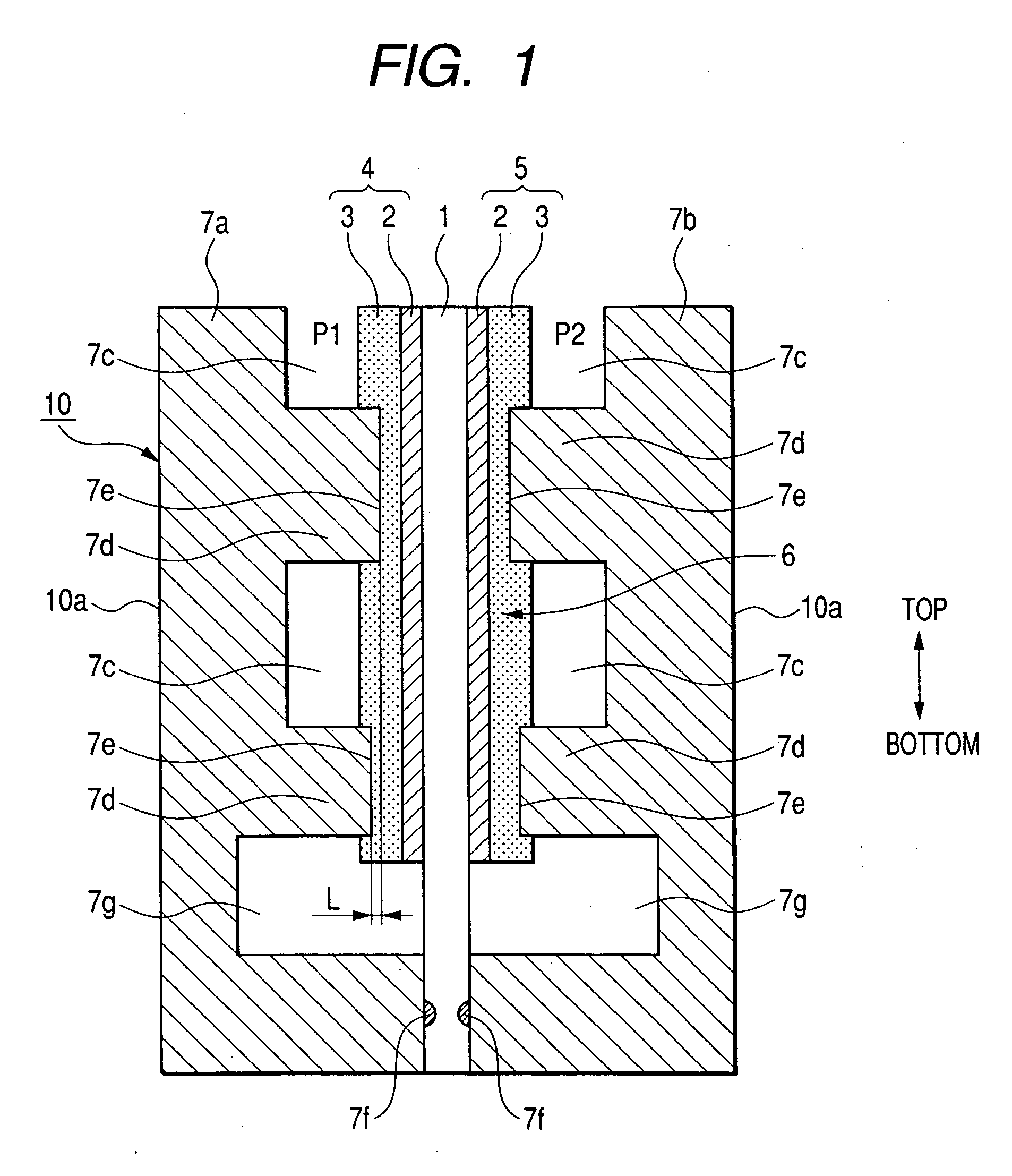

Venturi geometry design for flow-generator patient circuit

ActiveUS8100125B2Risk minimizationReduce gas pressureRespiratorsFire rescueGeometric designIntensive care medicine

Provided is a universal interface adapted for providing continuous positive airway pressure to a patient when the interface is used with a standard ventilator. The interface is configured to operate at a supply pressure no greater than about 120 centimeters of H2O in order to deliver pressure to the patient of up to about 15 cm of H2O at a flow rate of up to about 12 liters / minute. The universal interface may comprise an interface body having a space pair of breathing passageways intersecting a corresponding of supply passageways. Each one of the breathing passageways is comprised of a patient passageway and an exhalation passageway. Each one of the supply passageways includes a jet venturi having a taper portion. Each one of the exhalation passageways includes a taper portion which tapers outwardly along a direction from the patient passageway toward the exhalation passageway.

Owner:VYAIRE MEDICAL 211 INC

Vehicle-mounted battery cooling structure

ActiveUS8042637B2Increase resistanceIncrease the number ofElectric propulsion mountingElectric/fluid circuitEngineeringCooling medium

Owner:TOYOTA JIDOSHA KK +1

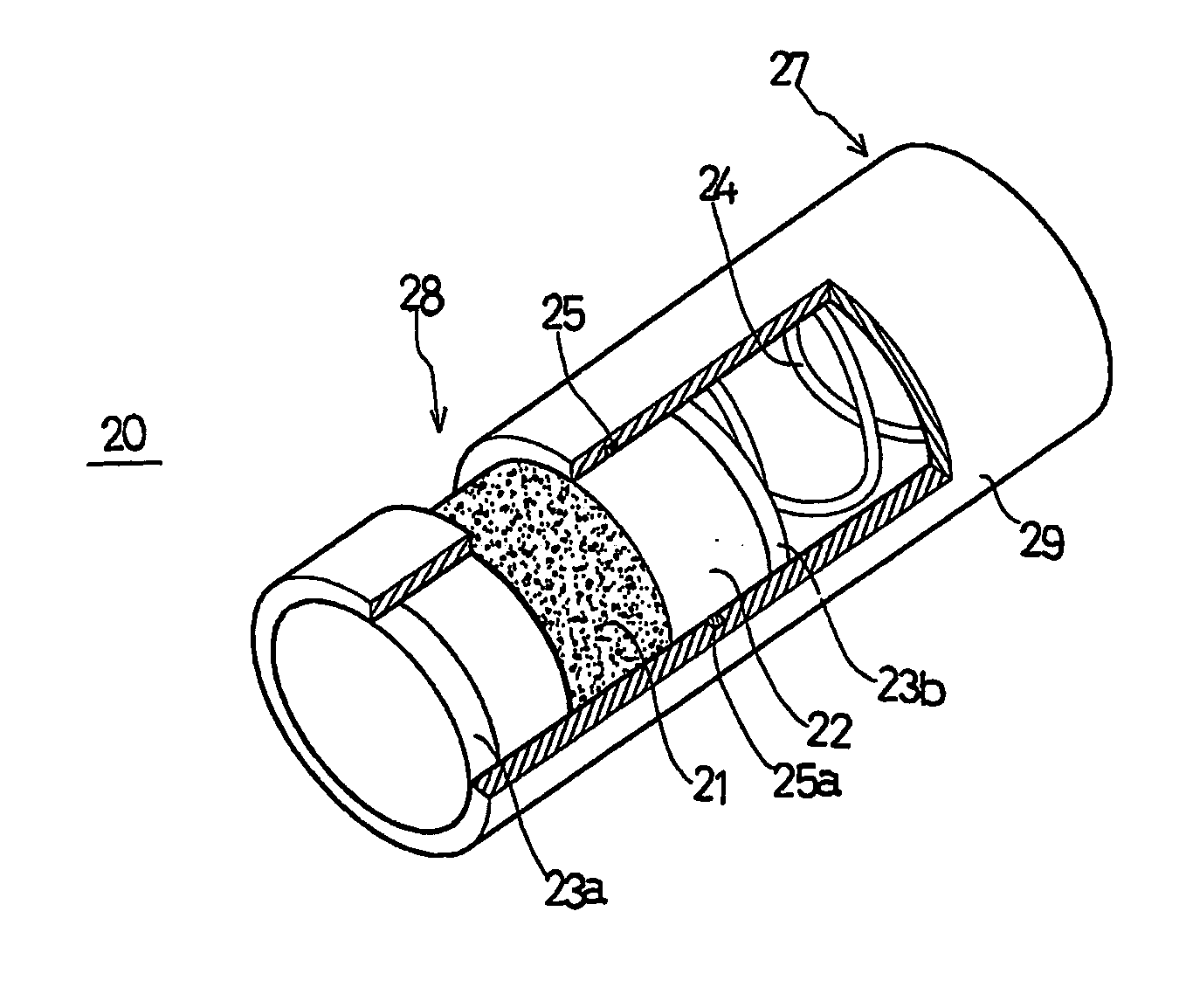

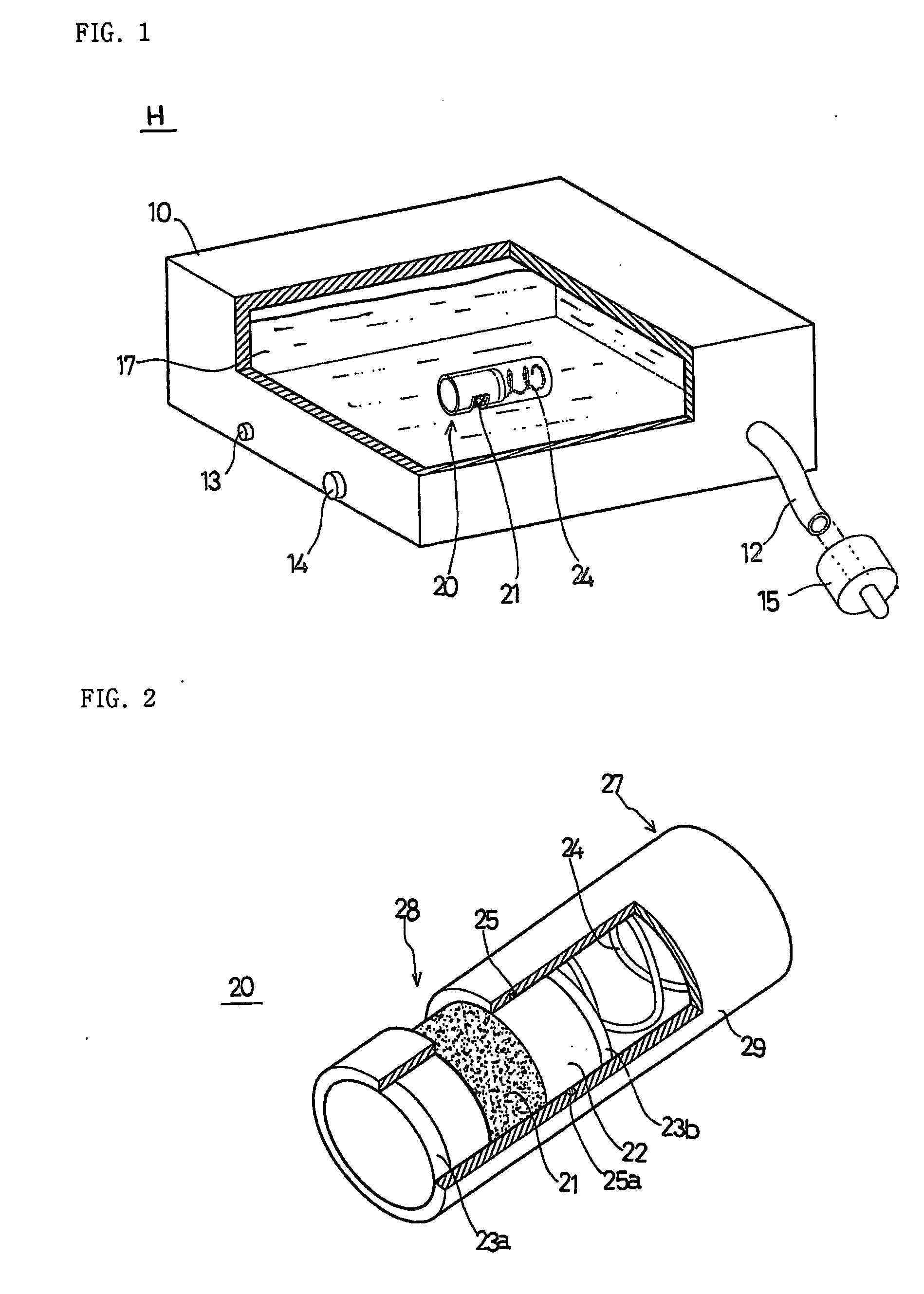

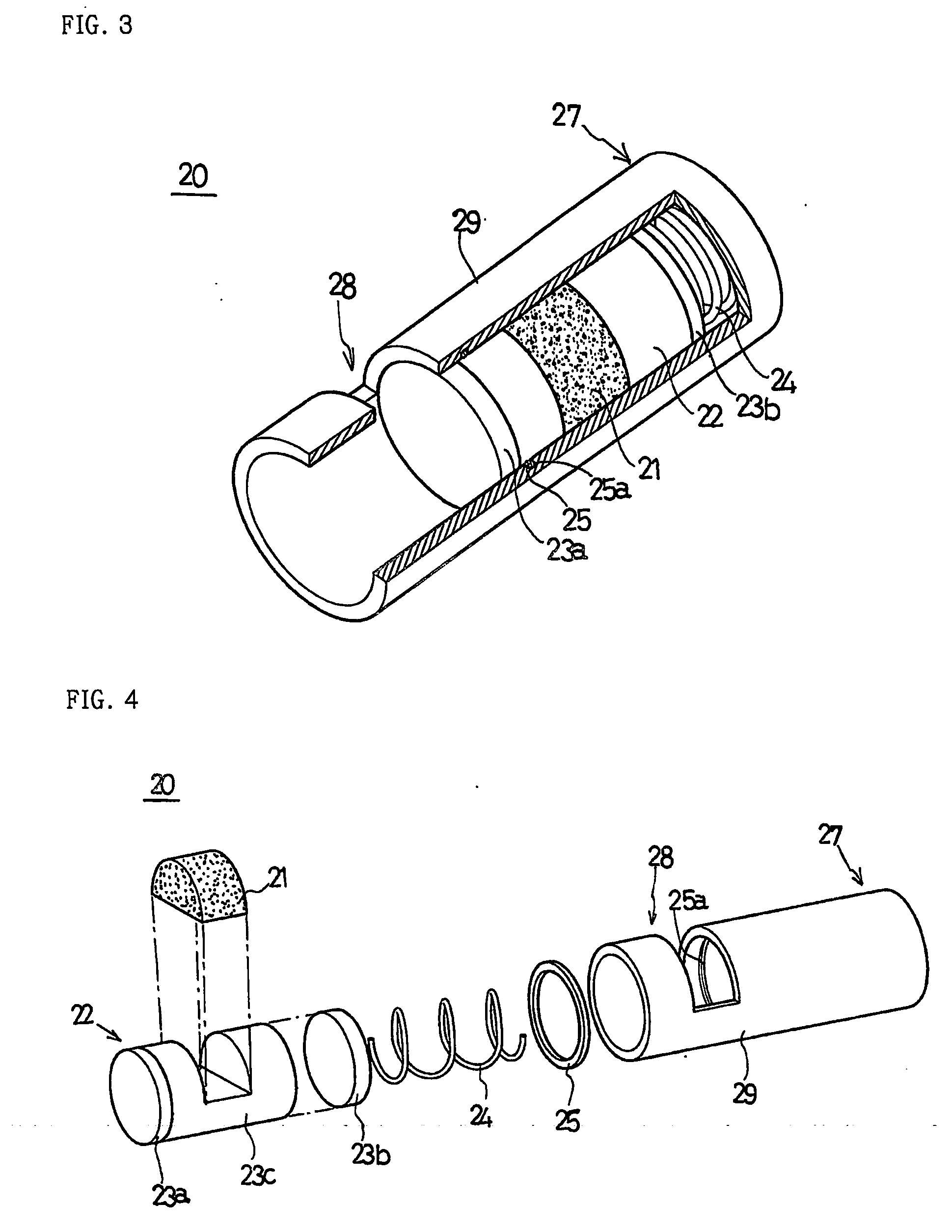

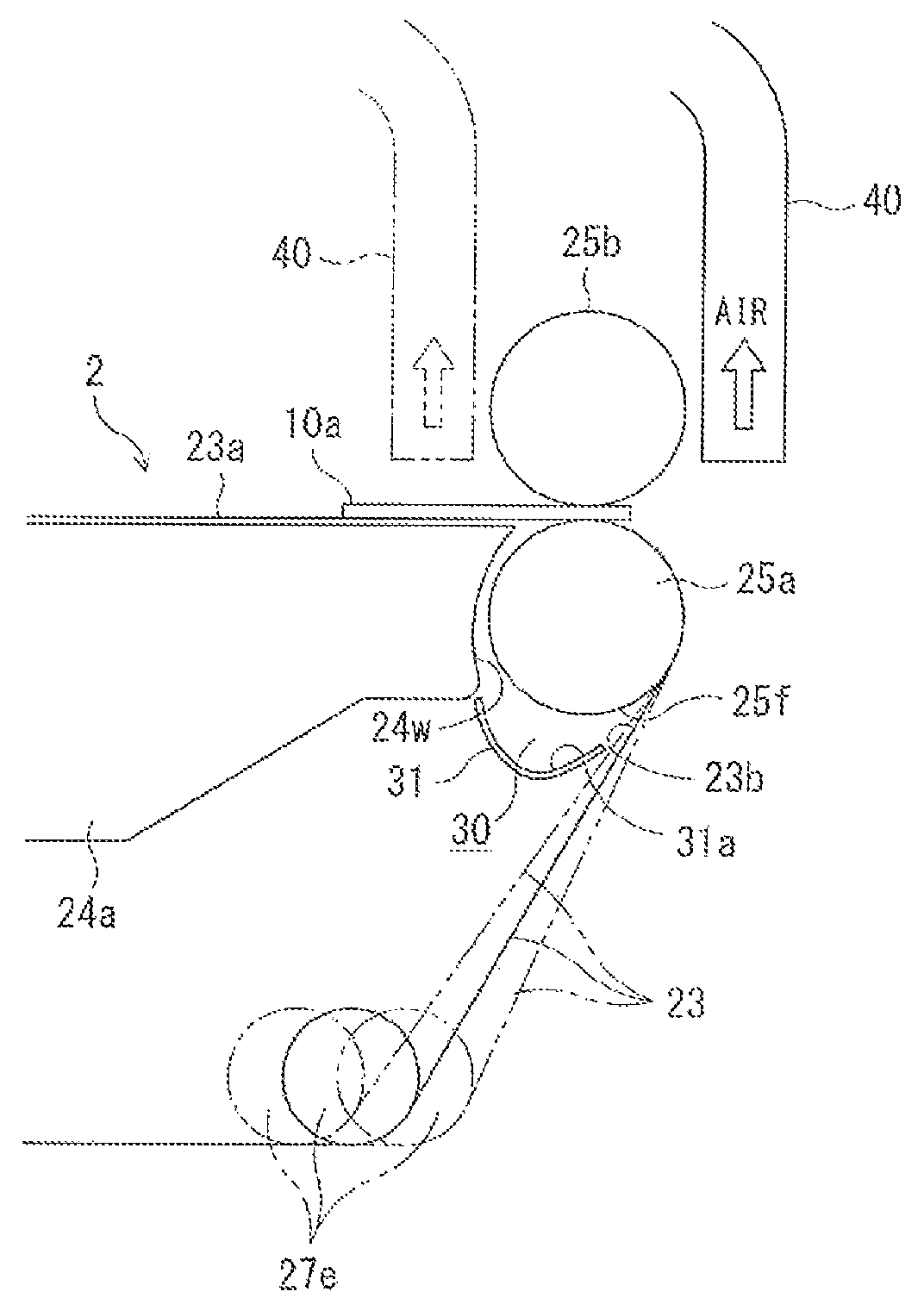

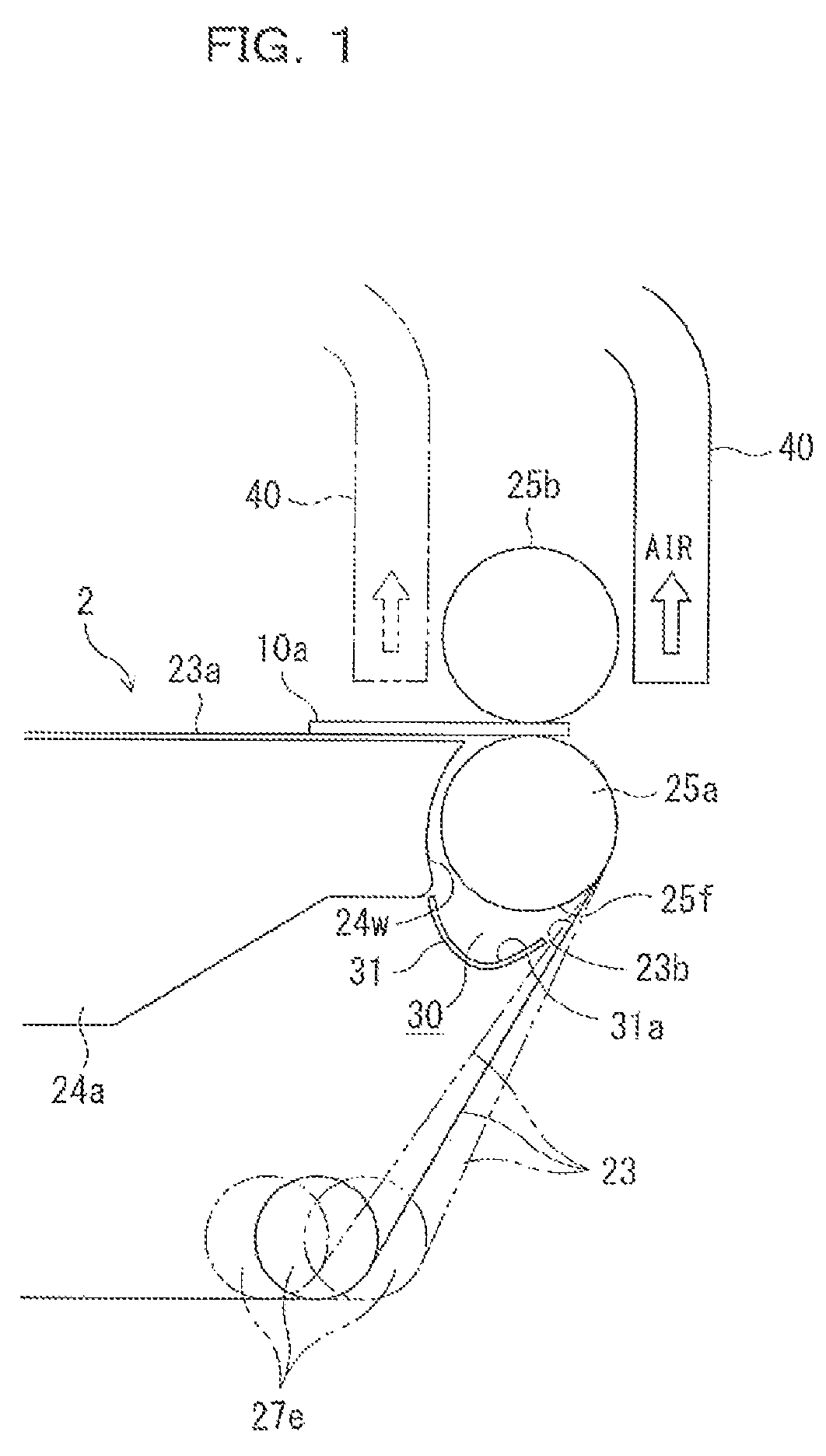

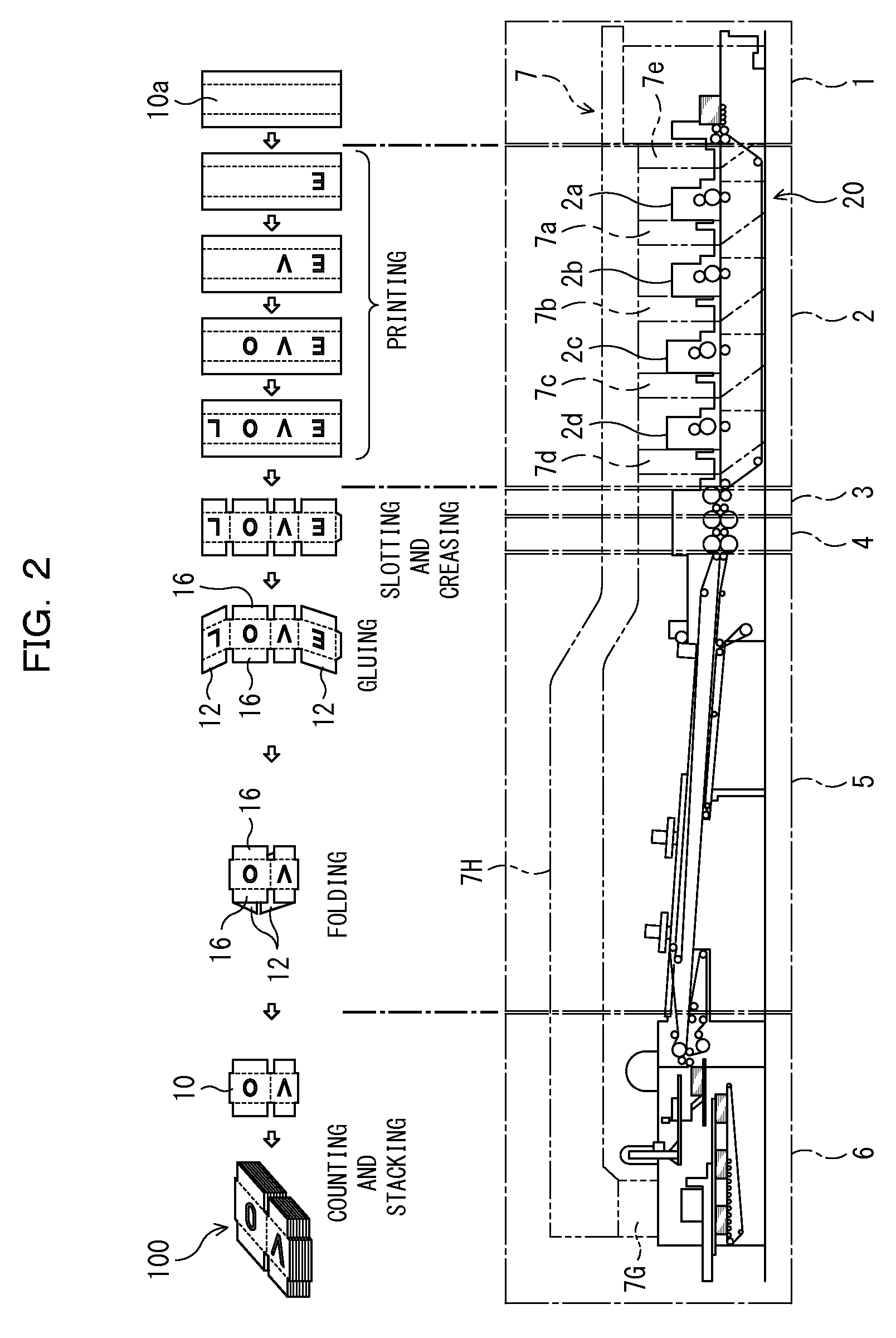

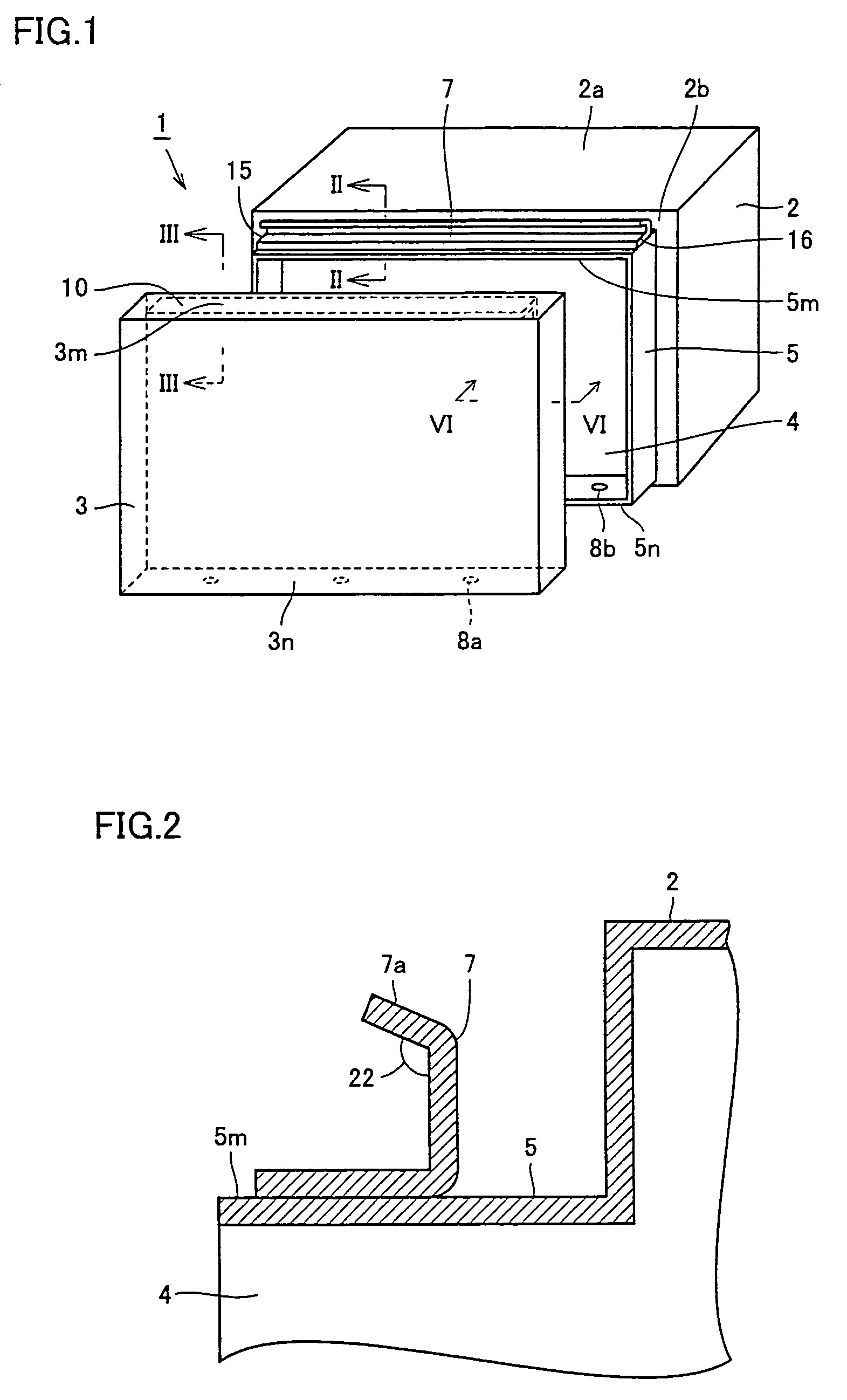

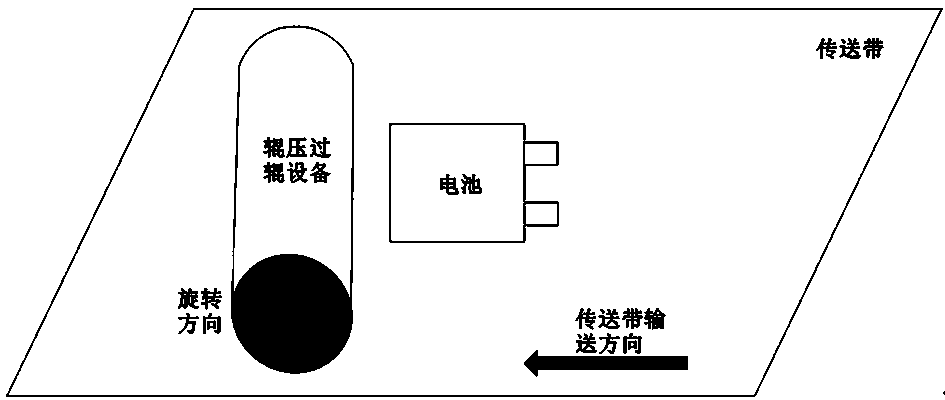

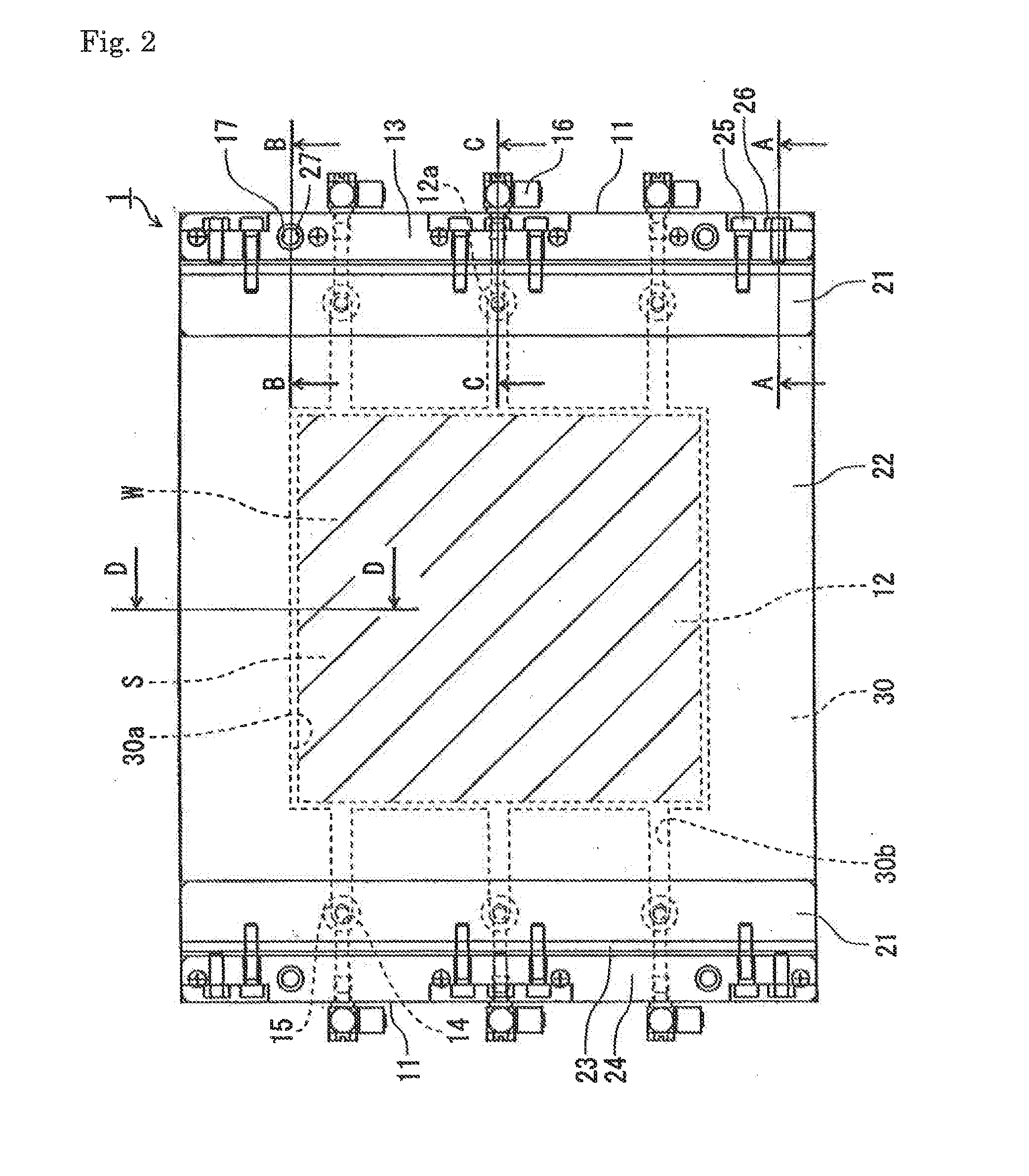

Conveyor, printing device, and box making machine

A conveyor that is disposed at a printing unit of a box making machine and conveys a corrugated sheet 10a that is to undergo printing, includes: a conveyor belt 23 having a conveying face that conveys the corrugated sheet; a suction box 24a that is disposed at a side of a back 23b of the conveying face of the conveyor belt and that suctions the corrugated sheet onto the conveying face with negative pressure; a plurality of guide rolls that guide or drive the conveyor belt. Air blowing means is disposed on the back side of the conveyor belt within a region from an outlet roll to an inlet roll of the guide rolls and blows air to an outside.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

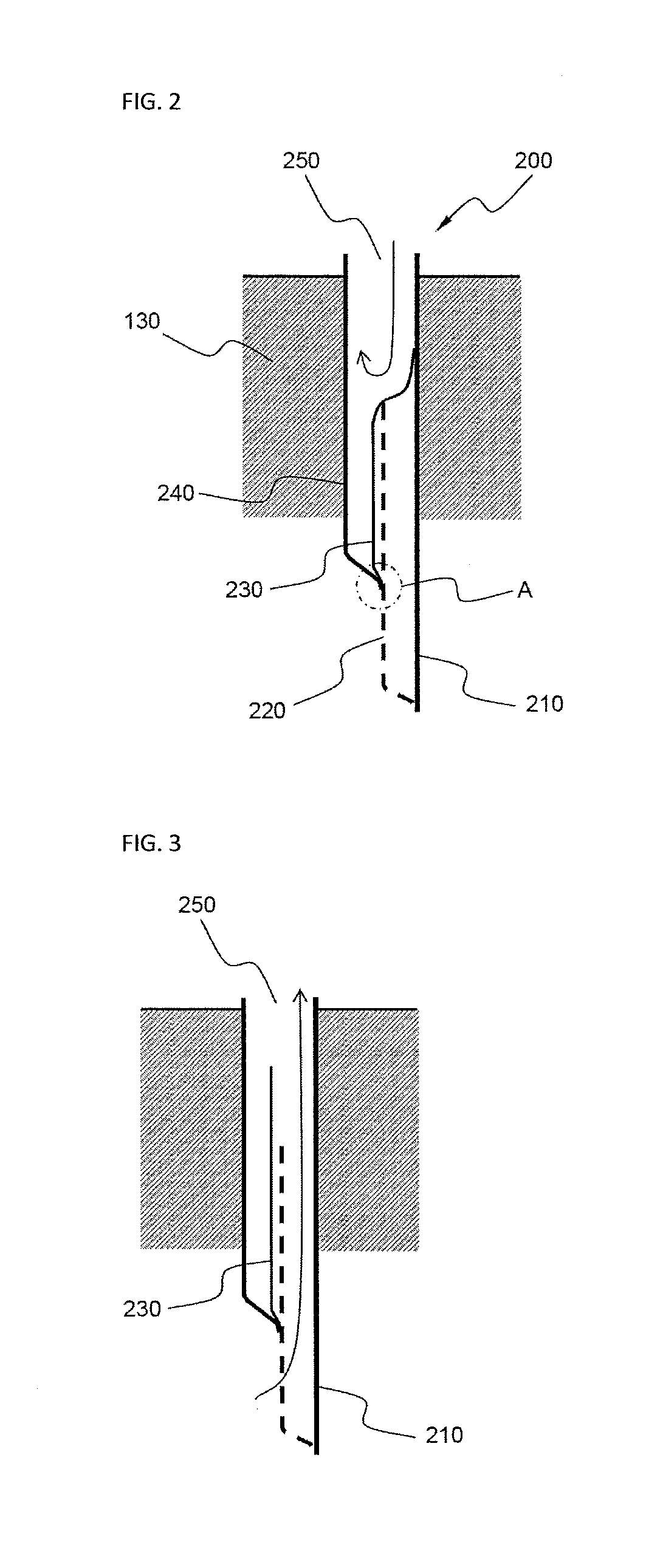

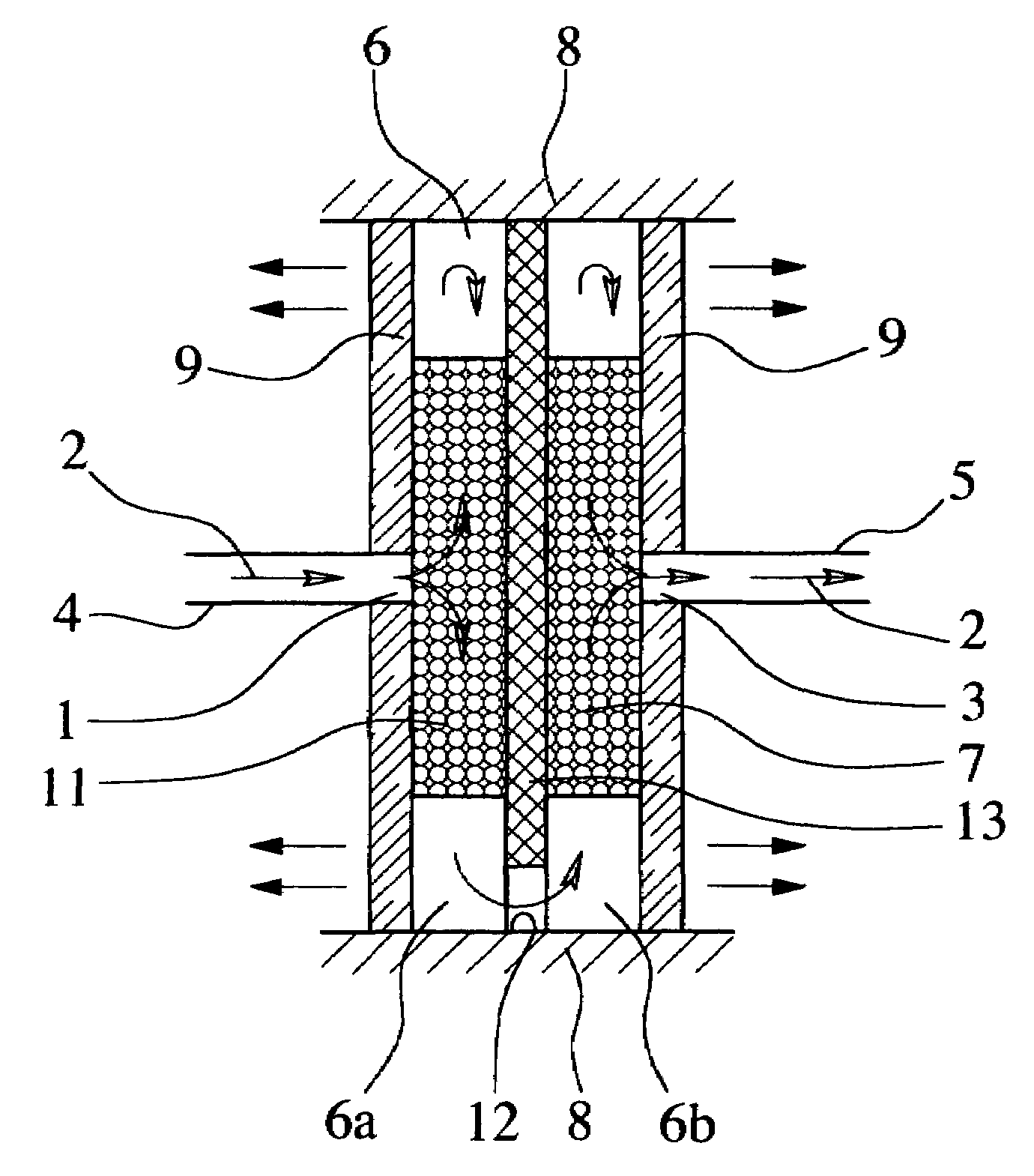

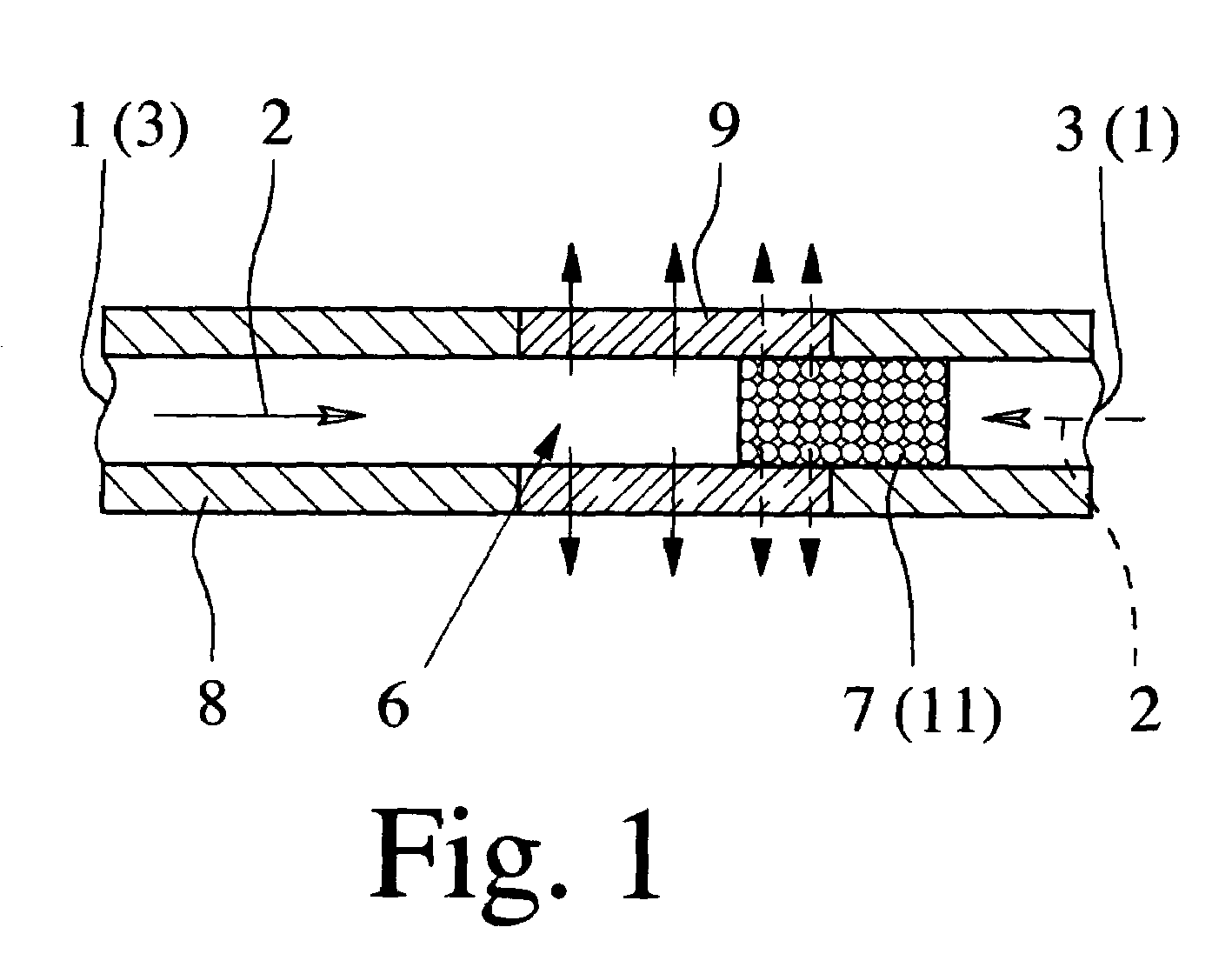

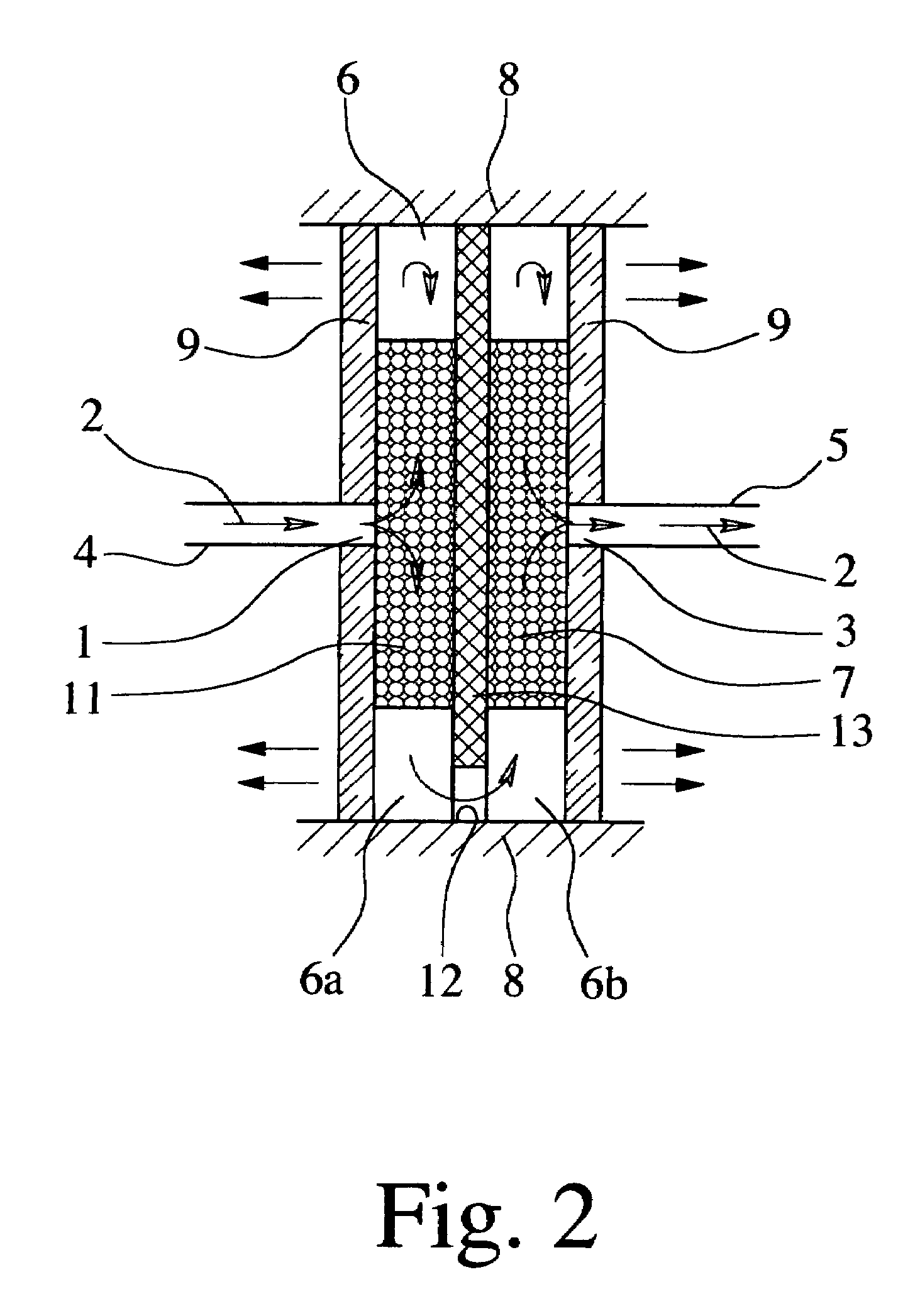

Process and device for separating and exhausting gas bubbles from liquids

ActiveUS20050066812A1Simple wayEasy to doSemi-permeable membranesIsotope separationProcess engineeringProduct gas

A process and a device for separating and exhausting gas bubbles from a flowing liquid, especially in a microfluidic system, are proposed. Radial deflection of the liquid, a preferably annular deaeration chamber from which gas can escape through gas separation material, and a following discharge filter are characteristic. The discharge filter is made of a hydrophilic material which forms pores or small channels. Optionally, there is an inlet filter of the corresponding material upstream of the deaeration chamber.

Owner:BOEHRINGER INGELHEIM MICROPARTS

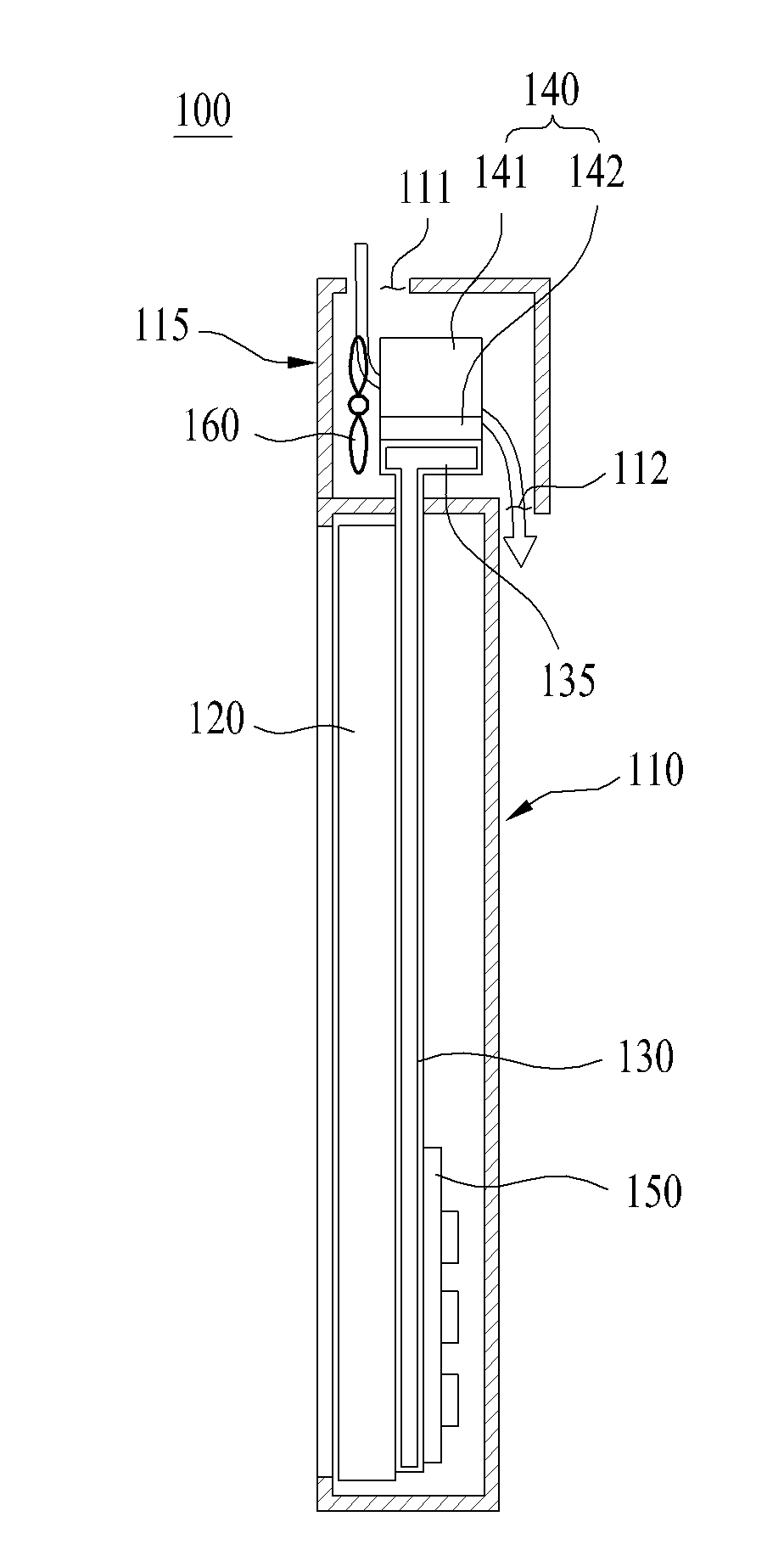

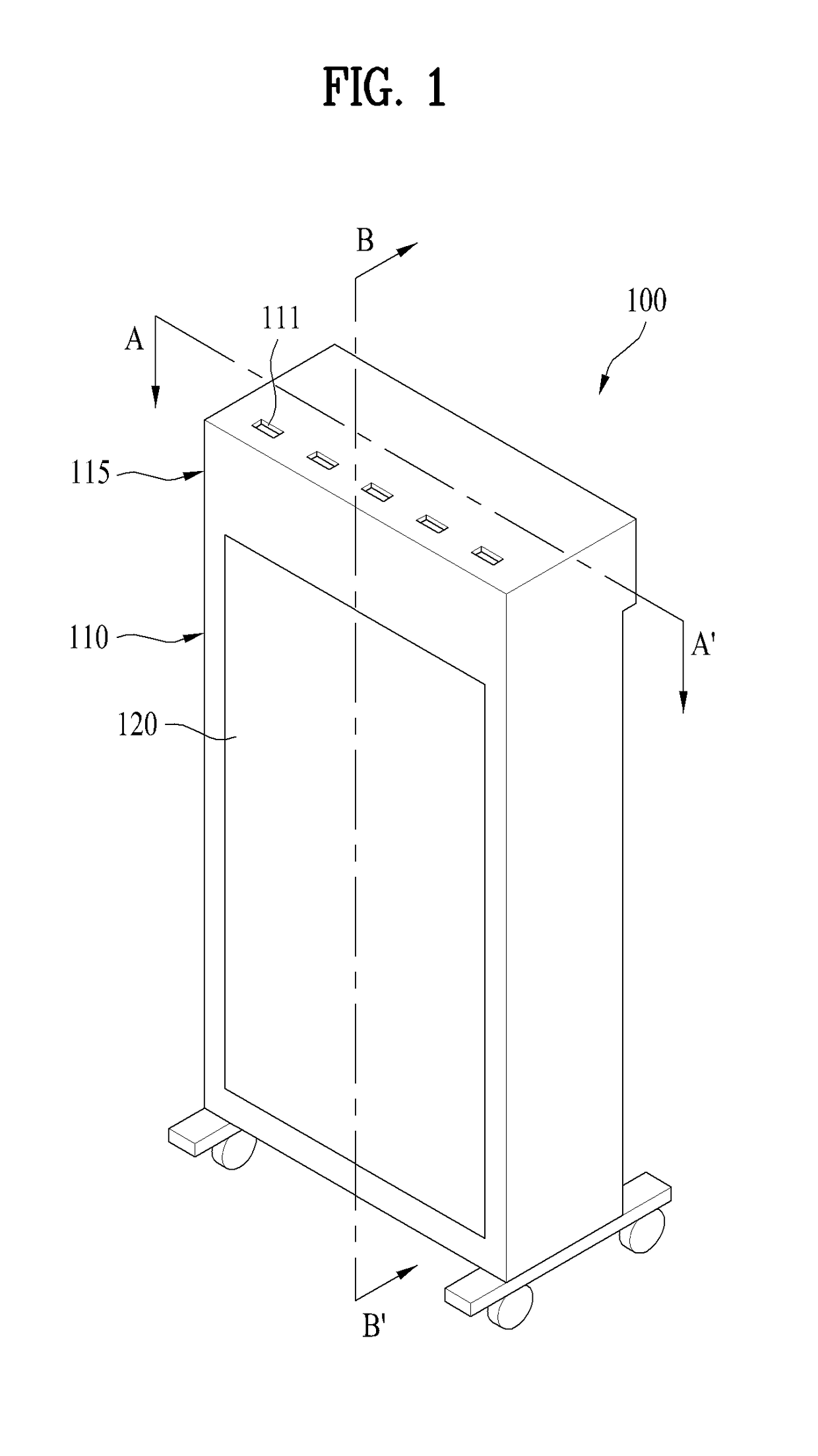

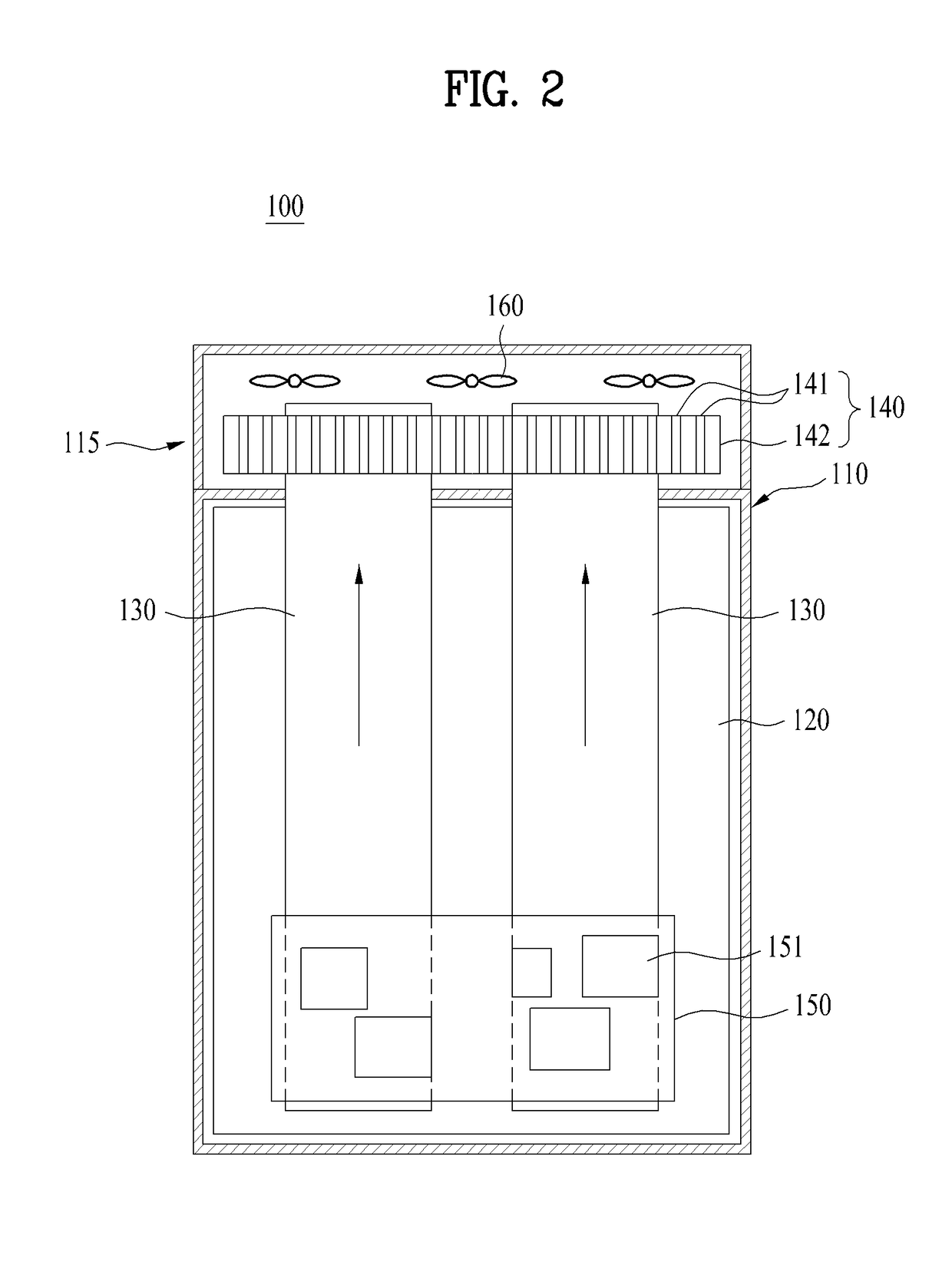

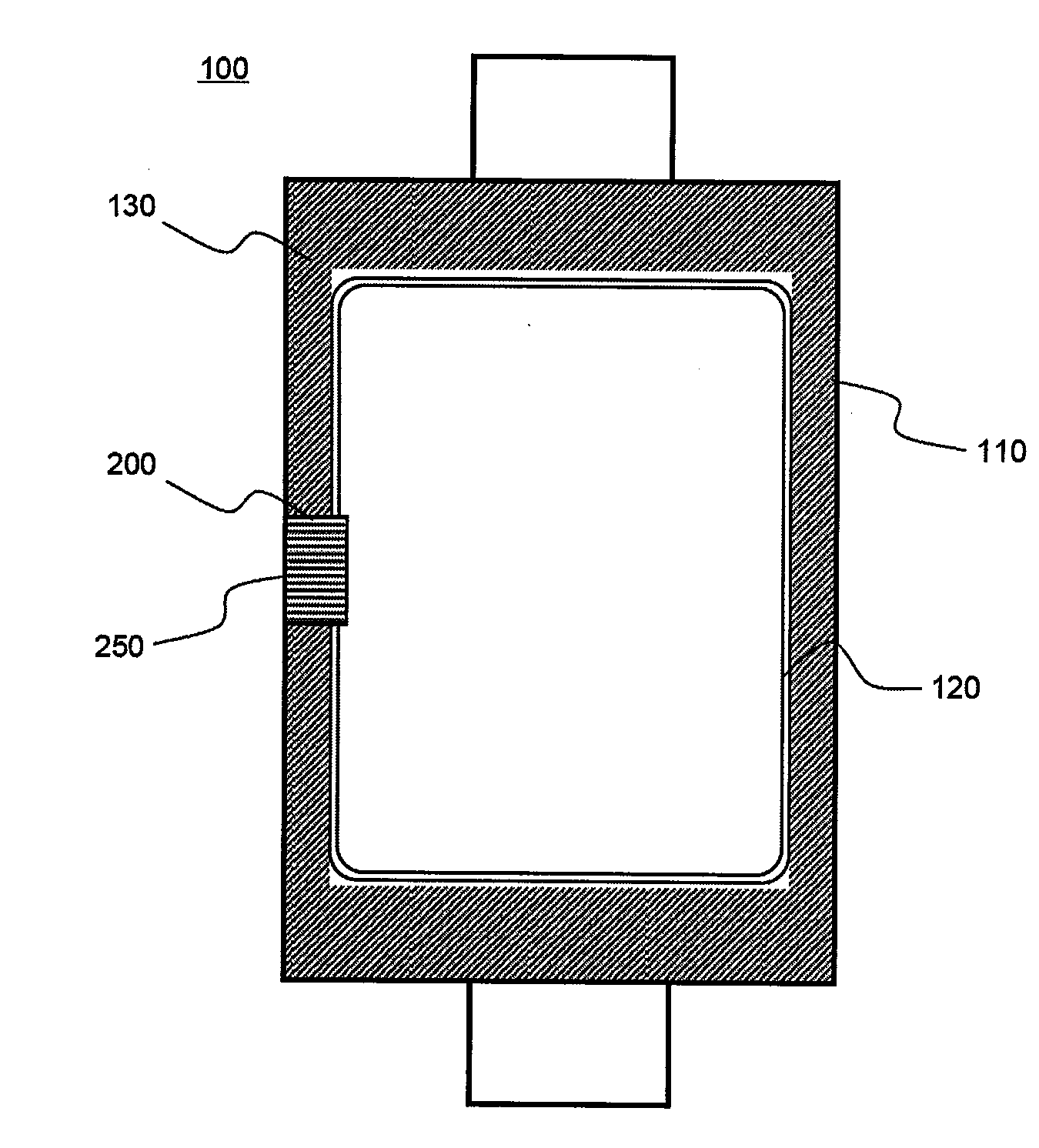

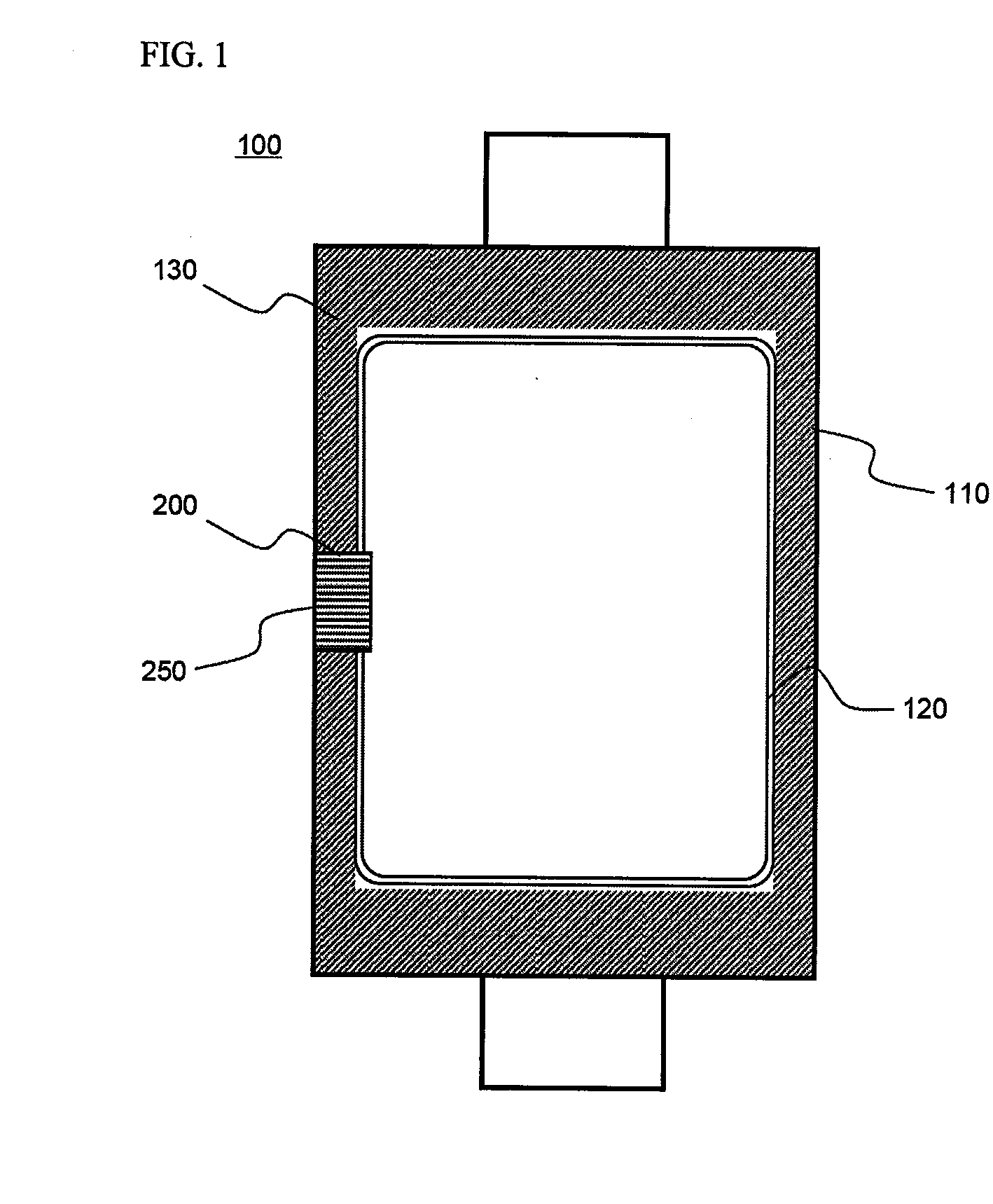

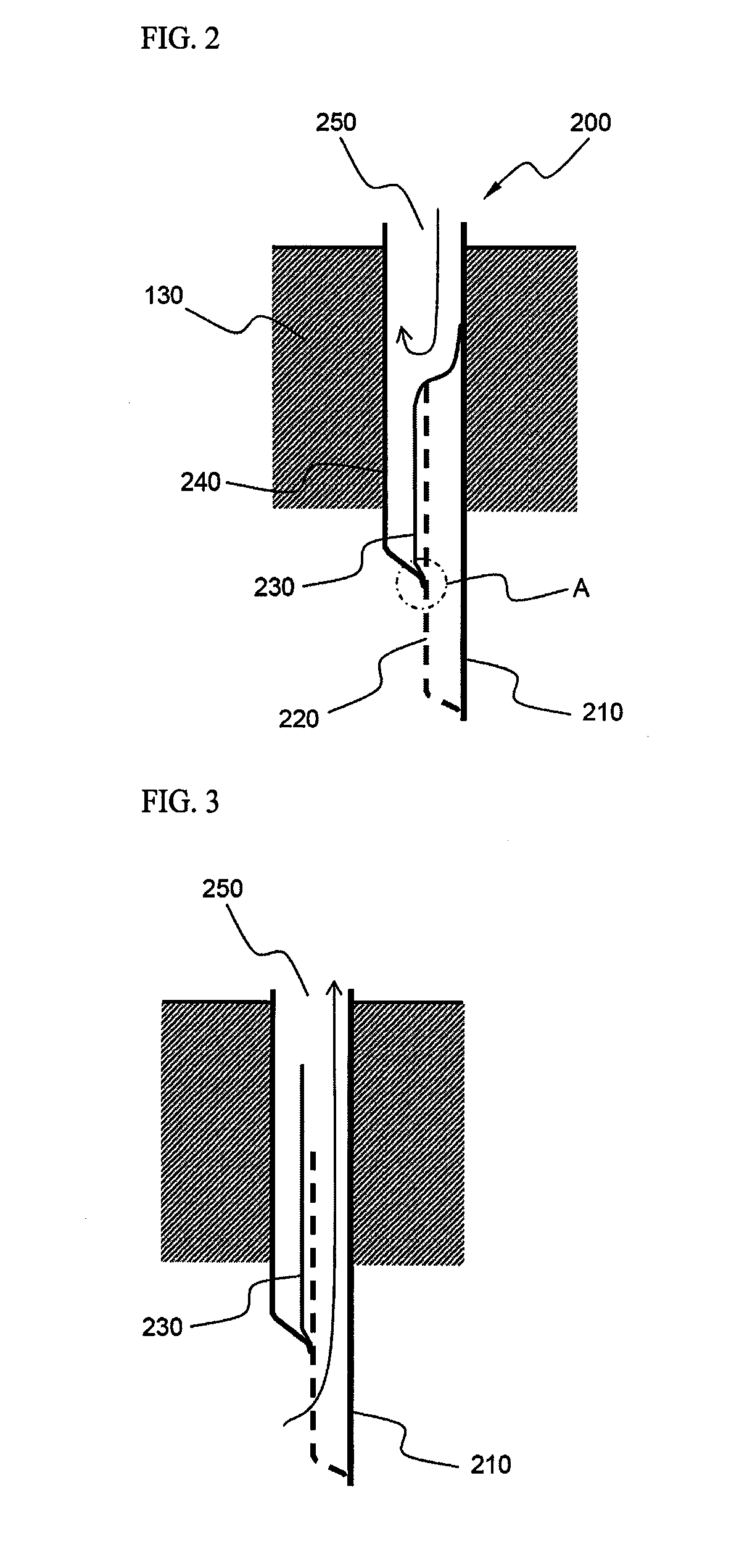

Digital signage

ActiveUS9861007B2Exhaust heatReduce designModifications for display panelsIdentification meansDisplay deviceHeat pipe

There is disclosed a digital signage including a display panel, a housing having the display panel arranged in one surface, the housing comprising a closed inner space, a cooling unit provided in a predetermined portion of the housing, the cooling unit comprising a hole configured to suck and exhaust external air, a heat pipe comprising one end positioned in the inner space of the housing to be coupled to a back surface of the display and the other end positioned in the cooling unit, with a liquid flowing therein to move heat, and a driving circuit board coupled to a back surface of the heat pipe to control driving of the display panel, such that the digital signage having a slim design can exhaust the heat generated from a display panel and a driving circuit board effectively.

Owner:LG ELECTRONICS INC

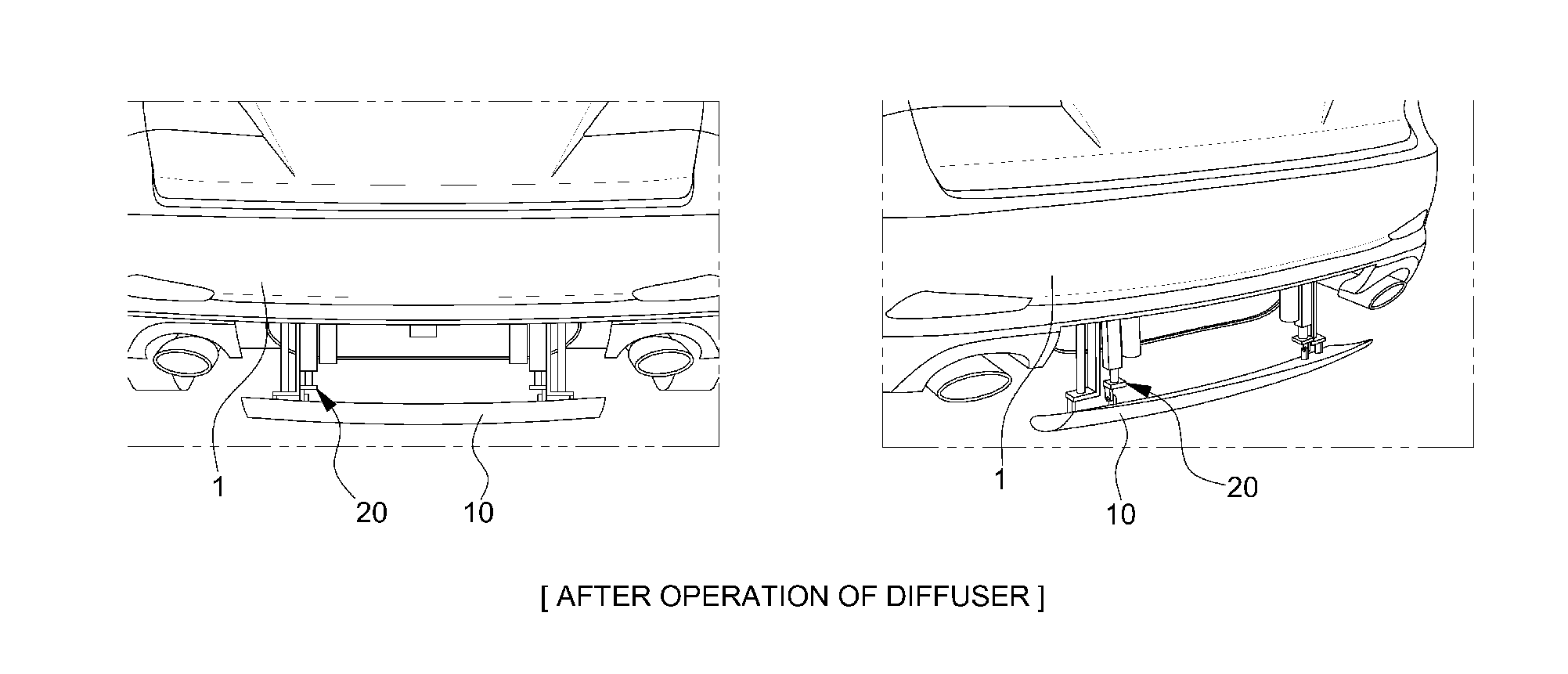

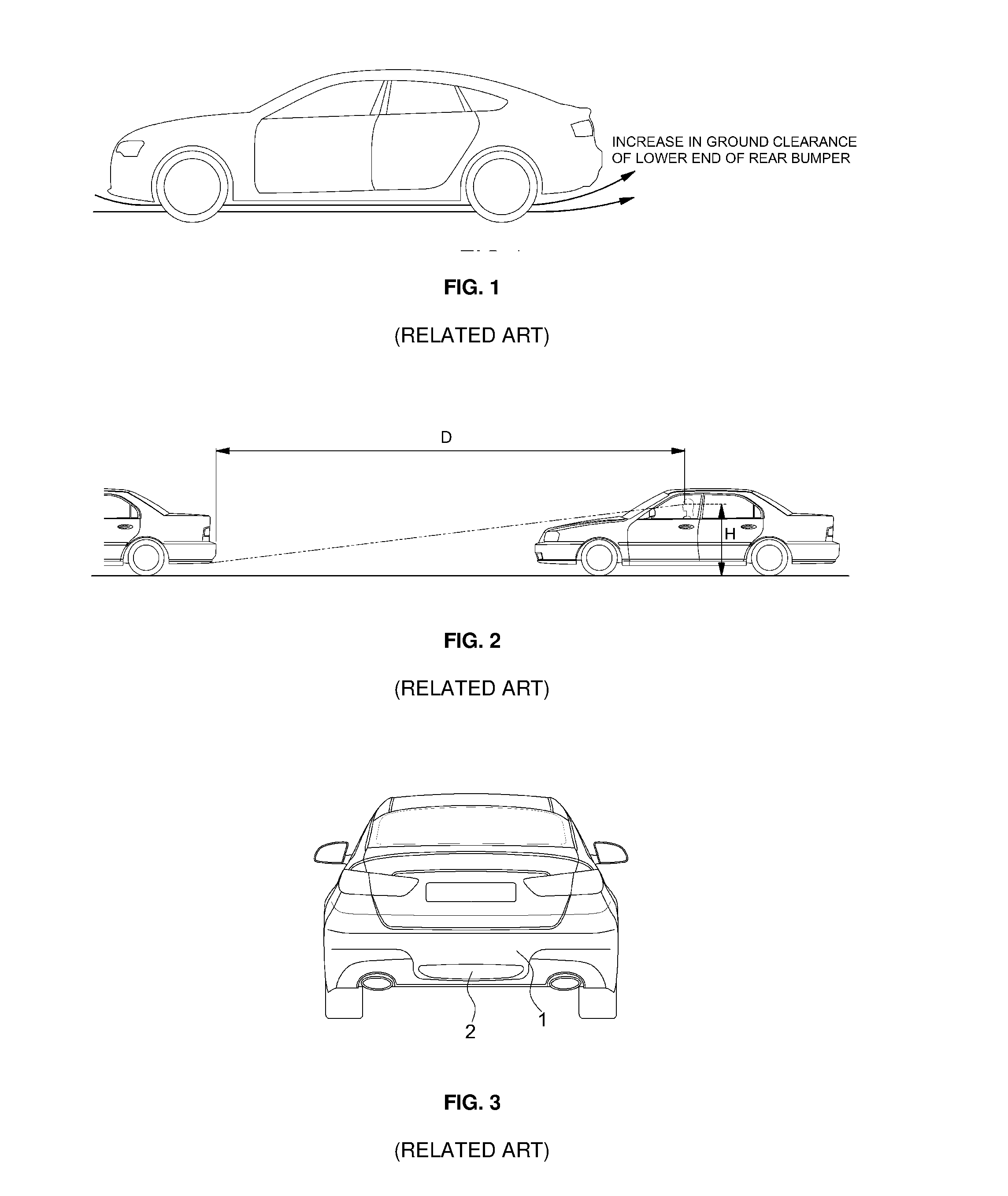

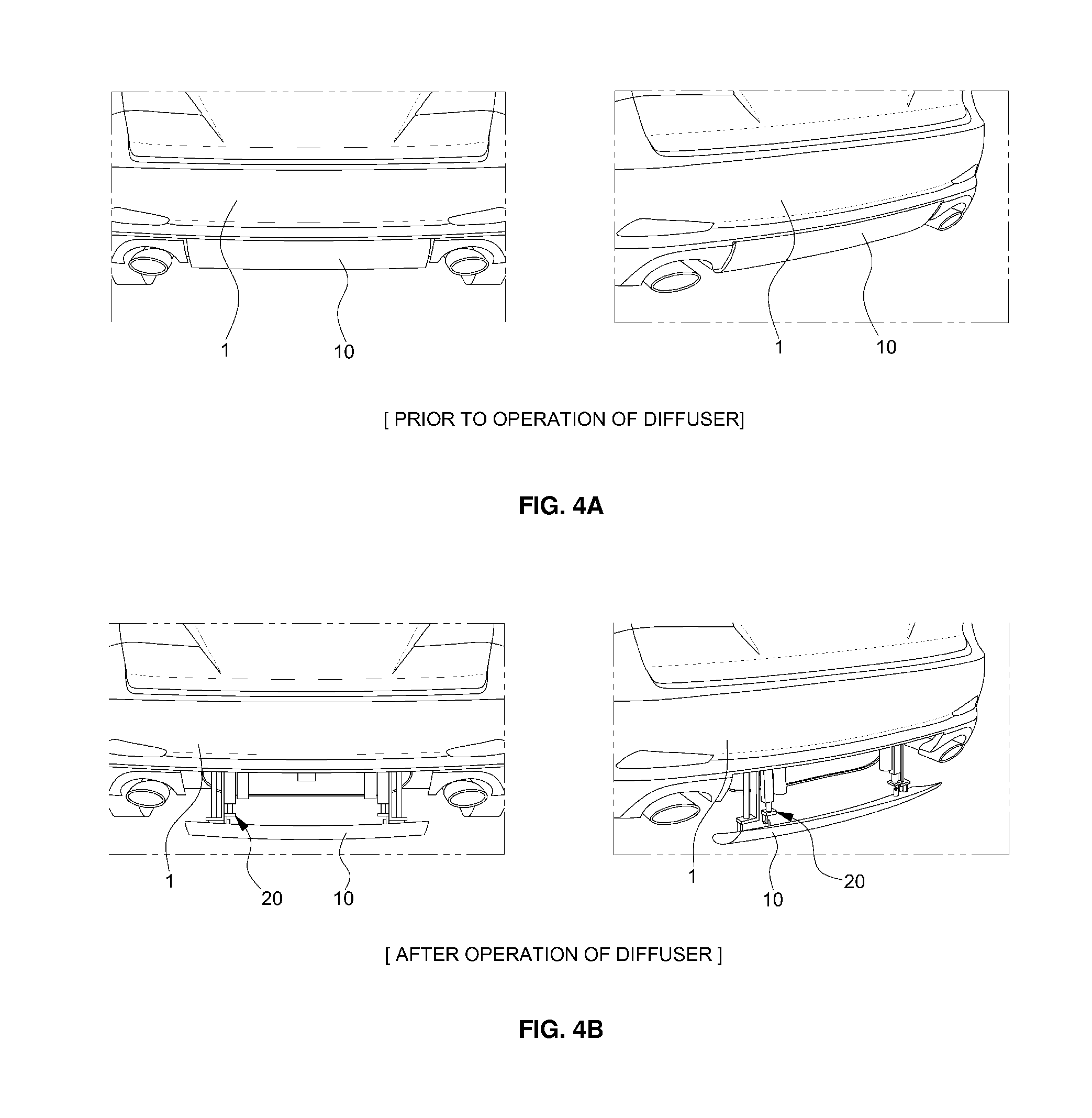

Aerodynamic control system for vehicles

ActiveUS20170050684A1Improve aerodynamic performanceIncreasing visible amountAerodynamics improvementComponent optimizationVehicle frameControl system

An aerodynamic control system for vehicles may improve aerodynamic performance of a vehicle and enhance fuel efficiency and driving stability of the vehicle. The aerodynamic control system includes a diffuser combined with a rear bumper at an ascending position so as to constitute part of a bumper surface of the rear bumper and separated from the rear bumper at a descending position so as to pass air exhausted from a lower part of the vehicle to a rear part of the vehicle along upper and lower surfaces of the diffuser, and a diffuser driving unit that connects a vehicle frame panel in a front of the rear bumper to the diffuser, supporting the diffuser on the vehicle frame panel, and adjusting upward and downward movement of the diffuser and the angle of the diffuser.

Owner:HYUNDAI MOTOR CO LTD

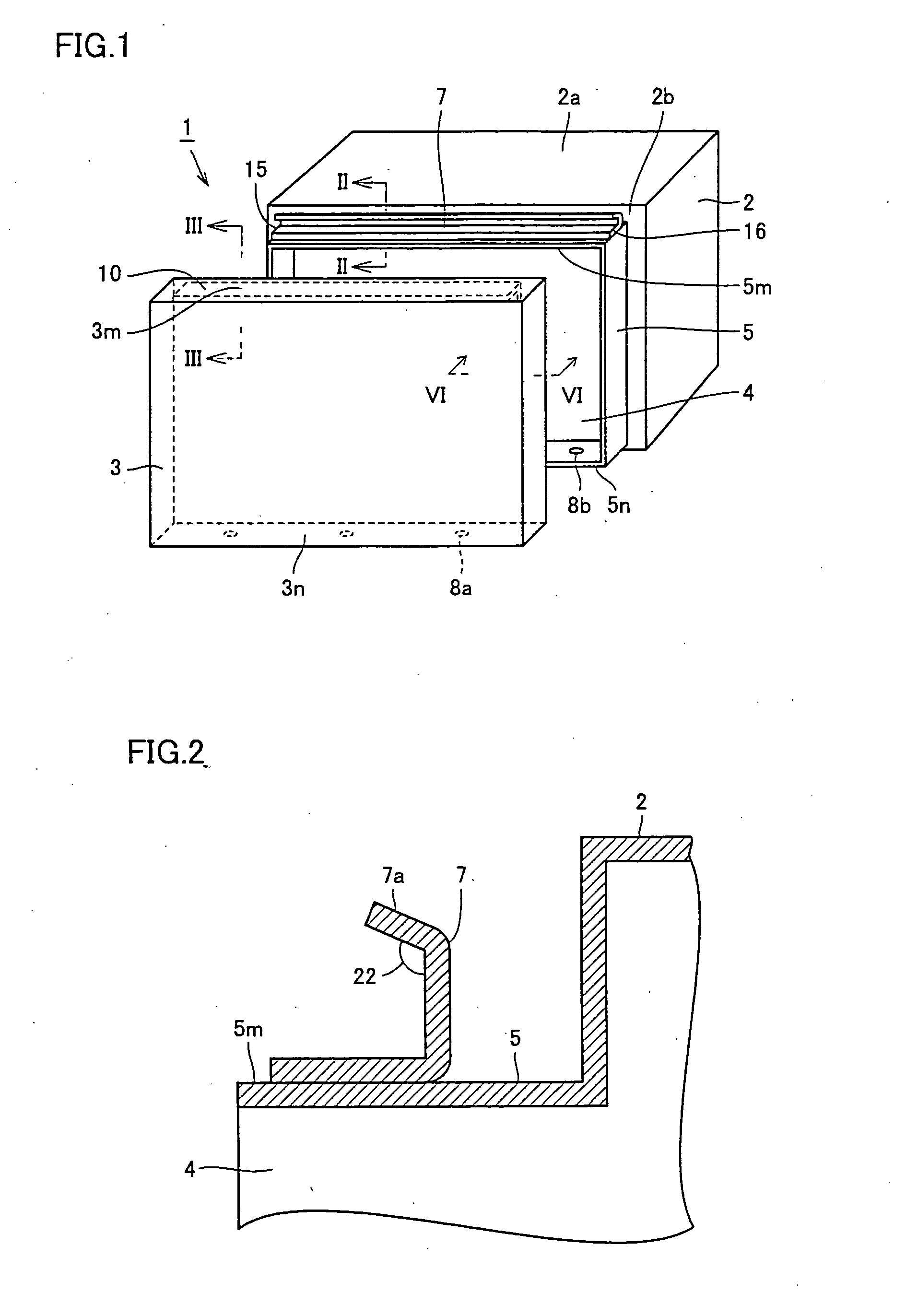

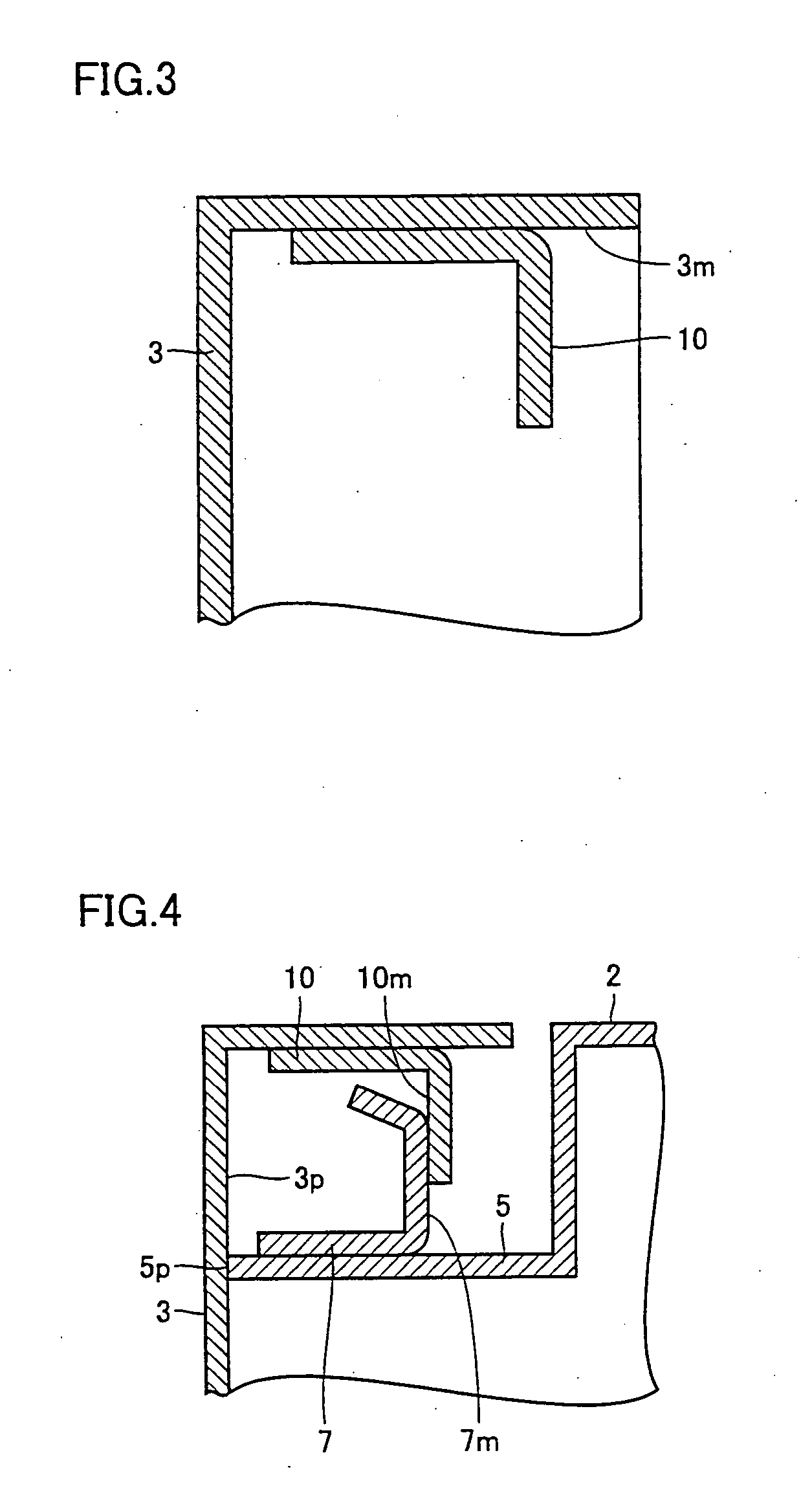

Outdoor-installed power conditioner device

InactiveUS7177148B2Nice appearanceImprove workabilityCoupling device detailsInsulated cablesPower conditionerEngineering

An enclosure is formed of an outer case and a lid. The outer case includes a first projecting strip portion provided on a top face side of the outer case and on an outer peripheral portion defining an opening, and extending to project outwardly from the outer case, and the lid includes a second projecting strip portion provided at a position facing the first projecting strip portion. With the opening of the outer case closed with the lid, the first and second projecting strip portions make close contact with each other along a direction in which these portions extend. This structure can protect the inside from an external factor such as rainwater or dust.

Owner:SHARP KK +1

Secondary battery including one-way exhaust valve

ActiveUS20100239895A1Small thicknessEffective exhaustFinal product manufactureSmall-sized cells cases/jacketsExhaust valveEngineering

Disclosed herein is a plate-shaped secondary battery constructed in a structure in which an electrode assembly of a cathode / separator / anode structure is mounted in a battery case, and the battery case is sealed by thermal welding, wherein the secondary battery has at least one valve (one-way exhaust valve), having a small thickness, mounted at a sealed portion, formed at the outer circumference of an electrode assembly receiving part of the battery case, for allowing internal high-pressure gas to be exhausted out of a battery cell and preventing external gas from being introduced into the battery cell. The secondary battery according to the present invention has the effect of effectively exhausting internal high-pressure gas generated during the abnormal operation of the battery, such as overcharge, out of the battery case, while maintaining the sealability of the battery case, thereby simultaneously improving the efficiency and safety of the battery.

Owner:LG ENERGY SOLUTION LTD

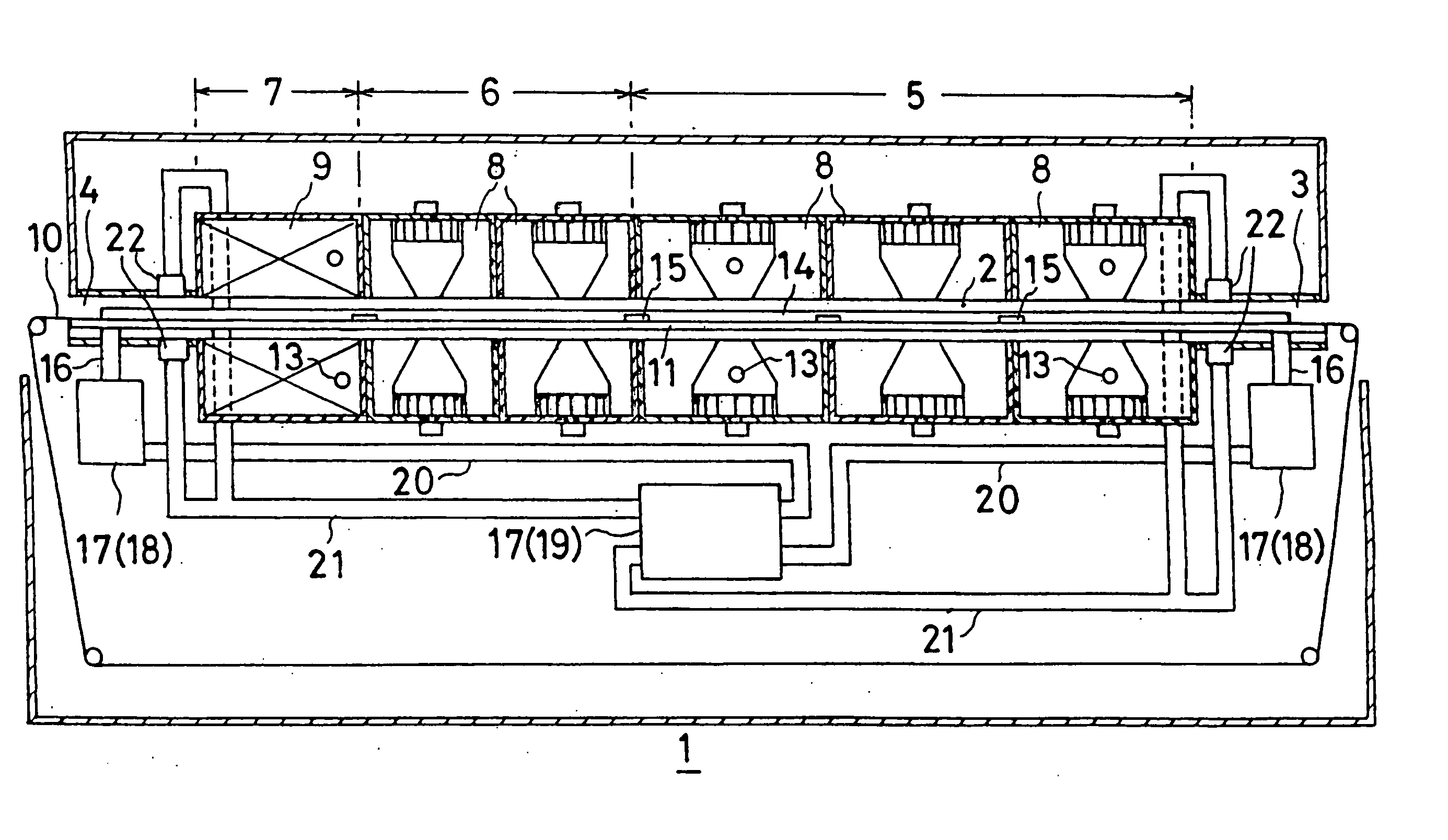

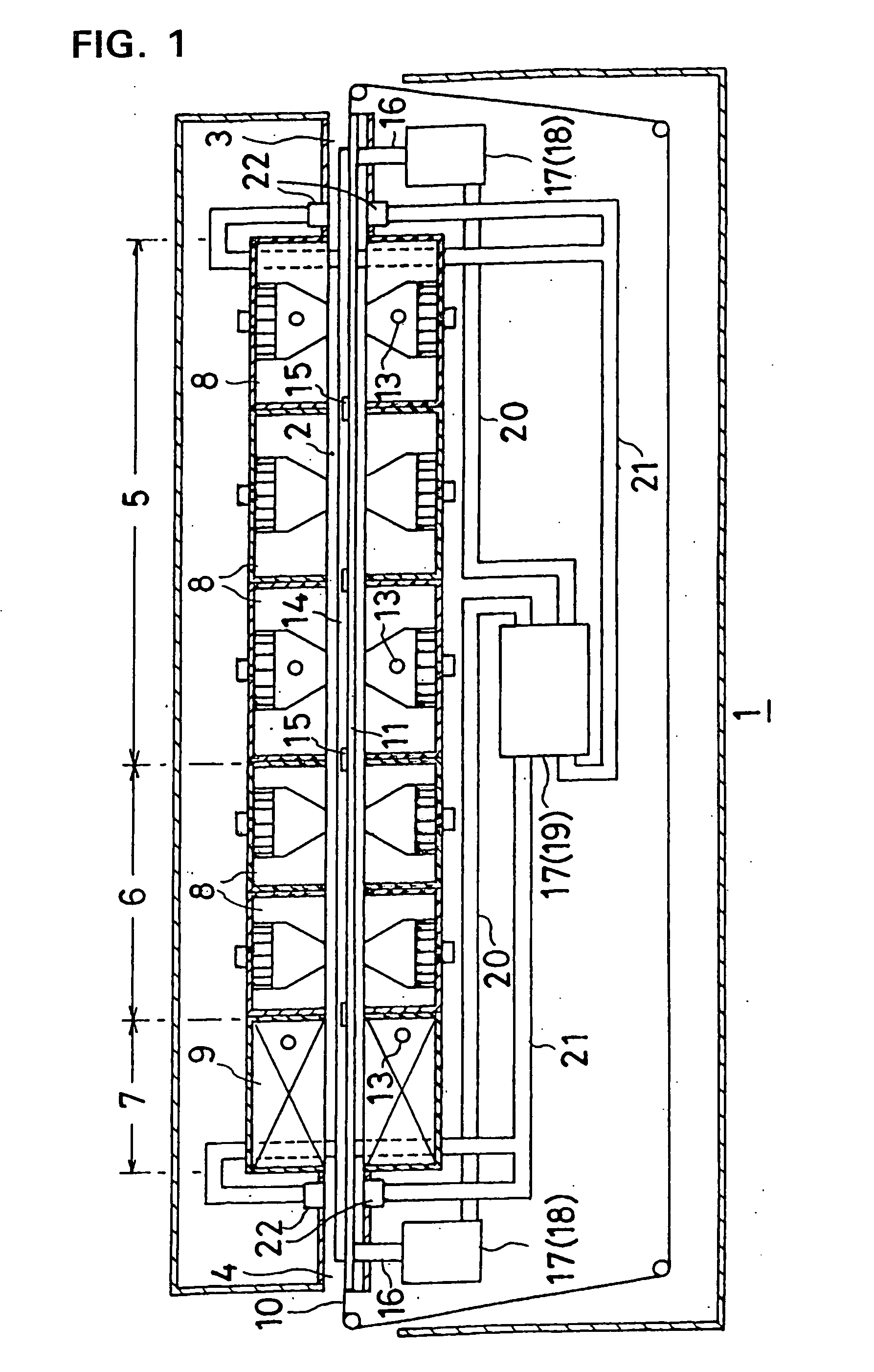

Reflow furnace

InactiveUS20100012709A1Efficiently suckedEffective exhaustHeating appliancesWelding/cutting media/materialsEngineeringMechanical engineering

A reflow furnace includes a suction pipe extending within a heating region along a rail on which a conveyor travels. Suction ports are formed on the inner side of the suction pipe. Flux fumes inside the reflow furnace are sucked into the suction ports and transported to the exterior of a tunnel of the furnace by the suction pipe. The flux fumes are removed by a flux fumes removal apparatus on the exterior of the tunnel, and cleaned gas is returned to the interior of the tunnel at the entrance and the exit of the tunnel, where it forms air curtains which prevent the ingress of outside air.

Owner:SENJU METAL IND CO LTD

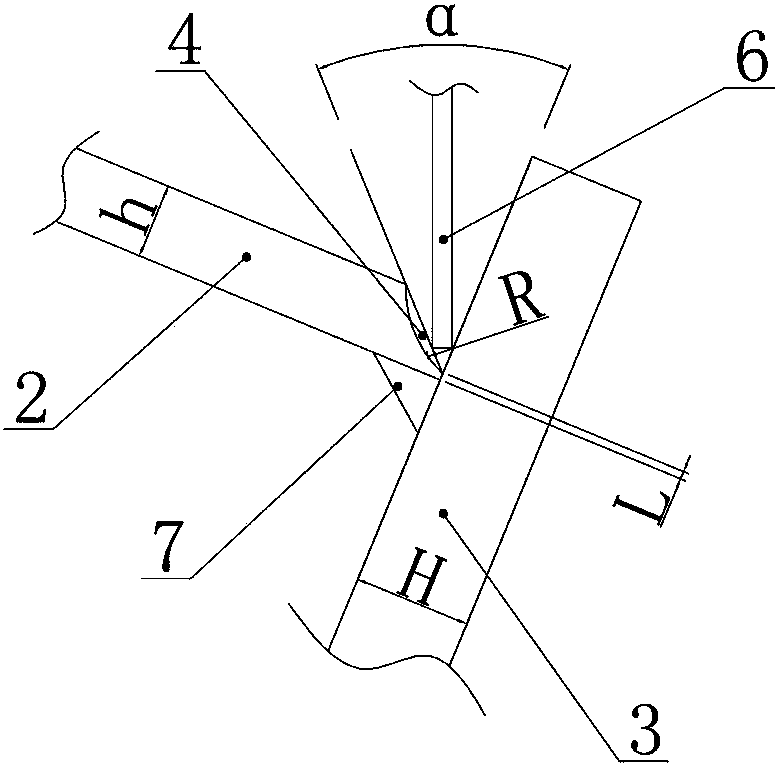

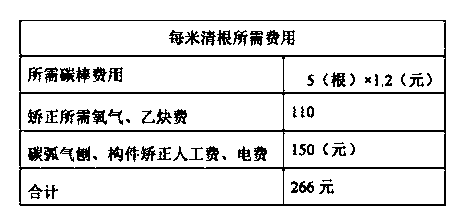

Full penetration fillet weld back-gouging-free welding technology

InactiveCN104259634AImprove rigidityImprove deformation resistanceArc welding apparatusWorkpiece edge portionsFillet weldEngineering

The invention belongs to the technical field of steel structure welding and provides a full penetration fillet weld back-gouging-free welding technology. The welding technology comprises the following steps of: 1) processing a groove of a web plate and decreasing the welding groove as much as possible, 2) fabricating a welding body, ensuring an inclination angle of the welding body to allow a center line of a welding wire to be located on a bisector of an included angle between the groove of the web plate and a wing plate during welding, 3) assembling and placing the web plate and the wing plate on the welding body in a push-against manner, ensuring the straightness and planeness of the web plate and the wing plate and accurately controlling focuses of the web plate and the wing plate, 4) selecting an appropriate welding wire material according to performance of a base material, and carrying out carbon dioxide gas shielded welding on a weld on the reverse side of the groove of the web plate to form a welding backing plate for later groove welding, 5) carrying out union melt welding as the first U-shaped groove welding, and 6) carrying out layered filling welding via the union melt welding, and finally carrying out cosmetic welding, wherein the groove of the web plate is a unilateral U-shaped or V-shaped groove.

Owner:CHINA SIXTH METALLURGICAL CONSTR

Secondary battery including one-way exhaust member

ActiveUS20120196161A1Treatment be easy and convenientPrevent introductionCell component detailsEngineeringOvercharge

Disclosed herein is a plate-shaped secondary battery constructed in a structure in which an electrode assembly of a cathode / separator / anode structure is mounted in a battery case, and the battery case is sealed by thermal welding, wherein the secondary battery has at least one-way exhaust member, mounted at a sealed portion, formed at the outer circumference of an electrode assembly receiving part of the battery case, for allowing internal high-pressure gas to be exhausted out of a battery cell and preventing external gas from being introduced into the battery cell. The secondary battery according to the present invention has the effect of effectively exhausting internal high-pressure gas generated during the abnormal operation of the battery, such as overcharge, out of the battery case, while maintaining the sealability of the battery case, thereby simultaneously improving the efficiency and safety of the battery.

Owner:LG ENERGY SOLUTION LTD

Outdoor-installed power conditioner device

ActiveUS20060012947A1Reduce in quantitySmooth bootCoupling device detailsInsulated cablesElectric forcePower conditioner

An enclosure is formed of an outer case and a lid. The outer case includes a first projecting strip portion provided on a top face side of the outer case and on an outer peripheral portion defining an opening, and extending to project outwardly from the outer case, and the lid includes a second projecting strip portion provided at a position facing the first projecting strip portion. With the opening of the outer case closed with the lid, the first and second projecting strip portions make close contact with each other along a direction in which these portions extend. This structure can protect the inside from an external factor such as rainwater or dust.

Owner:SHARP KK +1

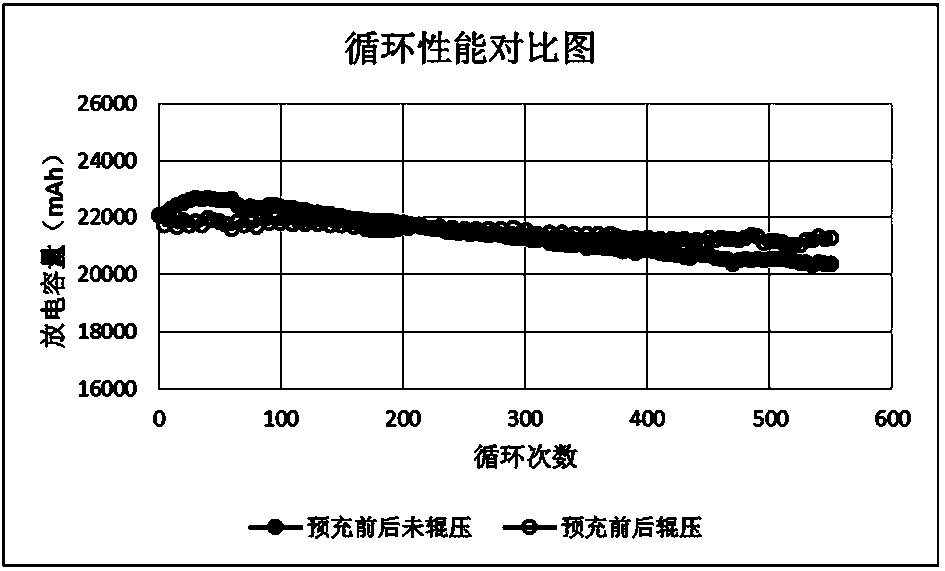

Novel control method for improving lithium ion soft-package laminated battery diaphragm fold

InactiveCN108155424AImprove performanceGuaranteed plastic effectFinal product manufactureSecondary cells charging/dischargingElectrical batteryPre-charge

The invention relates to a novel control method for improving lithium ion soft-package laminated battery diaphragm fold. The problem that the battery performance is influenced due to the fold of the soft-package laminated lithium ion battery diaphragm is solved. The control method comprises the following steps: laying down a battery after liquid injection, thereby ensuring that the electrolyte sufficiently infiltrates a pole piece; and then performing rolling on the lay-down battery, and controlling the pressure and speed of the rolling in the rolling process; pre-charging the battery after the rolling is ended; and performing secondary rolling on the completely pre-charged battery, further shaping the diaphragm, and releasing the gas to finish the secondary package. The contacting interface between a positive / negative pole piece and the diaphragm is better by comparing the lithium ion soft-package laminated battery prepared based on the control method with the battery without performing the rolling shaping, the dead lithium existing in the fold area caused by the diaphragm fold is avoided, thus the capacity of the positive / negative material is sufficiently played, and the batteryperformance is improved.

Owner:JIANGSU FRONT NEW ENERGY +1

Fuel cell, fuel cell stack, and fuel cell system

InactiveUS20060286426A1Efficiently exhaustExhausting the residual water efficientlyFuel cells groupingCell electrodesElectrochemical responseMembrane configuration

A fuel cell stack has plural fuel cells stacked in series along a direction vertical to a main surface of each fuel cell. Each fuel cell has a lamination body made of an anode, a cathode, and a polymer proton exchange membrane. The lamination body is sandwiched between a pair of separators. Each of the anode and cathode has a catalyst layer and a diffusion layer laminated. A water collecting groove and fuel gas passages are formed in the inner surface of each separator. The bottom end of the water collection groove is lower in position than the end of the catalyst layer and the diffusion layer. The water collecting groove is not joined to the fuel gas passages and collects water produced by electrochemical reaction in each fuel cell, and drains the collected water.

Owner:DENSO CORP

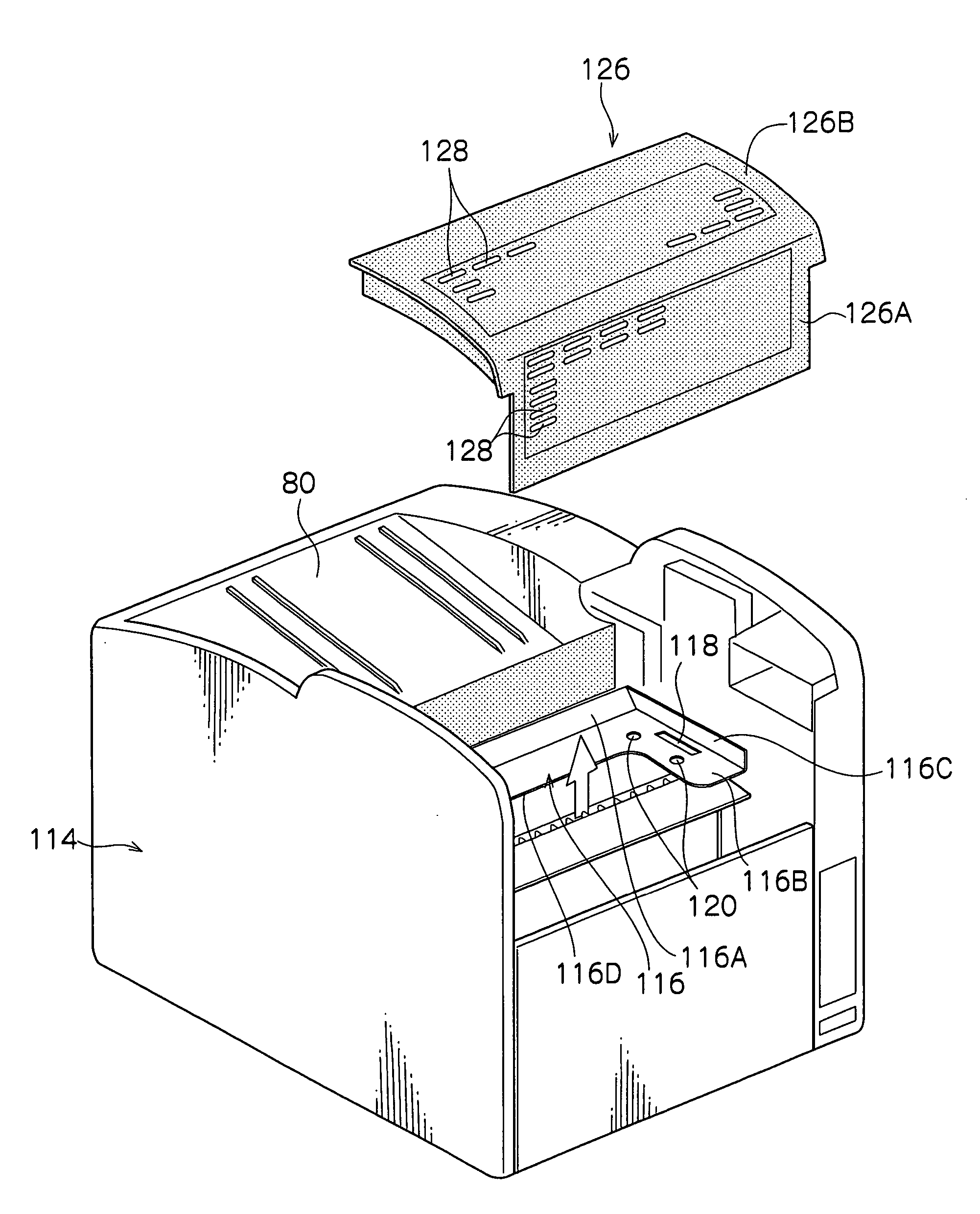

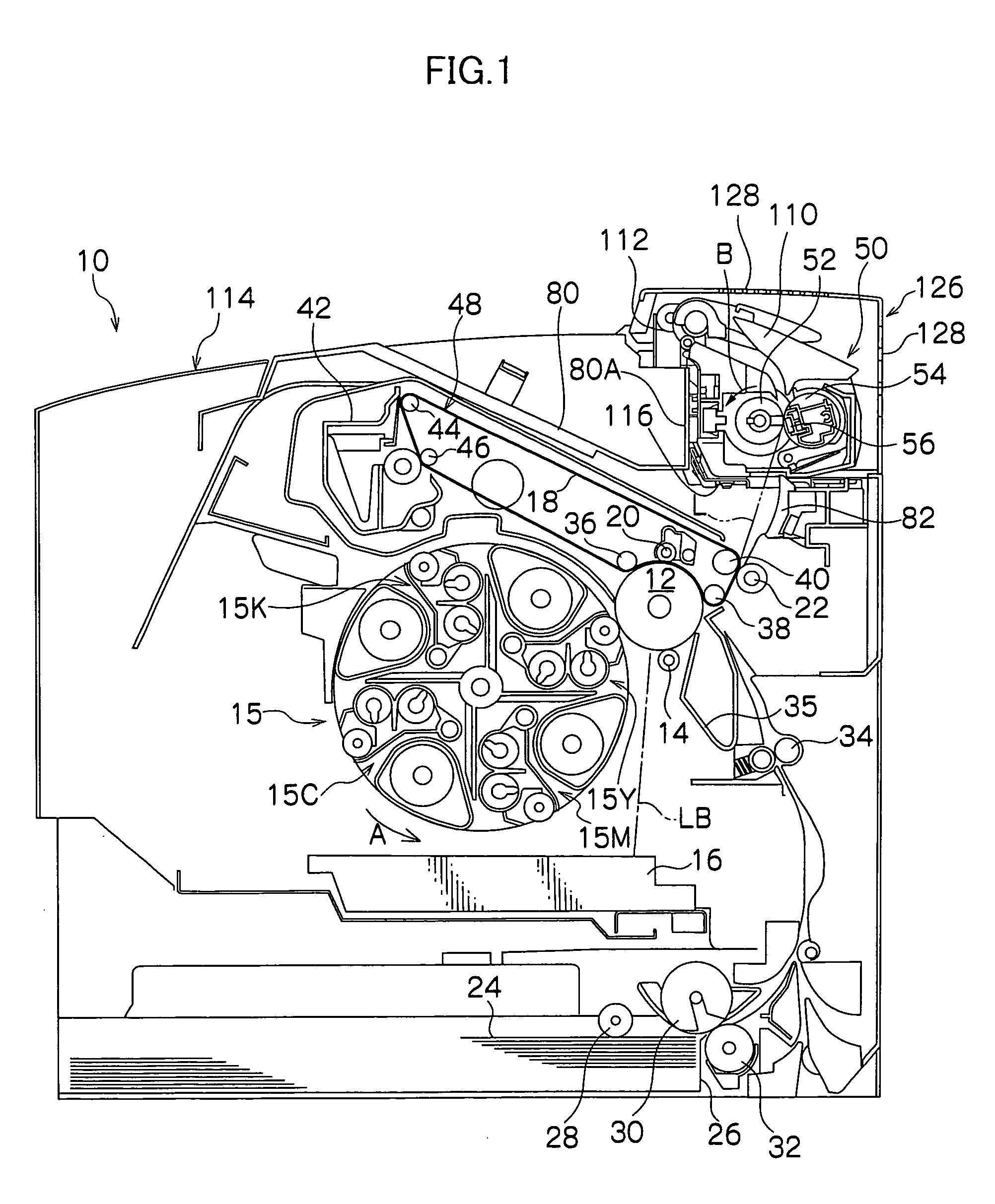

Image formation device

InactiveUS20060018679A1Eliminate emission of noiseLow costElectrographic process apparatusImage formationHeat shield

An image formation device is provided, at which a fixing device is disposed inside a housing of a printer main body, and which is configured in a fanless ventilation structure. This image formation device is provided with a fixing unit mounting portion positioned at an upper portion of the housing, and surrounded by a partition wall and a heat-shielding member extending from a side face of the partition wall, the fixing apparatus being placed on the heat-shielding member, and the fixing unit mounting portion being isolated such that hot air will not flow to equipment inside the housing; a cover member for covering the fixing unit mounting portion; a ventilation portion which includes ventilation apertures formed through the cover member, and a conveyance portion for the recording medium.

Owner:FUJIFILM BUSINESS INNOVATION CORP

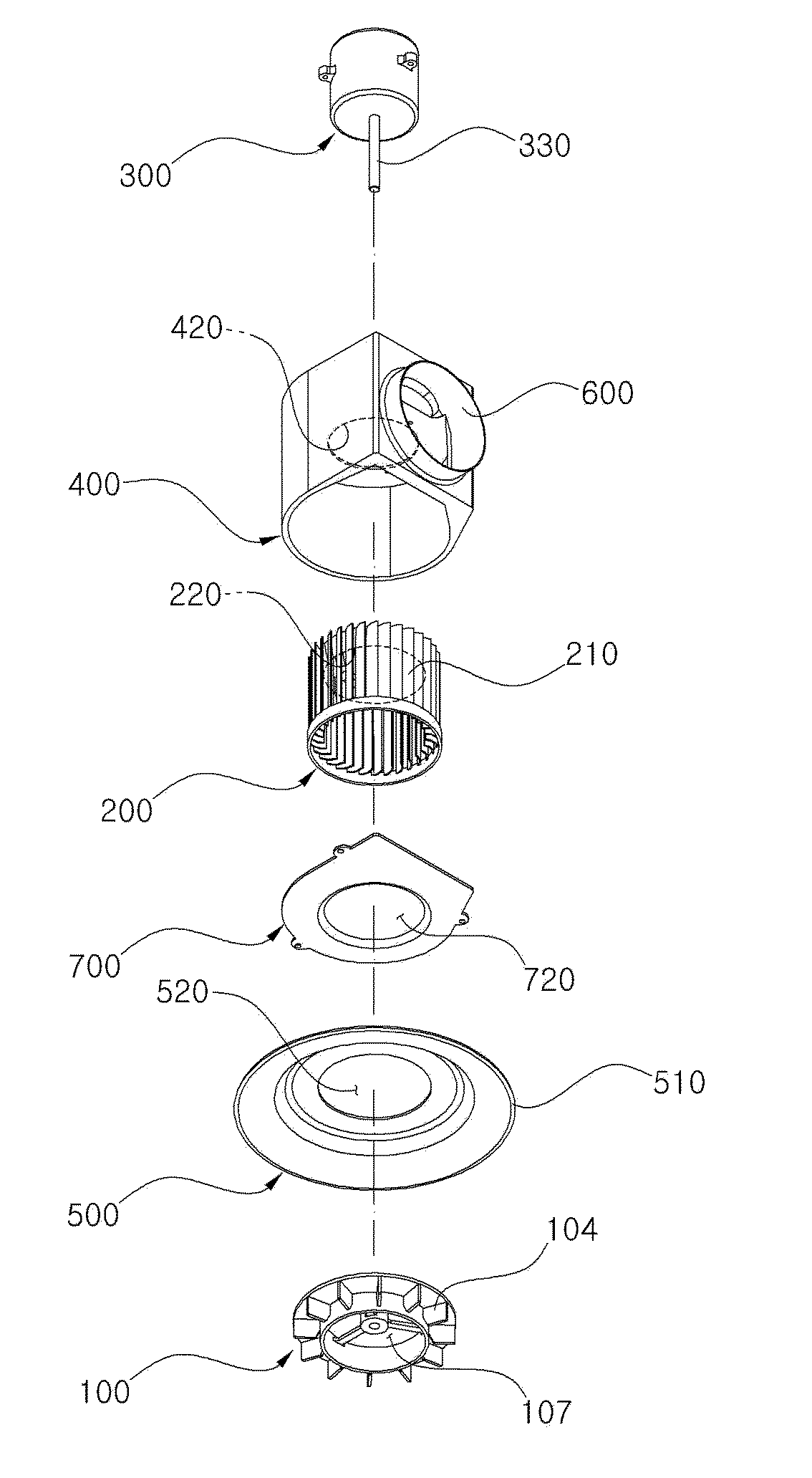

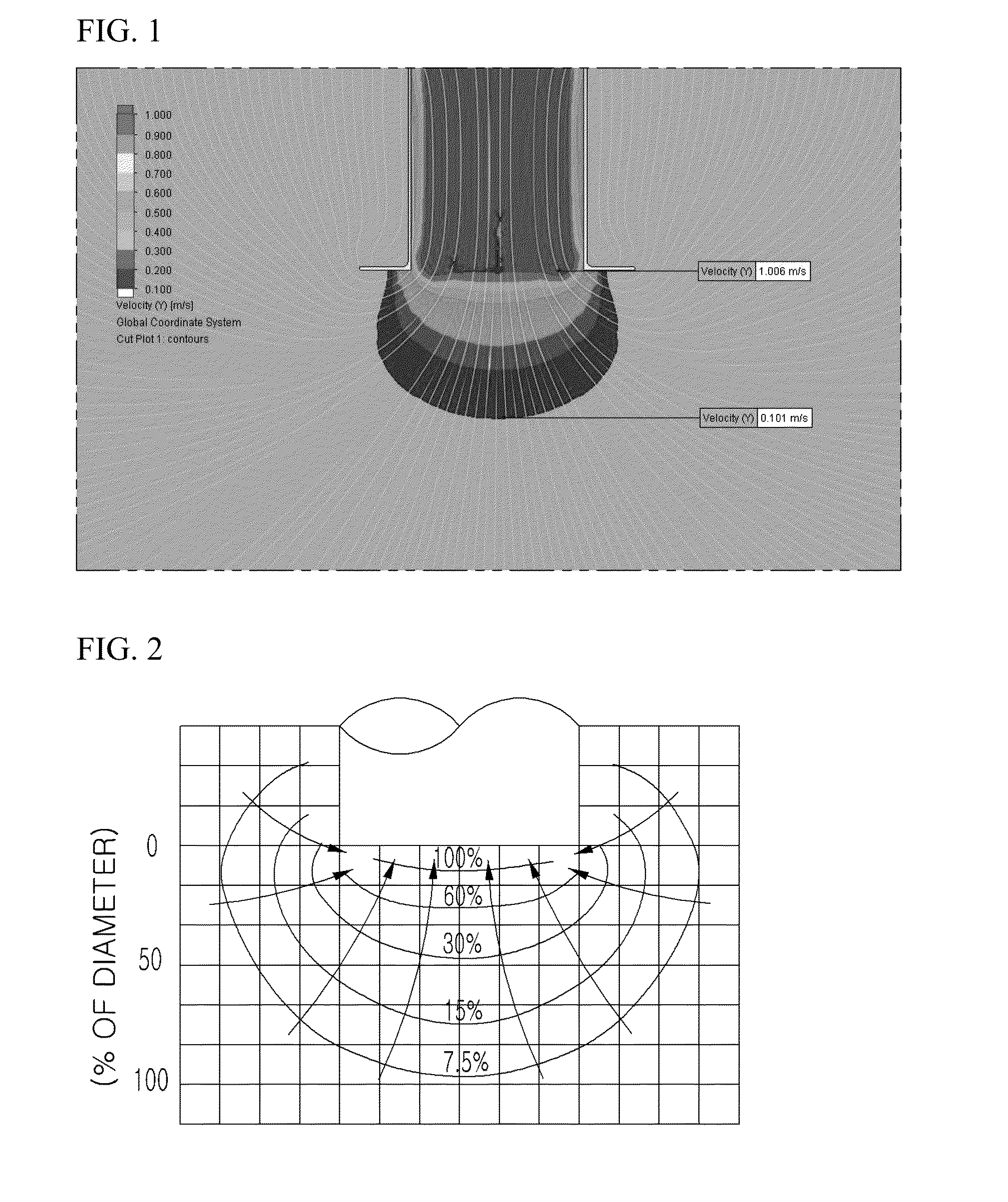

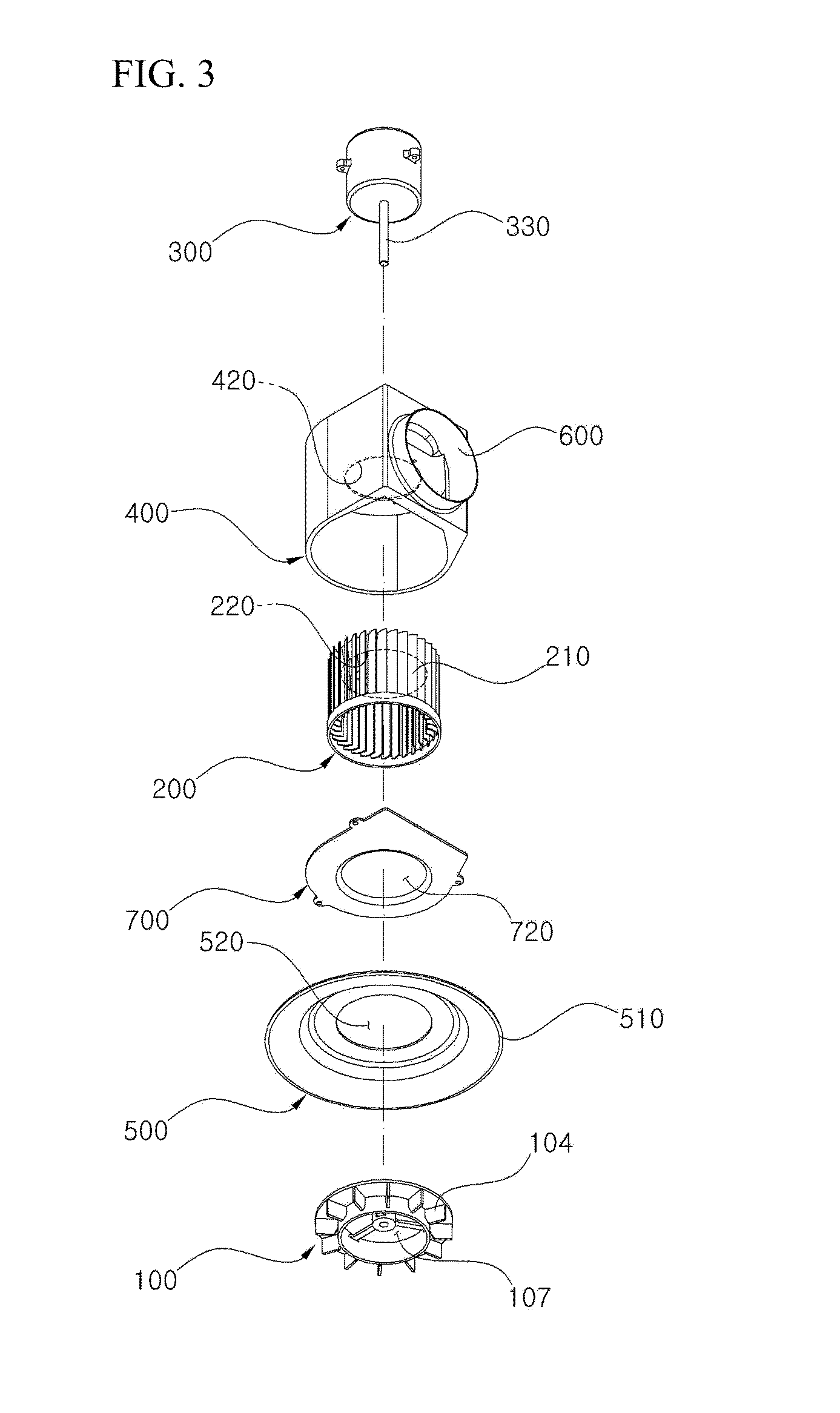

Ventilation module with swirler fan

ActiveUS20160161133A1Strong discharge powerStrong suctionDucting arrangementsPump componentsEngineeringWhirlwind

The disclosure aims to provide a ventilator module with improved efficiency. The ventilator module employs the dual structure of fans includes a swirler fan and a suction fan, in which the swirler fan is disposed at the front side and the suction fan is disposed at the rear side of the swirler fan so that a swirl formed by the drive of the swirler fan forms a donut-like low pressure zone around an inlet, and a tornado is formed by rotating the donut-like low pressure zone by the drive of the suction fan thereby cause the air below swirler fan to ascend at high velocity so as to be suctioned and discharged.

Owner:TORNADO SYST

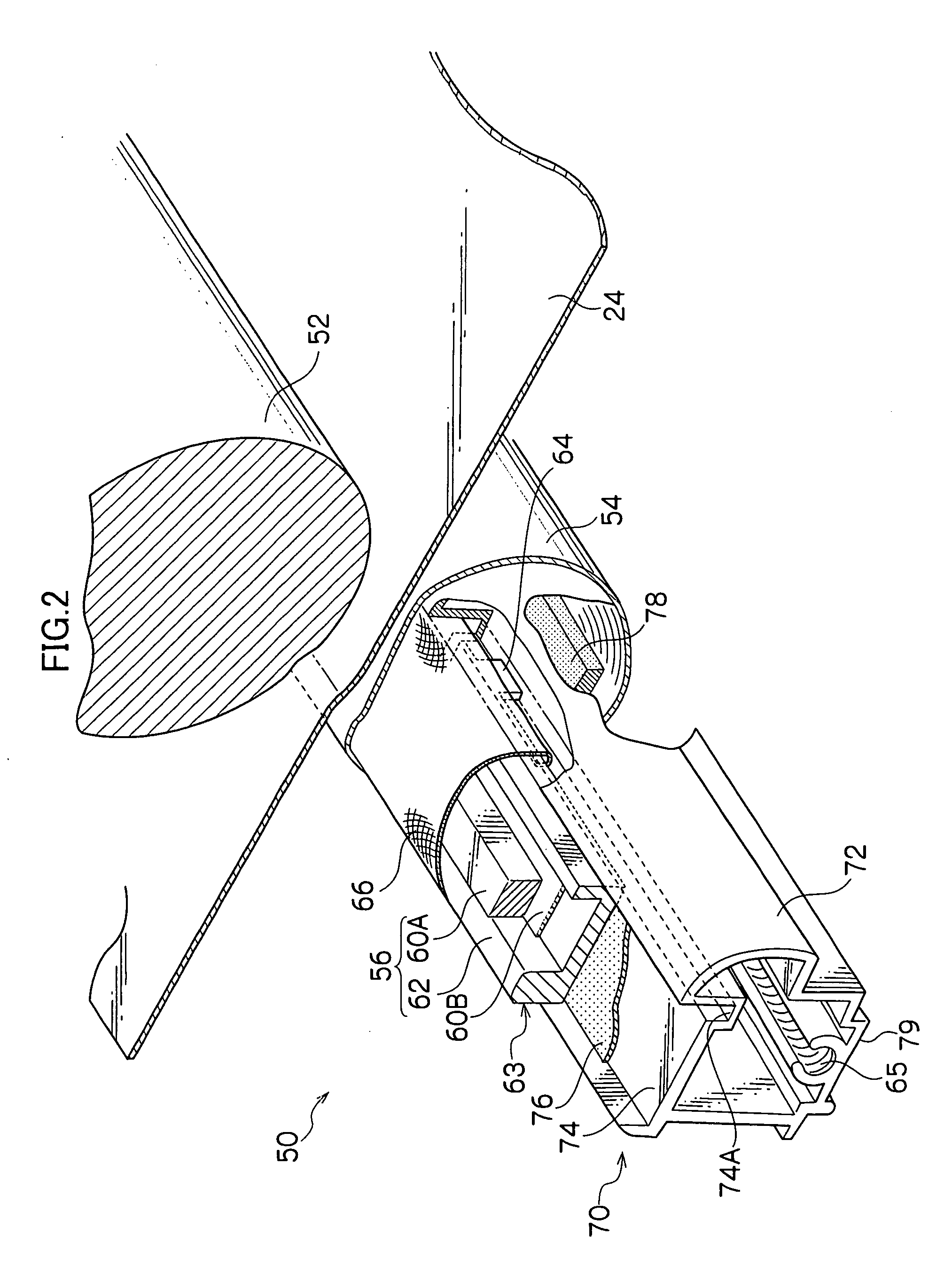

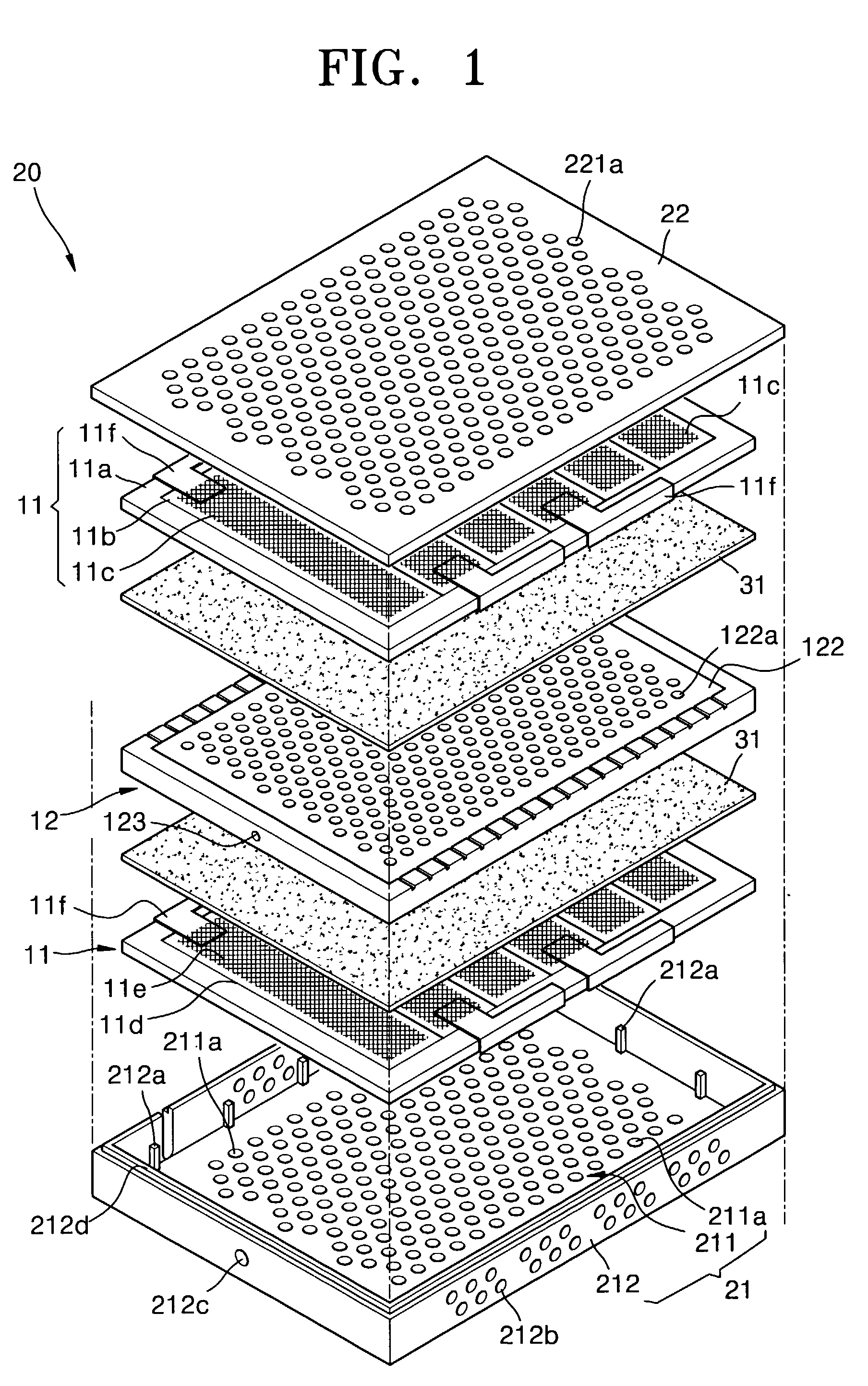

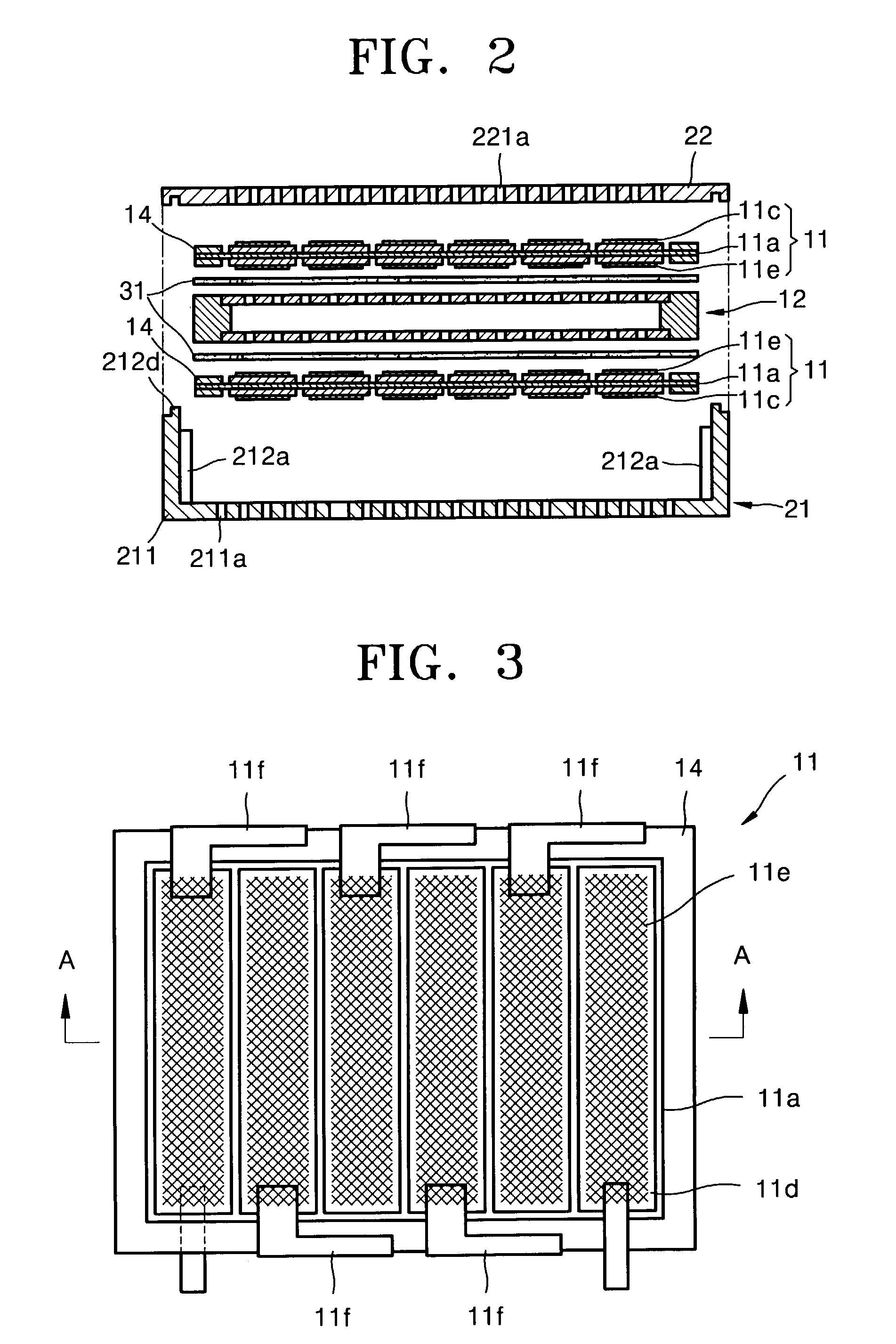

Air breathing direct methanol fuel cell pack

InactiveUS7166381B2Effective exhaustEfficiently exhaustedReactant parameters controlFuel cells groupingBody contactFuel supply

Provided is an air breathing direct methanol fuel cell pack including membrane electrode assemblies (MEAs) forming a plurality of single cells having an electrolyte membrane, a plurality of anodes on a first plane of the electrolyte membrane and a plurality of cathodes on a second plane of the electrolyte membrane correspondingly to the anodes, the second plane being opposed to the first plane, a fuel supply unit storing fuel fed to the anodes and having fuel supply plates with a plurality of fuel supply holes through which the fuel passes, and wicking sheets provided along a fuel supply path between the fuel supply plates and the MEAs, diffusing the fuel supplied through the fuel supply plates to supply the fuel to the anodes of the MEAs. fuel can be evenly supplied throughout MEAs, thereby attaining uniform power output, irrespective of a use posture of a cell pack. Also, current collectors of the present invention are of a mesh type so that current collection from all electrodes is allowed while allowing fuel supply. Further, since a gas communicating path for passage of byproducts is provided around the fuel supply unit and gas exhaust holes are provided on a wall body contacting the gas communicating path, byproducts can be effectively exhausted.

Owner:SAMSUNG SDI CO LTD

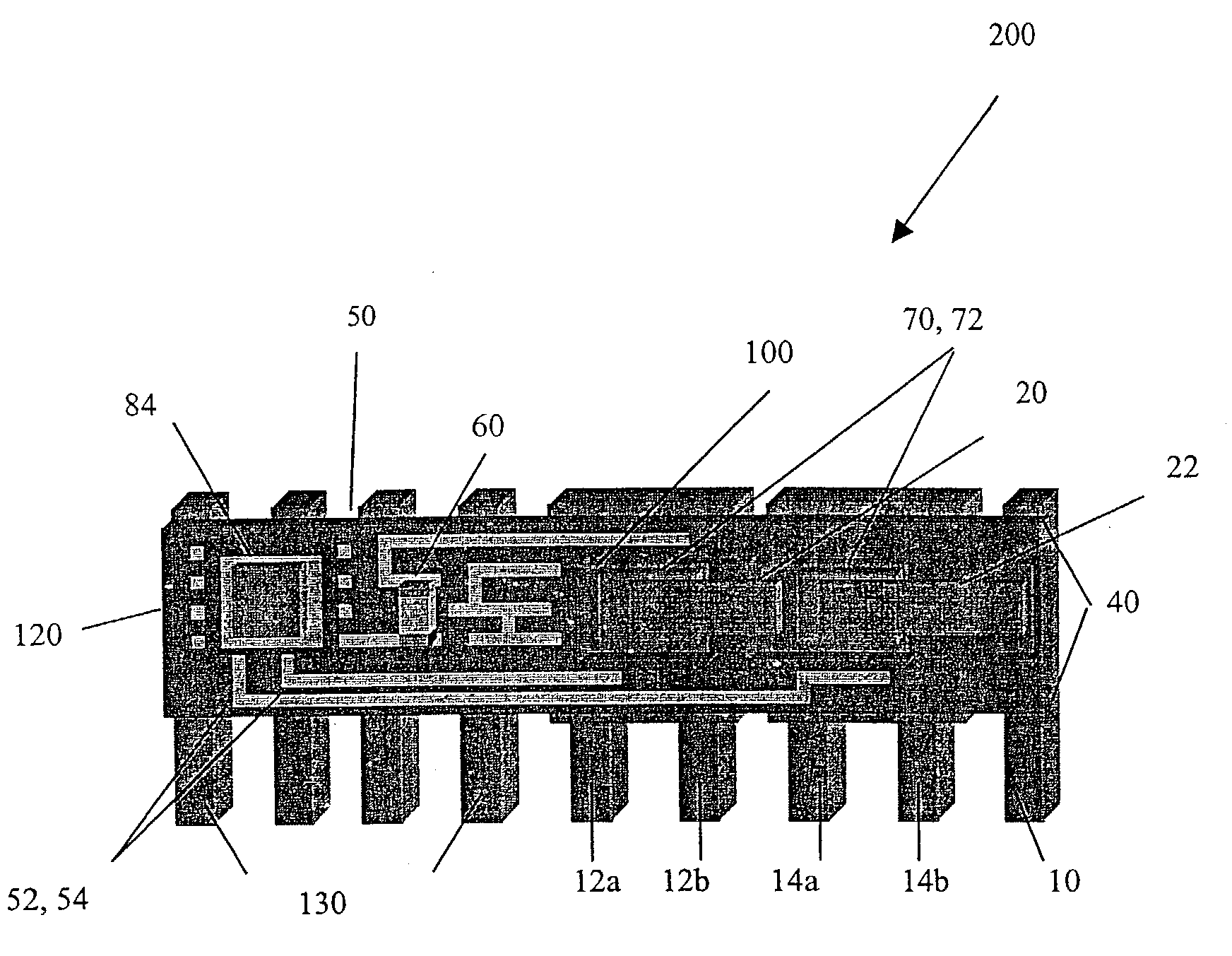

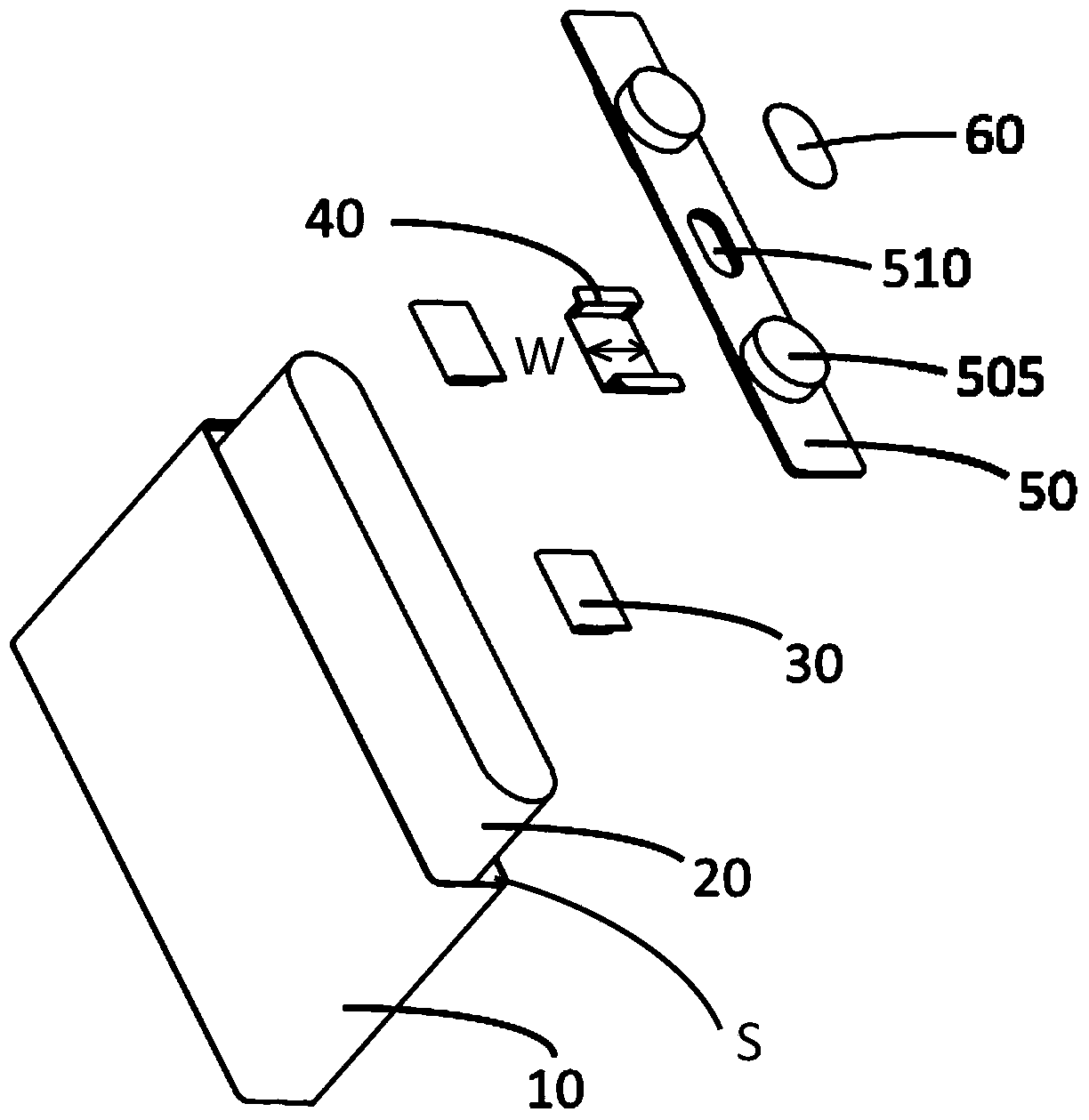

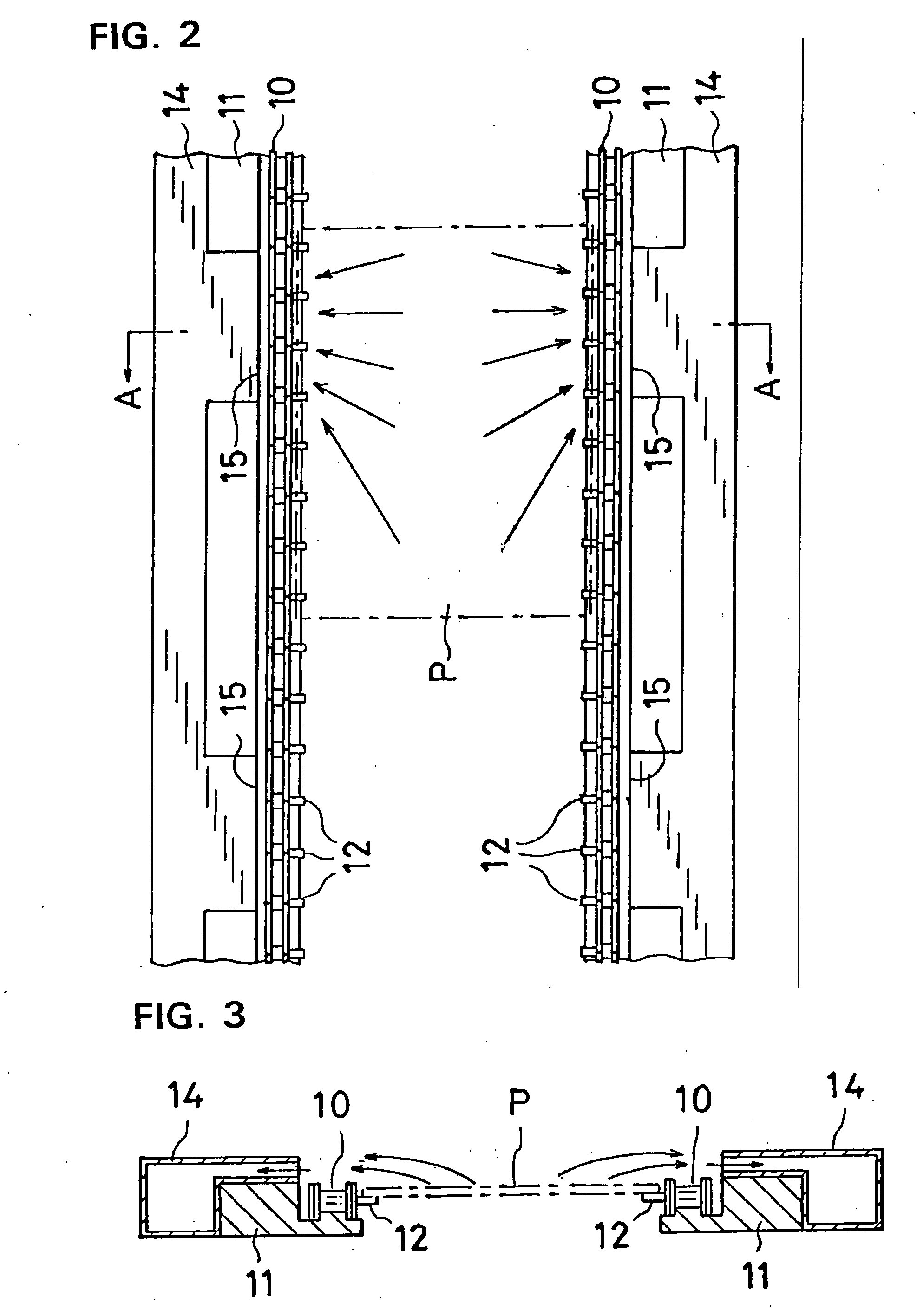

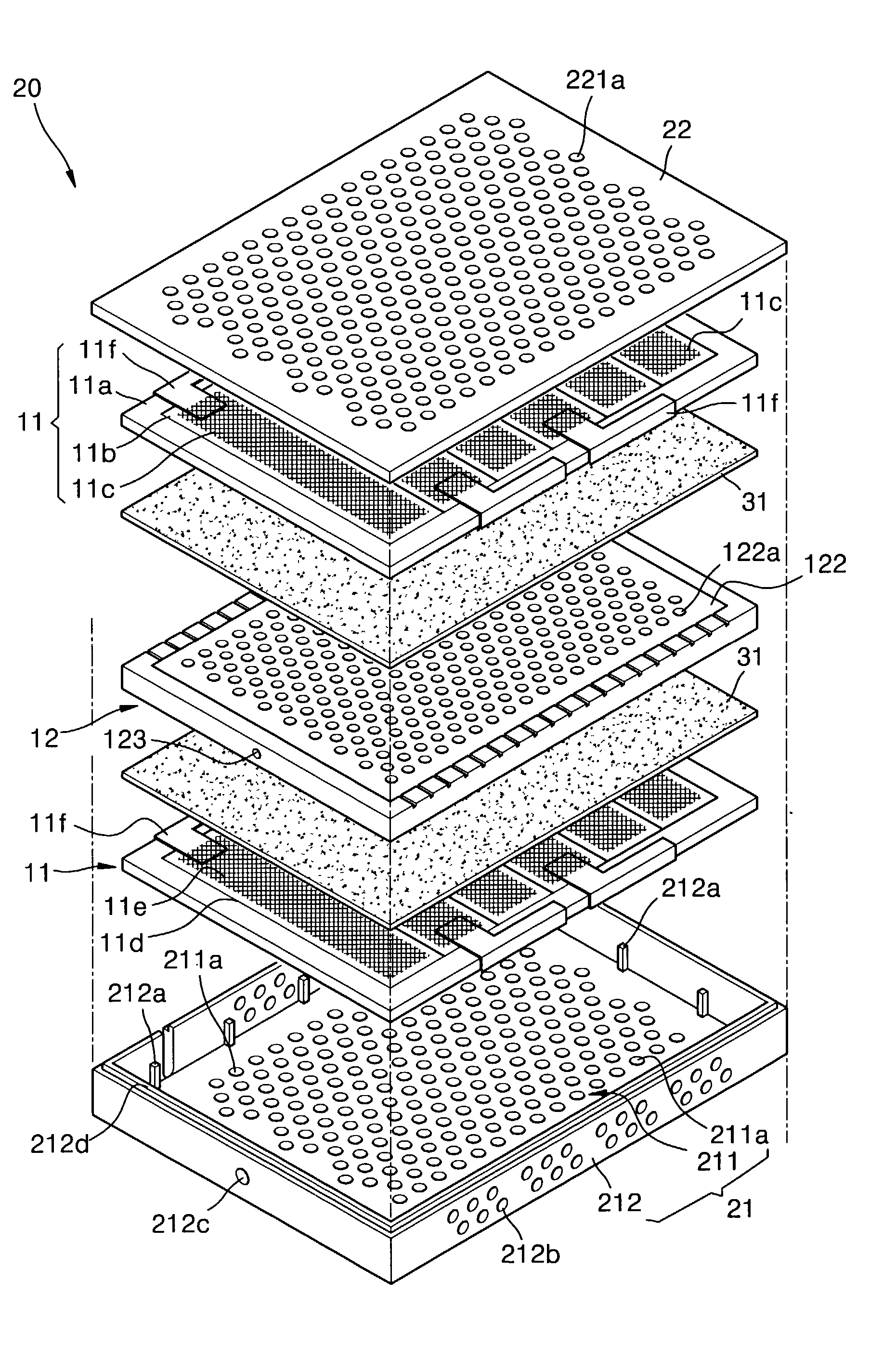

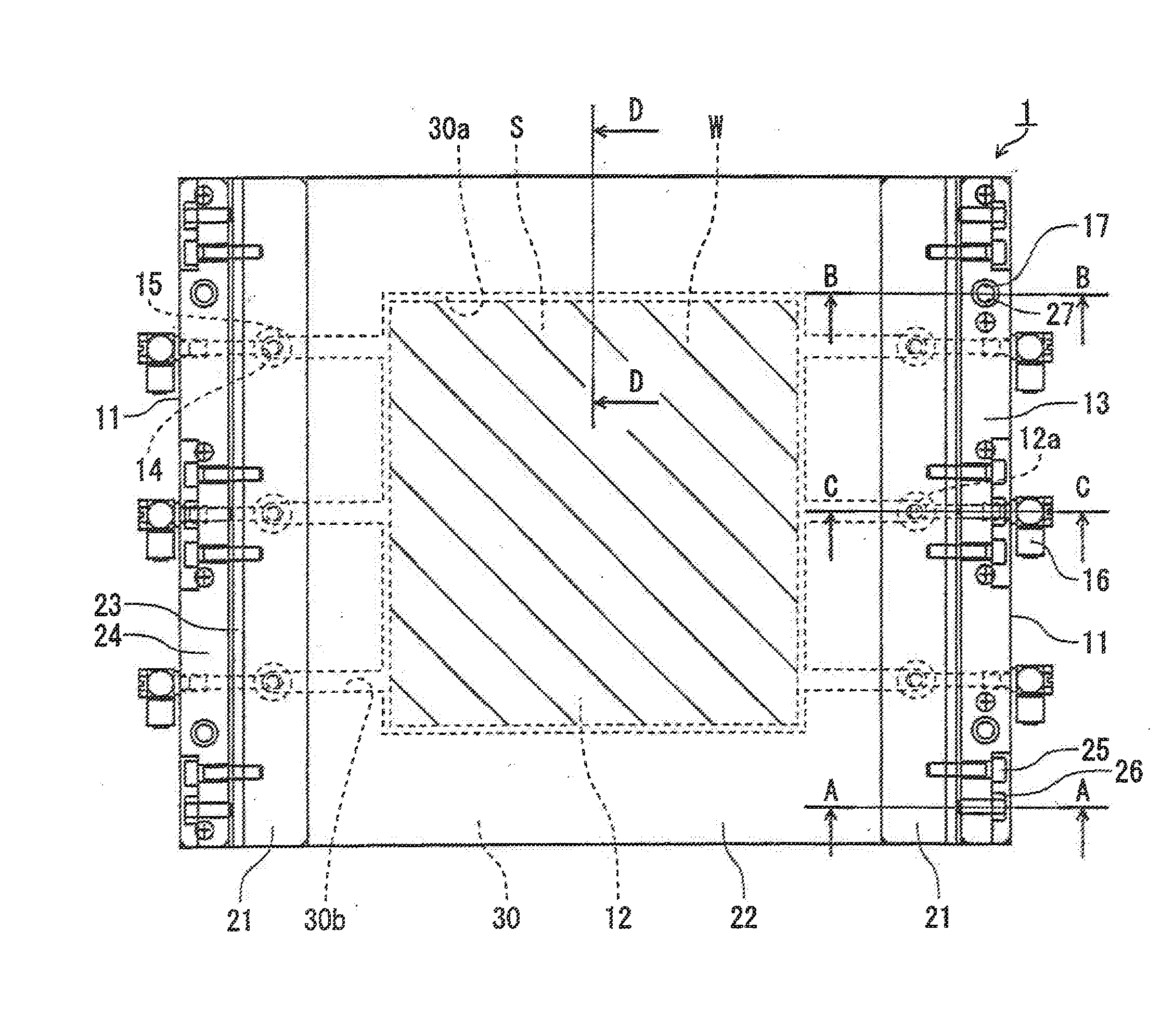

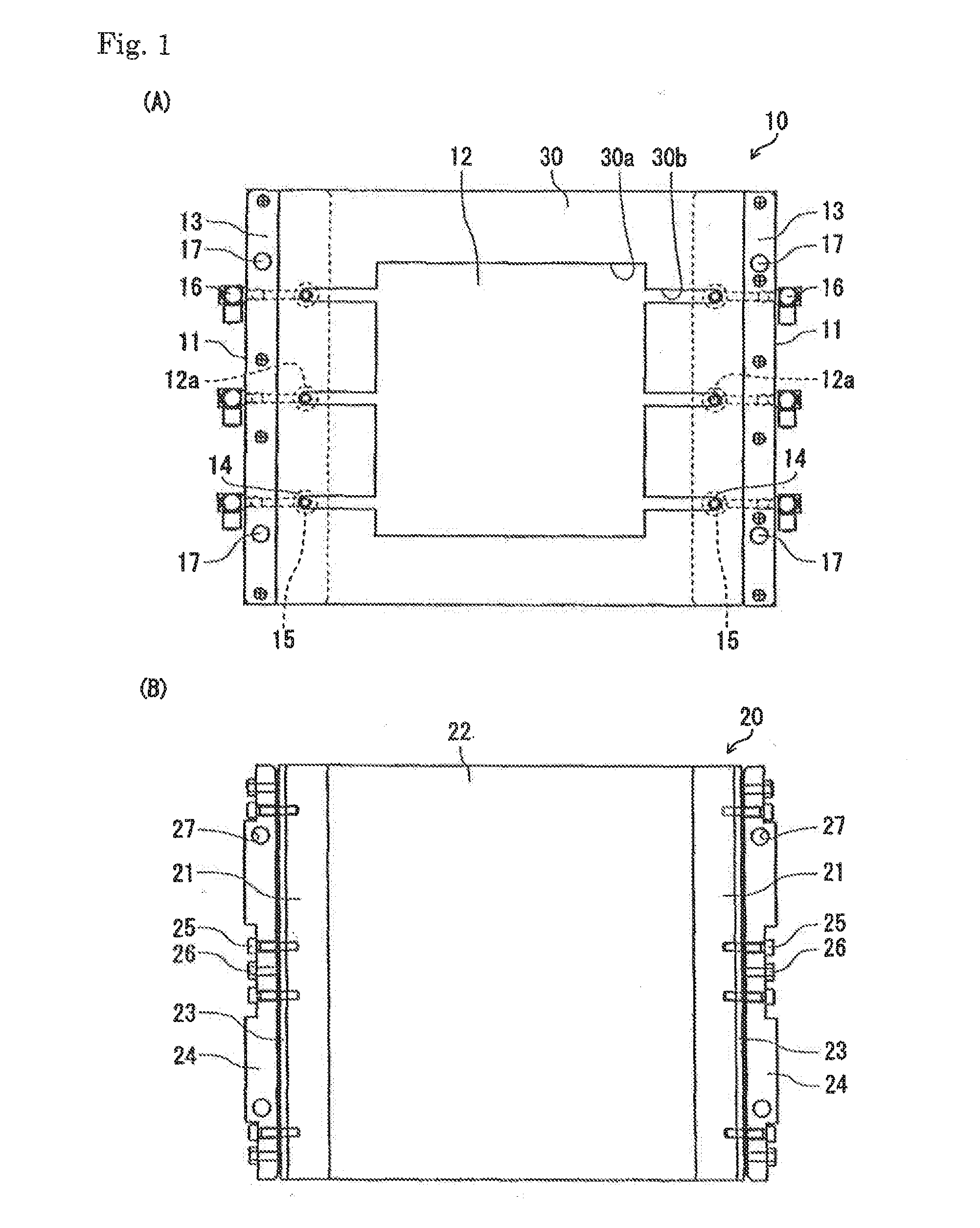

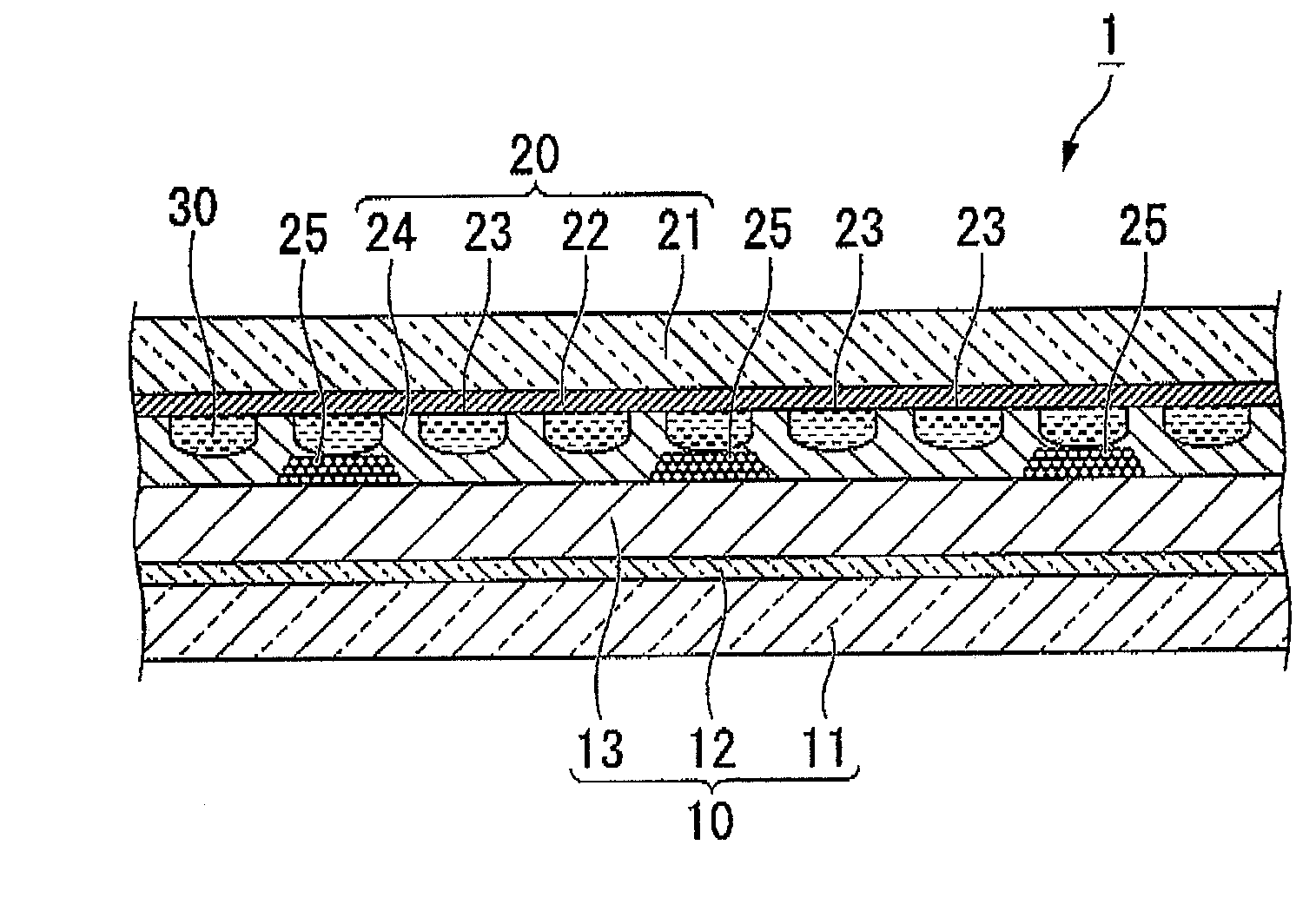

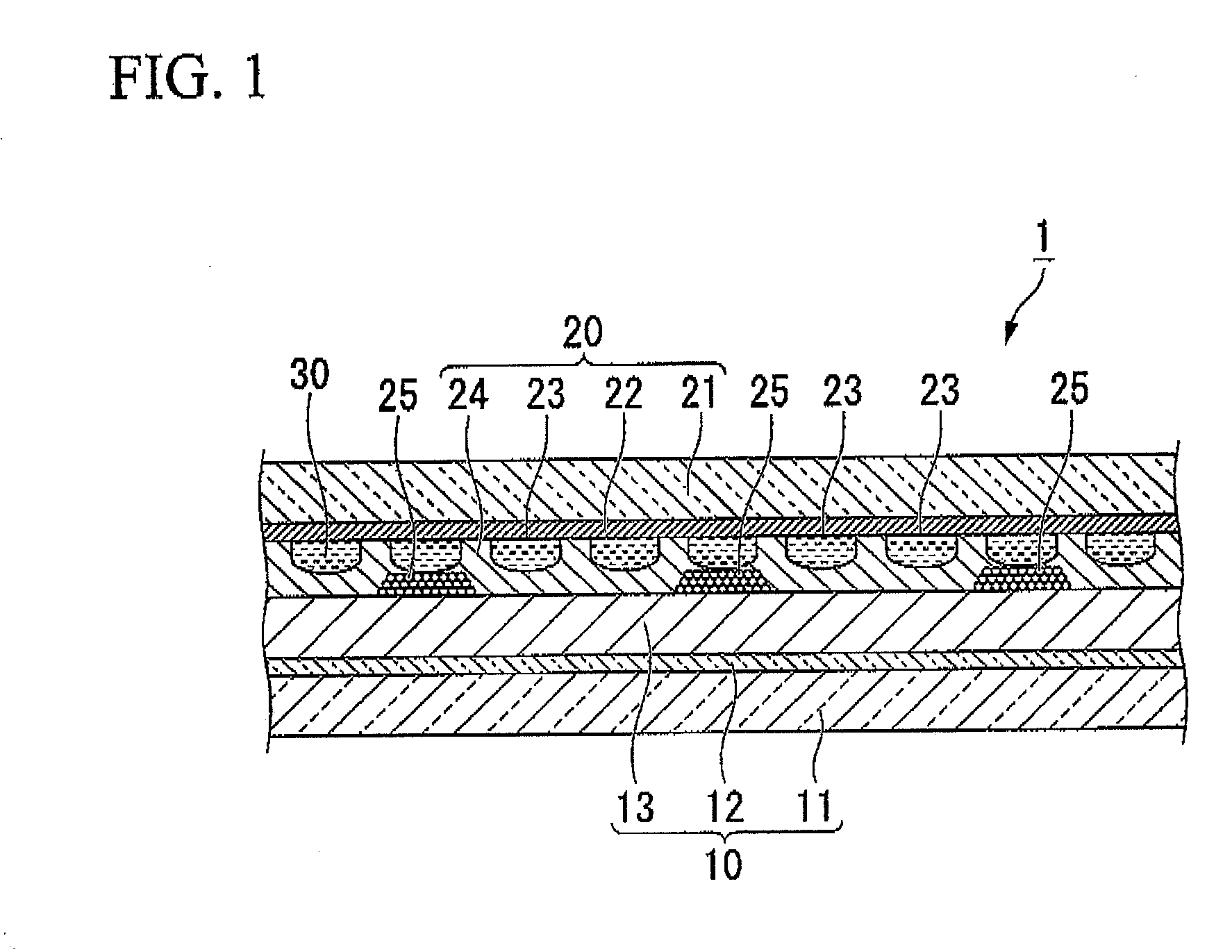

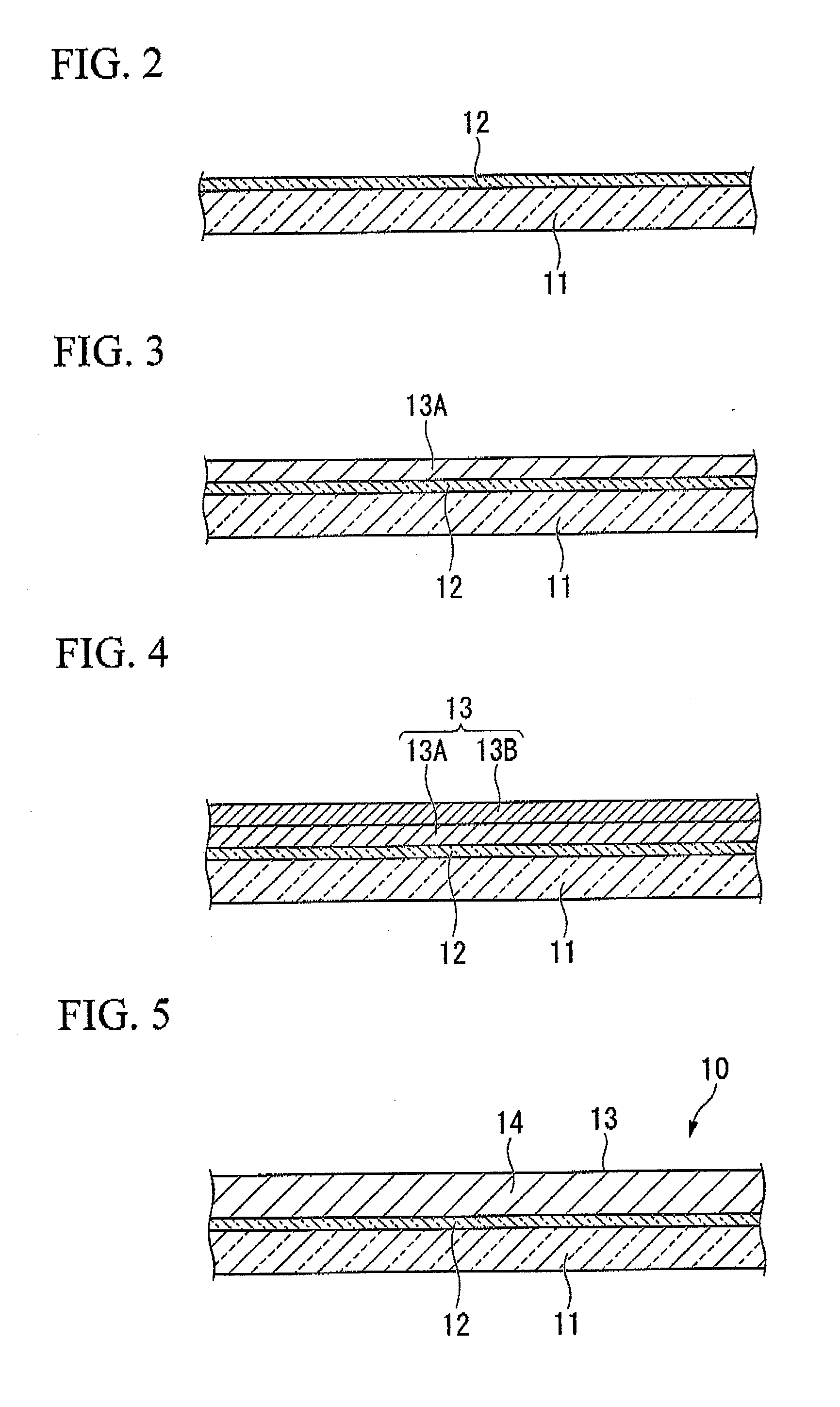

Jig for fixing laminated materials, a system for manufacturing bonded laminated materials, and a method for manufacturing bonded laminated materials

ActiveUS20130306237A1Large widthAvoid fatigueLamination ancillary operationsLayered product treatmentEngineeringMaterial storage

A jig for fixing laminated materials, a system for manufacturing bonded laminated materials, and a method of manufacturing bonded laminated materials are provided at a good yield factor and to efficiently manufacture the bonded laminated materials that are pressed and bonded after being laminated without a misalignment of the membranes or deformation of the laminated materials or any deficiency in bonding at the interface. The bonded laminated materials are manufactured by storing materials made of laminated membranes (W) in a housing space (S) formed by a first sheet-shaped member (12), a second sheet-shaped member (22), and a sealing member (30), exhausting the housing space (S) to sandwich the laminated membranes (W) between the first and second sheet-shaped members (12, 22) to fix them, and pressing and bonding them by hot-pressing rollers (51) and cold-pressing rollers (52) of a machine (50) for manufacturing the bonded laminated materials while they are fixed.

Owner:SINTOKOGIO LTD

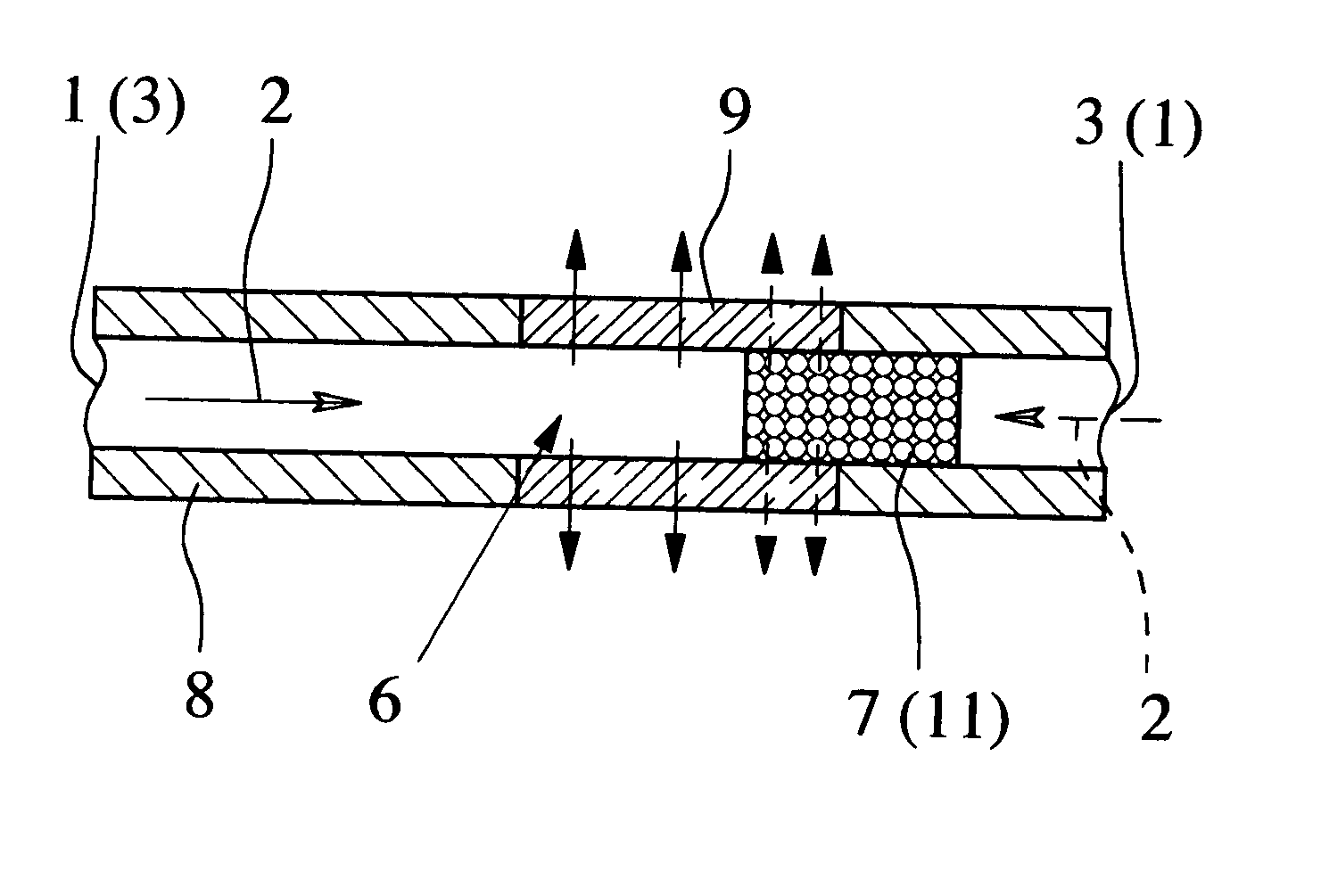

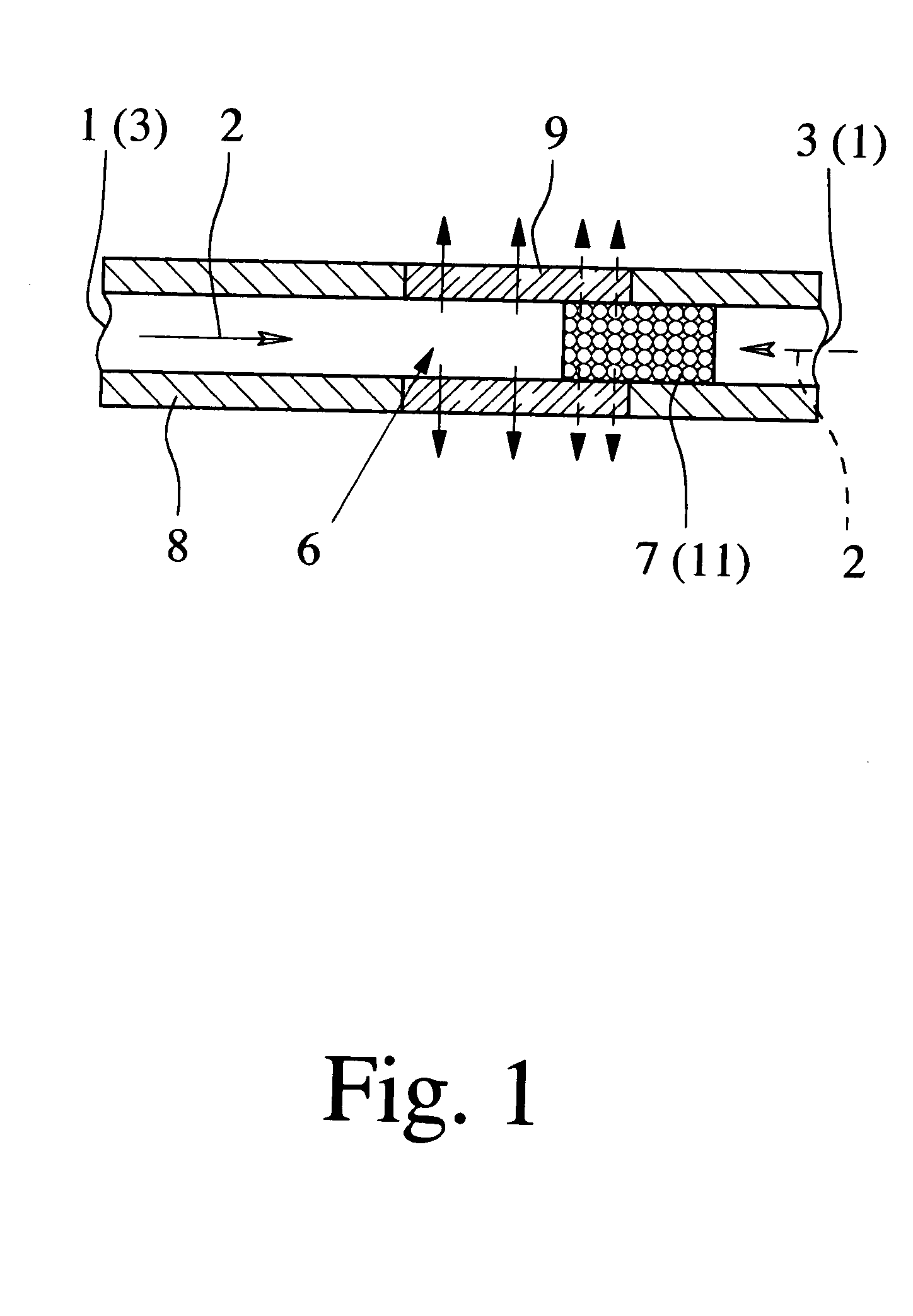

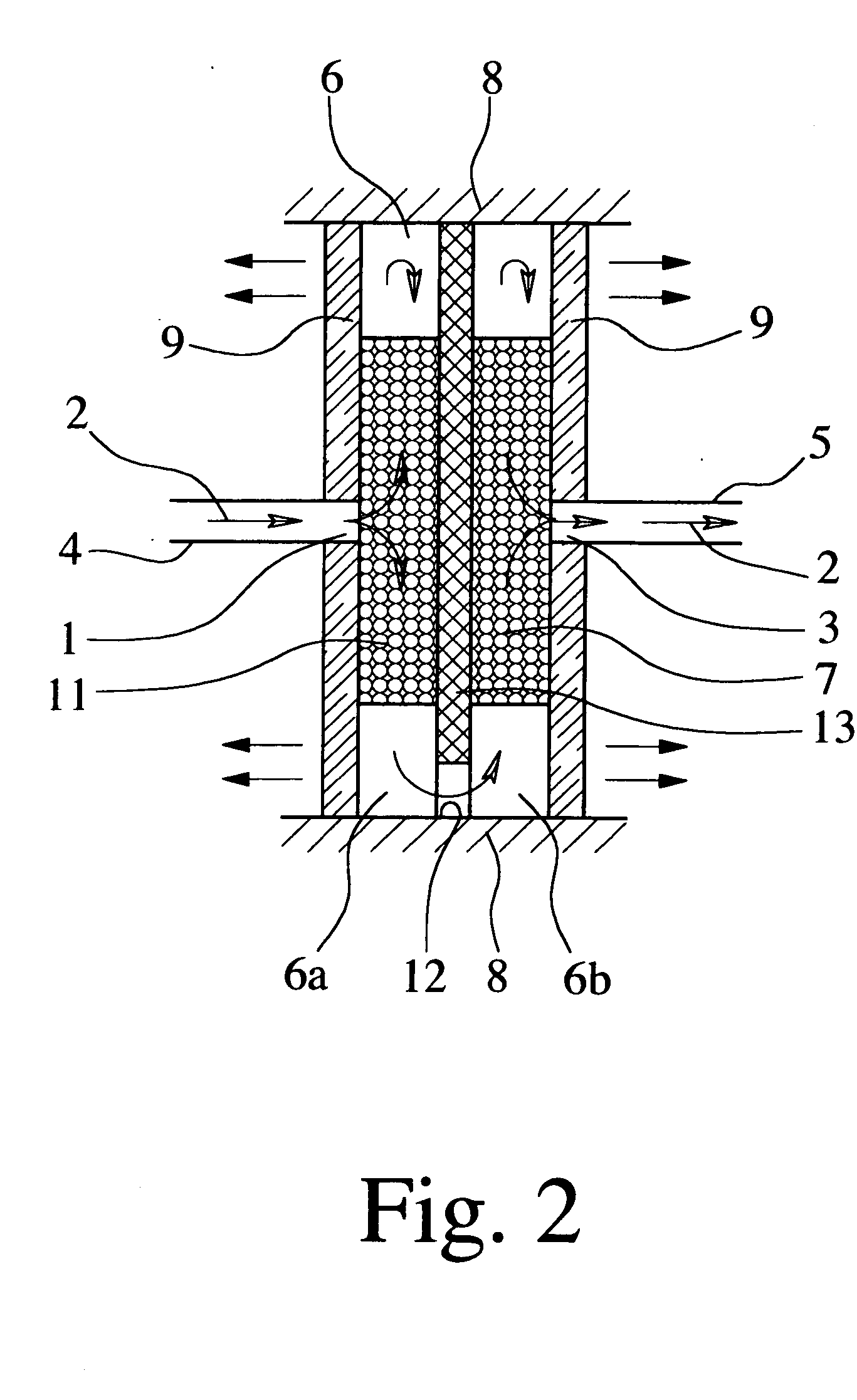

Process and device for separating and exhausting gas bubbles from liquids

ActiveUS7166147B2Simple wayEasy to doSemi-permeable membranesIsotope separationProcess engineeringProduct gas

A process and a device for separating and exhausting gas bubbles from a flowing liquid, especially in a microfluidic system, are proposed. Radial deflection of the liquid, a preferably annular deaeration chamber from which gas can escape through gas separation material, and a following discharge filter are characteristic. The discharge filter is made of a hydrophilic material which forms pores or small channels. Optionally, there is an inlet filter of the corresponding material upstream of the deaeration chamber.

Owner:BOEHRINGER INGELHEIM MICROPARTS

One-way exhaust valve bag

The invention discloses a one-way exhaust valve bag. The valve bag comprises a bag body and a self-sealing feed valve port, wherein, at least one one-way exhaust device is arranged on the bag body, the one-way exhaust device is a gas passage which is formed by closely fitting at least two films together and then sealing two sides, and adjacent surfaces of the two films are at least partially equipped with heat-resisting materials; the device is connected with the interior and exterior of the bag body, and is bonded or welded with the bag body or / and the bag bottom; and the gas passage in the packaging bag is stuck with air-permeable materials such as sponge and the like. In the invention, when the packaging bag is filled or extruded, gas in an accommodation cavity is quickly exhausted from the gas passage through the air-permeable materials under the action of pressure, and the air-permeable materials prevent leakage of packaged materials during the gas exhaust process; and the gas passage part outside the bag is ordinarily remained in a close fit status owing to attraction between the synthetic resin films and atmospheric pressure action so as to prevent entry of air. By utilizing the bag, the conflict that gas exhaust and moisture protection can not be realized at the same time is solved; and the packaging bag has the advantages of simple process and low cost.

Owner:王子颖

Formation method of soft-package lithium ion battery with high specific energy

InactiveCN108183262AStable growthReduce negative impactFinal product manufactureElectrolyte accumulators manufacturePole pieceEngineering

The invention relates to a formation method of a soft-package lithium ion battery with high specific energy. The method comprises the following steps: S1, after the battery is injected / filled with liquid and fully left to stand, charging is performed at a small rate of 0.01-0.05 C for 10-20 h; S2. The charged battery is left to stand for 12-60 h, pumping and sealing are performed under the condition of vacuum degree being minus 0.06 MPa-minus0.09 MPa, and part of an air bag is reserved; S3, the battery is fixed with a clamp and is charged to 4.2-4.7 V at 0.05-0.2 C; S4, pumping and sealing areperformed under the condition of vacuum degree being minus 0.06 MPa-minus 0.09 MPa; S5, discharging is performed to 3.0-1.5 V at 0.05-0.2 C, and small current activation is performed at 0.05-0.2 C for 1-10 weeks in the voltage interval. The method has the beneficial effects that the negative influence brought by gas production of the soft-package battery can be effectively improved, folds of polepieces of the soft-package battery due to gas production and expansion of the pole pieces are reduced, and the safety and electrochemical performance of the battery are improved.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

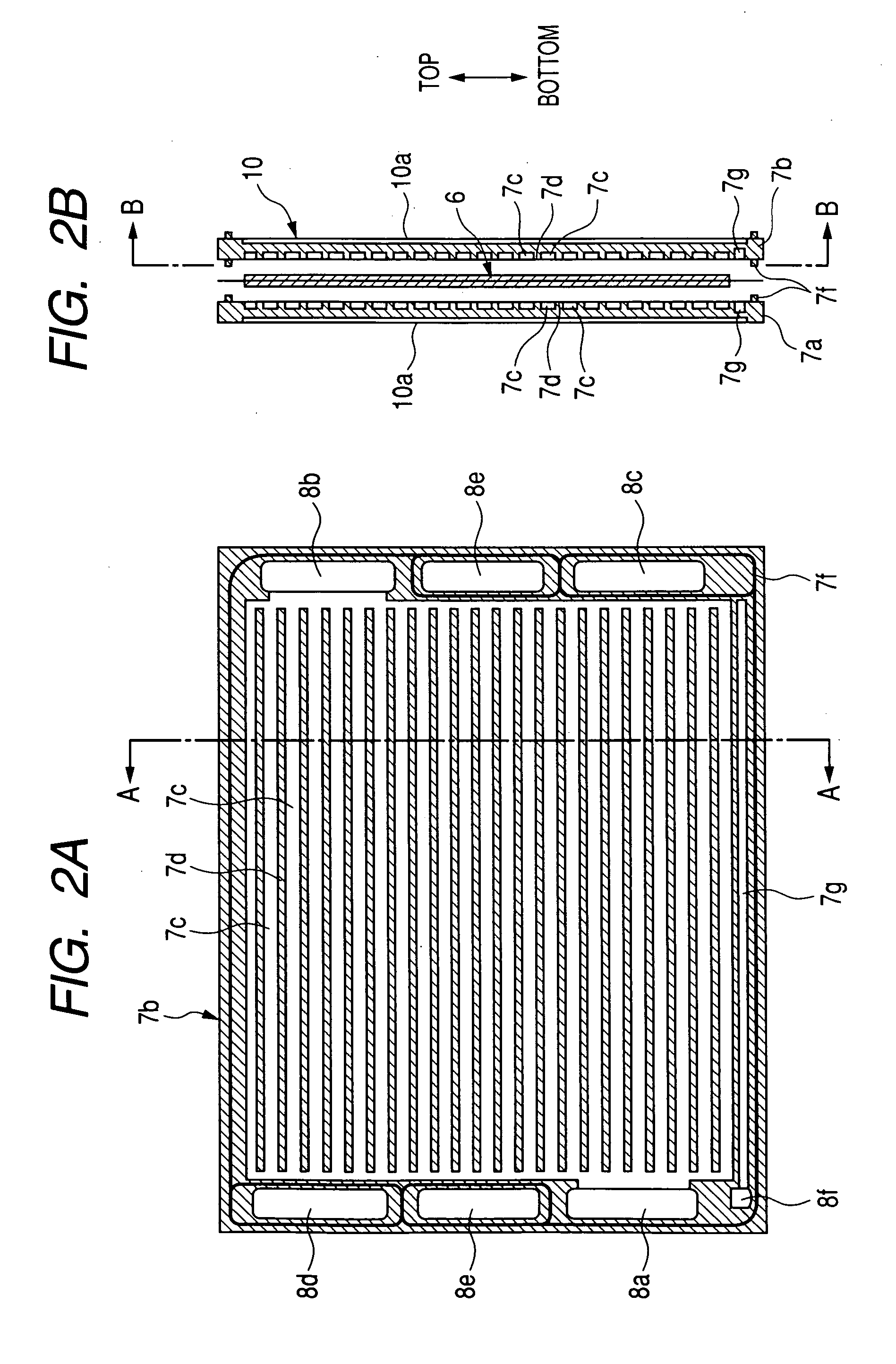

Photoelectric conversion element

ActiveUS20090235982A1Effective exhaustPowerfulElectrolytic capacitorsFinal product manufactureLong term durabilityEngineering

A photoelectric conversion element includes: a first electrode having a porous oxide semiconductor layer which supports a sensitizing dye on a surface thereof and functioning as a photo electrode; a second electrode disposed so as to oppose the first electrode; an electrolyte disposed in at least a part of a space between the first electrode and the second electrode; and a sump portion for the electrolyte disposed in at least a part of the space between the first electrode and the second electrode. According to the present invention, air bubbles can be exhausted effectively from power generating area, so that a photoelectric conversion element possessing an improved power generation property and a long-term durability can be provided.

Owner:THE FUJIKURA CABLE WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com