Hydrogen gas generator

a hydrogen gas and generator technology, applied in the field of self-regulating hydrogen gas generators, can solve the problems of increasing energy consumption, accelerating global warming and the destruction of the environment, and environmental pollution, so as to increase the utility of hydrogen gas and prevent environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

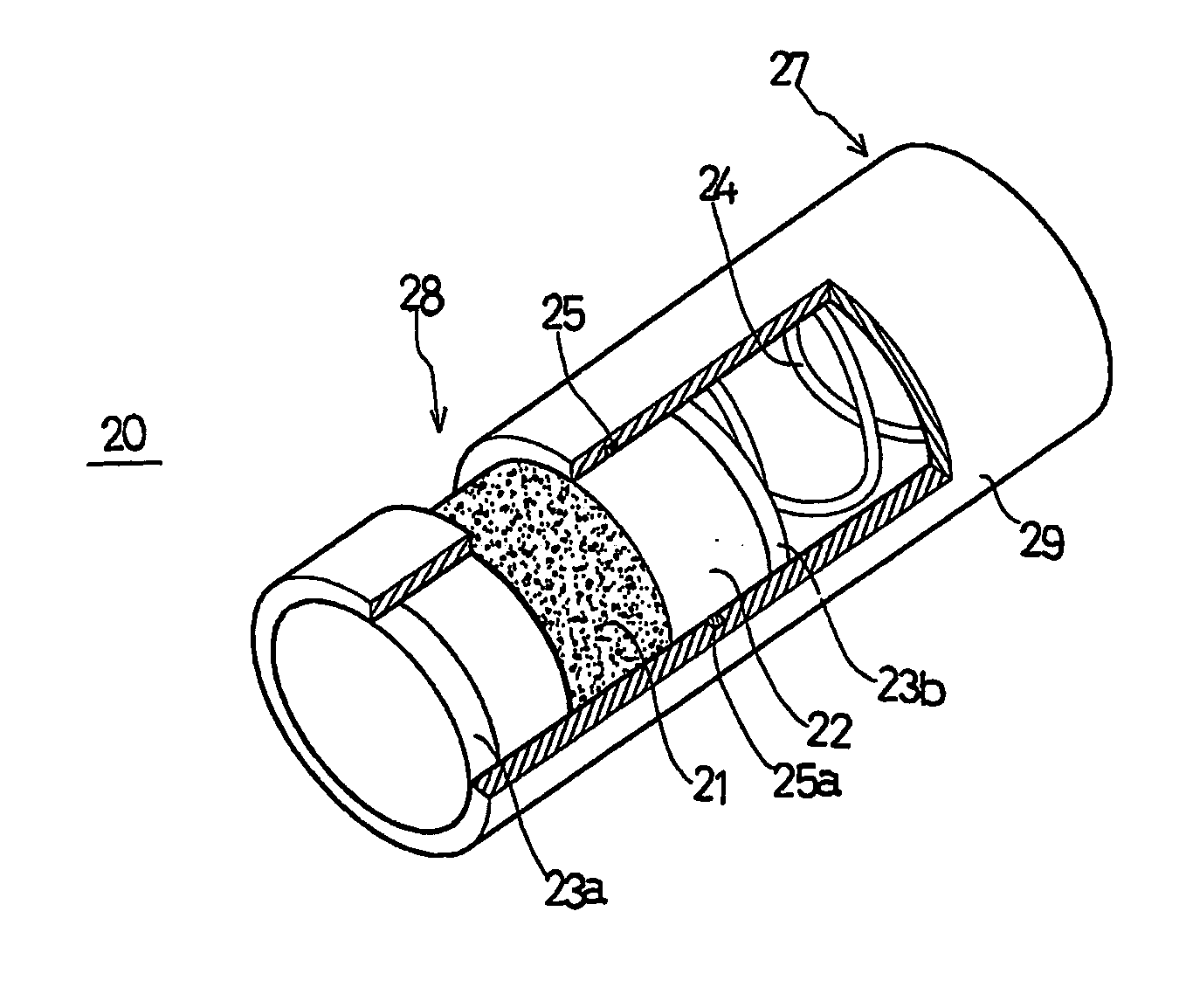

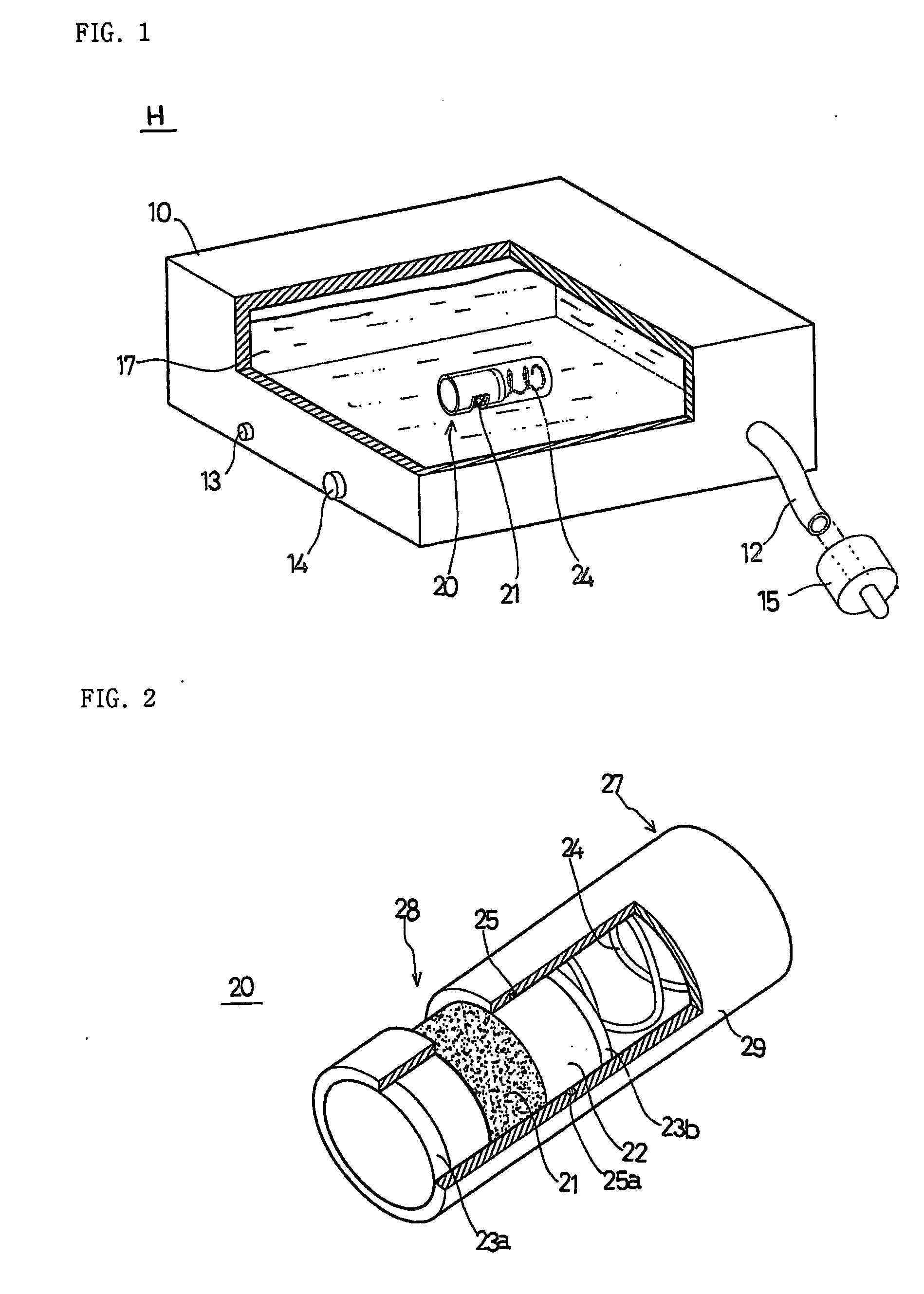

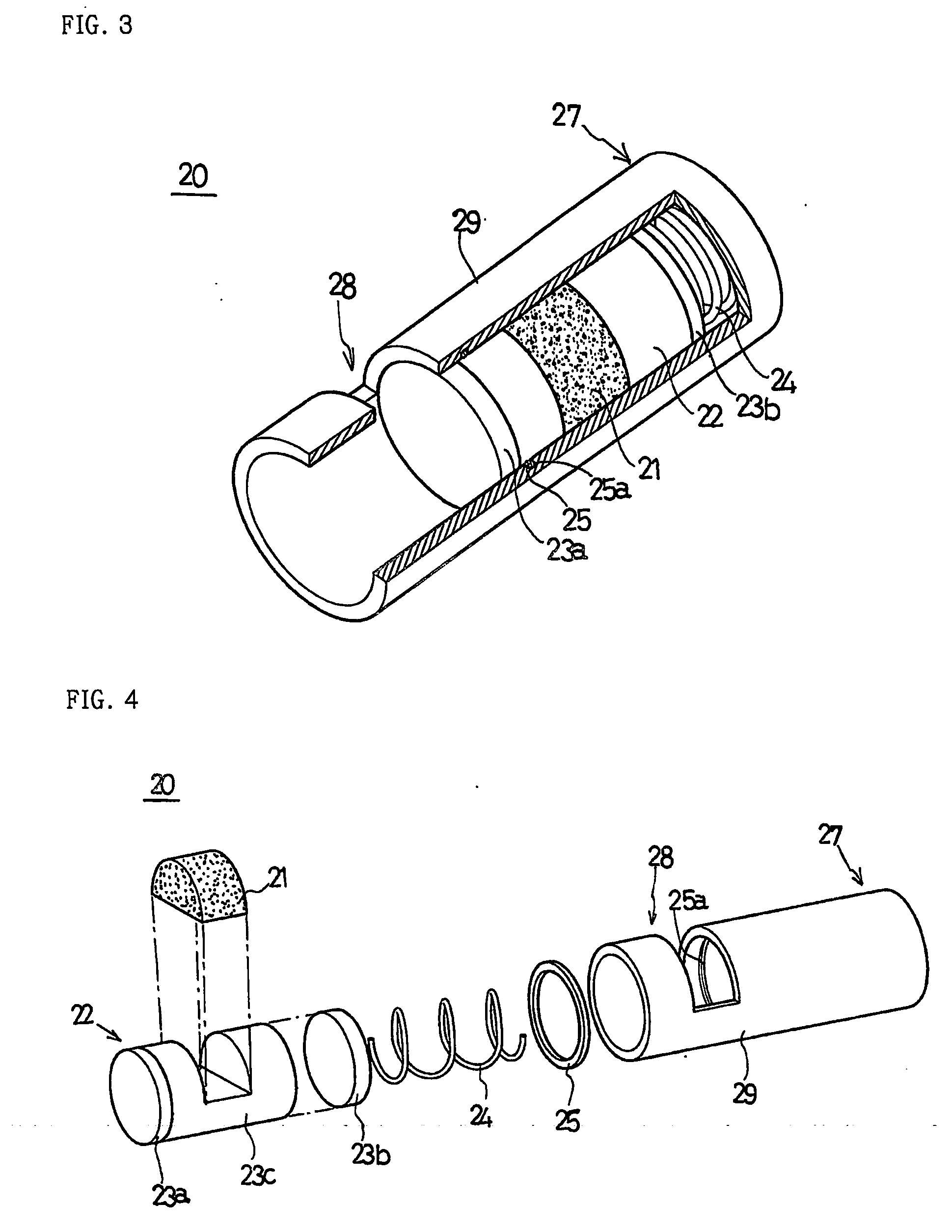

[0032] More specifically, the hydrogen gas generator (H) of the present invention comprises a fuel tank 10 having a designated size for maintaining a hermetically sealed space, a hydrogen storing material fuel solution 17 contained in the fuel tank 10, and a catalyst 21 contacting the hydrogen storing material fuel solution 17 for generating hydrogen gas. The catalyst 21 fills a catalyst reactor 20 having a designated shape. FIG. 1 is a perspective view of the hydrogen gas generator, in which the fuel tank 10 is partially exploded in accordance with the present invention.

[0033] As shown in FIG. 1, the fuel tank 10 has the designated size for containing the fuel solution having a certain volume, and the size and shape of the fuel tank 10 vary according to the purpose and kind of the fuel tank 10. An outlet 12 for discharging hydrogen generated in the fuel tank 10 is formed in one side surface of the fuel tank 10, and a valve, such as a quick connector 15, is installed on the outlet 1...

second embodiment

[0065] More specifically, in the second embodiment shown in FIGS. 23 and 24, a stopper 60a is protruded from one end of the catalytic reactor 20, and a stopper-fixture 60b for fixing the stopper 60a is formed in the front end of the inside of the installation groove 60. A through hole 62 communicating with the inside of the fuel tank 10 is formed at a designated position of the inner circumference of the installation groove 60, the elastic means 24 is positioned on the bottom of the installation groove 60 inside the through hole 62, a through hole sealing member 26 for sealing the through hole 62 is combined with the elastic means 24, a hydrogen generation regulating hole 64 communicating with the inside of the fuel tank 10 for introducing a fluid of the fuel tank 10 is formed through the bottom of the installation groove 60, and the gas-liquid separating film 42 is installed in front of the hydrogen generation regulating hole 64 in the fuel tank 10.

[0066] As shown in FIG. 23, befor...

third embodiment

[0068] In the third embodiment shown in FIGS. 25 and 26, a catalyst exposure regulating portion 66 having a sealed space is extended from the end of the above-described catalytic reactor 20, i.e., the outer surface of the catalyst-fixing member 22. A hydrogen generation regulating hole 64′, which coincides with the hydrogen generation regulating hole 64 when the catalytic reactor 20 is inserted into the installation groove 60 and regulates the generation of hydrogen gas by moving the catalyst-fixing member 22 based on the increase and decrease of the inner pressure of the fuel tank 10, is formed through a designated position of the catalyst exposure regulating portion 66.

[0069] The hydrogen gas generator (H) of the third embodiment is the same as the hydrogen gas generator (H) of the second embodiment in that the generation of the hydrogen gas and the interruption of the hydrogen gas are achieved by the increase and decrease of the inner pressure of the fuel tank 10. However, in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com