Automatic discharging, dough-pressing and shaping machine

A technology of automatic feeding and shaping machine, applied in the direction of dough sheeter/roller/rolling pin, dough forming and slitting combination, etc. The effect of the shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

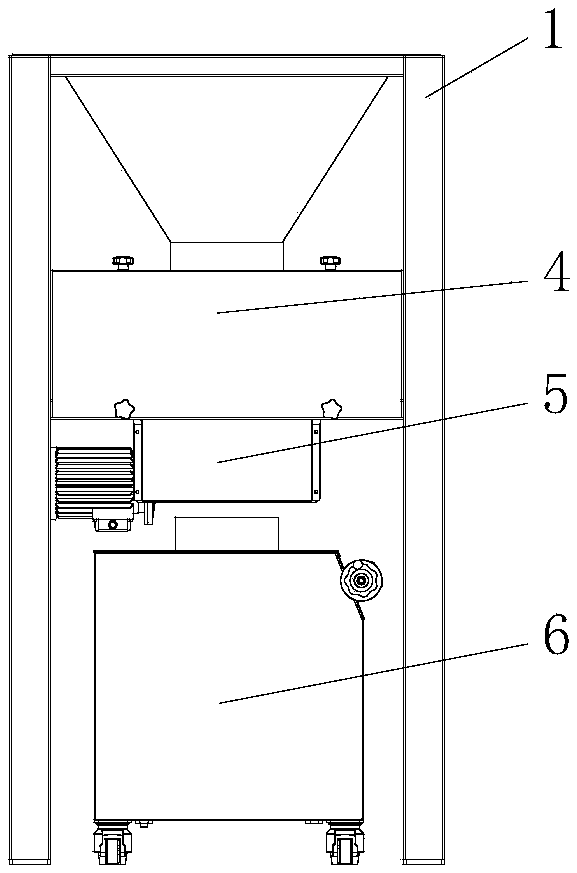

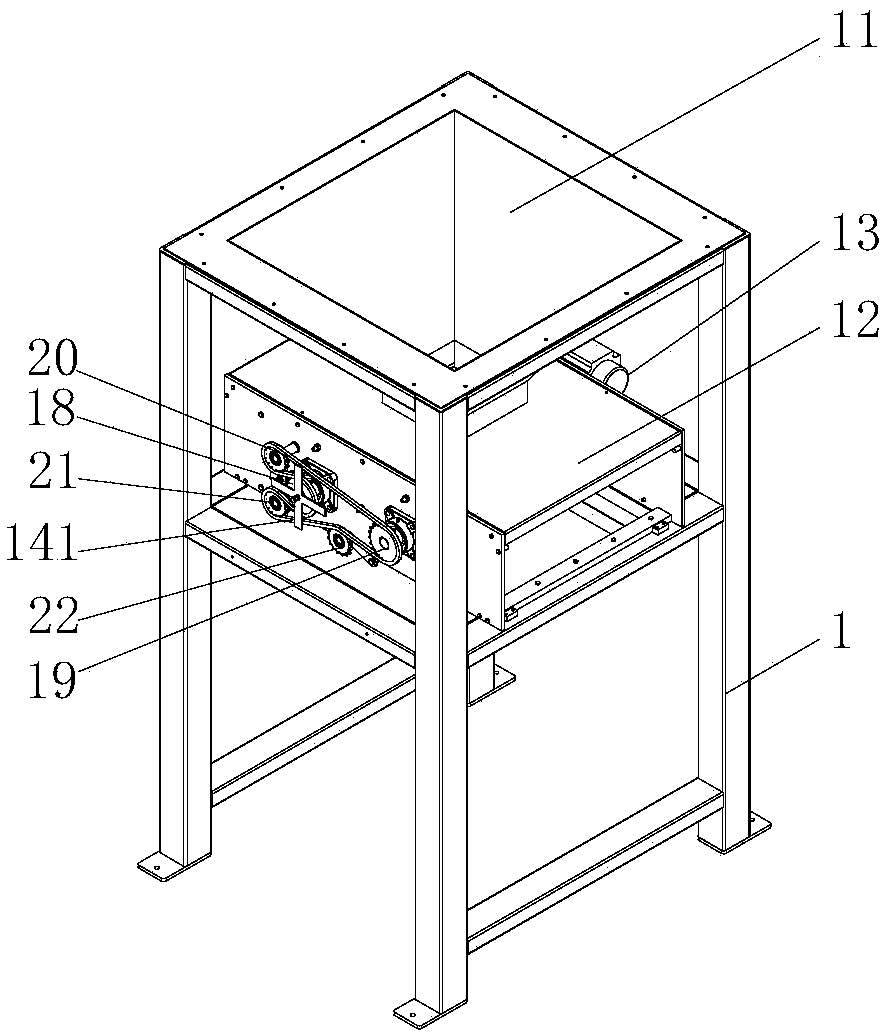

[0033] Such as Figure 1-8 As shown in one, the present invention discloses an automatic blanking and pressing noodle shaping machine, which includes a blanking mechanism 4, a tablet pressing mechanism 5 and a shaping mechanism 6 arranged sequentially from top to bottom,

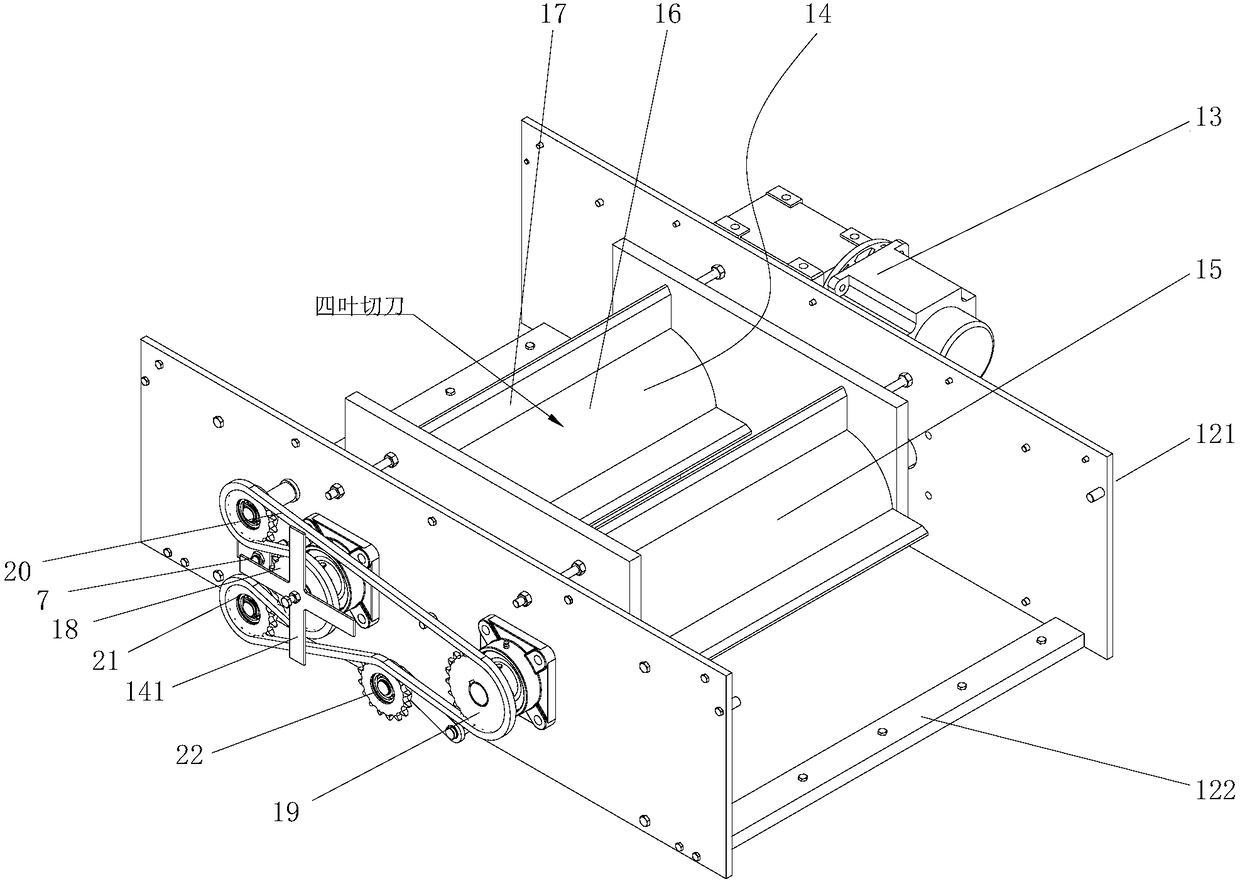

[0034] Such as Figure 2-4 As shown in one, the unloading mechanism 4 includes a support 1 and a lower hopper 11 and a rolling cutting mechanism that are successively arranged on the support 1 from top to bottom, the lower hopper 11 is installed on the top of the support 1, and the rolling cutting mechanism includes a fixed frame 12 and Transmission motor 13, fixed mount 12 is provided with driving drum cutter 14 and driven drum cutter 15, and one end of driving drum cutter 14 is located on the output shaft of transmission motor 13, and driving drum cutter 14 cuts with driven drum. The knife 15 is driven by the transmission and rotates synchronously. A blanking gap is reserved between the driving roller cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com