Atomization air cap

A technology of atomizing air and atomizing holes, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of unstable spraying effect and poor atomization effect, and achieve the effect of improving atomization effect and spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

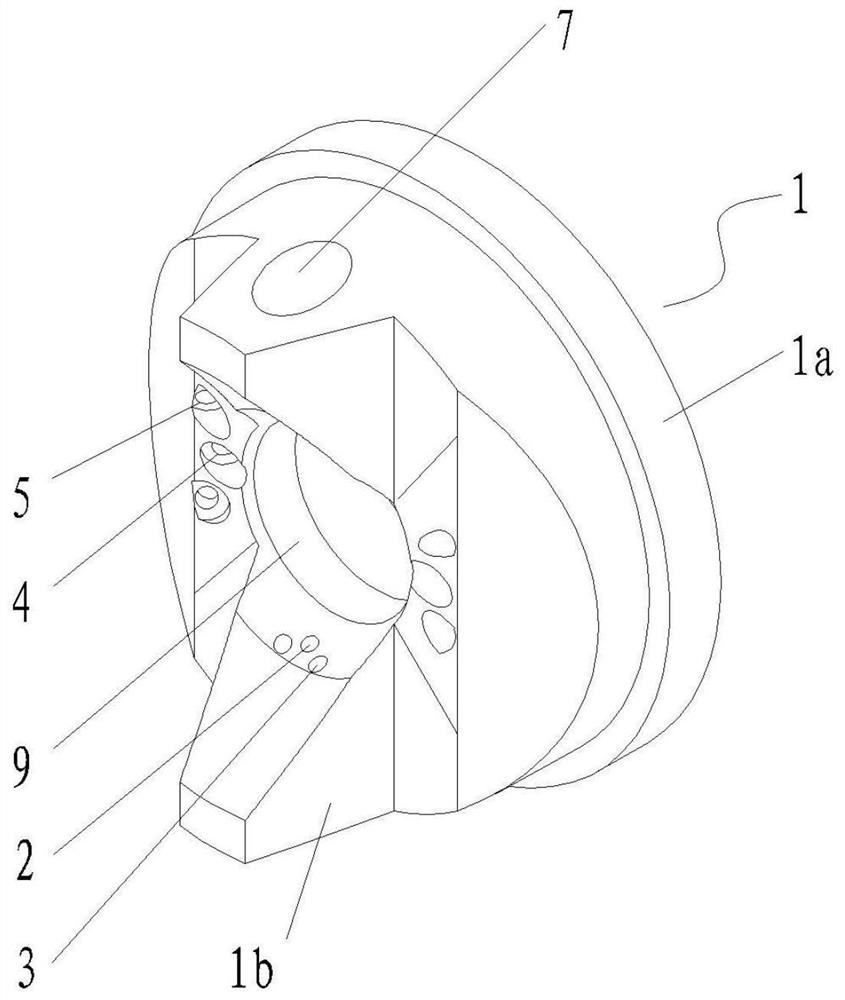

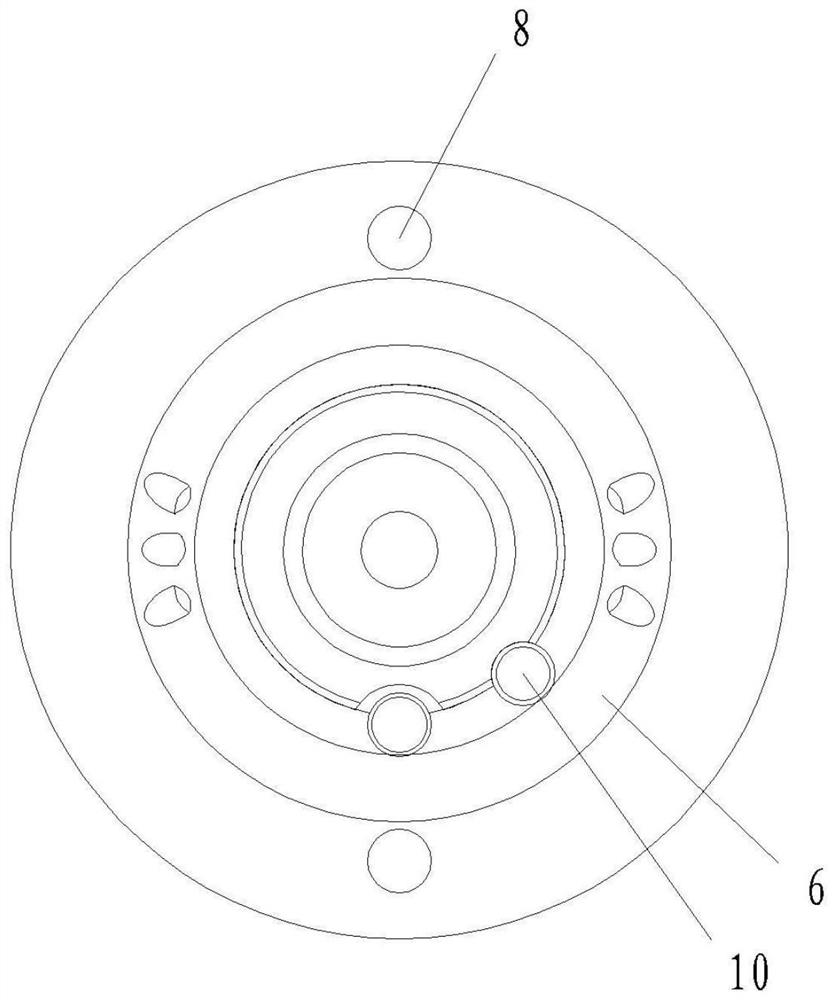

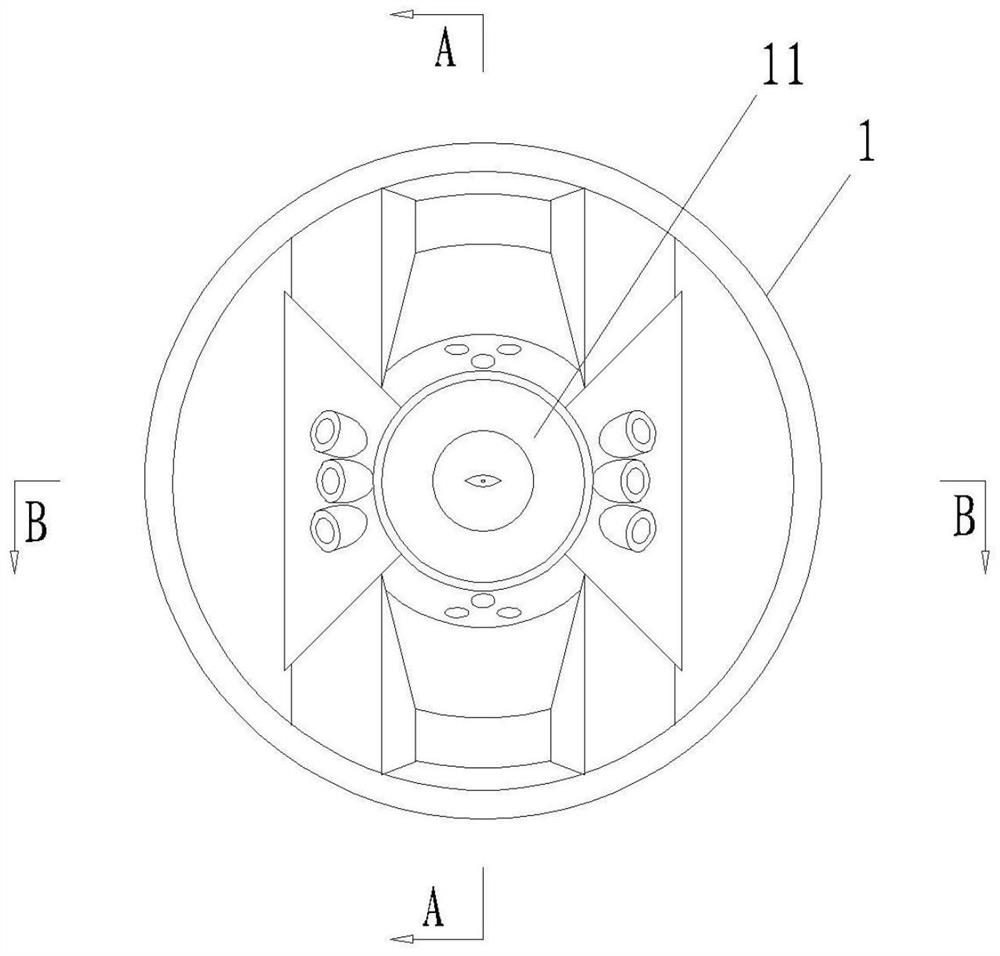

[0025] As shown in the figure, this embodiment provides an atomizing air cap, which includes a cap body 1, and the cap body is provided with an installation cavity 9 for installing a nozzle 11, and an atomization hole is opened on the cap body, so The above-mentioned atomizing hole is used to guide the high-pressure gas to spray out and intersect with the spraying direction of the nozzle to form secondary atomization. combine figure 1 As shown, the cap body has a circular structure, and there is a circular installation cavity in the middle of the cap body. The nozzle 11 is installed in the installation cavity. The nozzle head is in a spherical structure. Hole 11a, the spray hole is a strip-shaped hole elongated along the left and right directions, and the inner cavity of the spray hole is a tapered cavity that shrinks from the back to the front. The nozzle is used to connect with the feeding equipment and make the liquid paint pass through the spray hole. High and atomized sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com