Processing equipment for sheath-free wires

A wire processing and sheathing technology, applied in the direction of circuits, insulated cables, electrical components, etc., can solve the problems of no processing equipment, etc., and achieve the effects of remarkable fire resistance, enhanced compression resistance, and enhanced wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

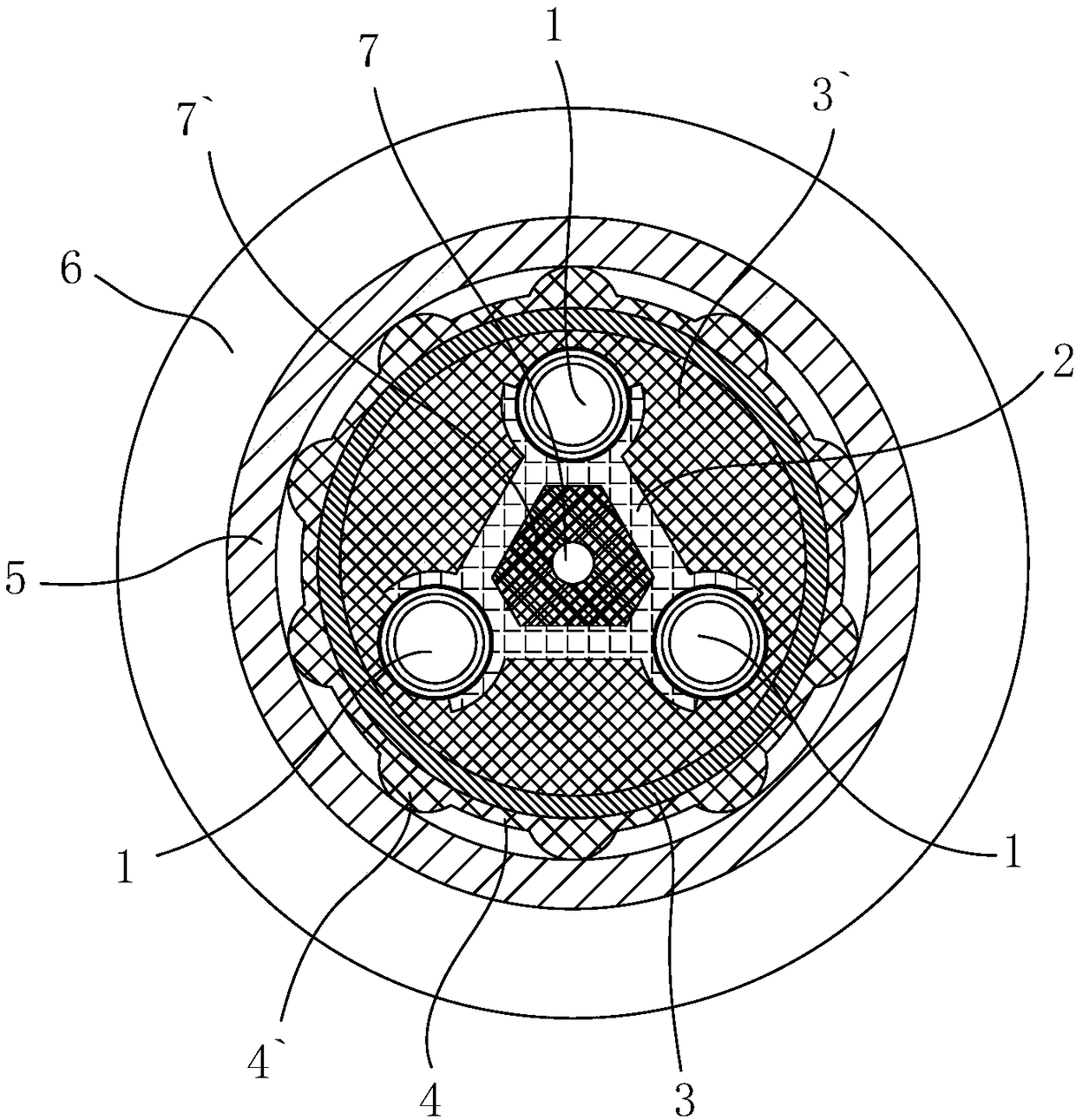

[0018] combine Figure 1-8 , the present invention is further described:

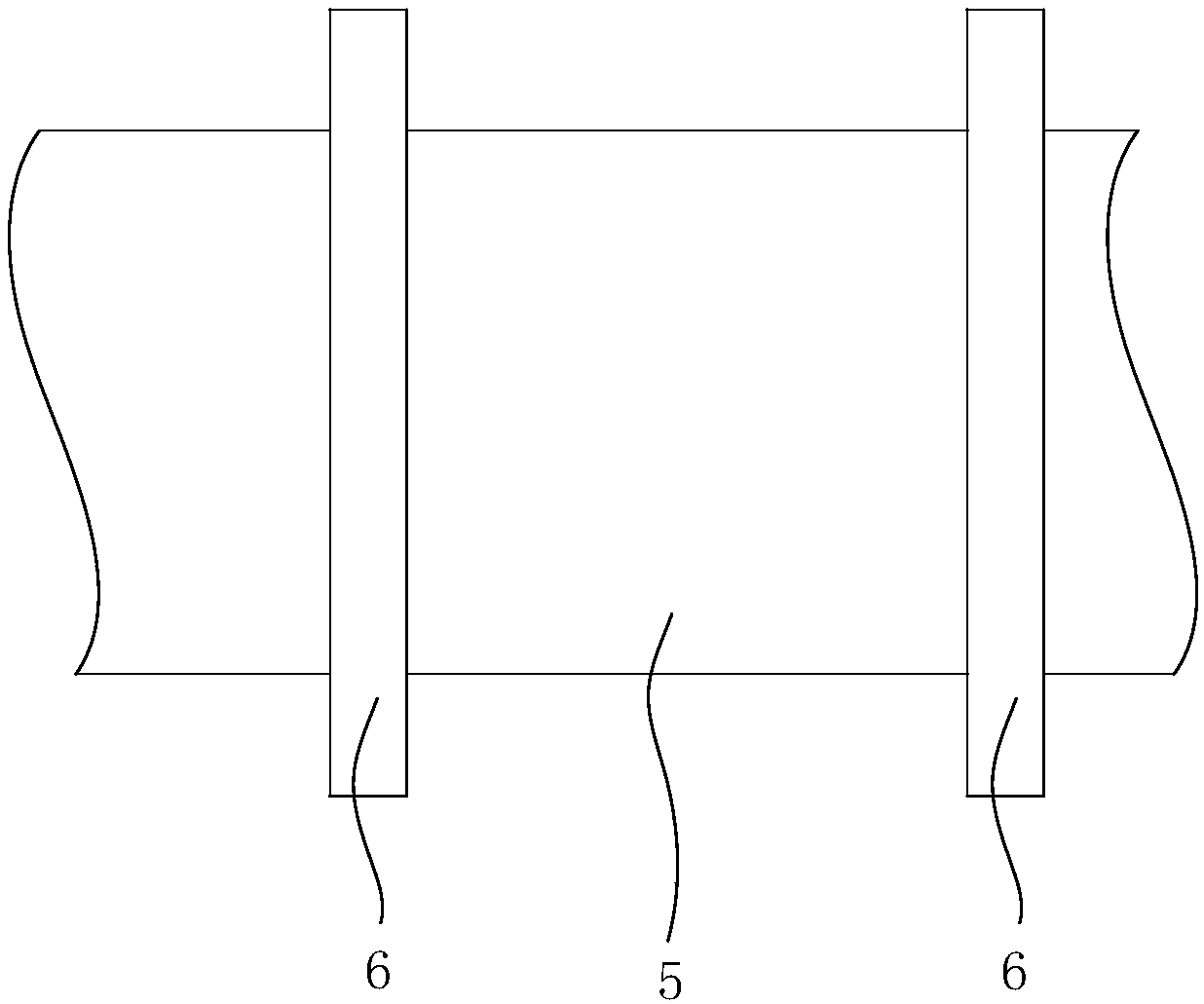

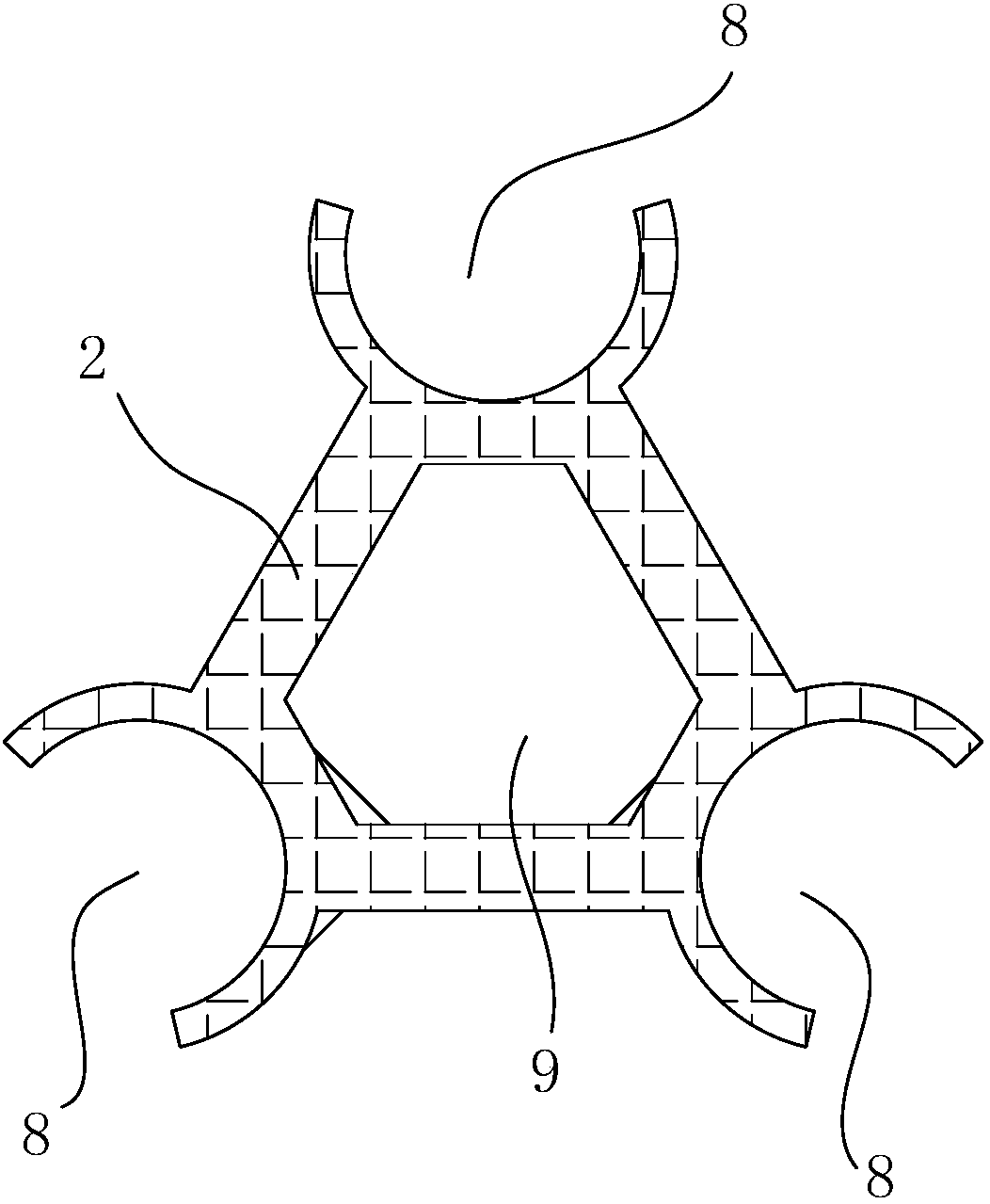

[0019] combine figure 1 - 4. Compression-resistant, wear-resistant and high-temperature-resistant unsheathed wires, including three wire cores 1, the three wire cores 1 are respectively arranged on the bracket 2, the central connection line of the three wire cores 1 is triangular, and the bracket 2 is provided with a rigid support sleeve 3, and the rigid support sleeve 3 is provided with a buffer sleeve 4, and the buffer sleeve 4 is provided with a fire-resistant sleeve 5, and the fire-resistant sleeve 5 is provided with a wear-resistant ring 6. A plurality of grinding rings 6 are arranged at intervals along the length direction of the electric wires, and a cooling medium pipe 7 is arranged at the center of the support 2 .

[0020] combine figure 1 and figure 2 As shown, the above-mentioned three wire cores 1 are arranged on the bracket 2, and a rigid support sleeve 3 is provided outside the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com