Tea leaf packing process

A packaging process, tea technology, applied in the direction of packaging, packaging by pressurization/gasification, etc., can solve the problems of the influence of tea freshness, many packaging processes, poor packaging effect, etc., to achieve better packaging effect, simple process, freshness preservation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

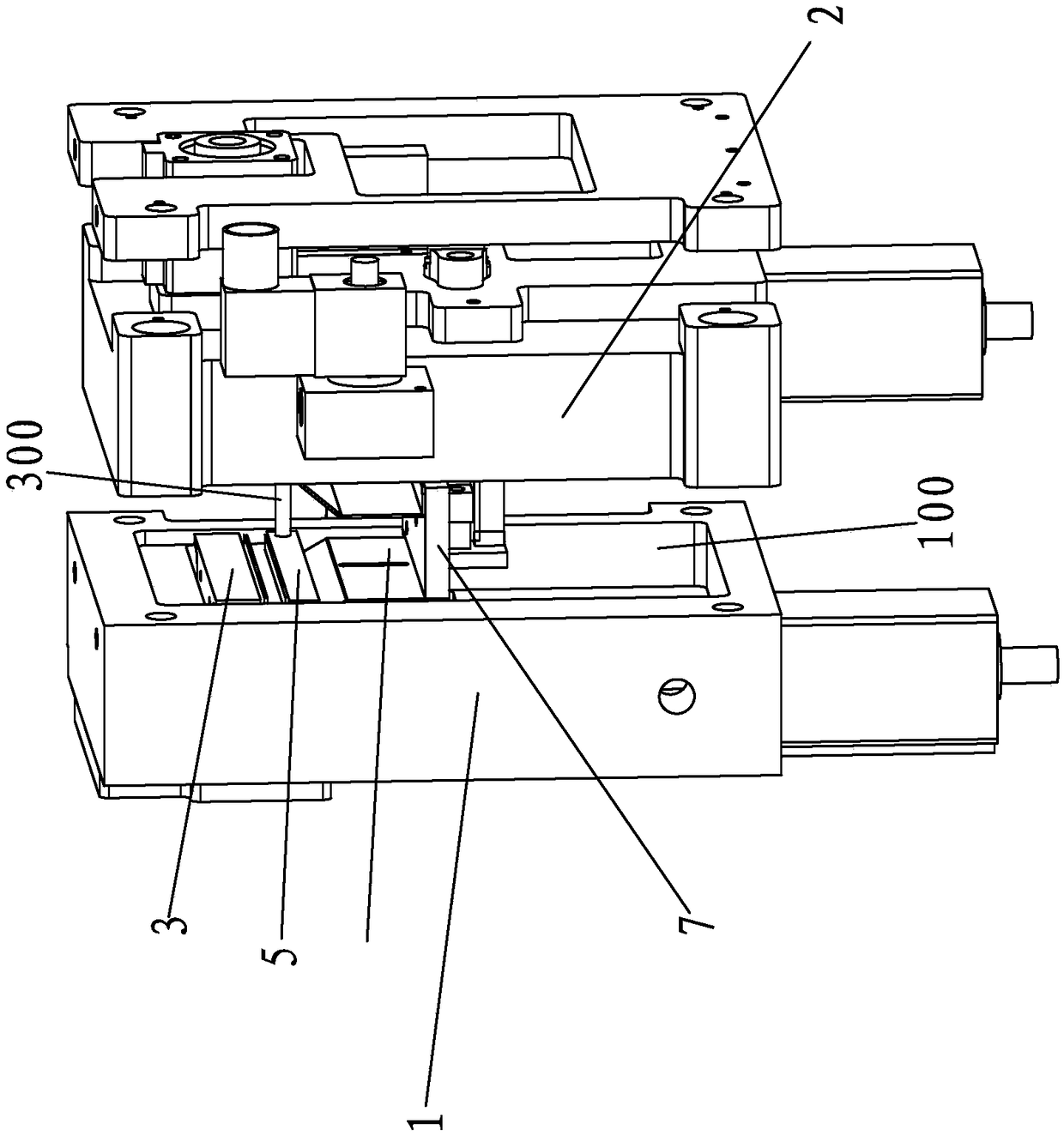

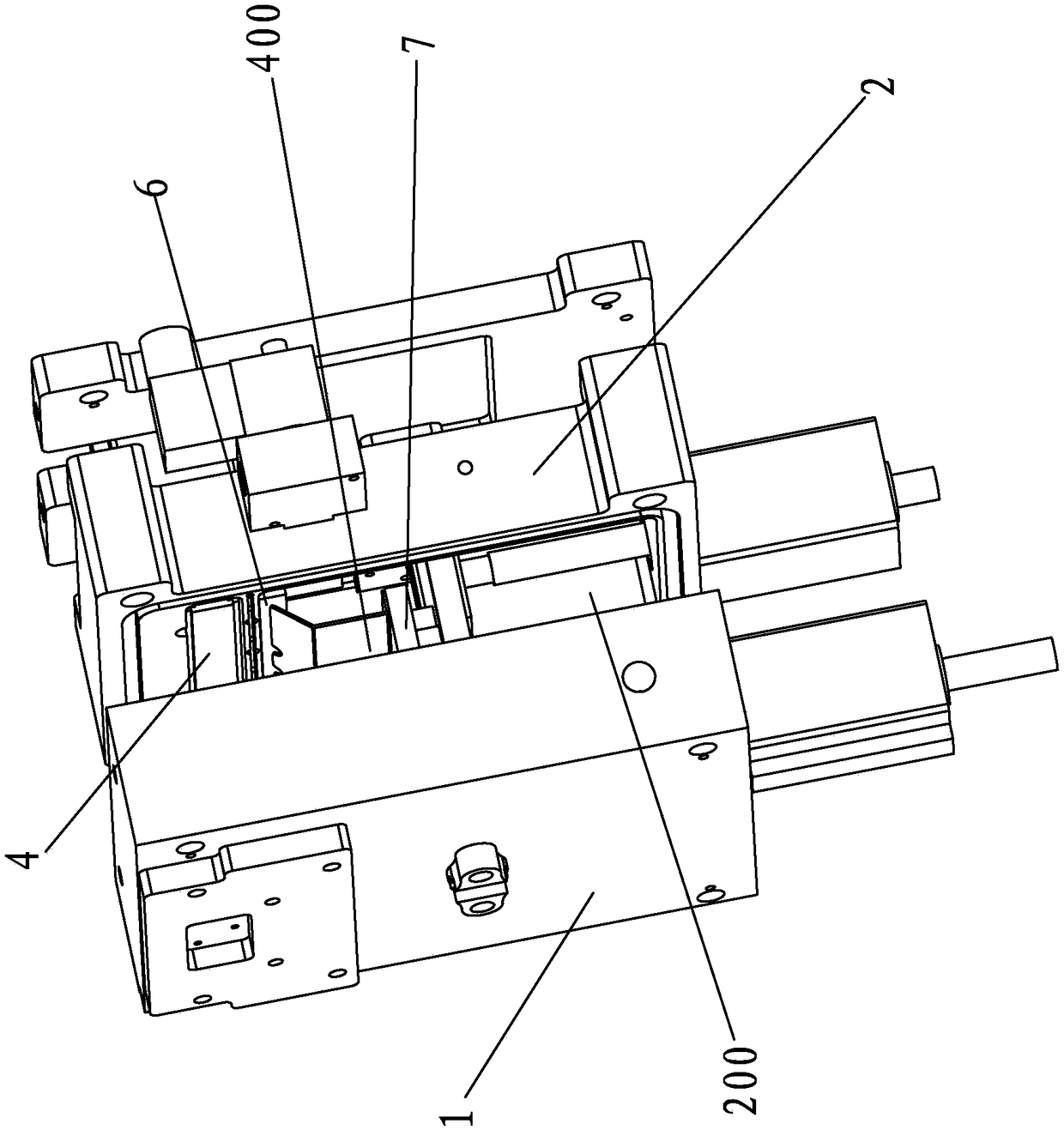

[0032] In order to further explain the technical solution of the present invention, it will be described in detail below with reference to the accompanying drawings.

[0033] The tea packaging process of the present invention includes a pretreatment process and a packaging process. The pretreatment includes a weighing process for weighing the tea leaves and a bagging process for the tea leaves to fall into the packaging bag after the weighing. The existing process in the automatic tea packaging machine is a well-known technology and will not be repeated here.

[0034] The innovation of the present invention lies in that the packaging process is realized through the following steps:

[0035] Step 1. Drop the bag, drop the packaging bag after the bagging process into the shaping chamber surrounded by the bottom plate and the two side panels. After dropping, the position of the packaging bag above the tea area is outside the shaping chamber, and the front of the packaging bag Correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com