Electric servo shaping arber press

An electric servo and press machine technology, applied in the direction of presses, punching machines, metal processing, etc., can solve the problems of inaccurate positioning, unstable pressure, slow speed, etc., to improve production safety, stable pressure without fluctuations, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

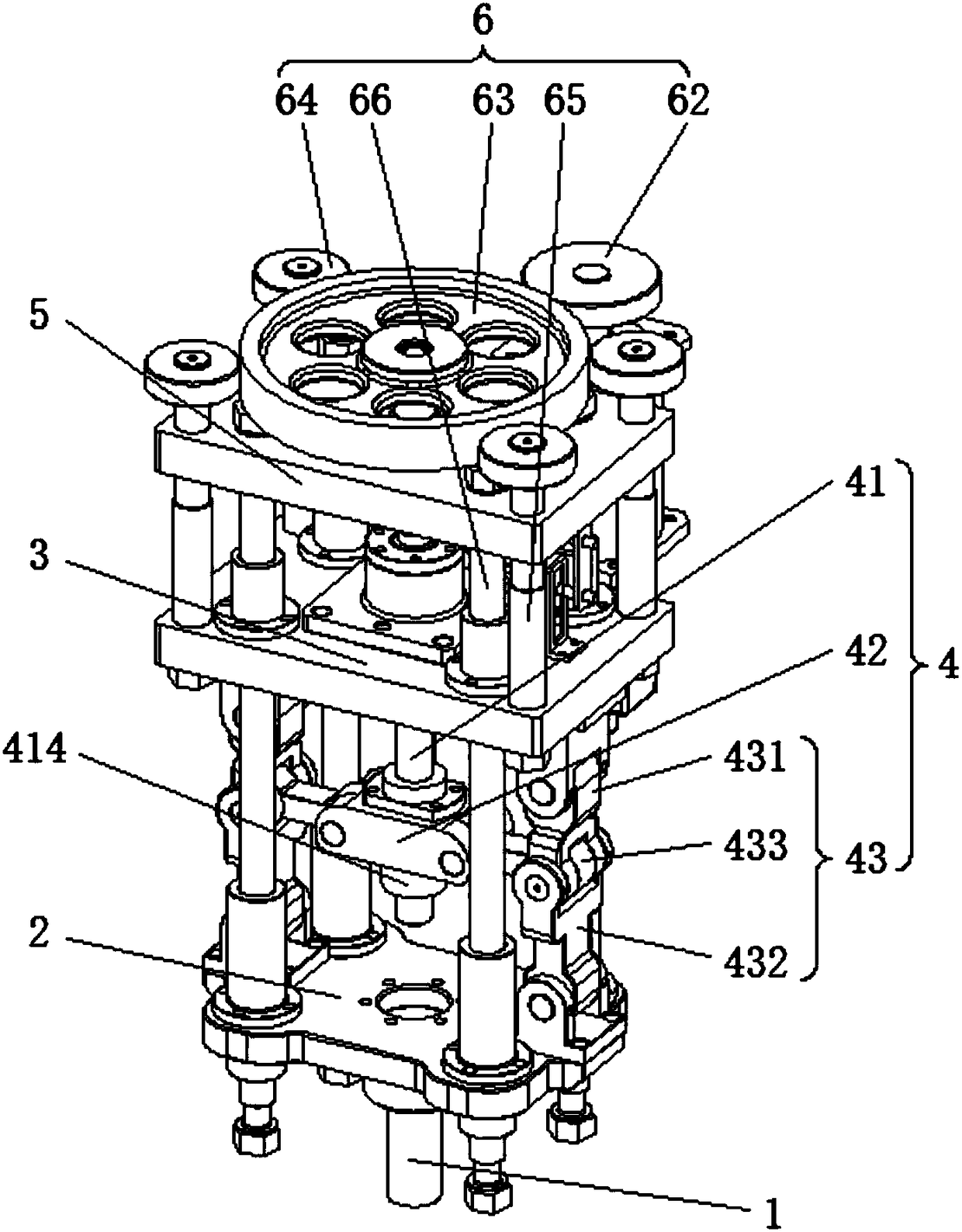

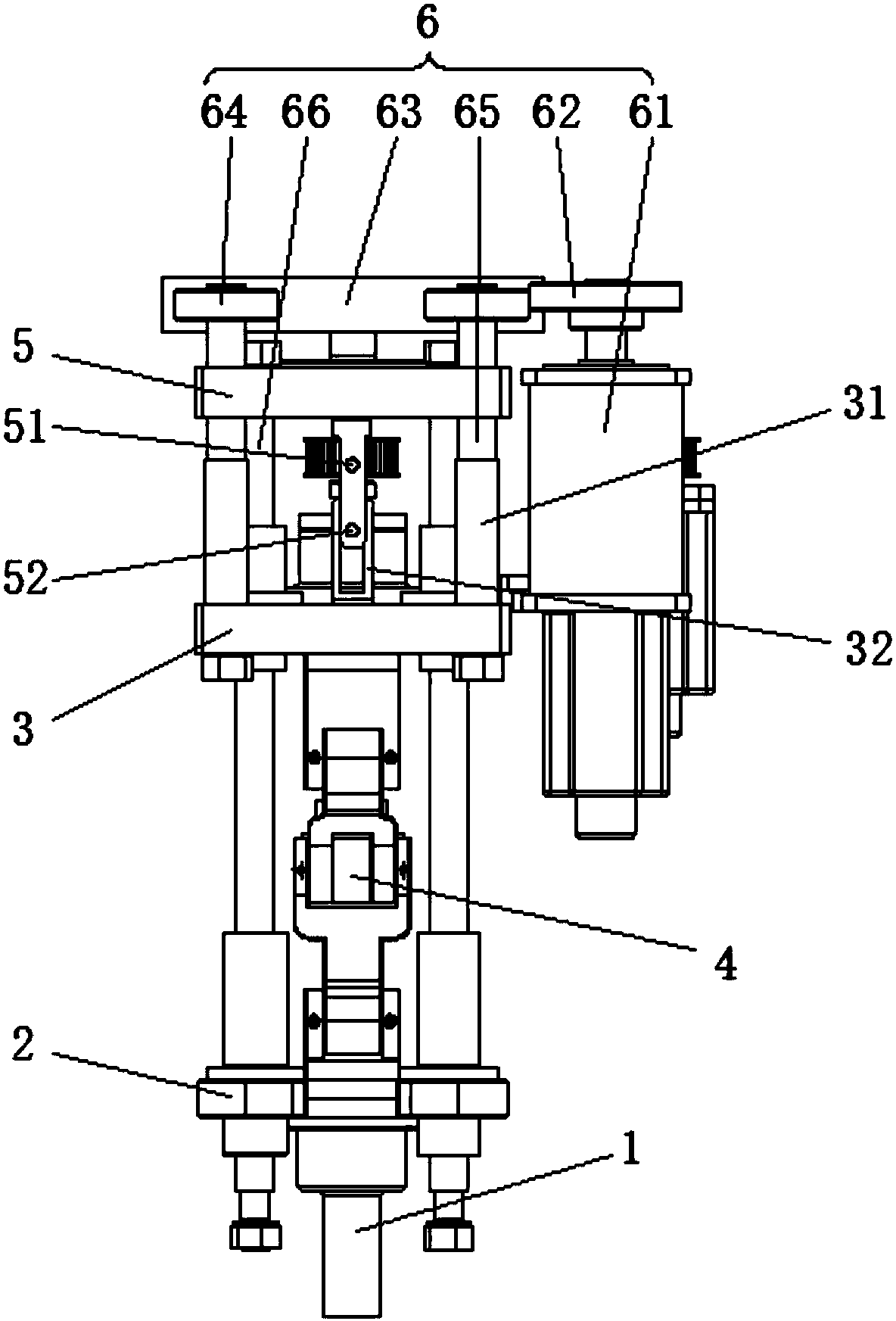

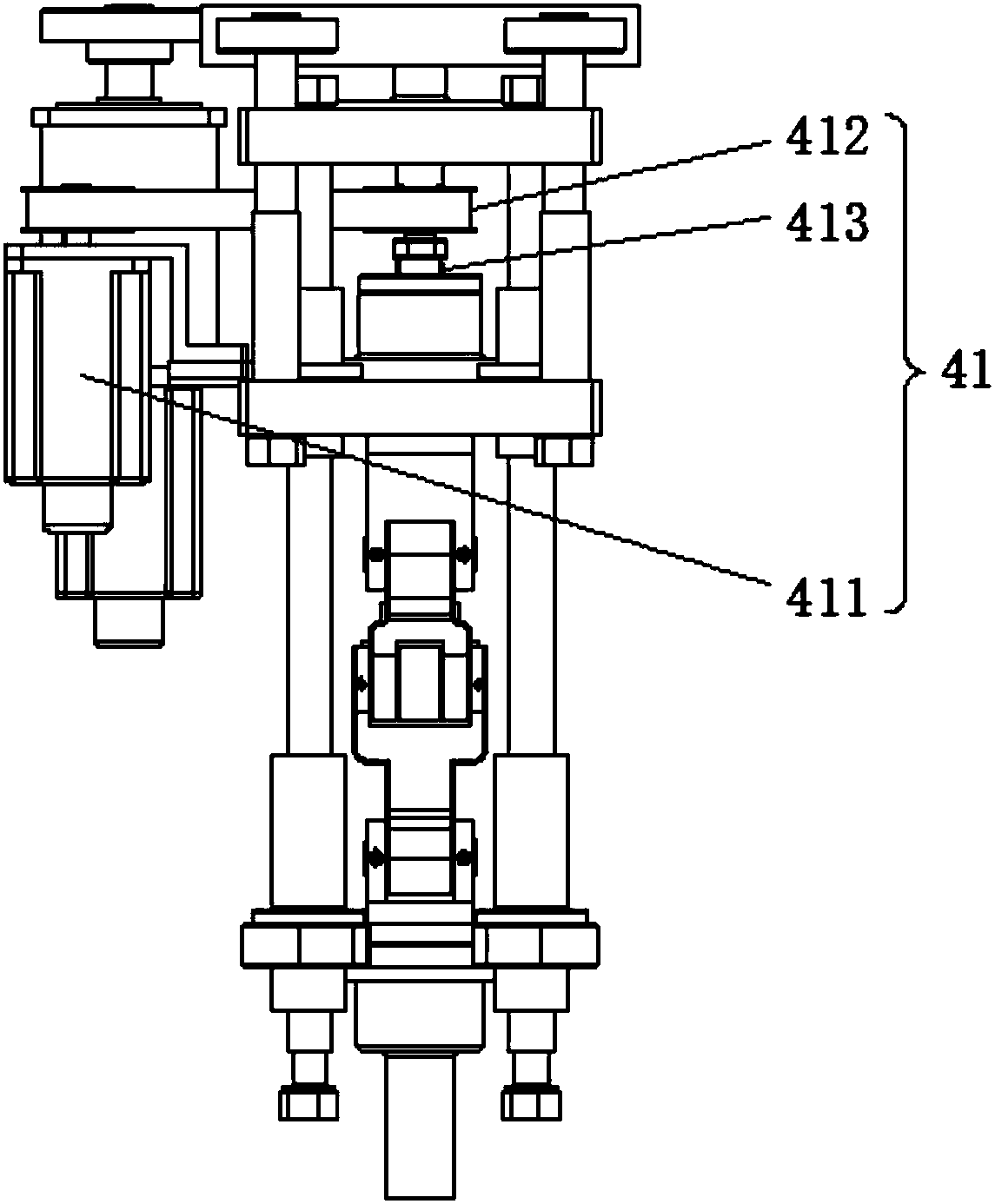

[0020] See figure 1 and image 3 , the present invention has a stamping head 1, a first base plate 2, a second base plate 3, a link mechanism 4, a third base plate 5 and an adjustment device 6; the link mechanism 4 is arranged between the first base plate 2 and the second base plate 3 Between; the linkage mechanism 4 includes a lifting device 41, an intermediate connecting body 42, and a connecting rod assembly 43 symmetrically arranged on both sides of the intermediate connecting body 42; the connecting rod assembly 43 includes an upper connecting rod 431, a lower connecting rod 432 And support connecting rod 433; one end of upper connecting rod 431, one end of lower connecting rod 432 and one end of supporting connecting rod 433 are rotatably connected together through a rotating shaft; the other end of upper connecting rod 431 is rotatably connected with second base plate 3, The other end of the lower link 432 is rotatably connected to the first base plate 2, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com