Rotating nipple for hydraulic shaping

A rotary sub-joint, hydraulic technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of uncertain orientation of the power motor, failure and damage of the power motor, etc., to achieve reliable use, ensure the shaping effect, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

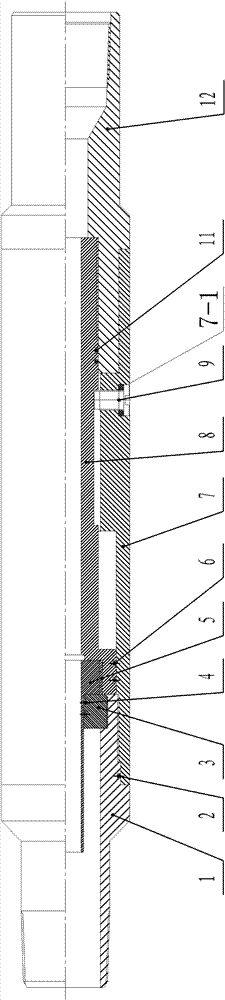

[0007] Specific implementation mode one: as figure 1 As shown, the rotating nipple used for hydraulic shaping in this embodiment includes a lower joint 1, a stop block 3, a guide block 5, a rotating sleeve 7, a steering rod 8, a positioning pin 9 and an upper joint 12. The steering rod 8 is inserted in the rotating sleeve 7, and the positioning hole 7-1 is processed on the rotating sleeve 7, and the positioning pin 9 is inserted in the positioning hole 7-1, and the positioning pin 9 is used for the steering rod 8 and the rotating sleeve 7, the lower end of the upper joint 12 is inserted into the rotating sleeve 7, and the lower end of the upper joint 12 is set on the upper end of the steering rod 8, and the upper part of the lower joint 1 is inserted in the rotating The lower end of the sleeve 7, and the upper end surface of the lower joint 1 is in contact with the lower end surface of the steering rod 8, the guide block 5 is located at the bottom of the steering rod 8, the st...

specific Embodiment approach 2

[0008] Specific implementation mode two: as figure 1 As shown, the rotating nipple in this embodiment further includes a first O-ring 2 , and the first O-ring 2 is located between the lower joint 1 and the rotating sleeve 7 . Designed in this way, it plays a sealing role. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as figure 1 As shown, the rotary nipple in this embodiment further includes a second O-ring 4 , and the second O-ring 4 is located between the stop block 3 and the guide block 5 . Designed in this way, it plays a sealing role. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com