Laminating mechanism of storage battery wrapping and laminating machine

A stacking machine and storage battery technology, which is applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of health impact of operators, increased structural complexity, and low quality of packaging. To achieve the effect of compact structure, less space occupation, firm and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

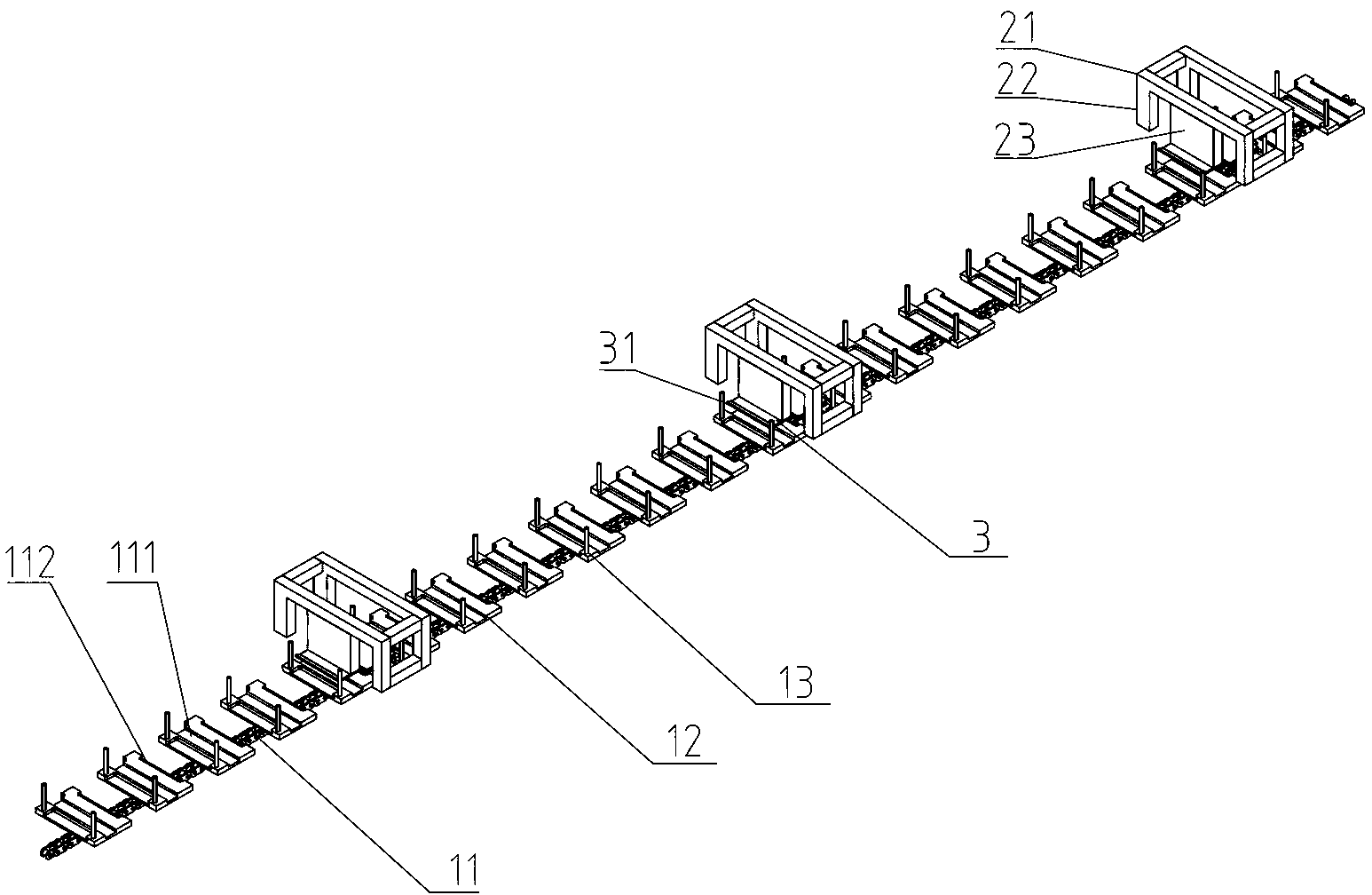

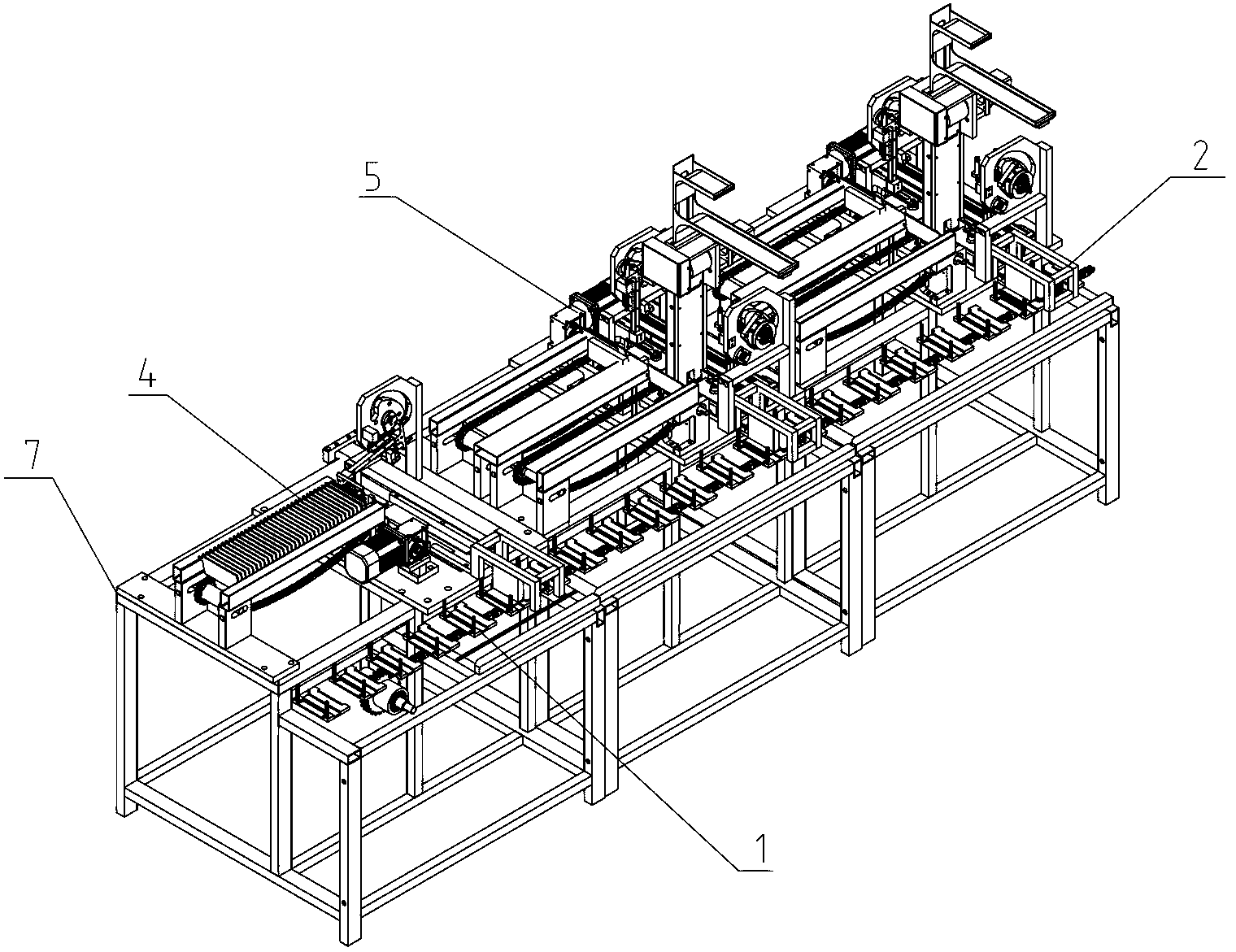

[0030] refer to figure 1 , the shown fixing frame 2 is provided with a fixing plate 23 extending downward to directly above the conveying device 1, and a supporting plate 3 is arranged at the bottom of the fixing plate 23, and the supporting plate 3 is volleyed above the conveying device 1 in this way, and the structure is simple and compact , maintenance and replacement are also convenient, and the fixed connection between the supporting plate 3 and the fixed plate 23 can improve the load-bearing capacity of the supporting plate 3.

[0031] The fixed frame 2 in the present embodiment comprises a top frame 21 and a column 22, and the column 22 is fixed on the frame 7 of the sheet stacker, and the fixed plate 23 is arranged on the top frame 21, between the column 22 and the frame 7 and The fixing plate 23 and the top frame 21 may be screwed or welded, and the structure of the fixed connection is firm. figure 1 The top frame 21 and the uprights 22 are shown as an integral struc...

Embodiment 2

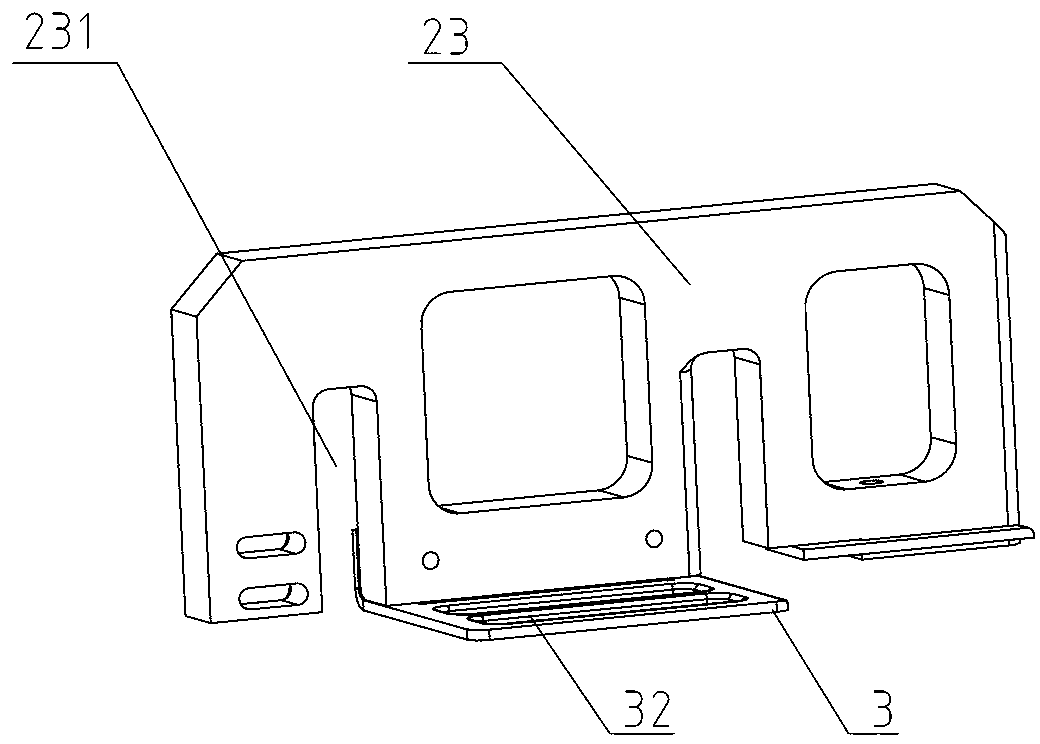

[0034] refer to figure 1 and figure 2 , another structural form of the fixing frame 2 , the fixing frame 2 only includes a fixing plate 23 arranged laterally along the conveying device 1 , and a supporting plate 3 is arranged at the bottom end of the fixing plate 23 .

[0035] In this embodiment, the end of the fixed plate 23 is fixedly connected to the frame 7 of the sheet stacker. The fixed plate 23 is provided with an avoidance groove 231. When the push rod 13 moves with the conveying device 1, it passes through the avoidance groove 231. . It can be welded or screwed between the fixed plate 23 and the frame 7 . Compared with Embodiment 1, the structure is simpler and the cost is relatively lower under the premise of completing the same function.

[0036] The conveying device 1 of the above-mentioned embodiment comprises a conveying chain 11, and the conveying chain 11 is provided with pallets 12 at intervals, and the conveying chain 11 can reciprocate. The boards are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com