Grabbing device for ultrasonic cleaning equipment

A technology for cleaning equipment and grabbing devices, which is applied in the directions of transportation and packaging, cleaning methods and utensils, and cleaning methods using liquids, etc., which can solve problems such as damaged samples, sample drop, and unstable clamping, and achieve improved clamping Stability, prevent the sample from falling, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

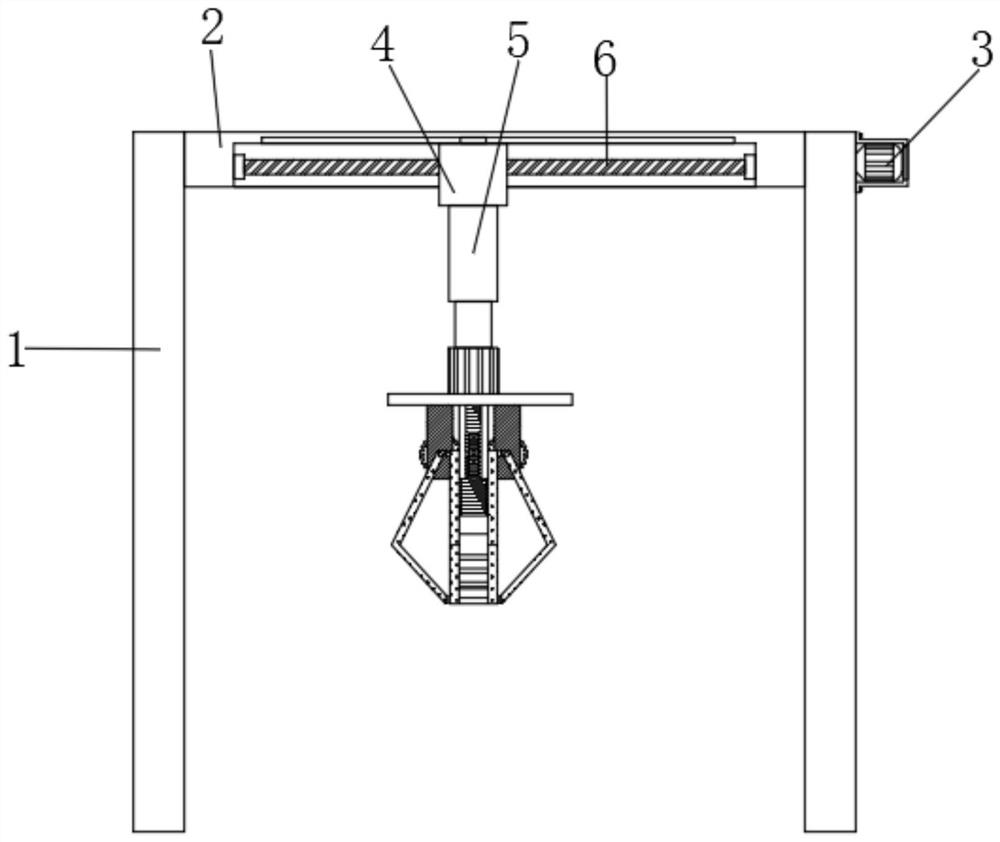

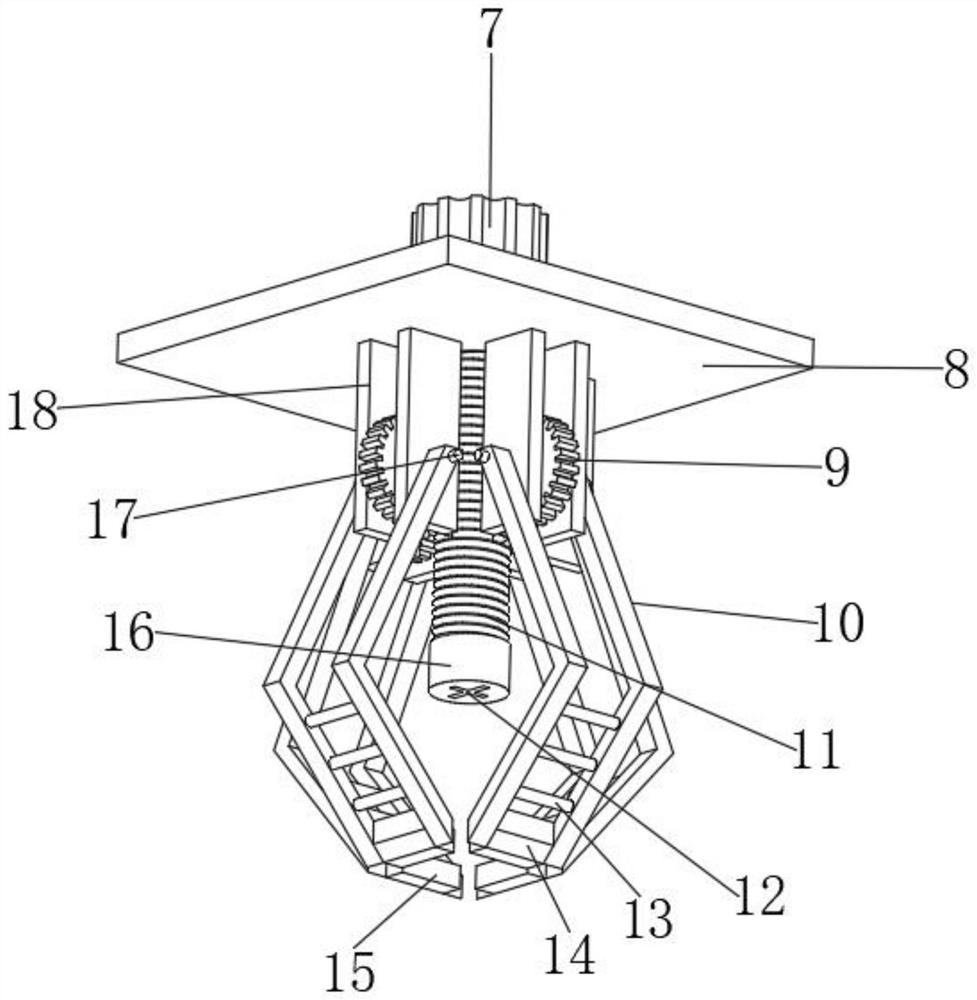

[0022] refer to figure 1 and figure 2 , the grasping device of the ultrasonic cleaning equipment, including a mounting plate 8 and a first support plate 2, the top outer wall of the mounting plate 8 is provided with a second rotating motor 7, and the second rotating motor 7 extends to the bottom outer wall of the mounting plate 8 The output shaft is connected with a cross shaft 12 through a coupling, the outer wall of the cross shaft 12 is sleeved with a worm 11, and the outer wall of one end of the cross shaft 12 is provided with a first stop ring 16, and the bottom outer wall of the mounting plate 8 is provided with a There are a plurality of second supporting plates 18, and the inner walls of the opposite sides of each adjacent two second supporting plates 18 are provided with rotating holes, the inner walls of the rotating holes are inserted with rotating shafts, and the middle part of the rotating shafts is provided with Turbine 9, the two ends of rotating shaft are all...

Embodiment 2

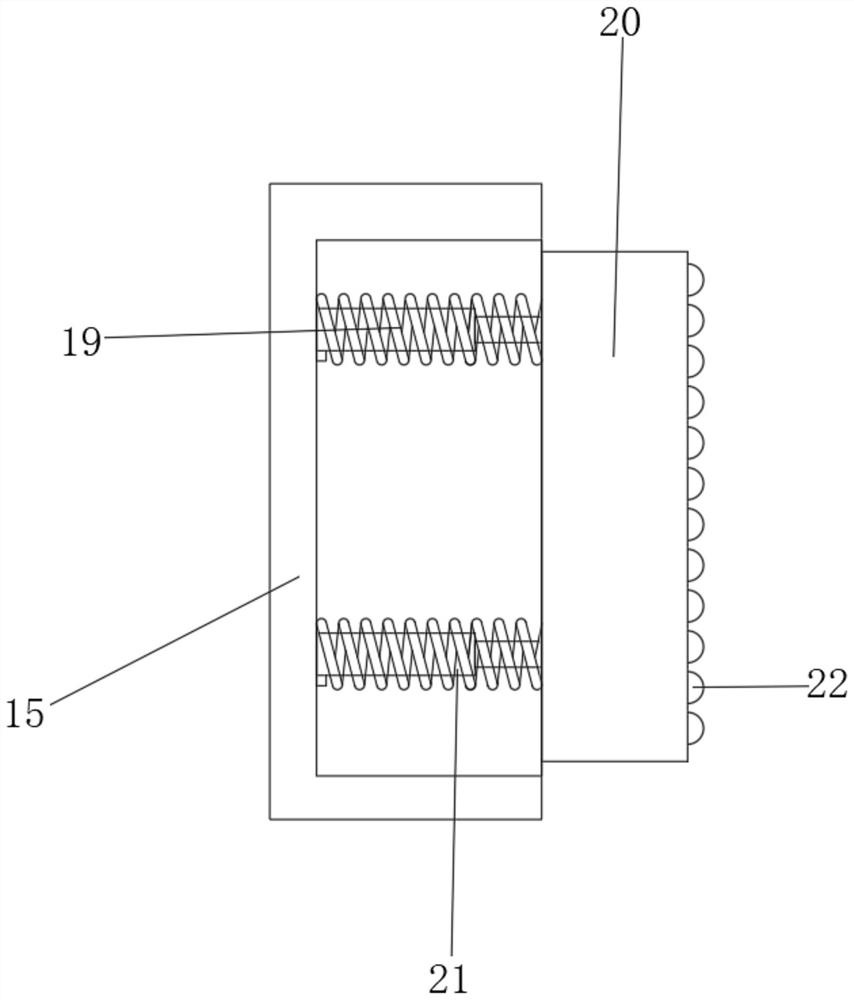

[0030] refer to image 3 , the grasping device of the ultrasonic cleaning equipment, compared with Embodiment 1, the outer wall of one side of the clamping block 15 has a groove, and the inner wall of one side of the groove is provided with a plurality of telescopic rods 21, and the plurality of telescopic rods The other end of 21 is provided with the same rubber block 20, and the outer wall of telescopic rod 21 is sleeved with spring 19, and the two ends of spring 19 are fixedly connected with groove side inner wall and rubber block 20 side outer wall respectively, and one of rubber block 20 The side outer wall is provided with a plurality of rubber bumps 22 .

[0031] When clamping, if the shape of the sample is irregular, one or more of the four clamping blocks 15 cannot clamp the sample effectively. position, so as to achieve the purpose of clamping irregular samples, and the rubber bump 22 provided at the same time increases the friction between the rubber block 20 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com