Lifting stacking machine with starting assembly

A component and transmission cavity technology, which is applied in the direction of unstacking of objects, stacking of objects, manipulators, etc., can solve the problems of cargo extrusion, re-finding effort, lack of position information, etc., to avoid slipping and avoid excessive clamping force big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

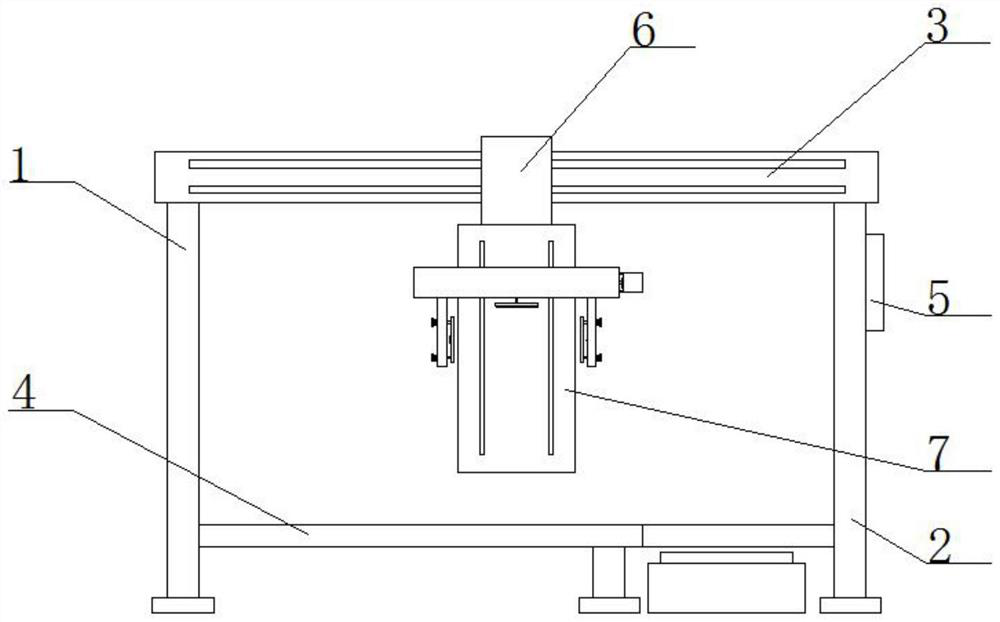

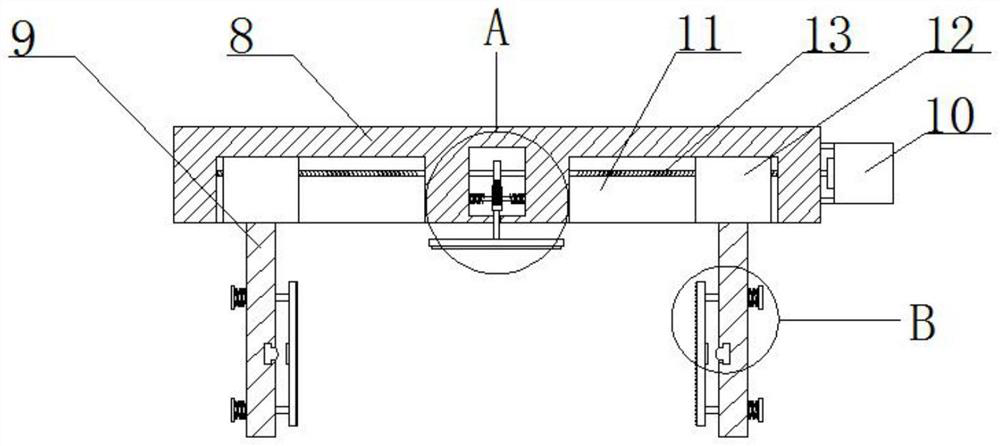

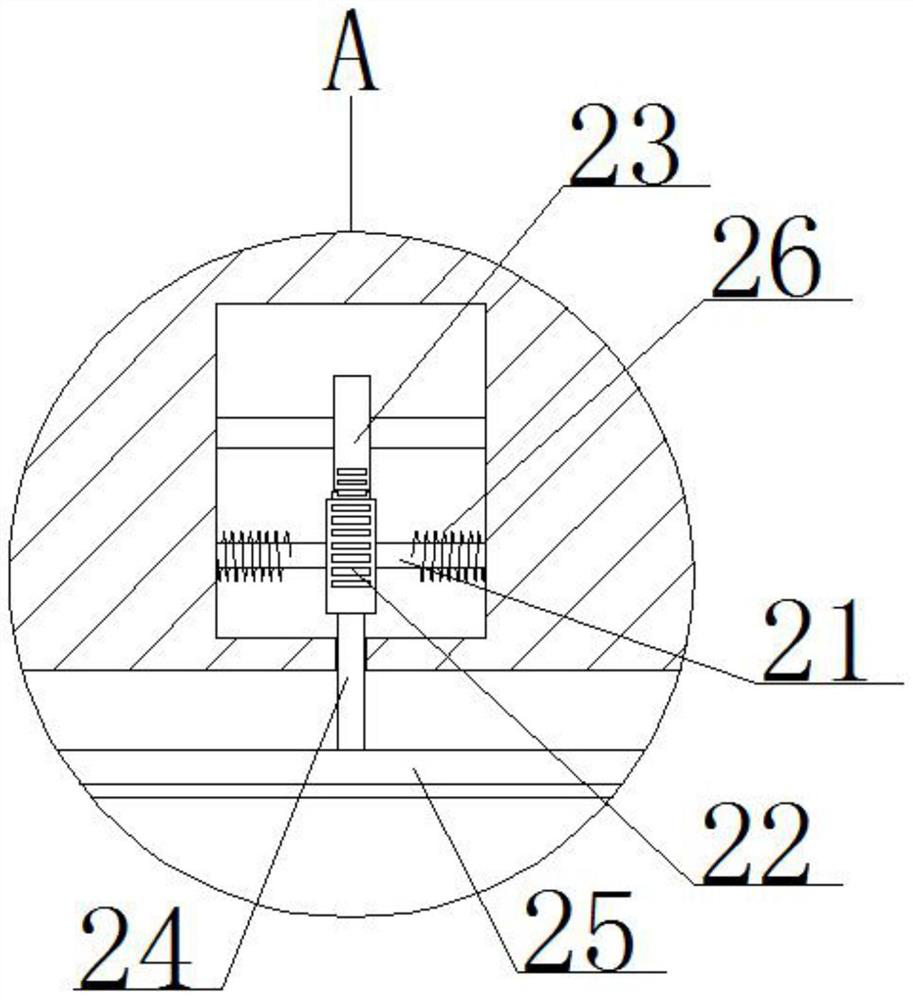

[0027] refer to Figure 1-5 , a lifting stacker with a start-up assembly, comprising a first support column 1 and a second support column 2, the top ends of the first support column 1 and the second support column 2 are fixedly connected with the same crossbar 3 by welding, and The first support column 1 and the second support column 2 are provided with the same stacking plate 4, the stacking plate 4 is provided with an operation port, the second supporting column 2 is provided with a PLC controller 5, and the cross bar 3 slides on A moving plate 6 is installed, the bottom of the moving plate 6 is fixedly connected with a side plate 7 by welding, a top plate 8 is slidably installed on one side of the side plate 7, and two clamping plates 9 are slidably installed at the bottom of the top plate 8. The plate 9 is provided with a buffering force-limiting mechanism, the bottom of the top plate 8 is provided with a scanning mechanism, one side of the top plate 8 is fixedly installed...

Embodiment 2

[0037] The difference from the first embodiment is that it includes a first support column 1 and a second support column 2, the top ends of the first support column 1 and the second support column 2 are fixedly connected with the same crossbar 3, and the first support column 1 and the second supporting column 2 are provided with the same stacking plate 4, the stacking plate 4 is provided with an operation port, the second supporting column 2 is provided with a PLC controller 5, and the cross bar 3 is slidably installed with a moving plate 6. A side plate 7 is fixedly connected to the bottom of the moving plate 6, a top plate 8 is slidably installed on one side of the side plate 7, and two clamping plates 9 are slidably installed at the bottom of the top plate 8, and both clamping plates 9 are provided with Buffer force limiting mechanism, the bottom of the top plate 8 is provided with a scanning mechanism, one side of the top plate 8 is fixedly installed with a motor 10, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com