Finished product warehouse discharging and transferring device

A transfer device, finished product warehouse technology, applied in the directions of transportation and packaging, packaging, loading/unloading, etc., can solve the problems of segregation, tedious vehicle operation, difficult to grasp the discharge amount of the finished product warehouse, etc., to achieve accurate discharge, reduce segregation, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

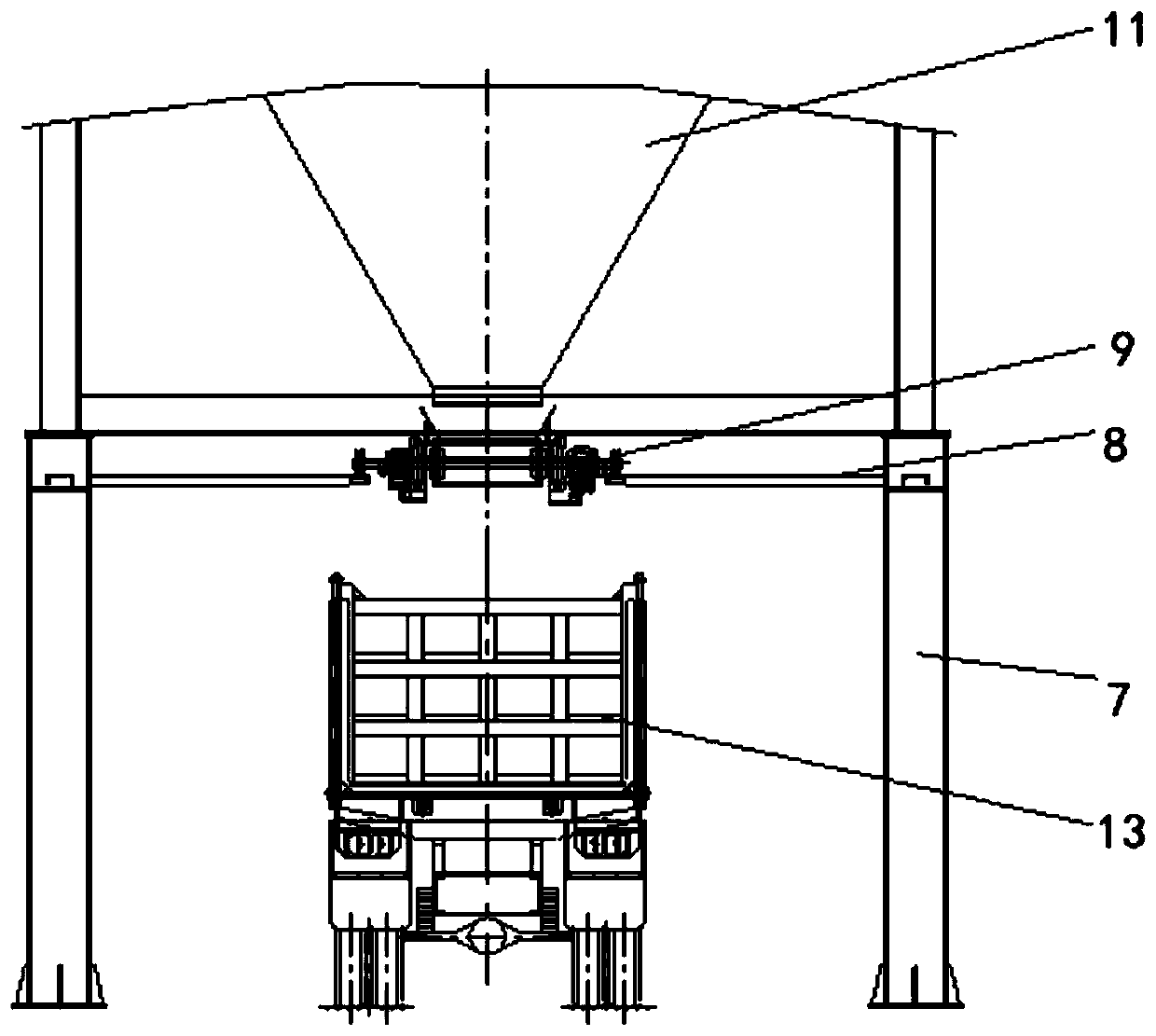

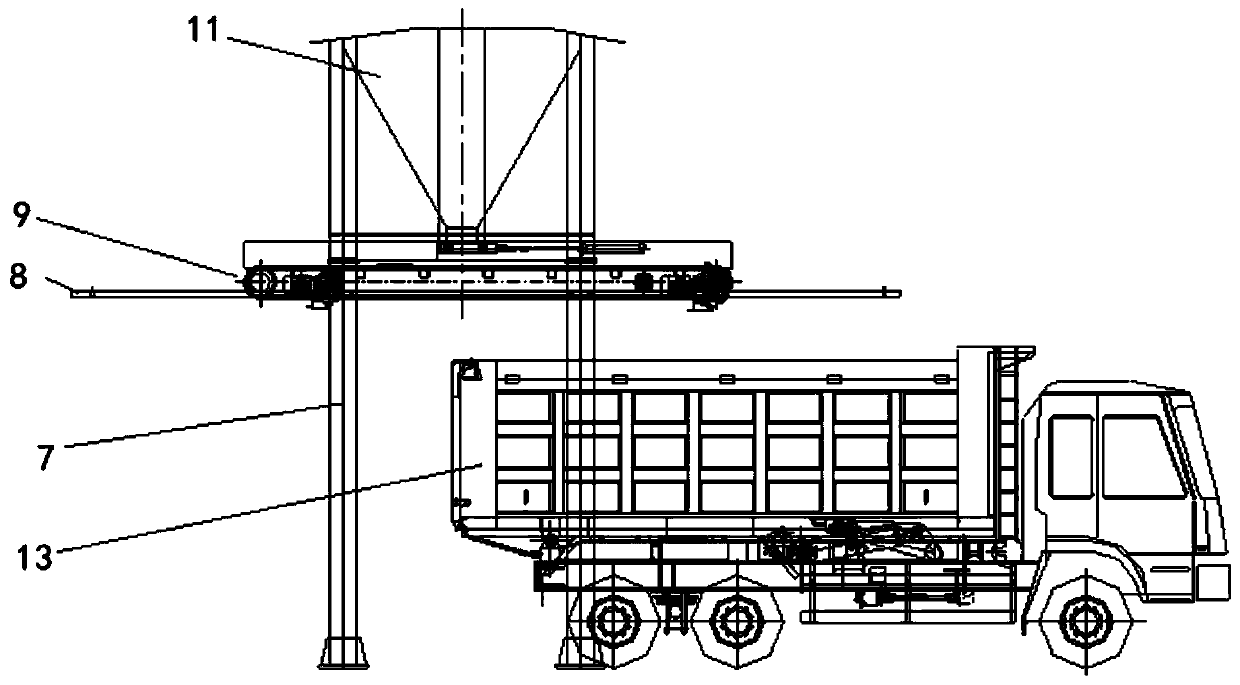

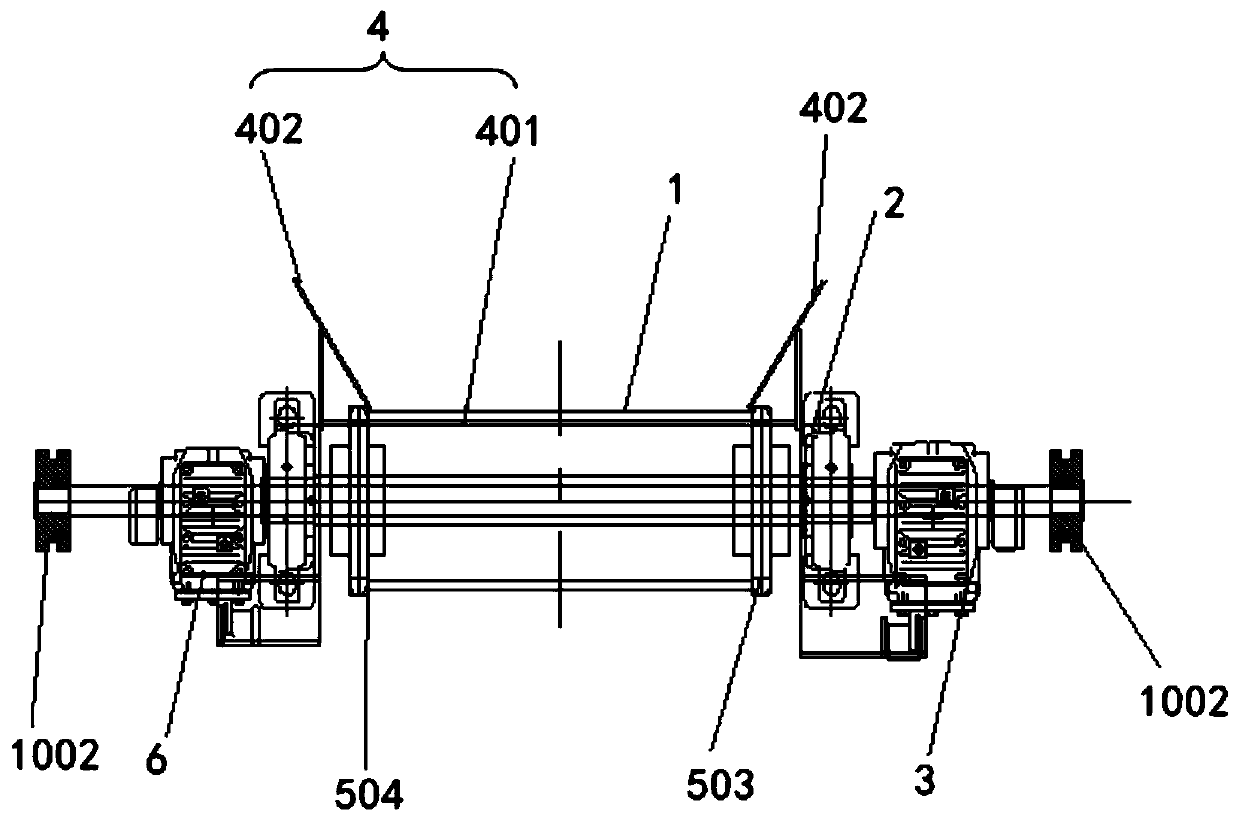

[0034] Such as Figure 1 to Figure 6 , a finished product bin discharge transfer device, including a first driver 6, a bracket 7, a rail 8 and a transmission mechanism 9; the rail 8 is fixed on the bracket 7; a sliding assembly is fixed on the transmission mechanism 9, and the sliding assembly and The rails 8 are matched; the transmission mechanism 9 is located directly below the finished product bin 11; the output end of the first driver 6 is connected with the slide assembly. Wherein, the transmission mechanism 9 includes a scraper 1, a material receiving plate 4, a second driver 3, a mounting frame 2, and a driving shaft 501 and at least one driven shaft 502 installed in parallel on the mounting frame 2; the driving shaft 501 Both ends of the driven shaft 502 and the driven shaft 502 are provided with a sprocket 503, and the sprocket 503 on the same side is covered with a chain 504, and the driving shaft 501 is coaxially fixedly connected with the output shaft of the second...

Embodiment 2

[0037] Such as Figure 1 to Figure 3 ,as well as Figure 7 , a finished product bin discharge transfer device, including a first driver 6, a bracket 7, a rail 8 and a transmission mechanism 9; the rail 8 is fixed on the bracket 7; a sliding assembly is fixed on the transmission mechanism 9, and the sliding assembly and The rails 8 are matched; the transmission mechanism 9 is located directly below the finished product bin 11; the output end of the first driver 6 is connected with the slide assembly. Wherein, the transmission mechanism 9 includes a second driver 3, a mounting frame 2, and a driving shaft 501 and at least one driven shaft 502 installed in parallel on the mounting frame 2; both ends of the driving shaft 501 and the driven shaft 502 are A pulley 505 is sheathed, and a belt 508 is sheathed on the pulley 505 . The driving shaft 501 is coaxially fixedly connected with the output shaft of the second driver 3 ; the sliding assembly and the second driver 3 are fixed on...

Embodiment 3

[0039]A finished product bin discharge transfer device, comprising a first driver 6, a support 7, a track 8 and a transmission mechanism 9; the track 8 is fixed on the support 7; a sliding assembly is fixed on the transmission mechanism 9, and the sliding assembly and the track 8; the transmission mechanism 9 is located directly below the finished product bin 11; the output end of the first driver 6 is connected with the slide assembly. Wherein, the transmission mechanism 9 includes a second driver 3, a mounting frame 2, and a driving shaft 501 and at least one driven shaft 502 installed in parallel on the mounting frame 2; both ends of the driving shaft 501 and the driven shaft 502 are A sprocket 503 is sheathed, and a chain 504 is sheathed on the same side of the sprocket 503, and the drive shaft 501 is coaxially fixedly connected with the output shaft of the second driver 3; the two chains 504 are coated with a belt 508; the sliding assembly and The second driver 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com