Leaning type automatic feeding device for down lamp springs

An automatic feeding and downlight technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, inconvenience, laborious manual operation, etc., and achieve the effect of streamlining structure, reducing cost and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

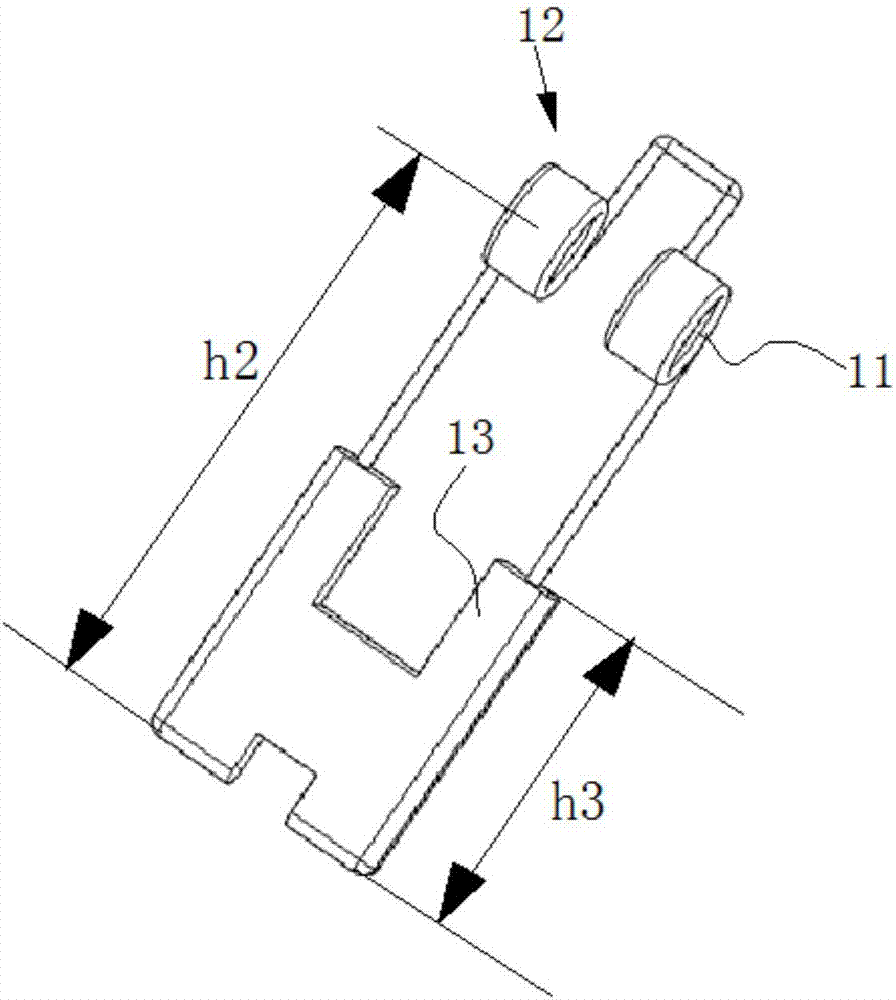

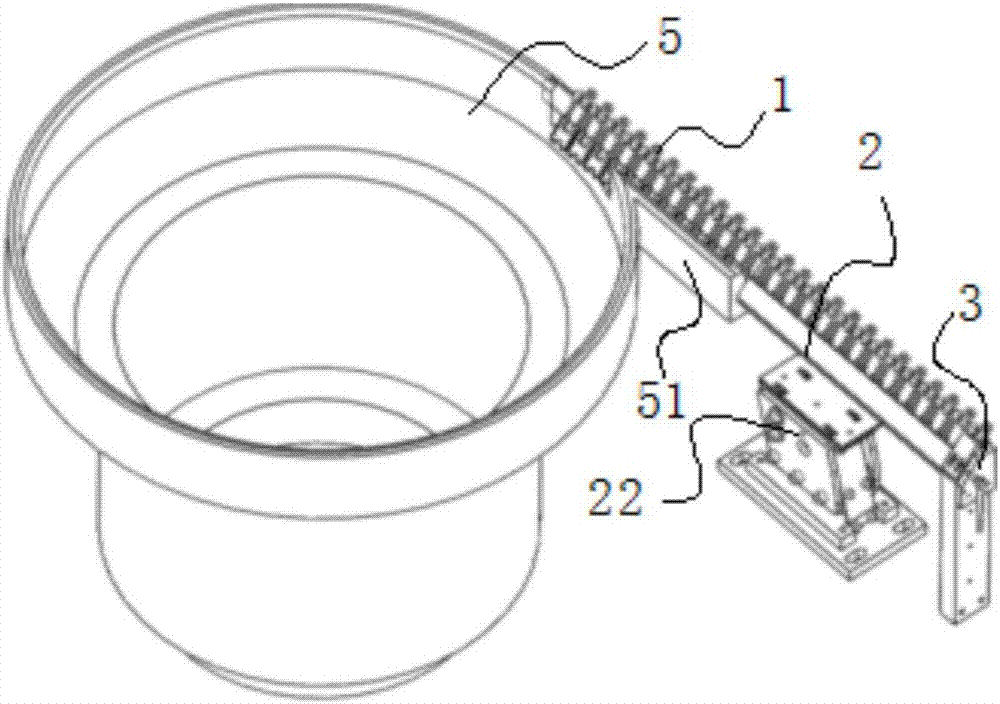

[0039] Embodiment: A spring automatic feeding device for leaning downlights, such as Figure 1 to Figure 7 As shown, one end of the spring 1 provided with the coil 11 is the head end 12, and the other end opposite to the head end is the tail end 13, with the conveying direction of the spring as the front, including the feeding mechanism 2 and the spring in place mechanism 3, so The spring in place mechanism is located in front of the feeding mechanism;

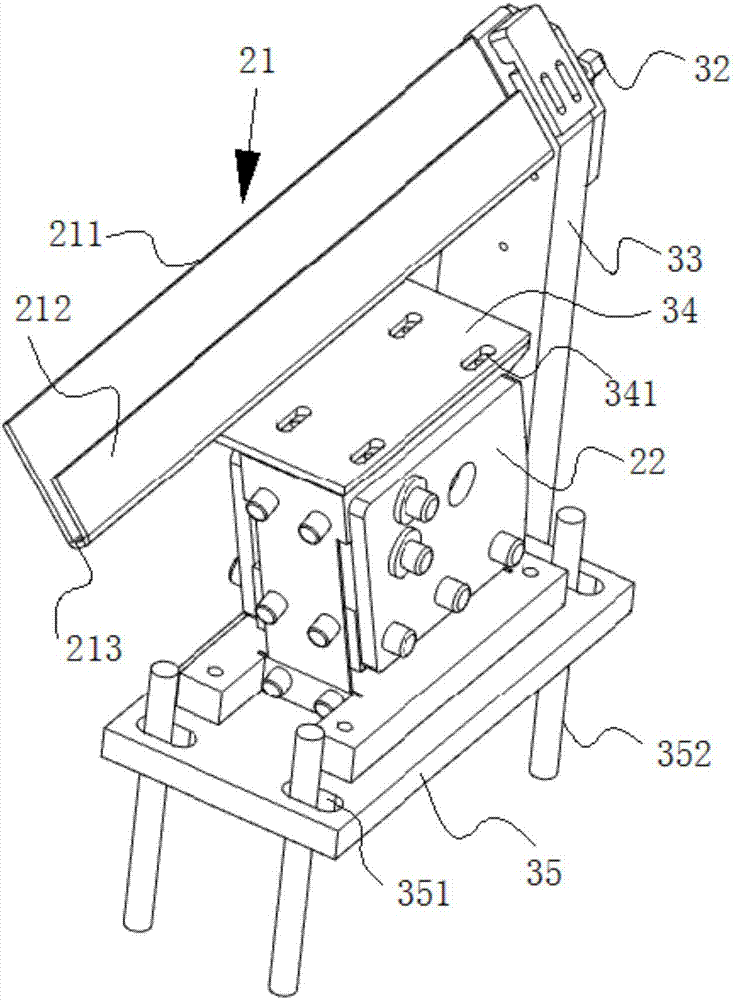

[0040] The feeding mechanism 2 includes a feeding chute 21 and a direct vibration auxiliary feeder 22 installed below the feeding chute, and the discharge end of the feeding chute is docked with the spring in place mechanism;

[0041] The feeding chute 21 includes a first feeding plate 211, a second feeding plate 212 and a bottom plate 213, the first feeding plate and the second feeding plate are all inclined and parallel to each other, and the bottom plate is connected to the lower end of the first feeding plate and Between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com