Patents

Literature

45results about How to "Easy to take by hand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

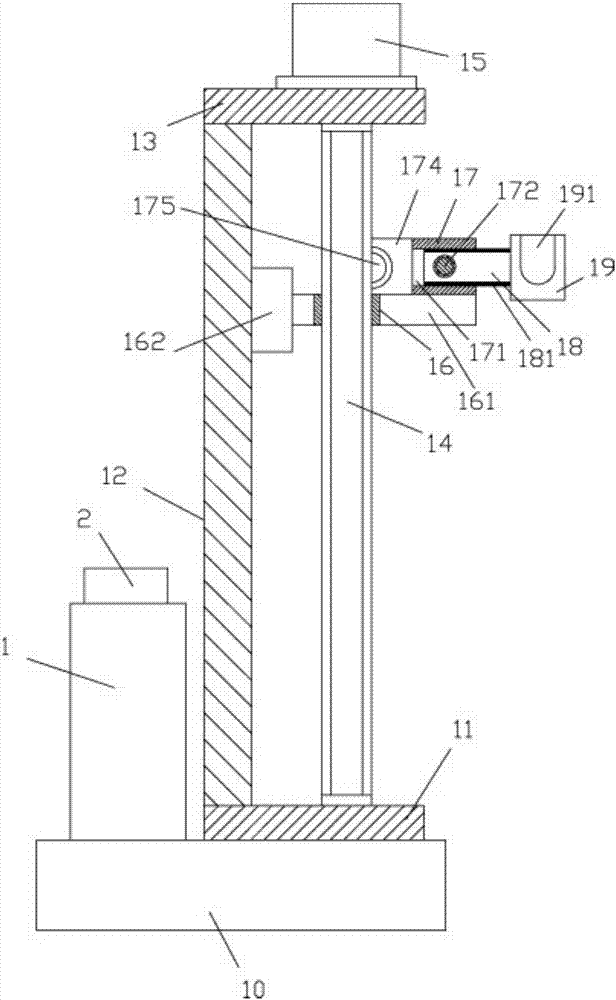

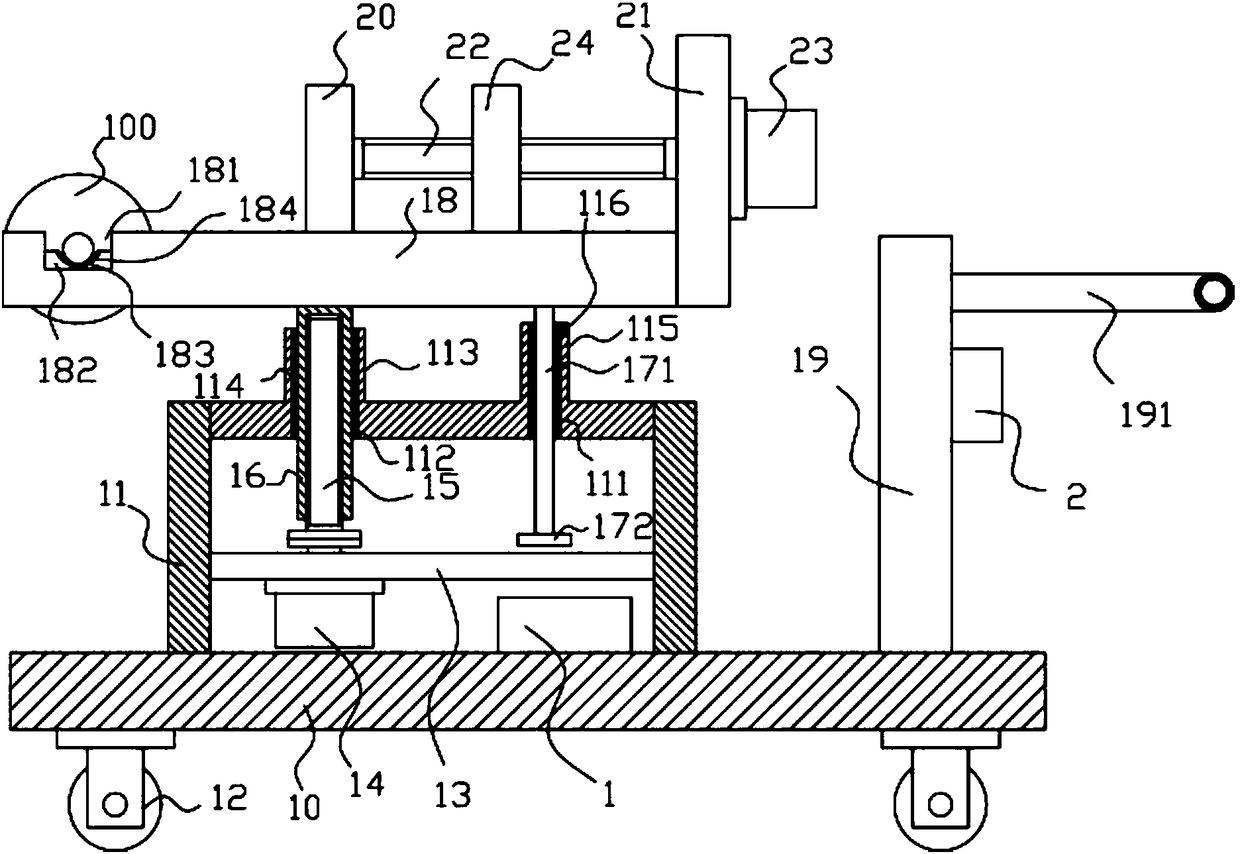

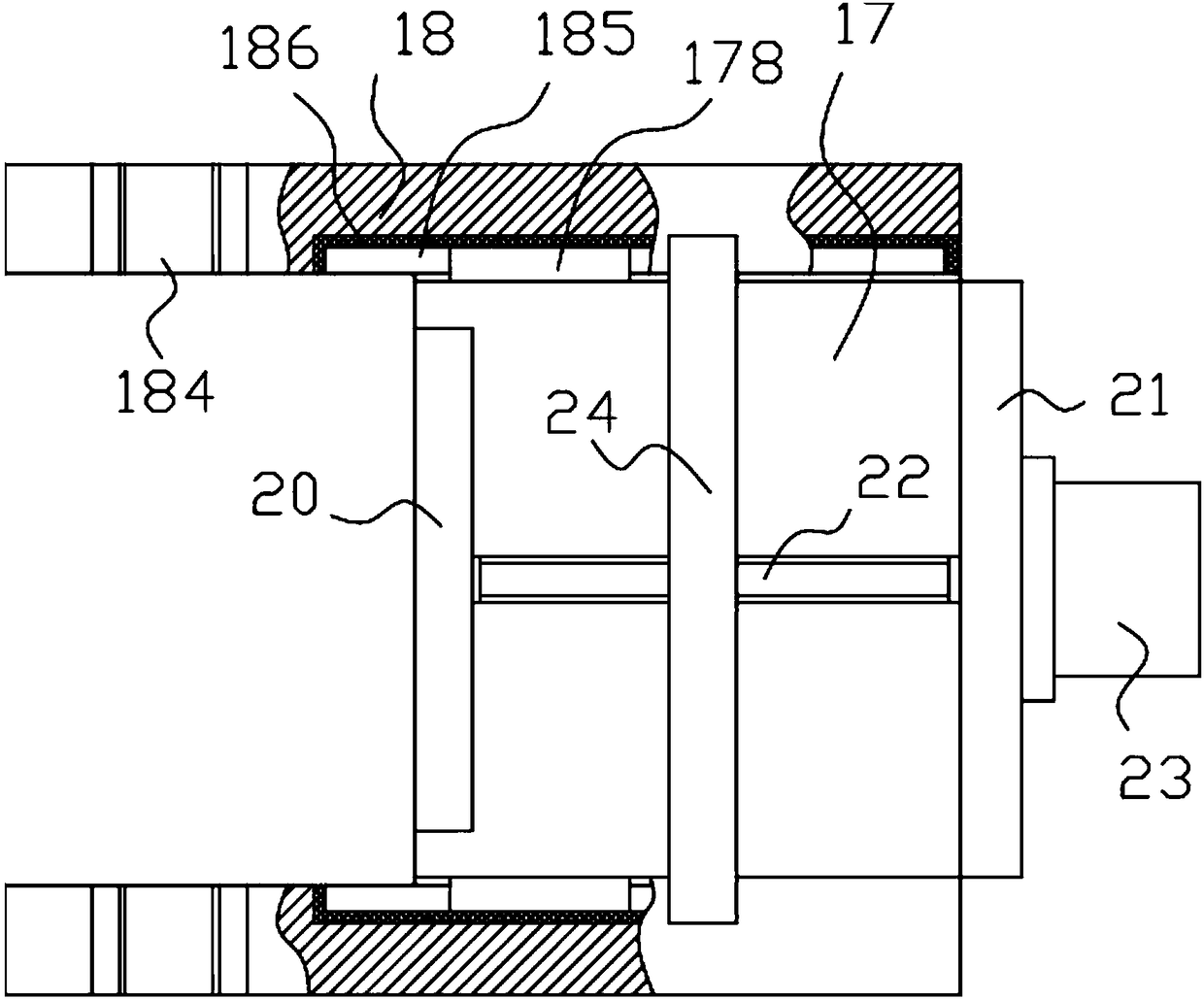

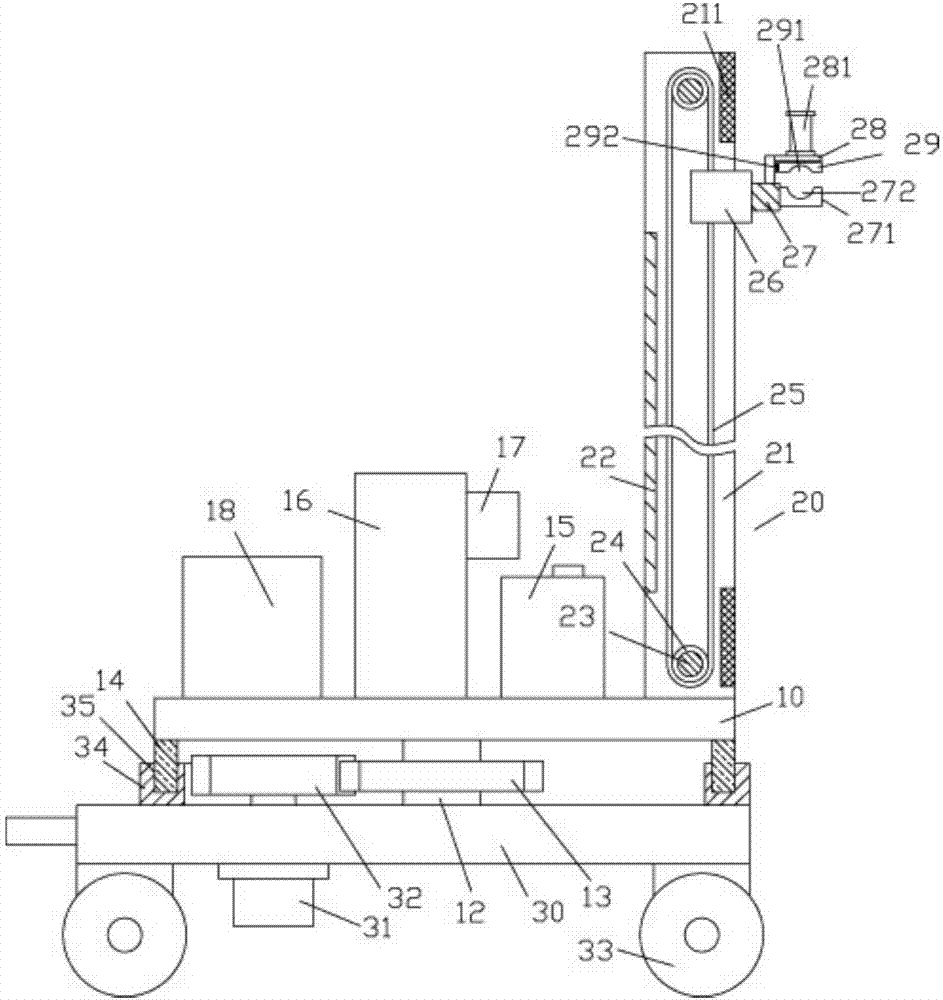

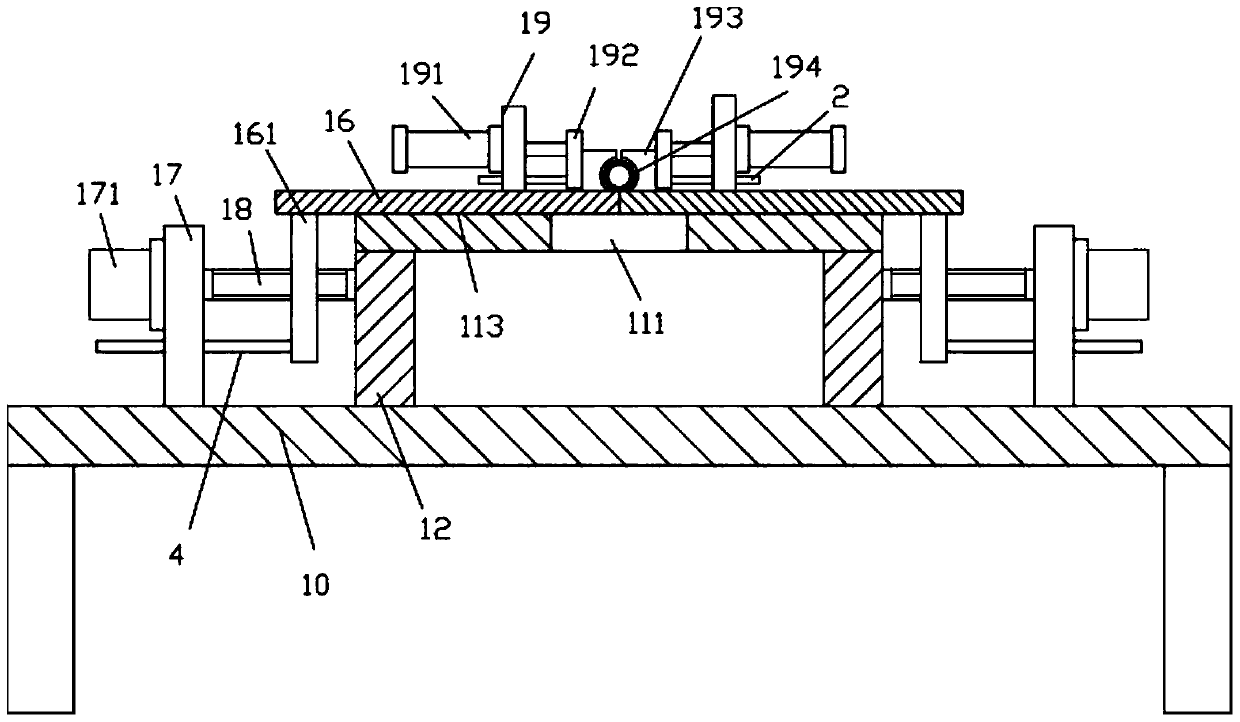

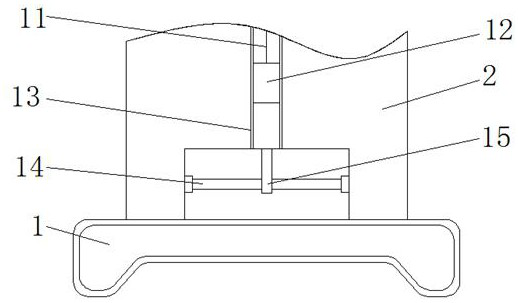

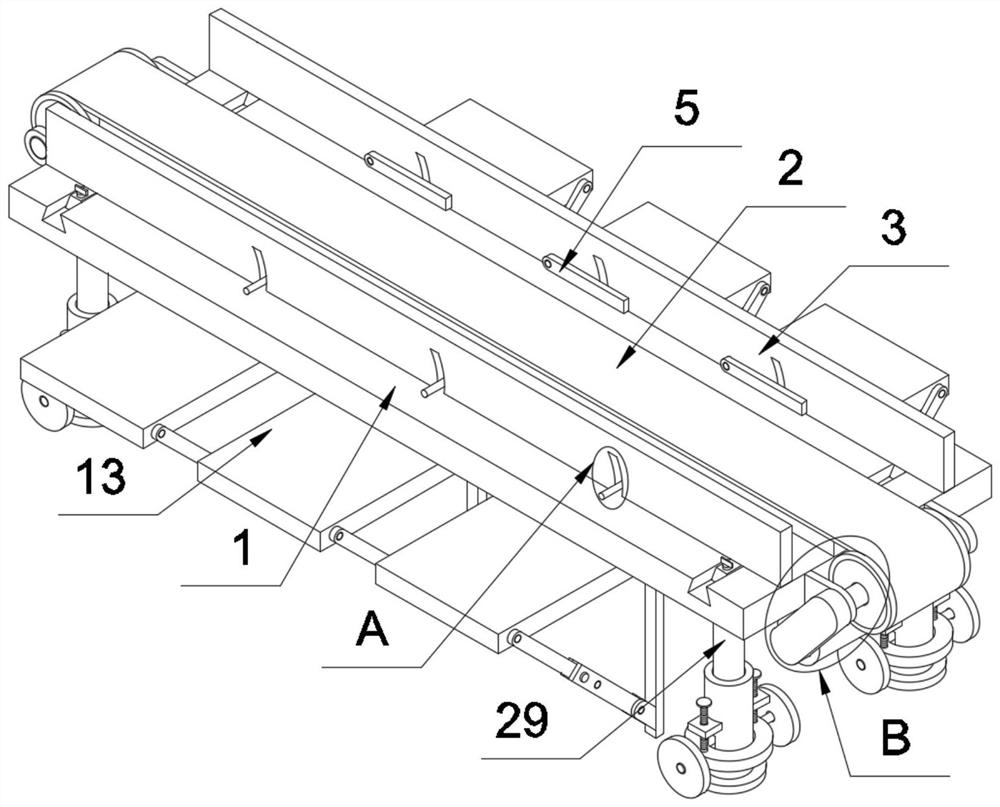

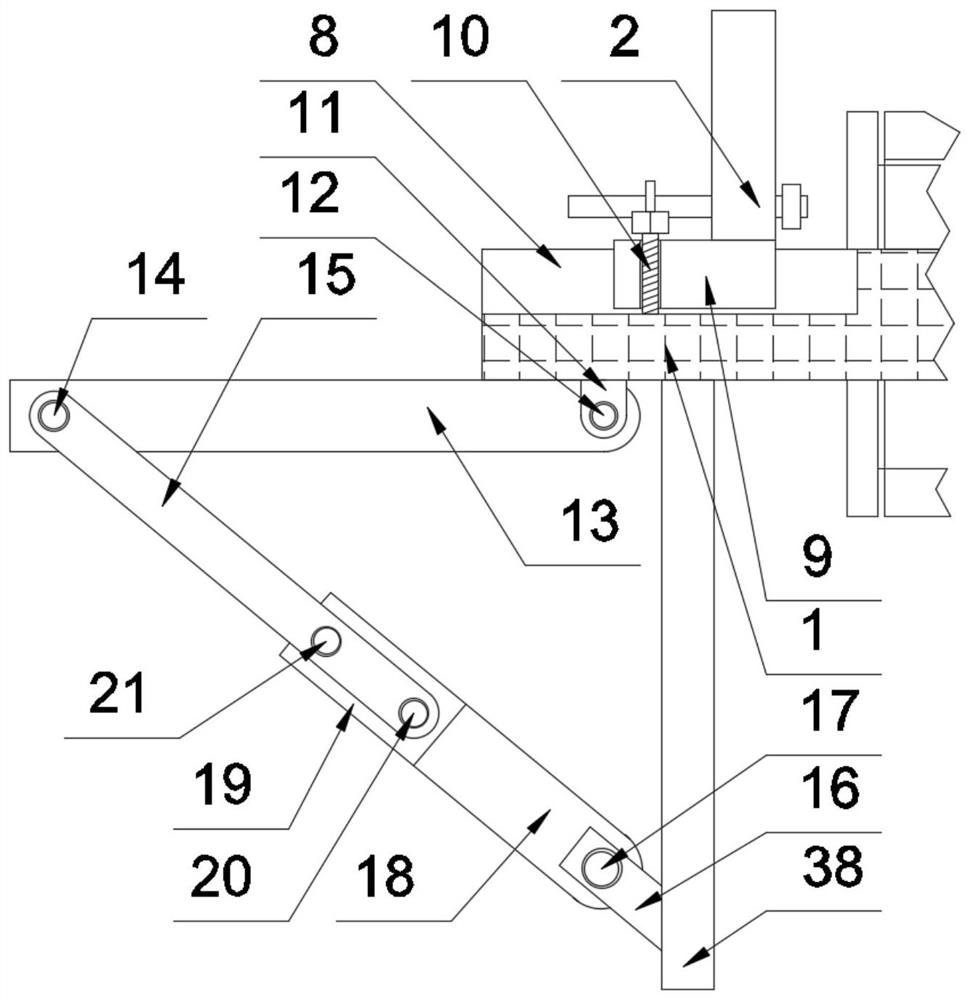

Telescopic heavy building pipe clamping and lifting mechanism

ActiveCN107399681AEasy to take by handReduce the amount of manual laborCranesLoad-engaging elementsArchitectural engineeringDrive motor

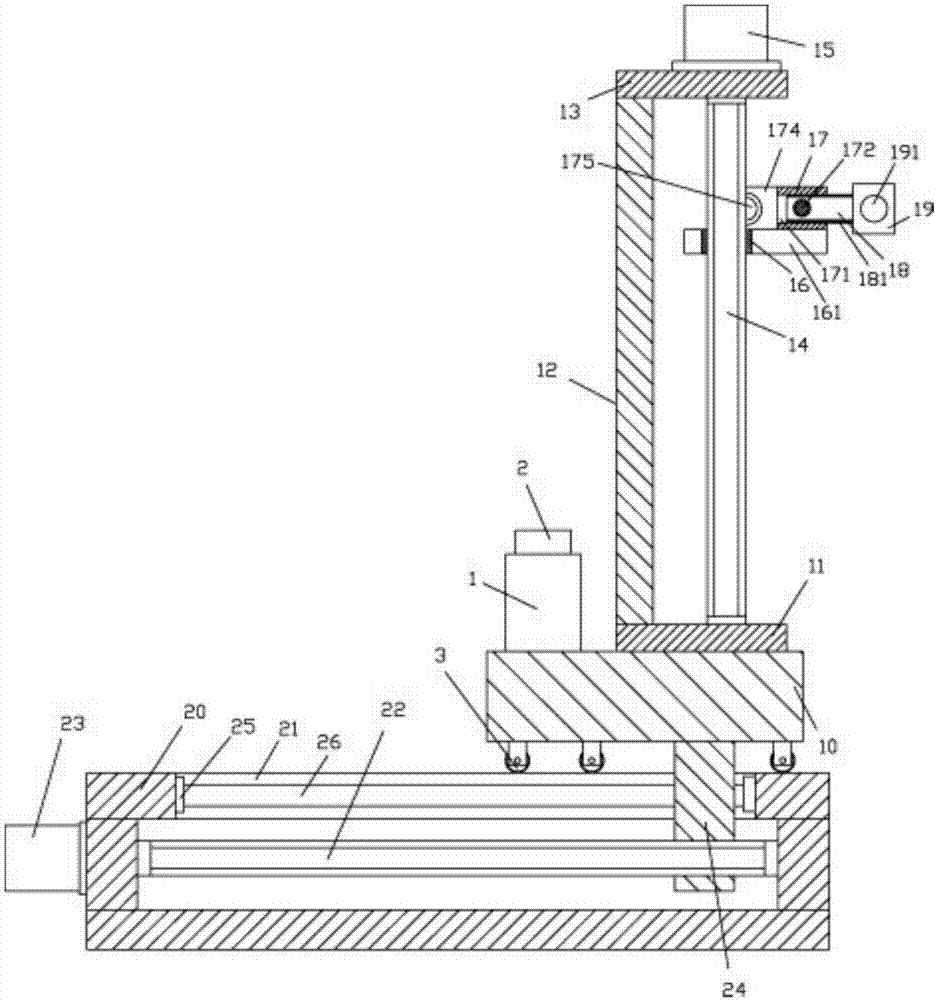

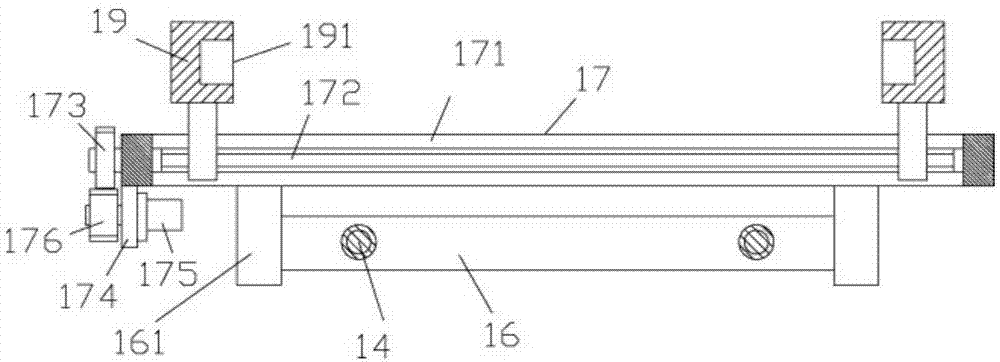

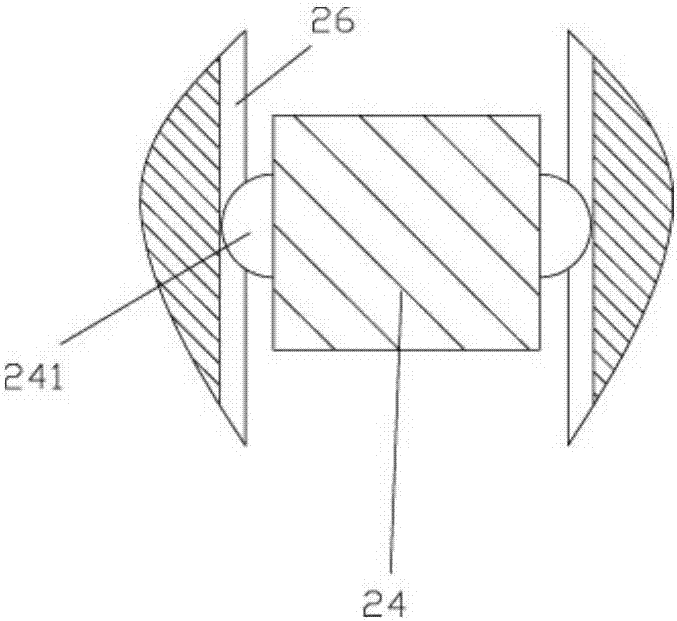

The invention discloses a telescopic heavy building pipe clamping and lifting mechanism which comprises a base and a mobile main frame body, wherein a transverse mobile straight groove is formed in the middle of a top plate of the mobile main frame body; a main transverse transmission screw rod is arranged in the middle of the mobile main frame body; two ends of the main transverse transmission screw rod are hinged with two side plates of the mobile main frame body; a transverse main drive motor is fixed on the outer side wall of one side plate; an output shaft of the transverse main drive motor is a spline shaft; the spline shaft is inserted into and sleeved with a splined hole in one end of the main transverse transmission screw rod; a push block is screwed into the main transverse transmission screw; the top of the push block extends out of the transverse mobile straight groove and is fixed on the bottom surface of the base; and a bottom support plate is fixed on the top surface of the base. The telescopic heavy building pipe clamping and lifting mechanism can be arranged on a push vehicle, and two ends of a pipe can be automatically clamped and lifted and pushed to the upper connecting part of a building, so that manual taking for installation is facilitated, the manual labor is greatly reduced and the efficiency is improved.

Owner:郴州恒邦建筑工程有限公司

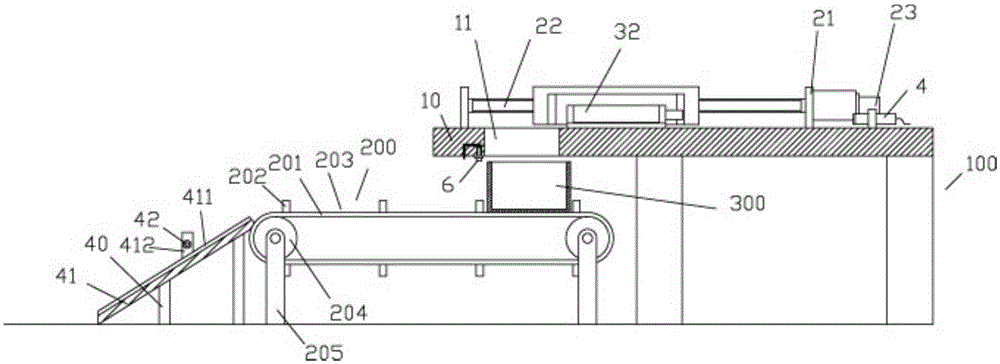

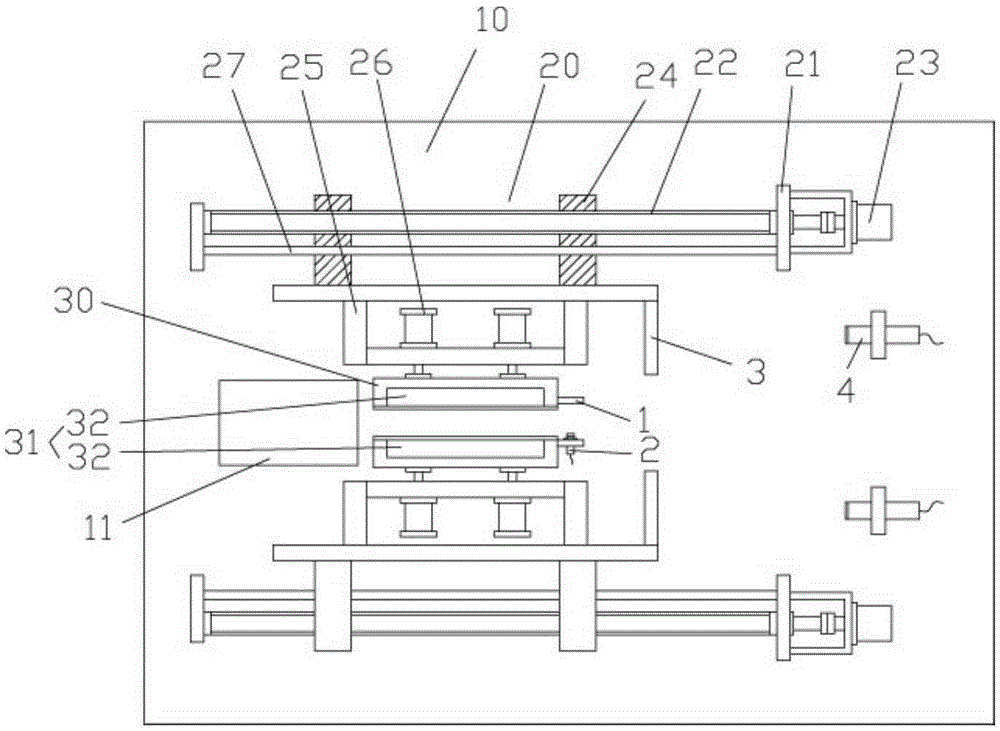

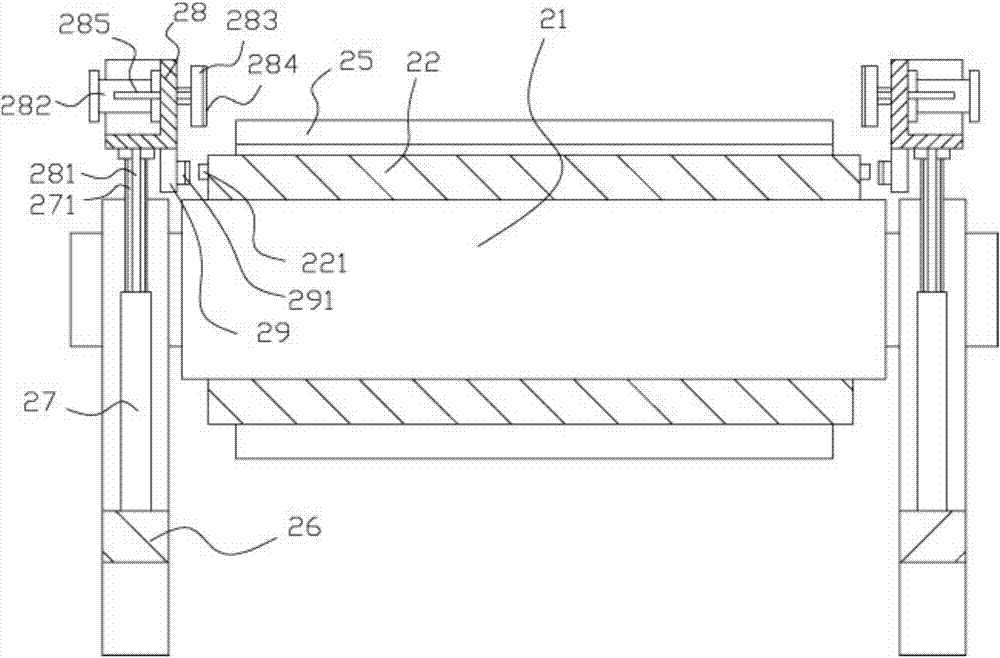

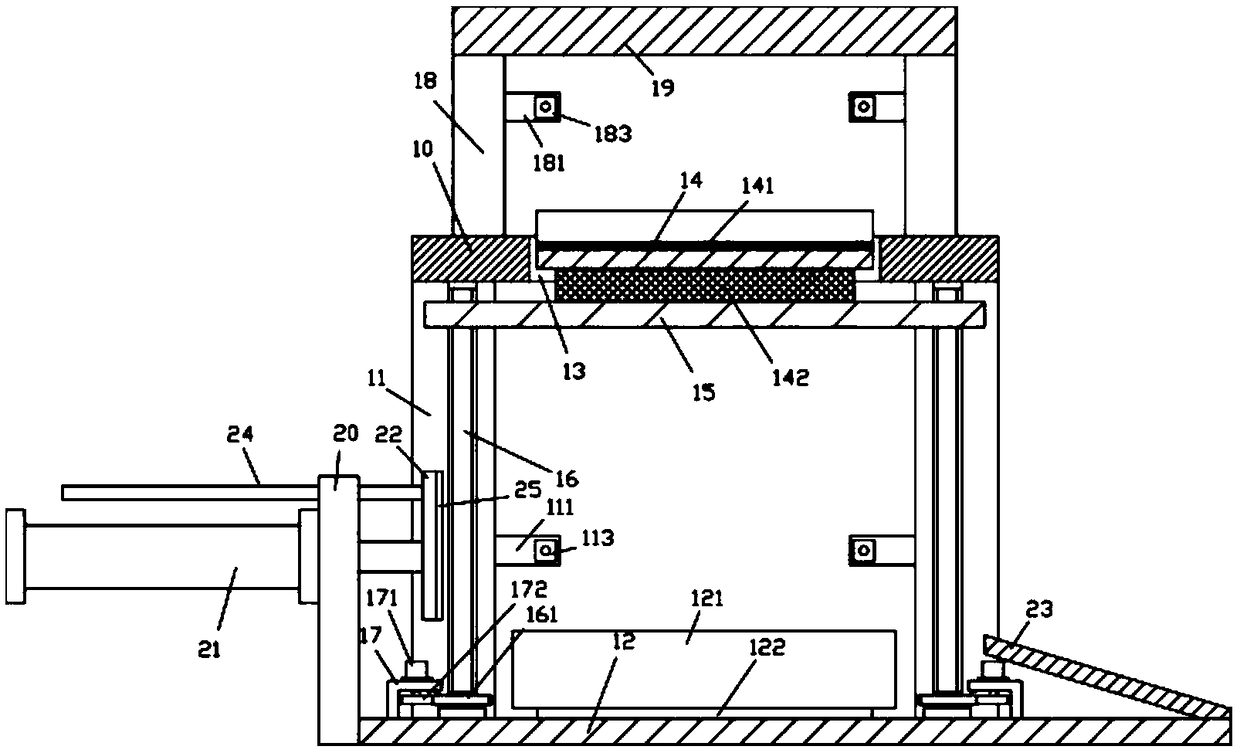

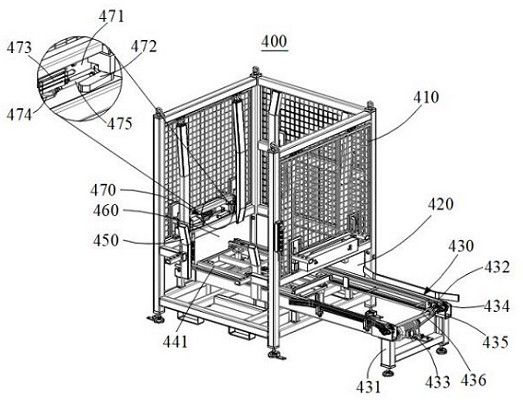

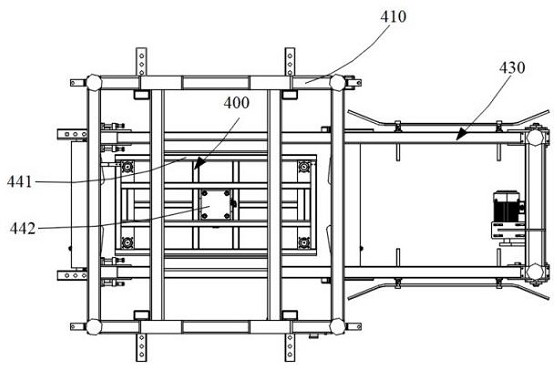

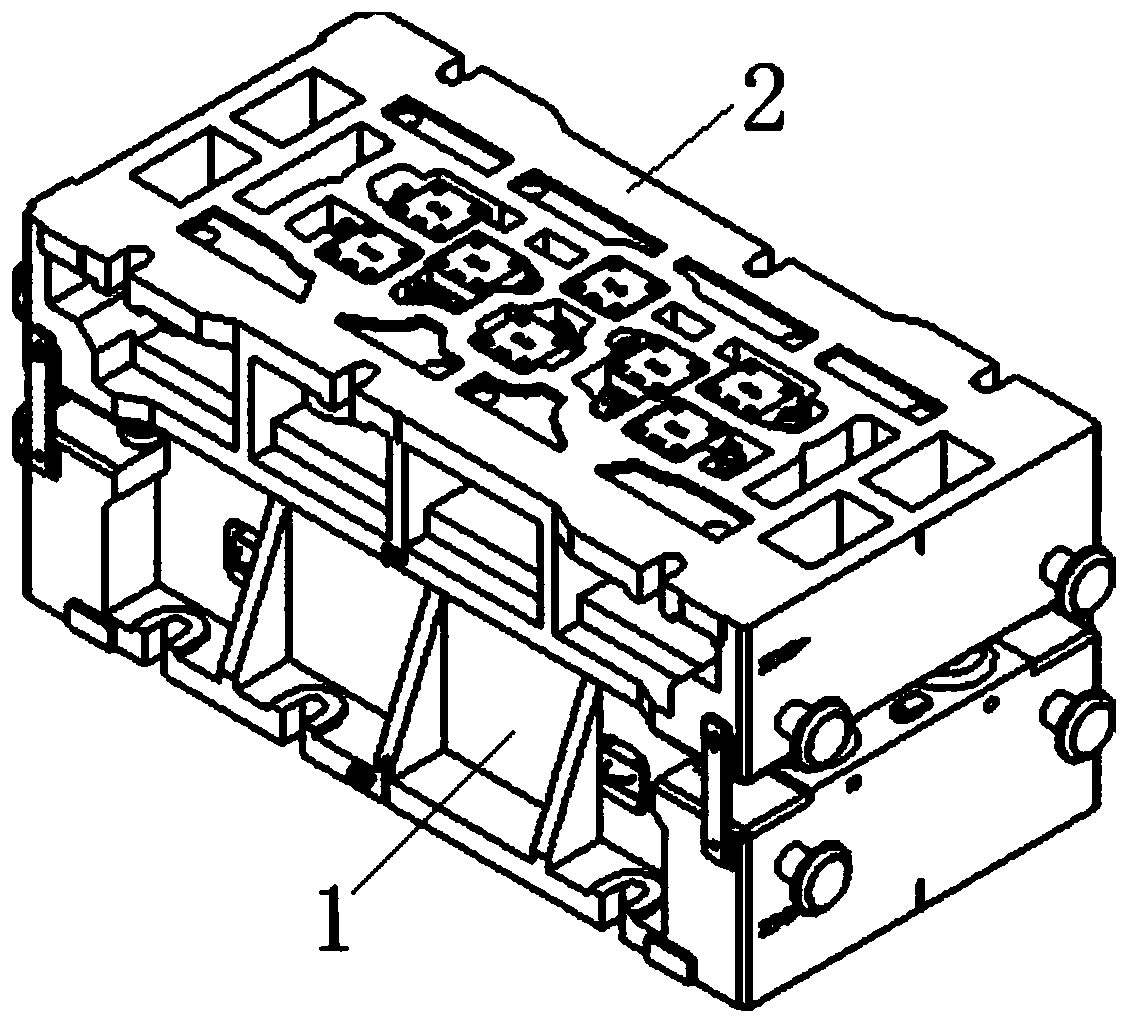

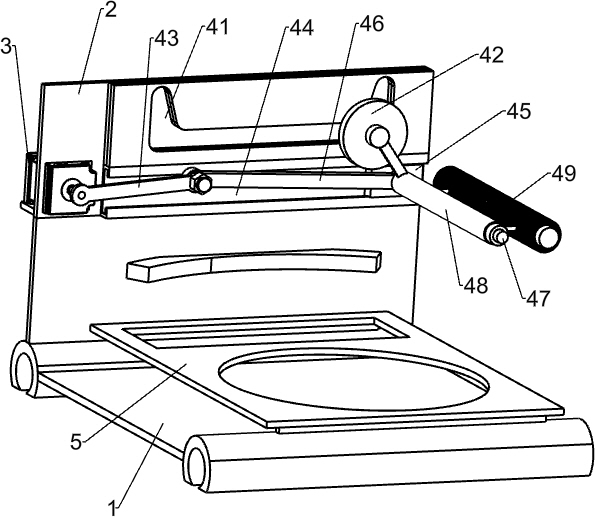

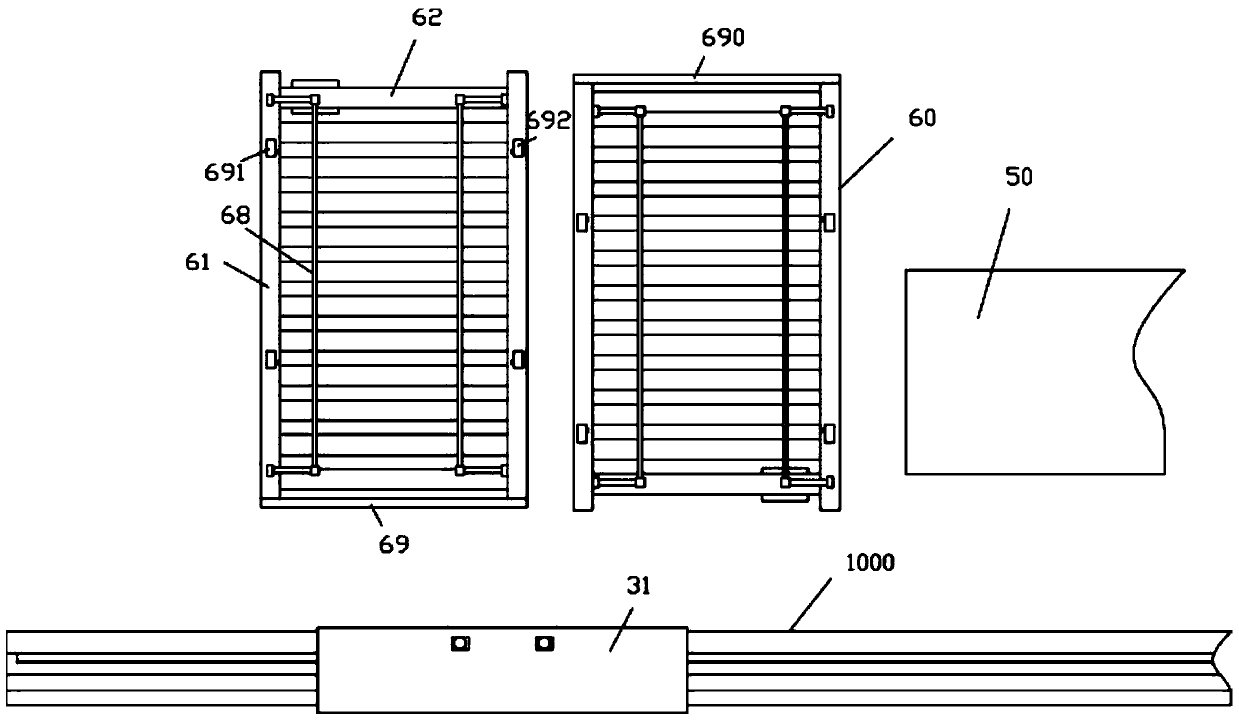

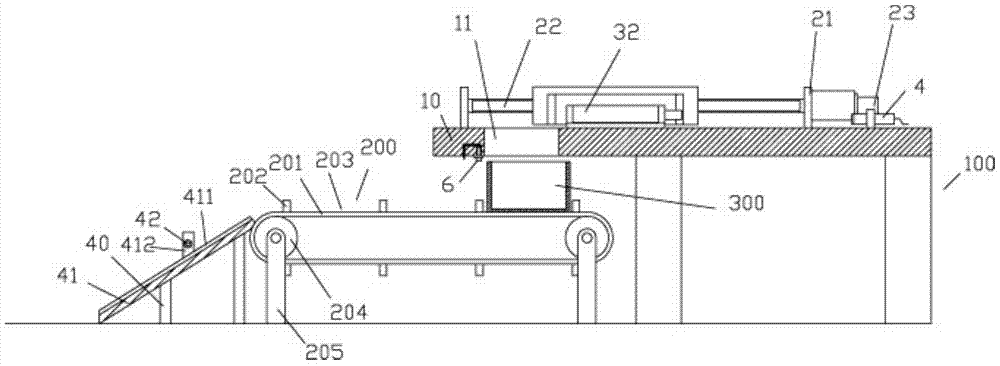

Mask packaging, conveying and metering device

The invention discloses a mask packaging, conveying and metering device which comprises a main supporting frame. A main supporting plate is arranged at the upper portion of the main supporting frame. The front and back sides of the main supporting plate are each fixedly provided with a moving mechanism. Each moving mechanism is structurally characterized in that two supporting plates are fixed to the main supporting plate, the two ends of a rotating screw are hinged to the two supporting plates, a driving motor is fixedly arranged on one supporting plate, moving blocks are in screw connection with the rotating screw, a pushing frame is fixedly arranged on the moving blocks, and at least one pushing air cylinder is fixedly arranged on the pushing frame. Push rods of the pushing air cylinders of the two pushing frames stretch out oppositely and are fixedly provided with receiving frames. A discharging through hole is formed in the left end of the main supporting plate. A conveying frame is fixedly arranged on the ground below the main supporting frame. The lower portion of the discharging through hole is just opposite to a conveying belt of the conveying frame. The mask packaging, conveying and metering device can receive a certain number of packaged masks, automatically convey the masks and place the masks into a box, automatically count the number of the masks and move the masks to the ground, facilitates manual taking for follow-up arrangement and is quite convenient to use.

Owner:贵州中开生物科技有限公司

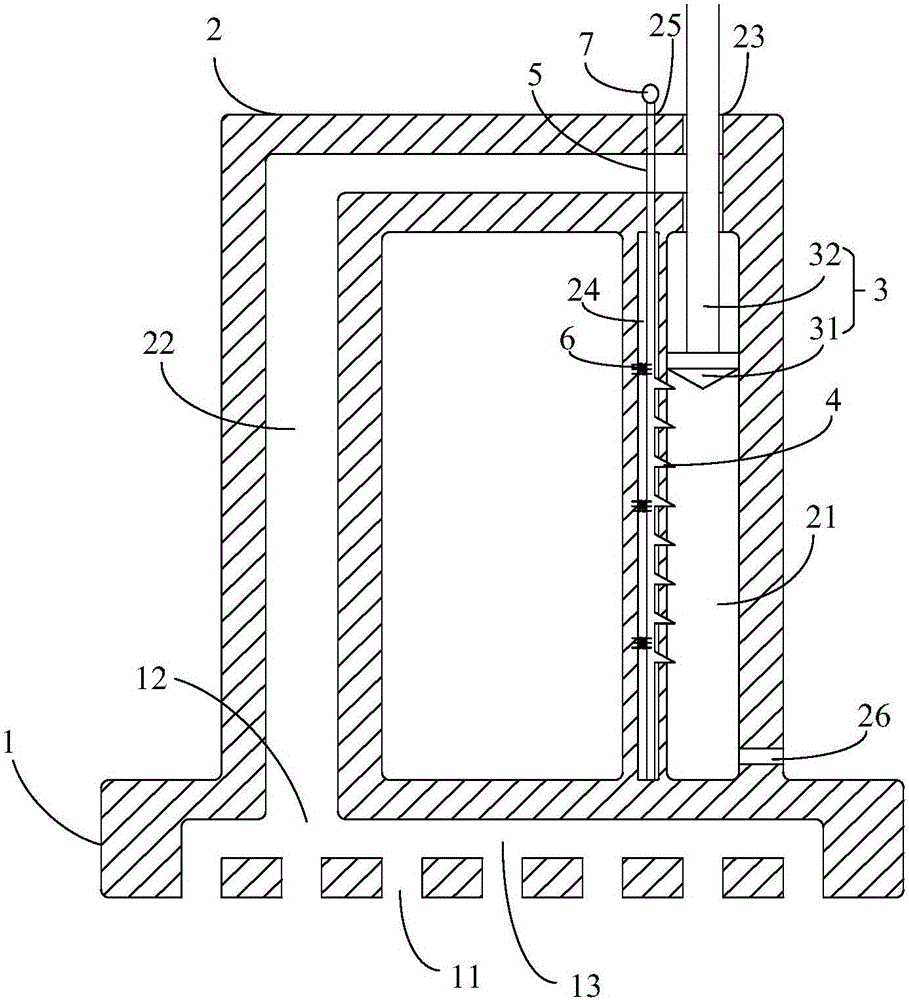

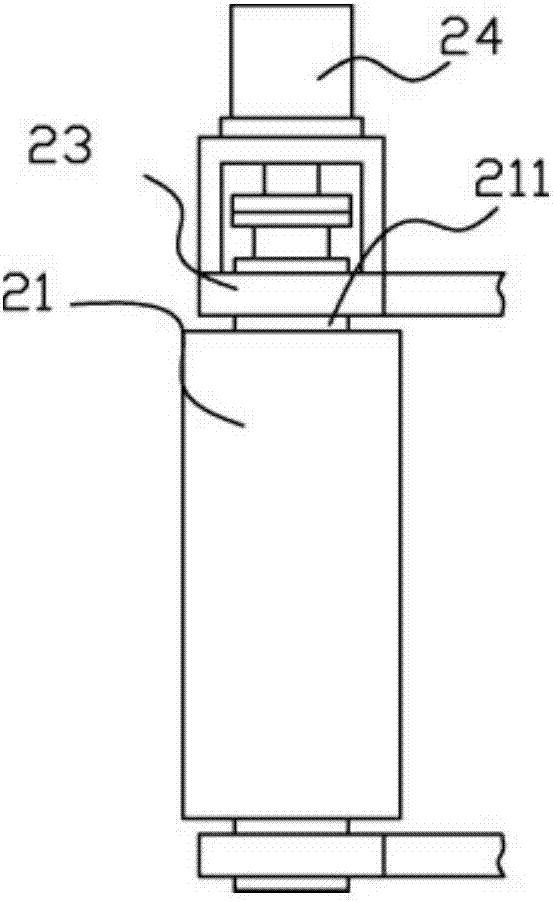

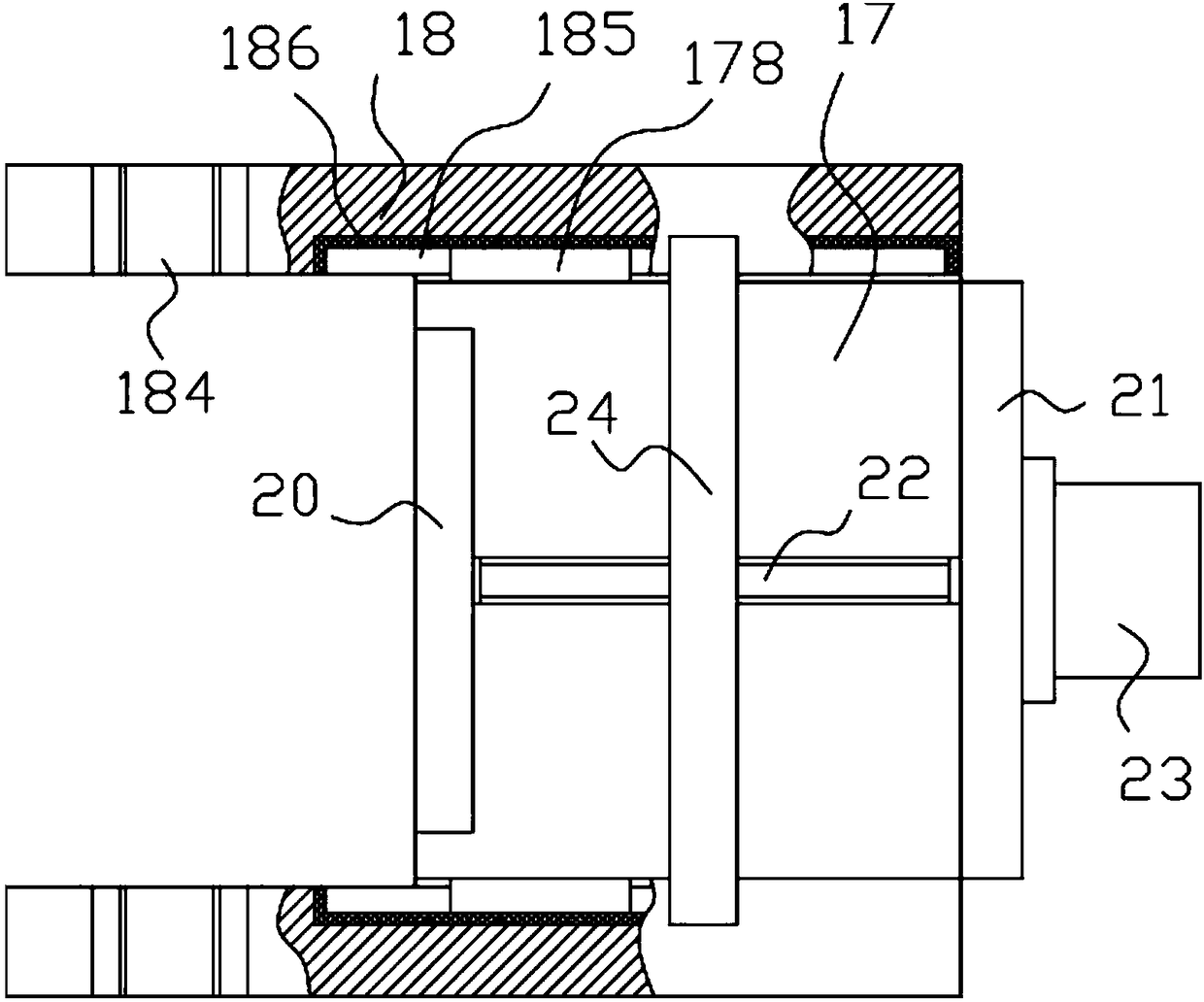

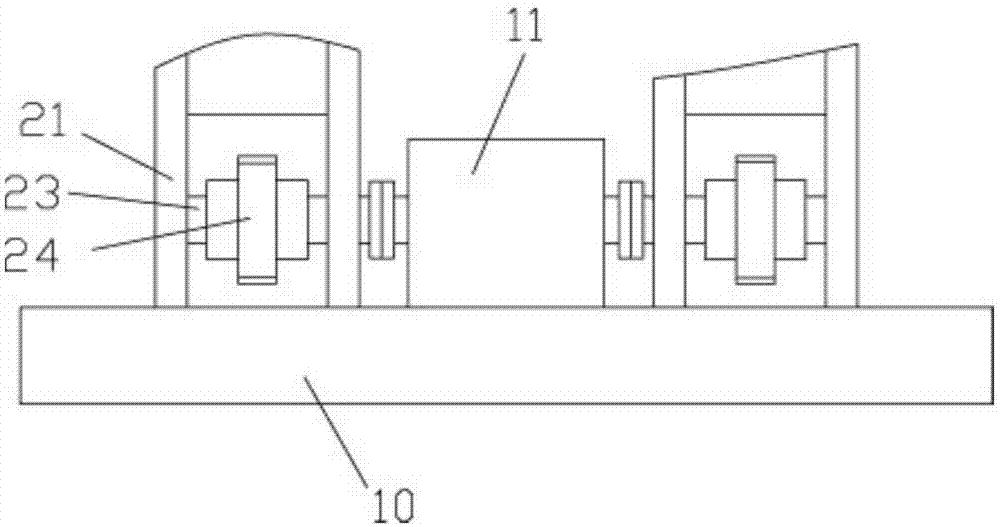

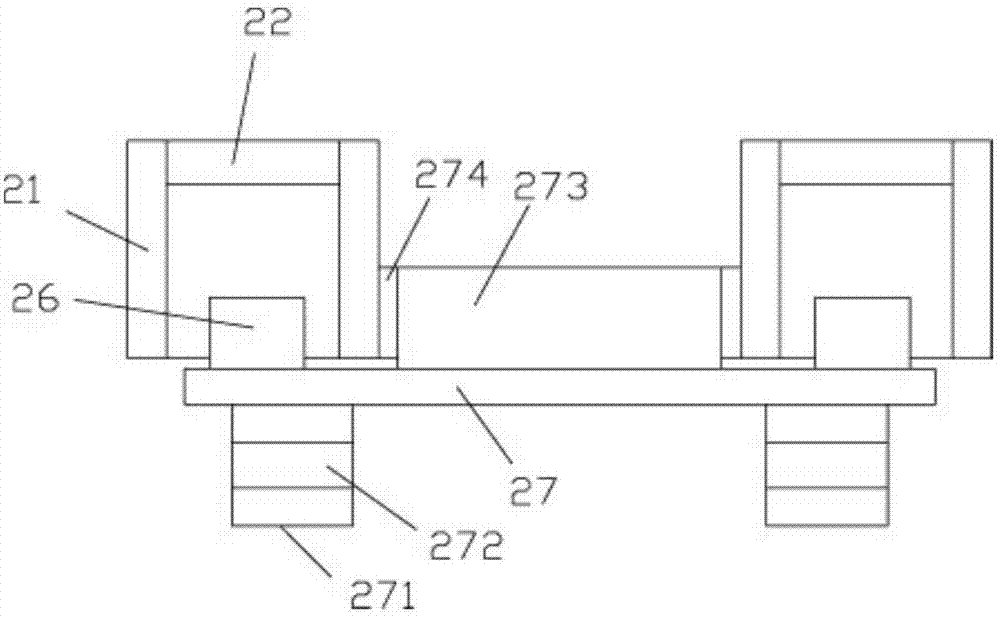

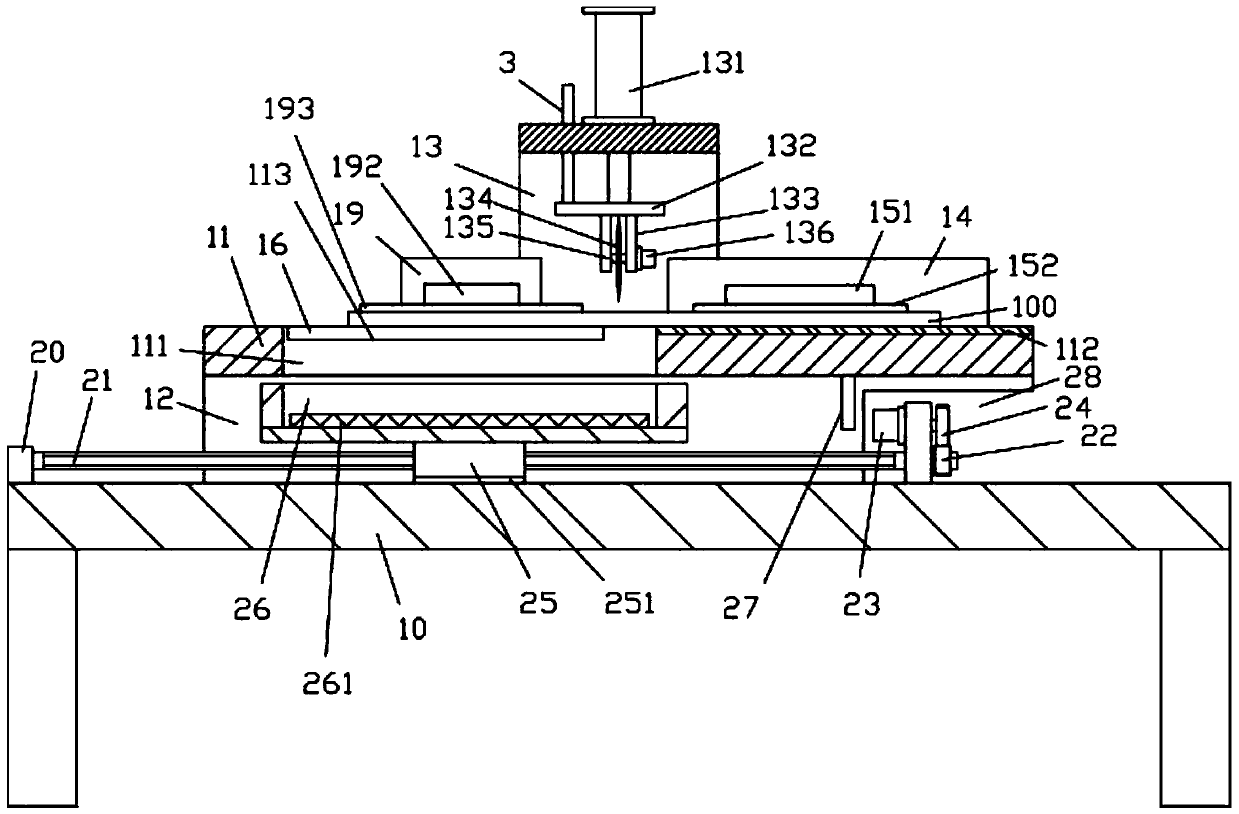

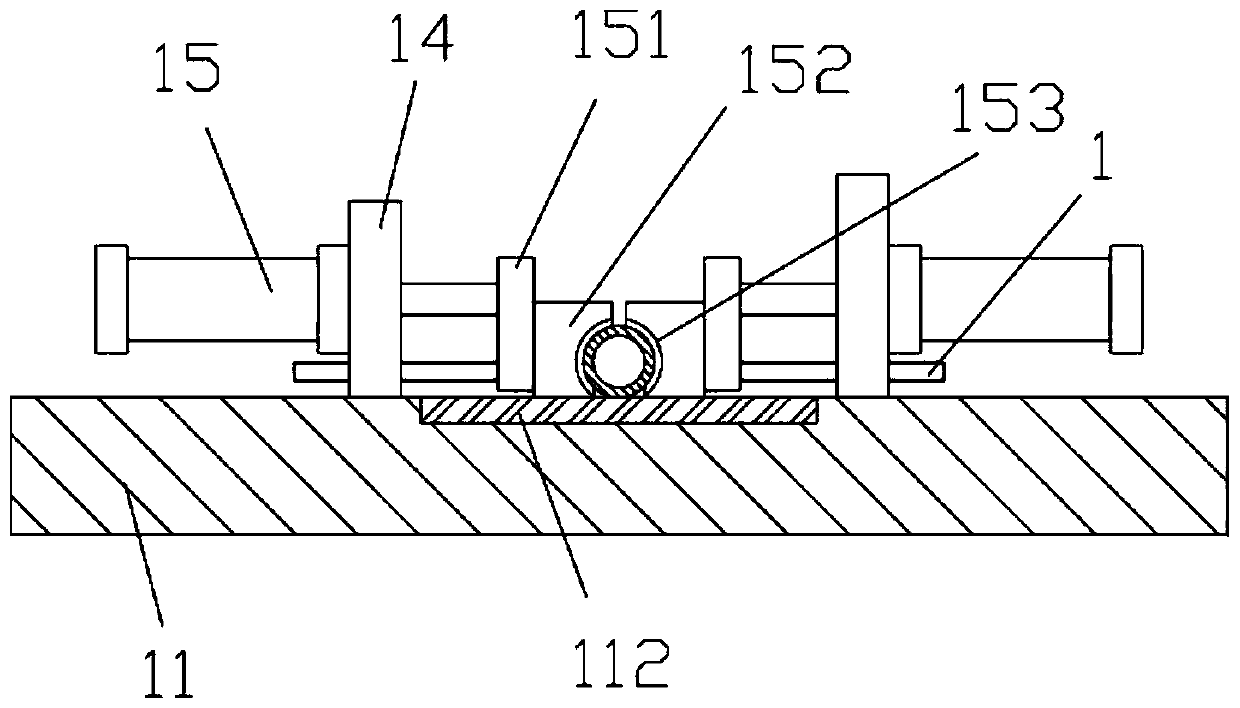

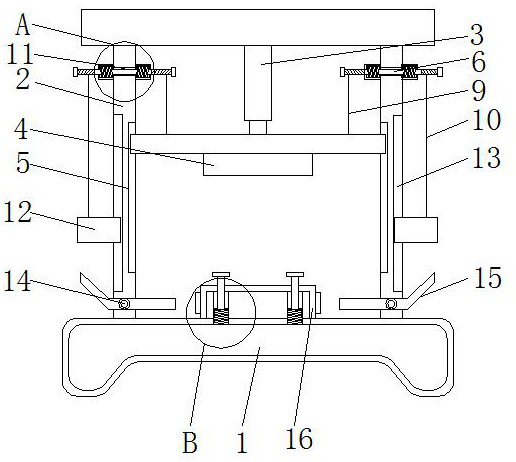

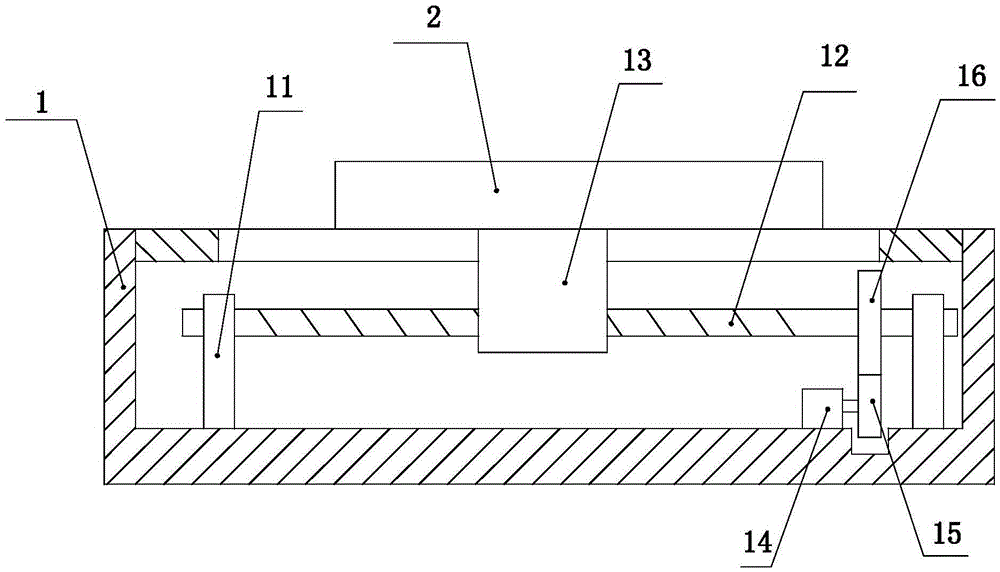

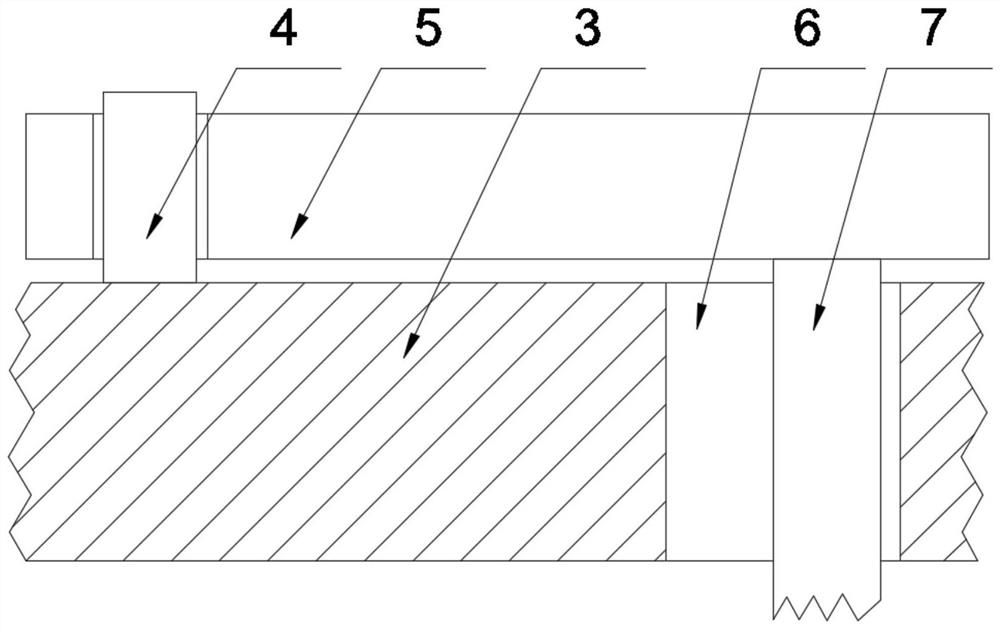

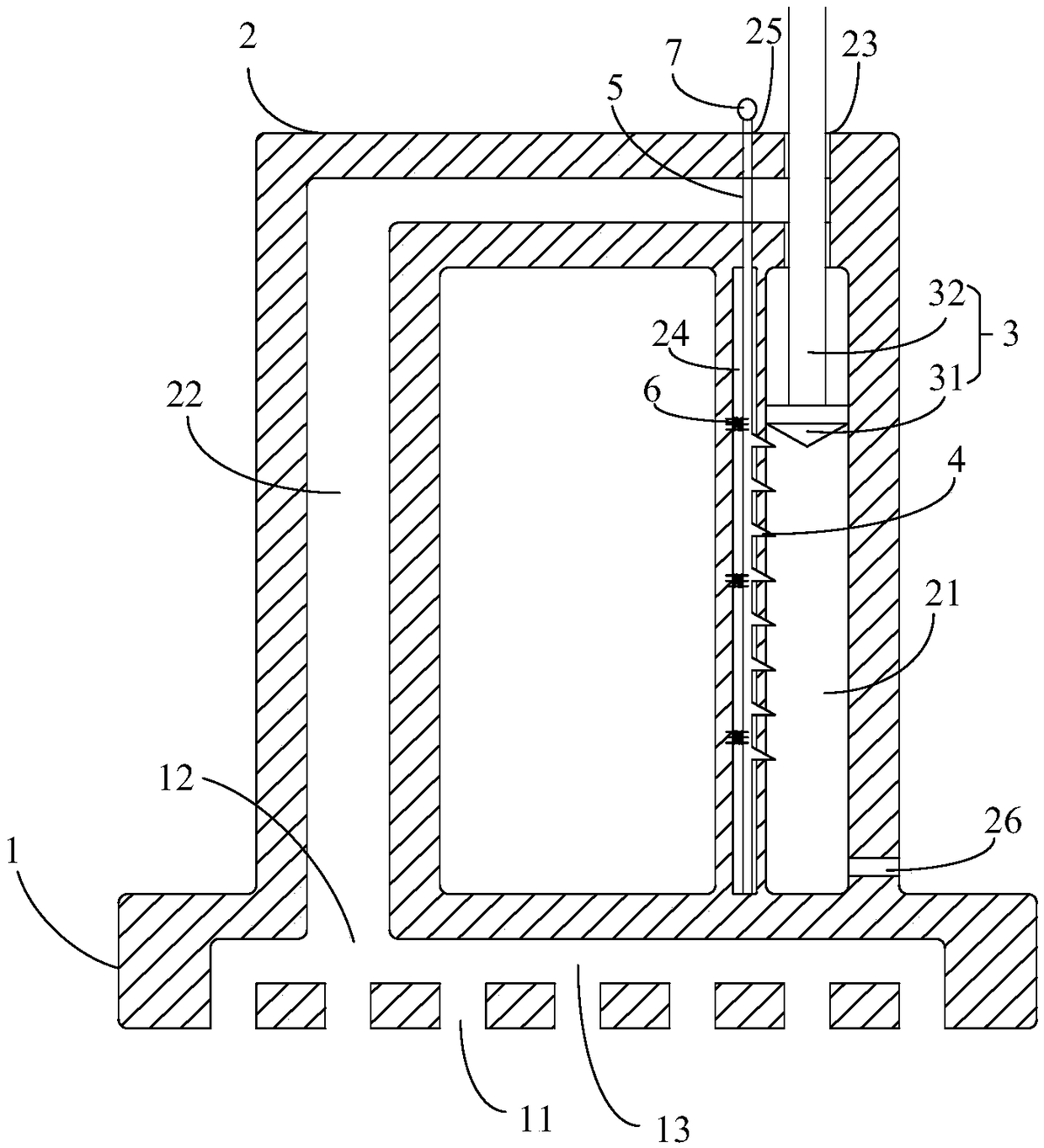

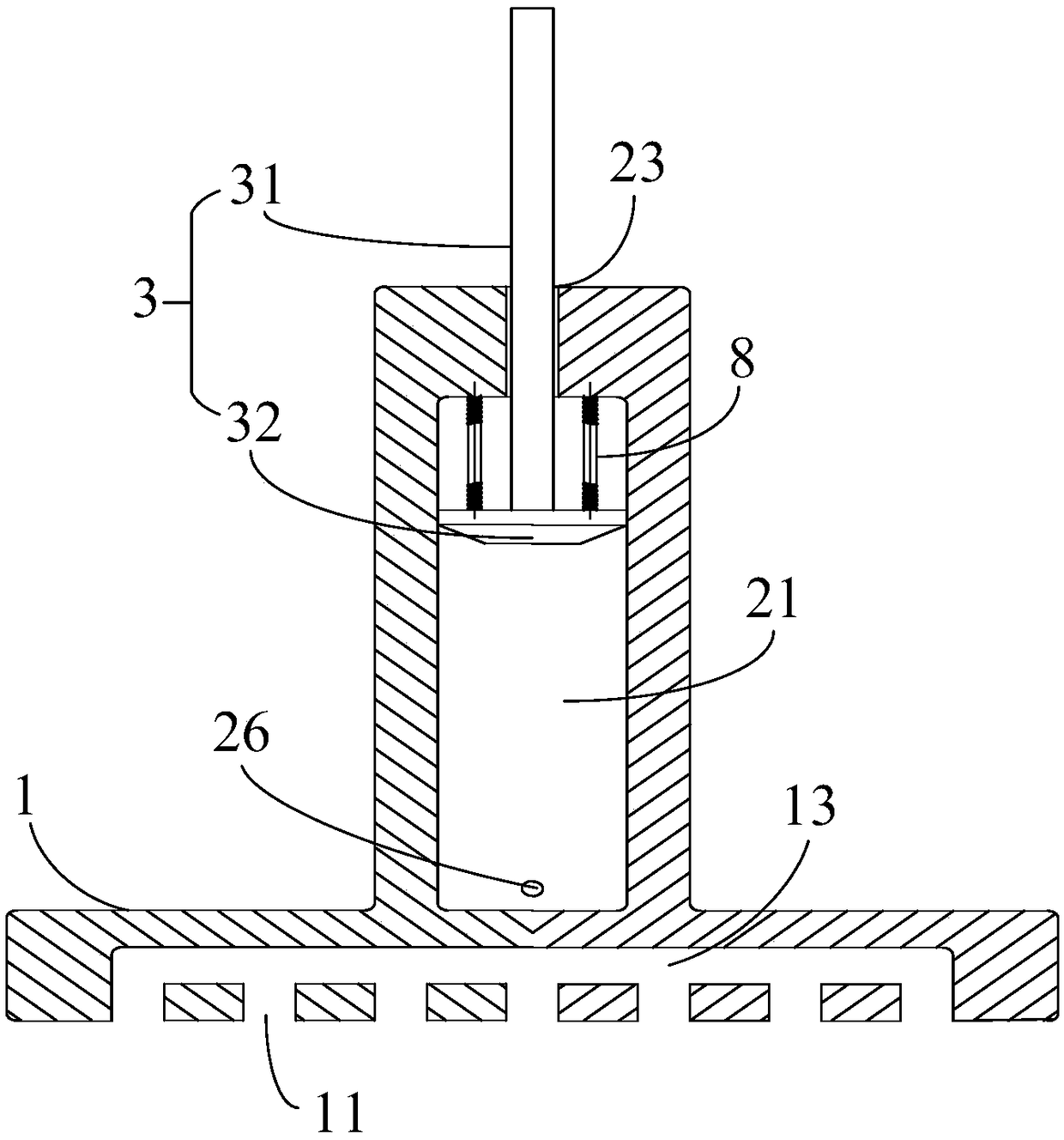

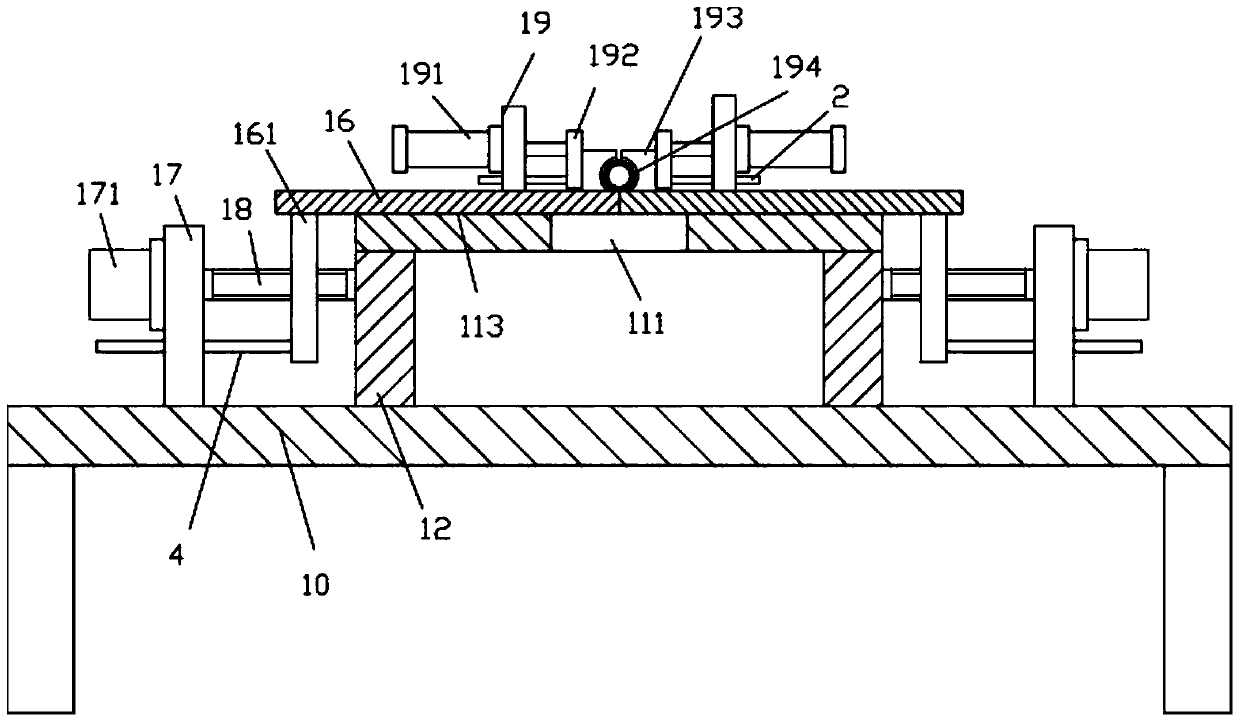

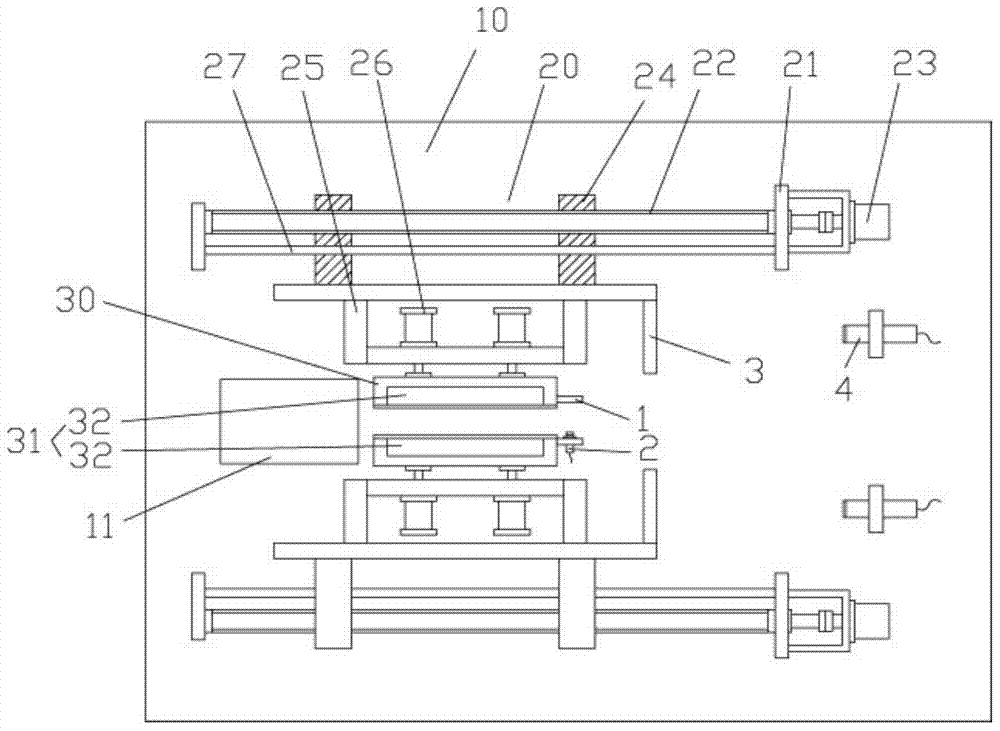

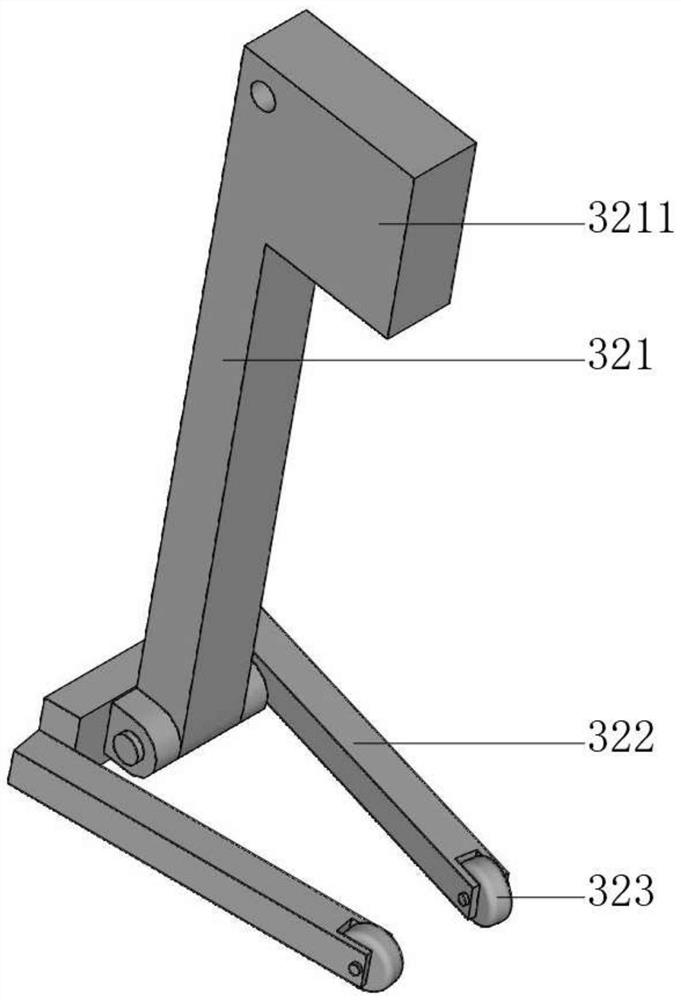

Heavy building pipe material clamping and lifting mechanism

InactiveCN107399692AEasy to take by handReduce the amount of manual laborLifting framesArchitectural engineeringDrive motor

The invention discloses a clamping and lifting mechanism for heavy-duty construction pipe materials, which includes a base, a bottom support plate is fixed on the top surface of the base, a vertical main board is fixed on the rear top surface of the bottom support plate, and a vertical main board is fixed on the top surface of the vertical main board. An upper support plate is fixed, and at least two vertical screws are located on the left and right sides of the bottom support plate. The bottom ends of the vertical screws are hinged on the bottom support plate, and the top ends of the vertical screws are hinged on the upper support plate. There are drive motors fixed on the left and right sides of the top surface, the output shaft of the drive motor is a spline shaft, and the spline shaft is inserted into the spline hole at the top of the vertical screw rod, and the moving block is screwed into the two vertical screw rods. A transverse beam is fixed on the moving block, and the front wall of the transverse beam has a transverse through groove protruding backward. The invention can be installed on a push cart, which can automatically clamp and lift both ends of the pipe material to the upper part of the building to facilitate manual picking and installation, greatly reducing the amount of manual labor and improving efficiency.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Panel grabber

ActiveCN106800186AEasy to take by handGreat suctionWork holdersConveyor partsSuction stressEngineering

The invention provides a panel grabber comprising: a suction cup, a U-shaped tube and a piston, wherein the suction cup is provided with a suction cup inner cavity, and comprises a first surface and a second surface which are arranged oppositely; the first surface of the suction cup is provided with at least one first hole communicated with the suction cup inner cavity, and the second surface of the suction cup is provided with a second hole communicated with the suction cup inner cavity; a first end and a second end of the U-shaped tube are arranged on the second surface of the suction cup, and the second end is connected with the second hole to enable the suction cup inner cavity to be communicated with the U-shaped tube; the U-shaped tube comprises a first side tube and a second side tube, the first end is positioned on the first side tube, and the second end is positioned on the second side tube; the other end, opposite to the first end, of the first side tube is provided with a first opening; and one end of the piston is inserted in the first opening, and can move in the first side tube, the width of one end of the piston is matched with the width of the first side tube, and the width of the other end of the piston is matched with the width of the first opening. The magnitude of suction for grabbing a panel can be controlled by controlling the distance of piston movement.

Owner:BOE TECH GRP CO LTD +1

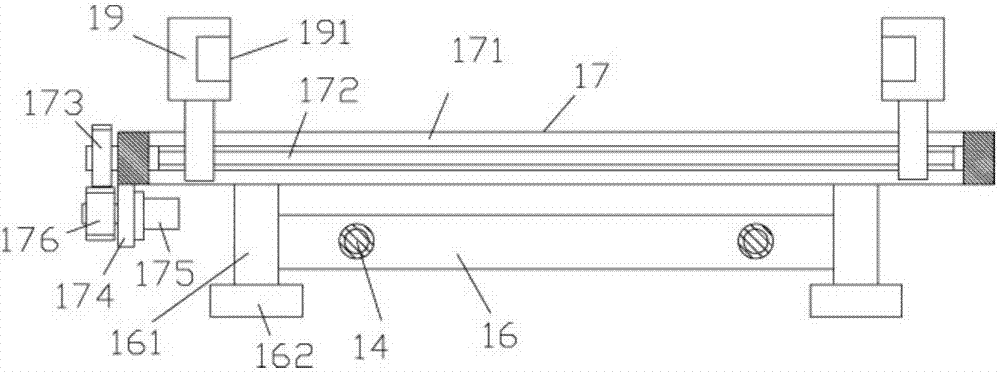

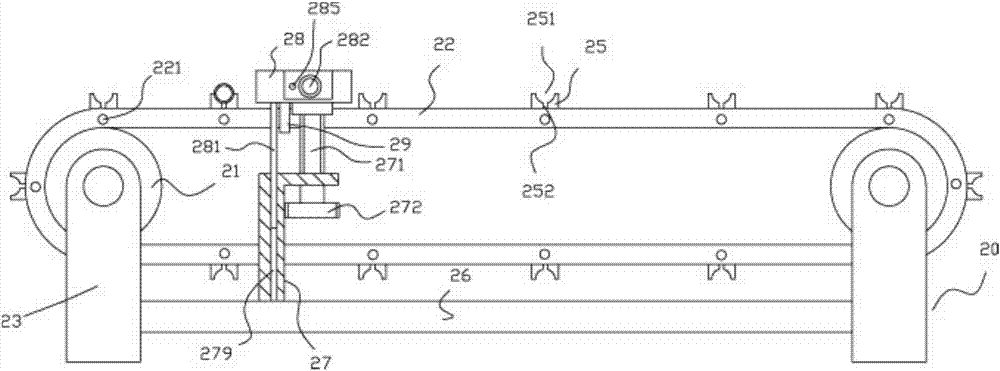

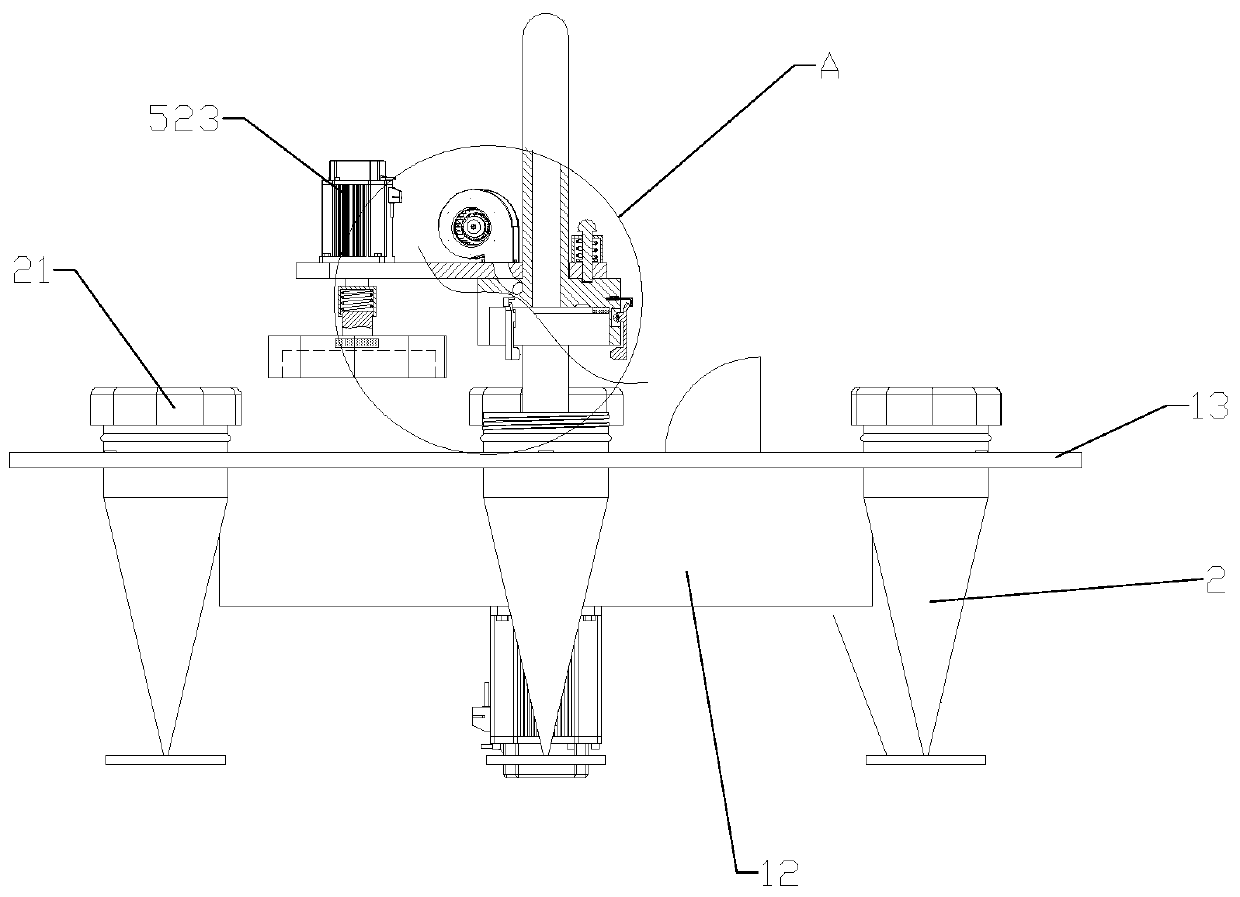

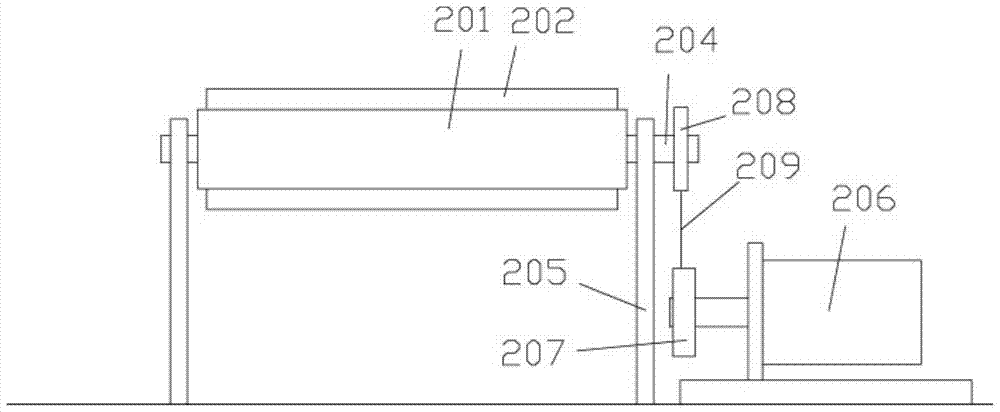

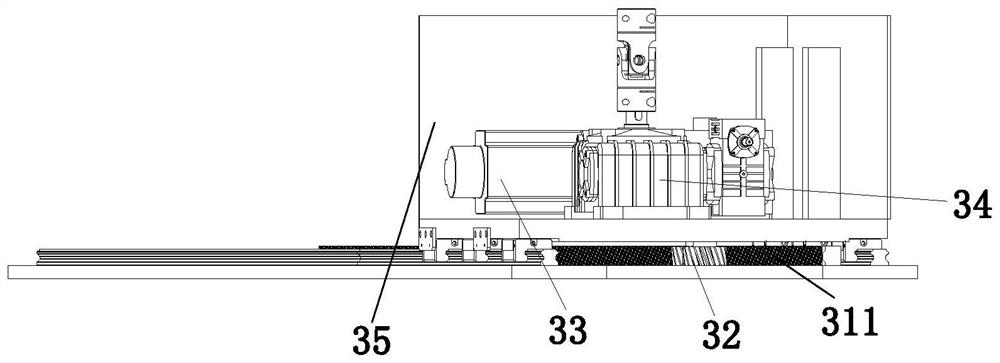

Automatic conveying mechanism of illuminating fluorescent tubes with automatic adjustment mechanism

InactiveCN107380974AHigh degree of automationImprove efficiencyConveyorsControl devices for conveyorsCouplingEngineering

The invention discloses an automatic conveying mechanism for lighting fluorescent tubes with an automatic adjustment mechanism, which includes a conveying frame. Drive rollers are hinged at the left and right ends of the conveying frame. The conveyor belt is stretched on the two driving rollers. One end is formed with a protruding column, which extends out of the legs of the conveyor frame and is connected with the output shaft of the transmission motor fixed on the leg through a coupling, and a plurality of lamp tube placement blocks are fixed on the outer wall of the conveyor belt , the outer wall surface of the lamp tube placement block is formed with an installation groove; the conveying frame includes four legs, and an intermediate beam is arranged between the two legs on the same side, and the two ends of the intermediate beam are fixed on the two legs Above, the middle top surface of the middle beam is fixed with a vertical support frame, and the top plate of the vertical support frame is screwed with an adjusting stud. It can automatically transport multiple lamp tubes and automatically adjust the placed lamp tubes. It has a high degree of automation, is convenient for manual picking, does not need manual handling, and has high efficiency and good effect.

Owner:FOSHAN KERUIFEI NEW ENERGY TECH CO LTD

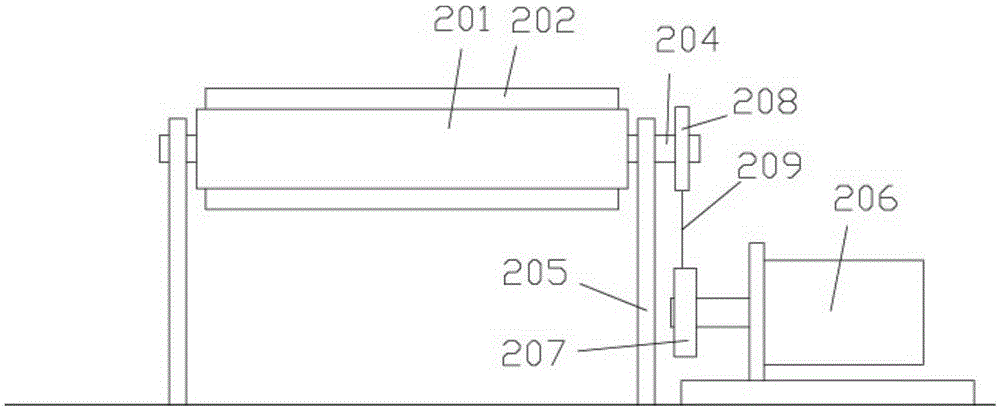

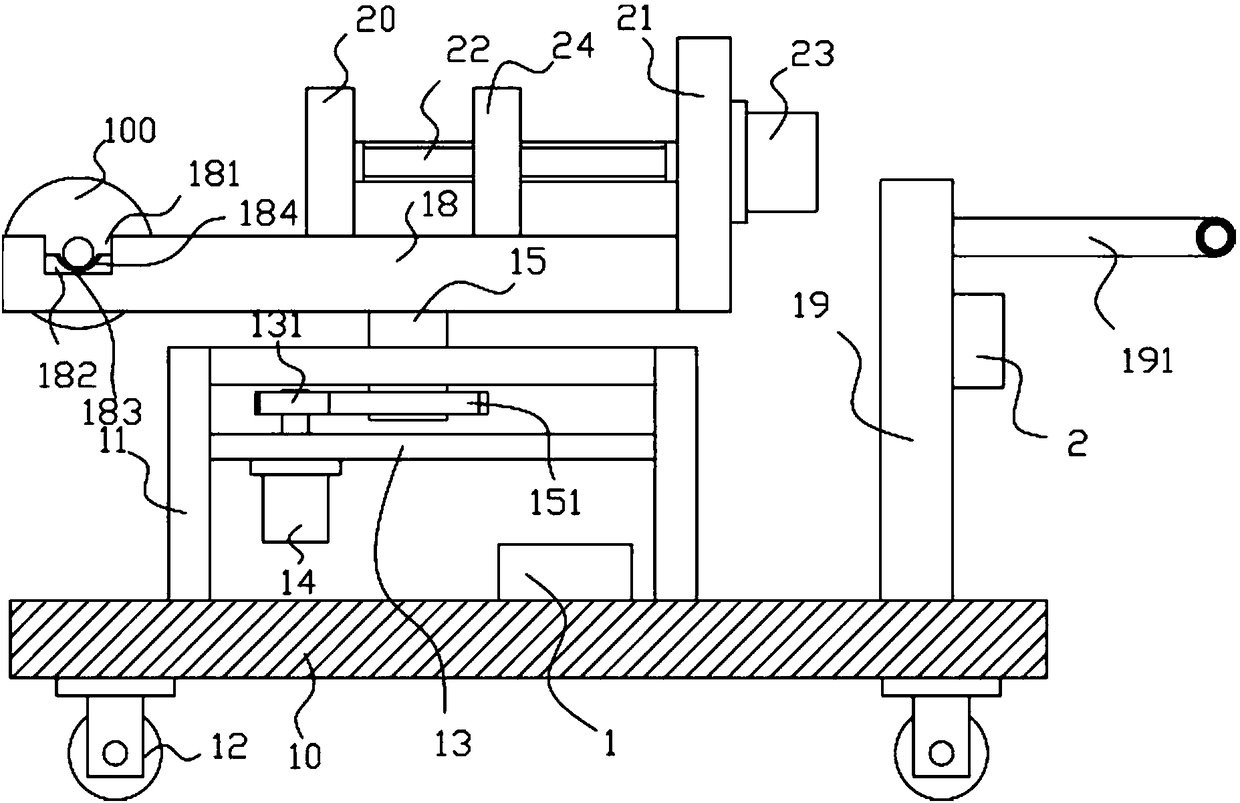

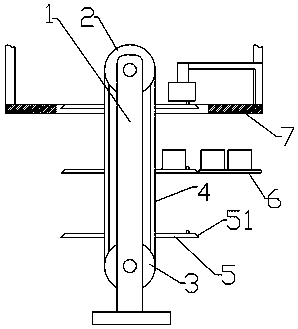

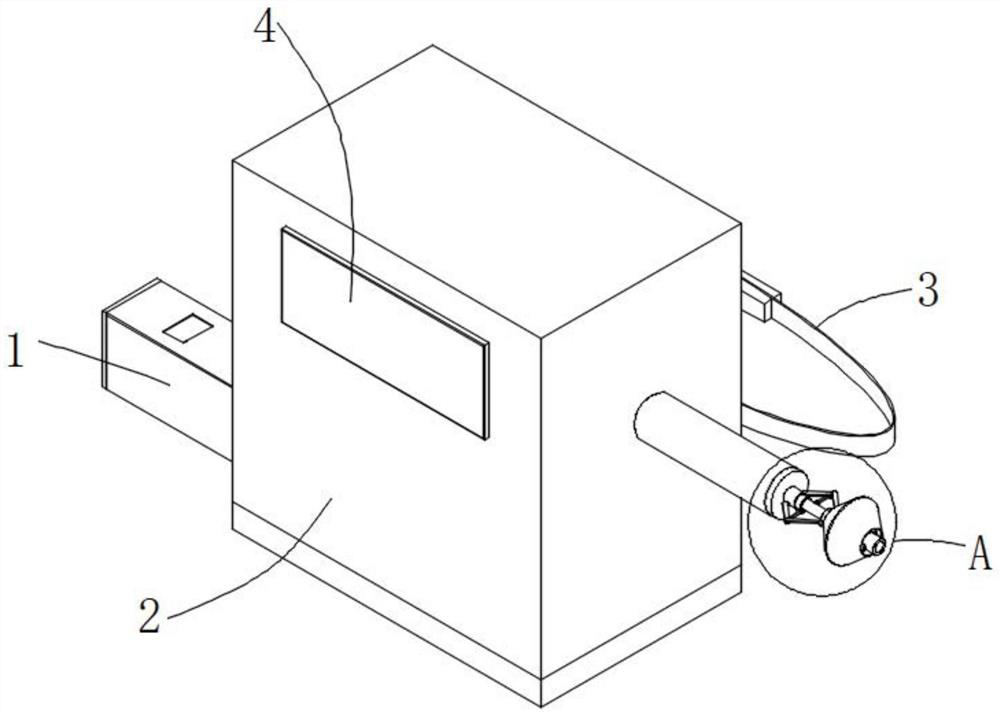

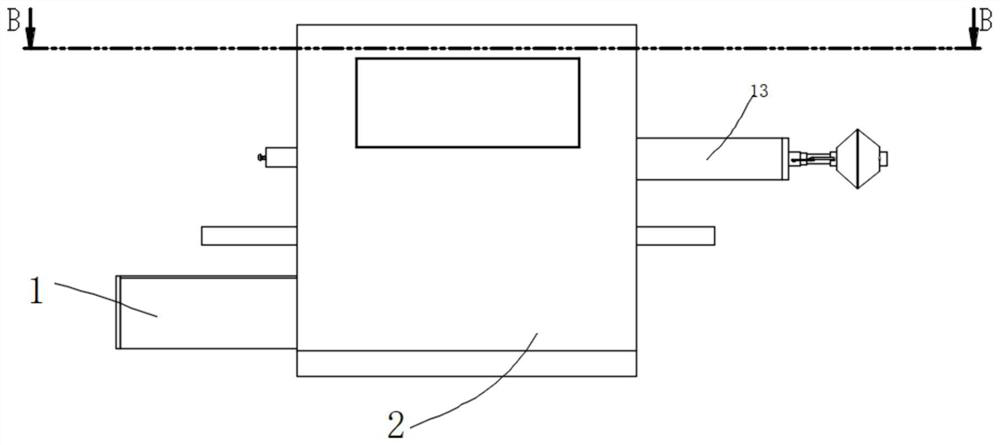

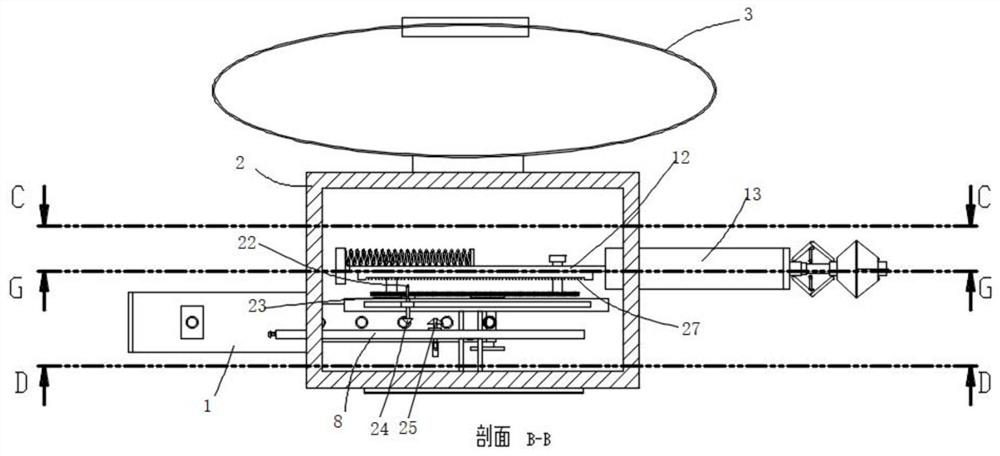

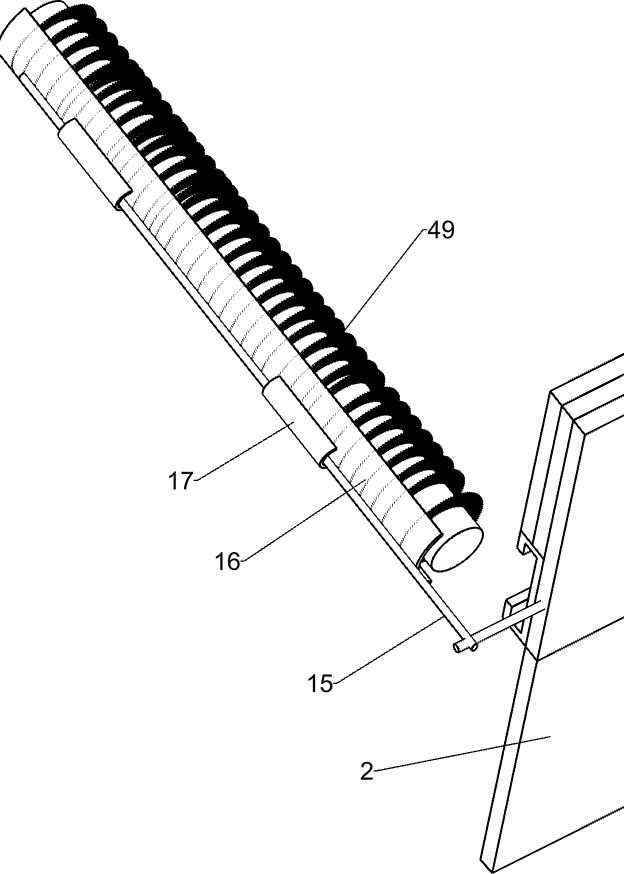

Carrier for lifting and horizontally moving fabric reels

InactiveCN108100731AImprove efficiencyEasy to take by handHand carts with multiple axesWebs handlingCouplingEngineering

The invention discloses a carrier for lifting and horizontally moving fabric reels. The carrier comprises a carrier bottom plate. A supporting frame is fixed to the top face of the carrier bottom plate, and a transverse plate is arranged in the supporting frame. A plurality of rotary motors are fixed to the bottom face of the transverse plate, and output shafts of the rotary motors penetrate through the transverse plate and are connected with a vertical screw through a coupling. The top end of the vertical screw stretches out of a top plate of the supporting frame and is in screw connection with an adjusting screw sleeve. The top end of the adjusting screw sleeve is located above the top plate of the supporting frame and fixed to the bottom face of a lifting plate. Supporting beams are arranged on the front side and the rear side of the lifting plate, a left supporting plate is fixed to the top face of the left end of the lifting plate, and a right supporting plate is fixed to the right side wall of the lifting plate. The two ends of a transverse screw are hinged to the left supporting plate and the right supporting plate, and a moving motor is fixed to the right side wall of the right supporting plate on the right side. According to the carrier, the fabric reels can be lifted by a certain height and horizontally moved to needed mounting positions, the fabric reels are manuallytaken conveniently to be mounted, the effect is good, the efficiency is high, and the manual labor intensity is relieved.

Owner:FOSHAN XUNAOJIE AUTOMATION TECH CO LTD

Carrier capable of horizontally moving and rotating fabric reels

InactiveCN108116468AEasy to take by handGood effectSupporting partsHand carts with multiple axesDrive shaftChassis

The invention discloses a carrier capable of horizontally moving and rotating fabric reels. The carrier comprises a carrier bottom plate, wherein a supporting frame is fixed on the top surface of thecarrier bottom plate; a plurality of wheels are fixed on the bottom surface of the carrier bottom plate; a horizontal plate is arranged in the supporting frame; the side wall of the horizontal plate is fixed on the inner side wall of the supporting frame; an adjusting rotary motor is fixed at the bottom surface of the horizontal plate; an output shaft of the adjusting rotary motor penetrates through the horizontal plate and is fixedly provided with a driving gear; a transmission shaft is hinged with a top plate of the supporting frame; the bottom end of the transmission shaft is positioned under the top plate of the supporting frame and is fixedly provided with a transmission gear which is meshed with the driving gear; the top end of the transmission shaft extends out of the top plate of the supporting frame and is fixedly provided with a lifting plate which is positioned above the top plate of the supporting frame. The carrier disclosed by the invention has the beneficial effects thata carrier chassis can be pushed by manual work to carry the fabric reels, simultaneously the fabric reels can be horizontally moved and rotated, so that the fabric reels can be ensured to be close toa place for installation and convenience is brought for workers to take and install the fabric reels; the effect is good, the efficiency is high and the manual labor is reduced.

Owner:FOSHAN XUNAOJIE AUTOMATION TECH CO LTD

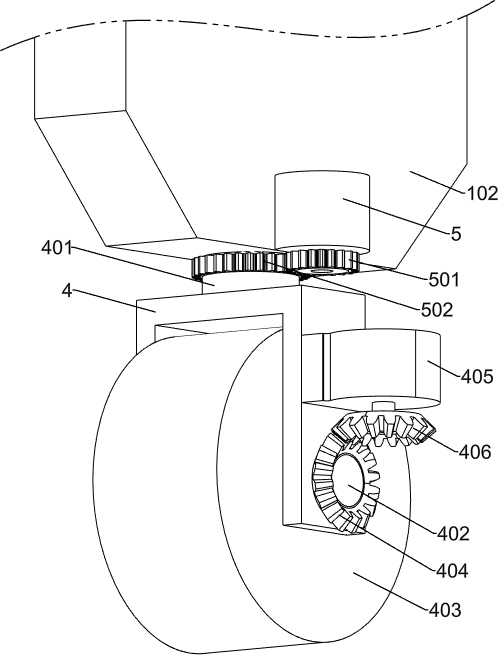

Building pipe lifting and rotating mechanism

InactiveCN107364818AEasy to take by handReduce the amount of manual laborLifting devicesGear wheelArchitectural engineering

The invention discloses a construction pipe material lifting and rotating mechanism, which includes a machine base and a connecting base. A rotating motor is fixed on the bottom surface of the middle part of the top plate of the connecting base. The output shaft of the rotating motor passes through the top plate of the connecting base and is fixed with a driving gear. , the bottom surface of the middle part of the base is fixed with a main shaft, the bottom of the main shaft is hinged in the top plate of the connection base, the transmission gear is fixed on the main shaft, the transmission gear meshes with the drive gear, and the bottom surface of the connection base is hinged with a plurality of wheels; Two vertical guide mechanisms are fixed on the front top surface of the support, and each vertical guide mechanism includes two vertical guide plates. The invention can be installed on the driving car body to move, it can automatically clamp and lift the pipe material and rotate the position, which is convenient for manual picking and installation, greatly reduces the amount of manual labor and improves efficiency.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

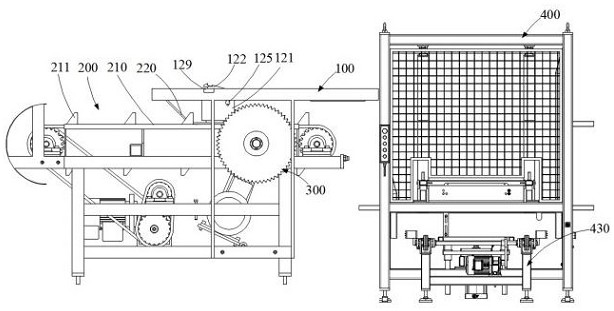

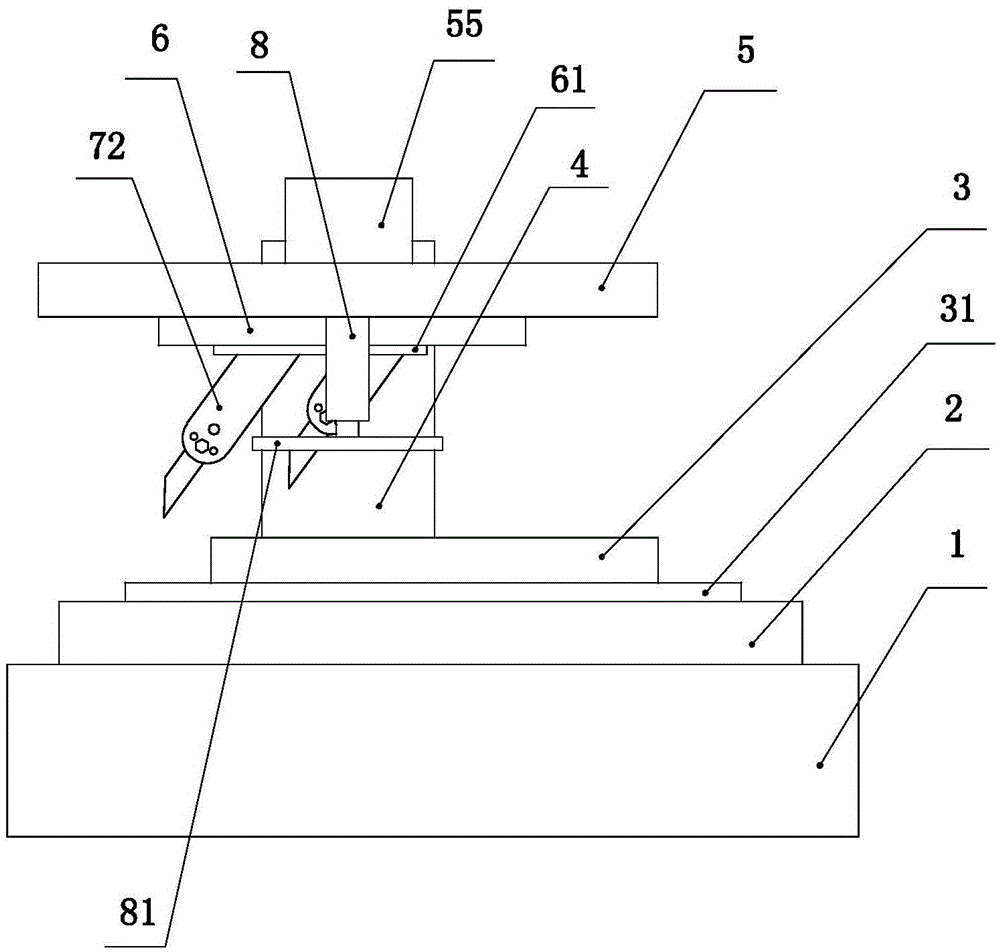

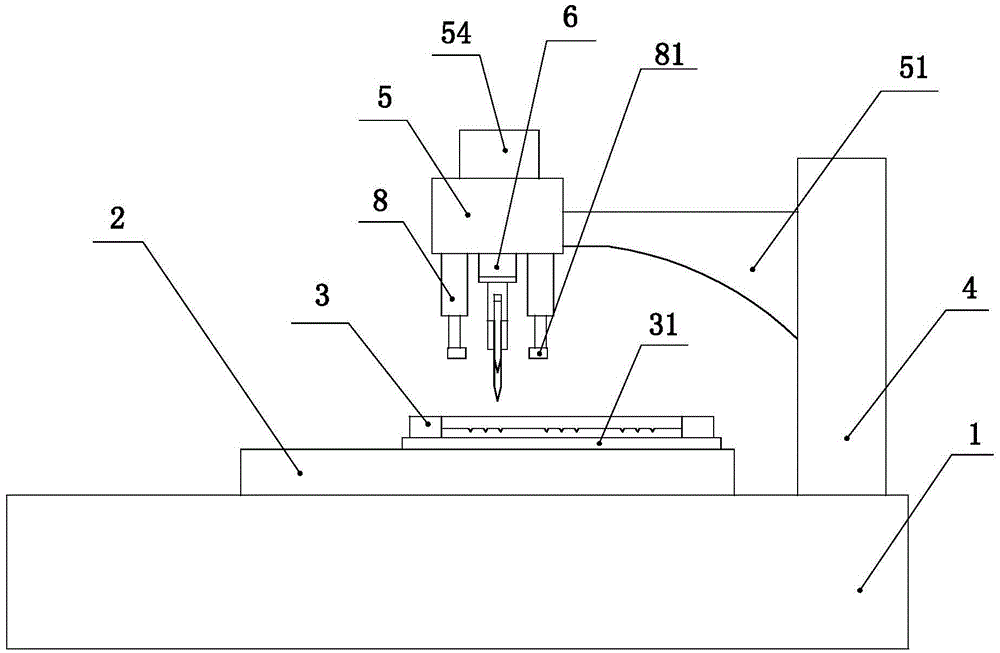

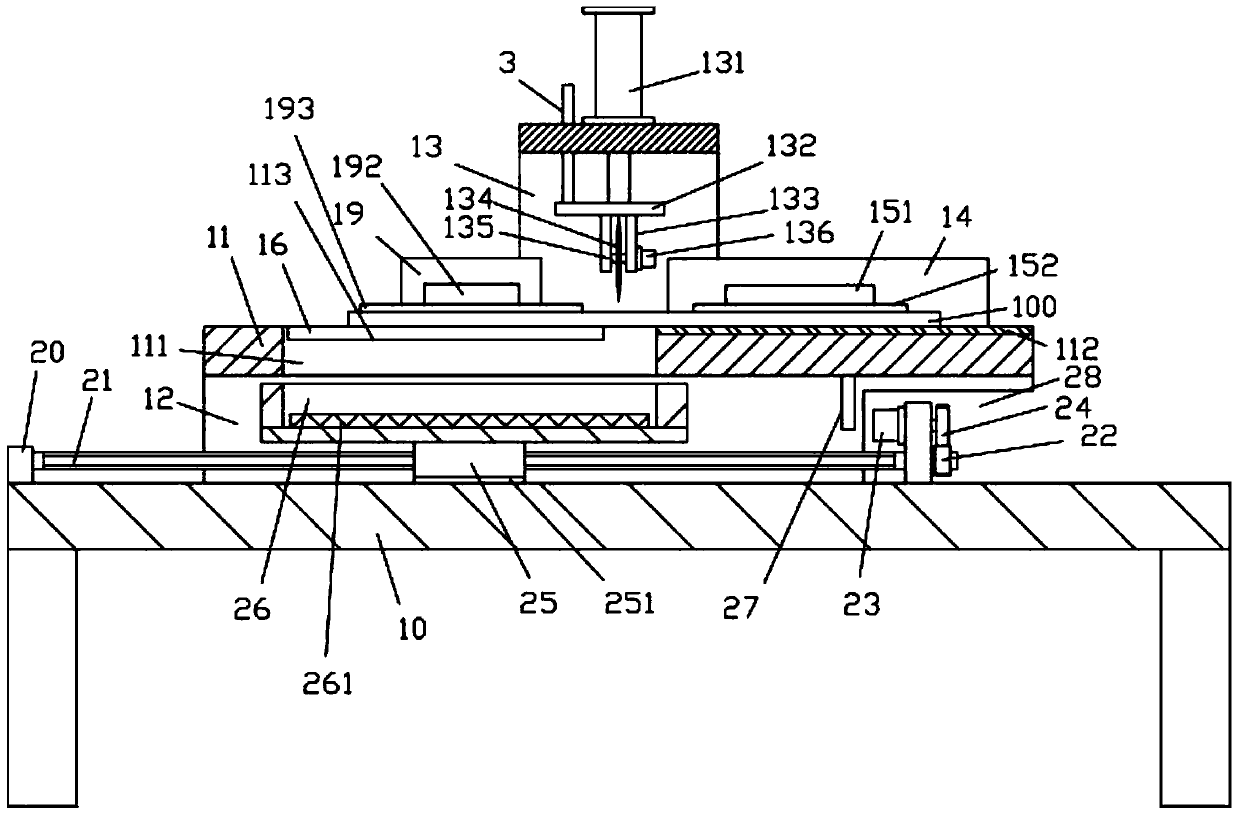

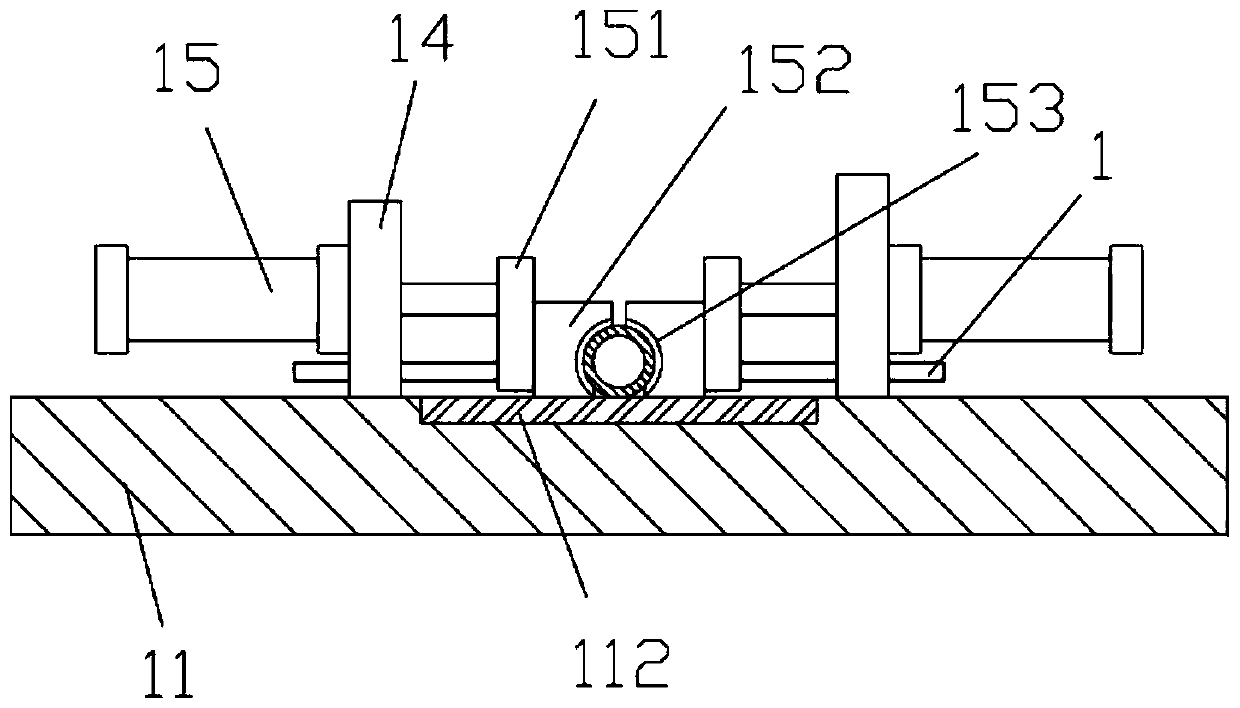

Metal pipe automatic clamping and cutting mechanism with receiving tank body

ActiveCN109702268AEasy accessHigh degree of automationTube shearing machinesMetal working apparatusEngineeringMetal

The invention discloses a metal pipe automatic clamping and cutting mechanism with a receiving tank body. The metal pipe automatic clamping and cutting mechanism comprises a rack; a horizontal plate is arranged above the top face of a top plate of the rack, and lower supporting plates are fixed to the front part and the rear part of the bottom face of the horizontal plate correspondingly; the bottom faces of the lower supporting plates are fixed to the top face of the top plate of the rack; receiving supporting plates are fixed to the left side and the right part of the middle of the top faceof the top plate of the rack correspondingly; a receiving moving screw is hinged to the two receiving supporting plates through bearings; and the right end of the receiving moving screw stretches outof the receiving supporting plate on the right side, a transmission gear is fixed to the right end of the receiving moving screw, and a moving driving motor is fixed to the upper part of the left sidewall of the receiving supporting plate on the right side. A to-be-machined metal pipe can be automatically clamped and fixed and is automatically cut and automatically discharged to fall into the receiving tank body, the receiving tank body can automatically move out of the lower part of the horizontal plate, and thus manual taking is convenient; and the metal pipe automatic clamping and cuttingmechanism is high in automation degree and good in effect, people do not need to be at the cutting position, thus people are not prone to being touched during cutting, and safety is high.

Owner:TAIZHOU FUNAIJIE AUTOMATION CO LTD

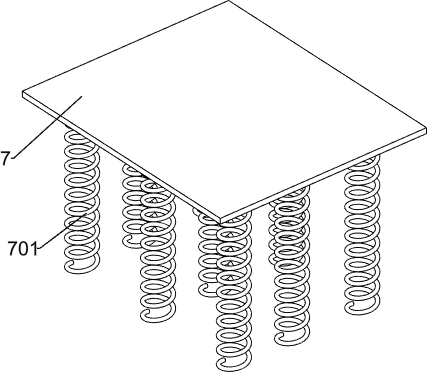

Scaffold with lifting and moving functions for building construction

ActiveCN112982928AGuarantee job securityAchieve risePhotovoltaic energy generationScaffold accessoriesArchitectural engineeringBolt connection

The invention relates to a scaffold for building construction, and particularly relates to a scaffold with lifting and moving functions for building construction. The scaffold with the lifting and moving functions for building construction is high in working efficiency and capable of allowing workers to sit down to ensure working safety. The scaffold with the lifting and moving functions for building construction comprises a supporting mechanism and two stabilizing mechanisms, and the supporting mechanism comprises a transverse frame plate and the like; and two vertical frame plates and two lifting plates are provided, one end of each of the two vertical frame plates is connected to the lower side of each of the two ends of the transverse frame plate through bolts, the two lifting plates are slidably connected to the two vertical frame plates correspondingly, and the two stabilizing mechanisms are arranged at one end of each of the two lifting plates correspondingly. The scaffold with the lifting and moving functions for building construction achieves the effects that the scaffold and a rotatable seat mechanism can be pushed at will to achieve the required working direction through the stabilizing mechanisms and the rotatable seat mechanism, and the working safety of the workers is ensured.

Owner:中建六局第一建设有限公司

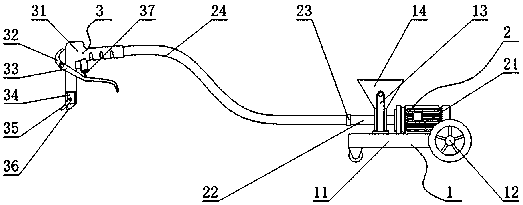

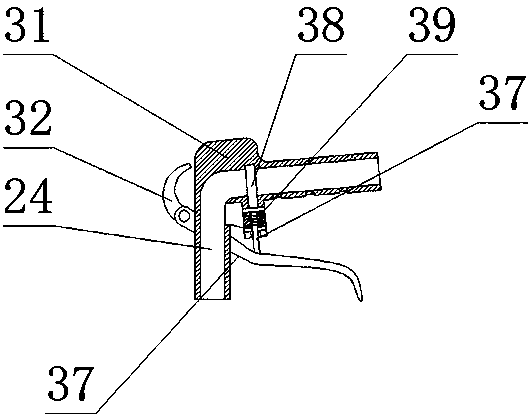

Ceramic tile seam beautifying machine for building engineering

InactiveCN108590137AImprove work efficiencyQuality improvementBuilding constructionsMotor driveSpiral blade

The invention is applicable to the field of building decoration, and provides a ceramic tile seam beautifying machine for building engineering. The ceramic tile seam beautifying machine comprises a supporting assembly, a transmission assembly and a smearing assembly; the supporting assembly comprises a supporting seat, wheels, a supporting rod and a loading hopper; and the wheels are rotatably connected to the supporting seat. A transmission motor drives a spiral blade on an output shaft to rotate, and when a handle is pinched, thrust is applied to a valve through a transmission rod; and by arranging the valve to be of a hollow structure, white cement of a conveying pipe flows into a discharging outlet through the valve, thus the conveying amount of the white cement can be controlled by pinching the handle, the situation of taking the ceramic tile seam beautifying machine to fill seams of ceramic tiles is facilitated, in the moving process during filling the seams, the filled white cement can be extruded through a pressing plate, the situation that a gap exists in the white cement after seam filling is avoided, and the working quality is improved.

Owner:FUJIAN JINZHUAN INTPROP SERVICES CO LTD

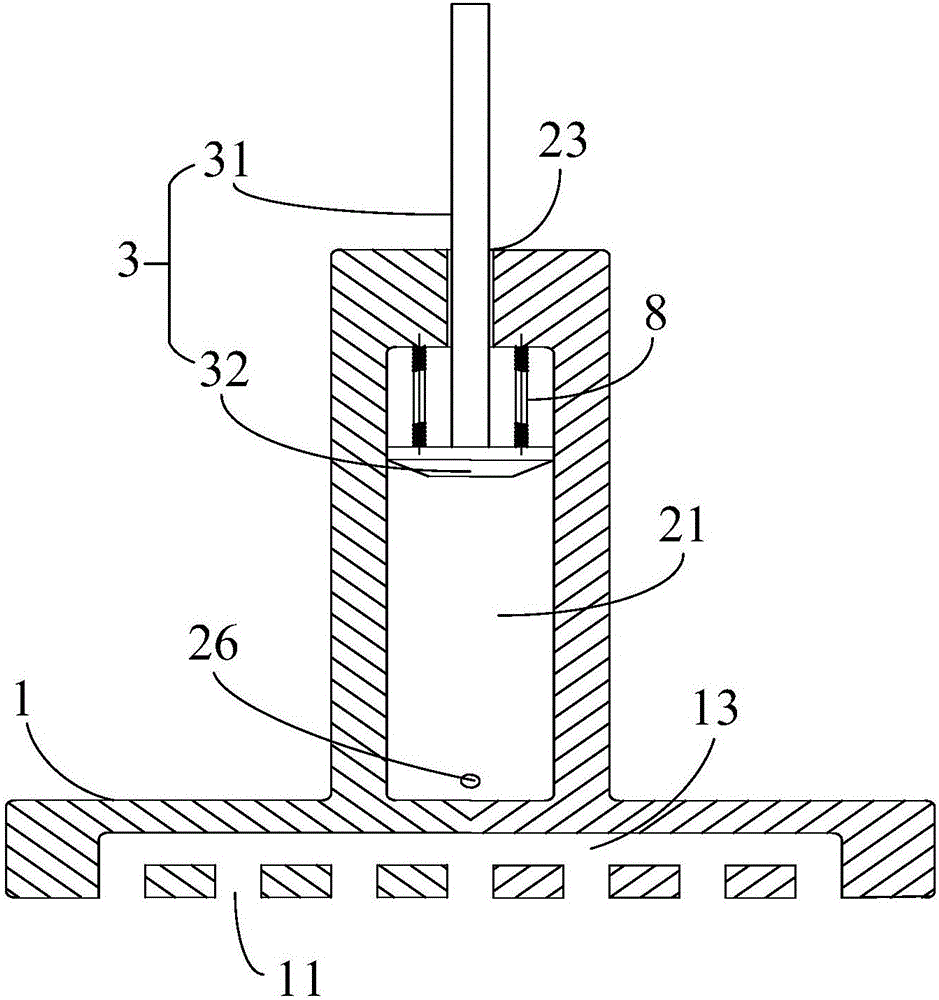

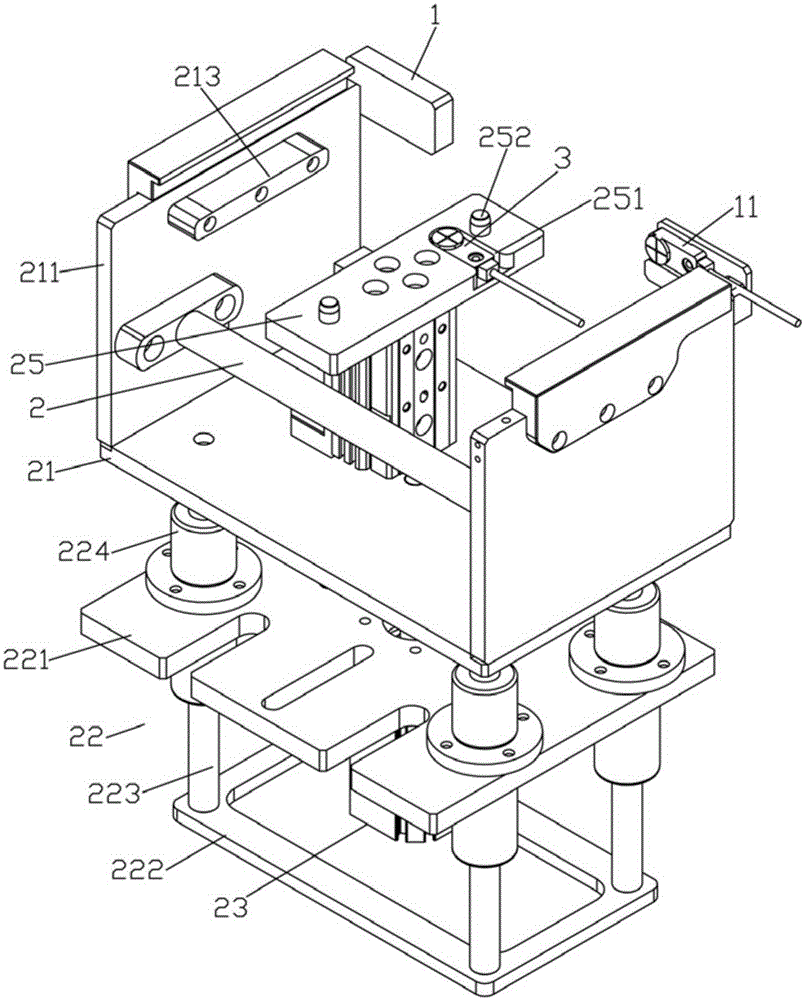

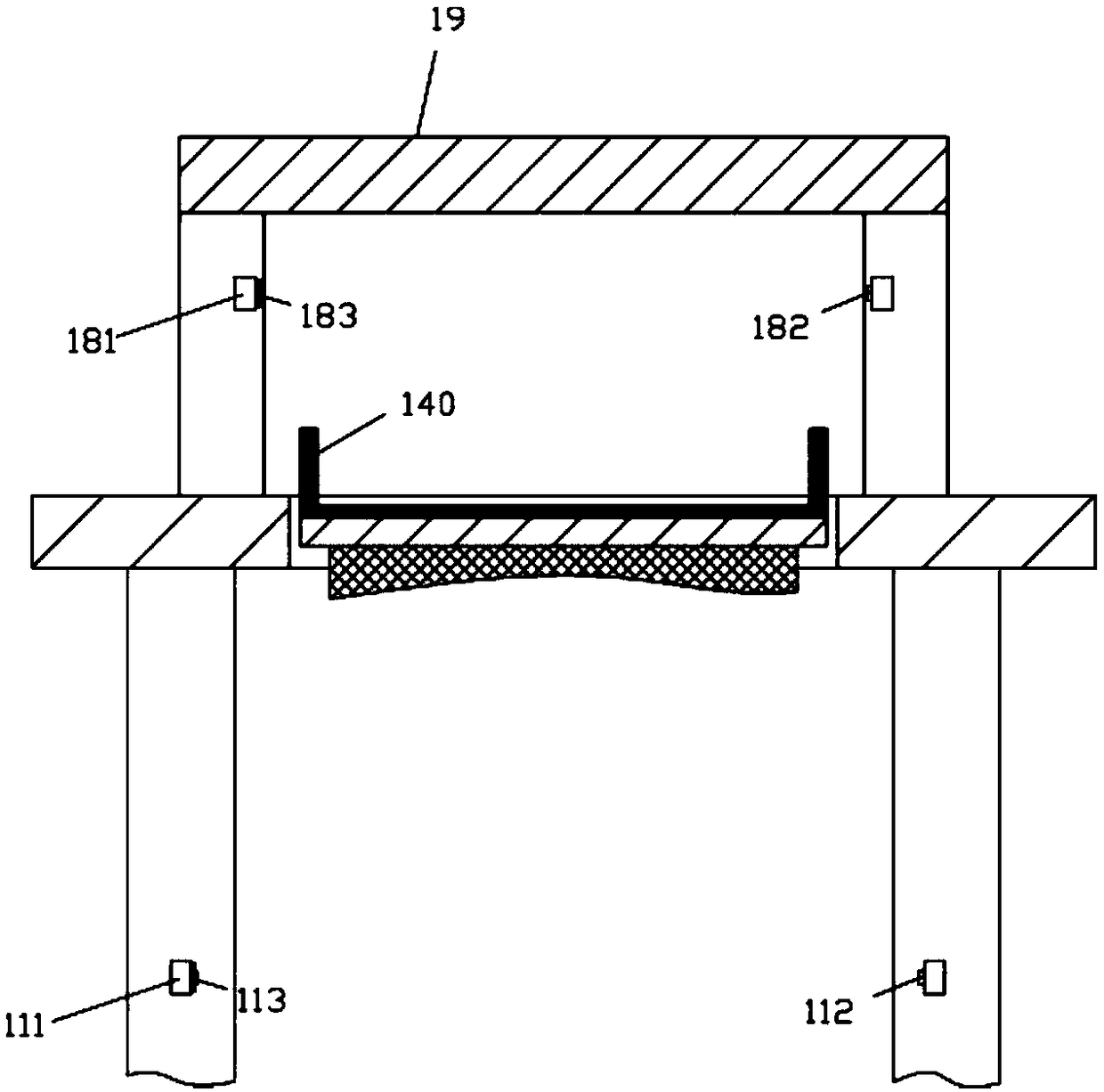

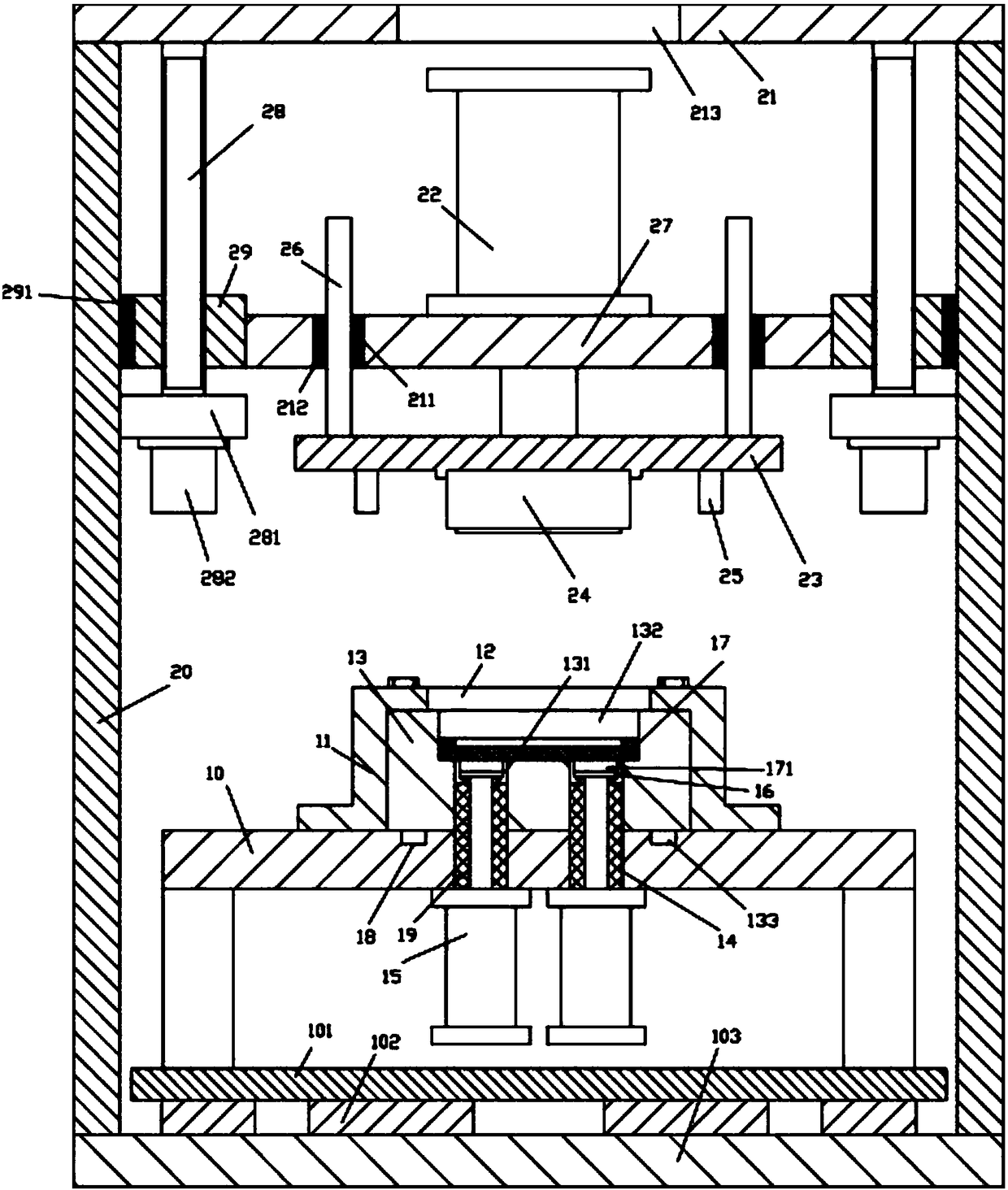

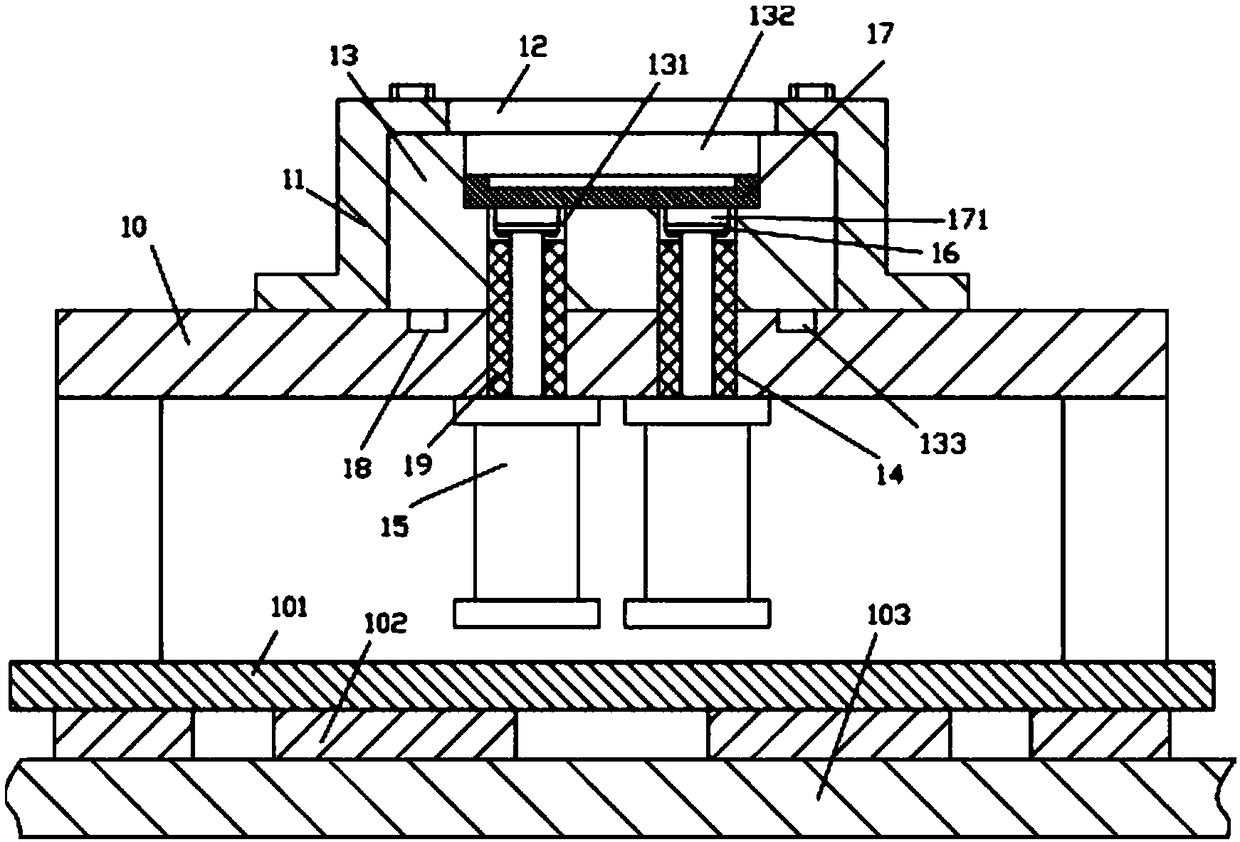

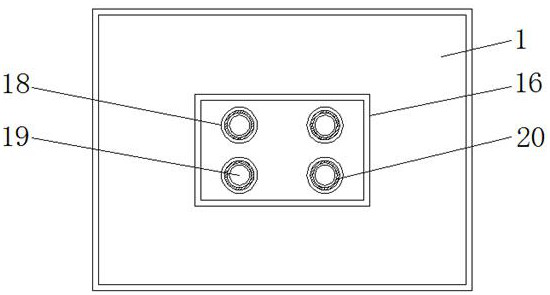

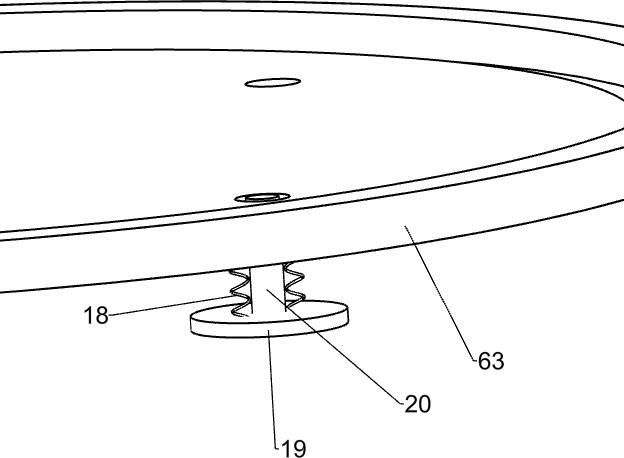

Material tray bottom lifting mechanism with detecting device

InactiveCN105151764AEasy to take by handImprove efficiencyControl devices for conveyorsEngineeringManipulator

The invention discloses a material tray bottom lifting mechanism with a detecting device. The material tray bottom lifting mechanism comprises a base, a lifting cylinder is fixed in the base, and a push rod of the lifting cylinder vertically and upwards penetrates through a base top plate of the base to be fixed to the bottom face of a lifting frame; a jacking cylinder is fixed to a bottom plate of the lifting frame, and a jacking block is fixed to a push rod of the jacking cylinder; two baffles are fixed to the upper portions of the rear ends of lifting side plates and located between the two lifting side plates, and a baffle proximity switch is fixed to one baffle; a jacking proximity switch is fixed to the jacking block, a sensing head of the jacking proximity switch is vertically upward and is located in a groove of the jacking block, and two locating columns are fixed to the top face of the jacking block. The material tray bottom lifting mechanism can receive material trays conveyed through a conveying mechanism, lift the material trays to a manipulator working zone and descend the material trays with materials being taken to the lower portion of the conveying mechanism, and the material trays can be taken and unloaded manually and conveniently; the automation operation effect of equipment is improved through the baffle proximity switch and the jacking proximity switch.

Owner:BOZHON PRECISION IND TECH CO LTD

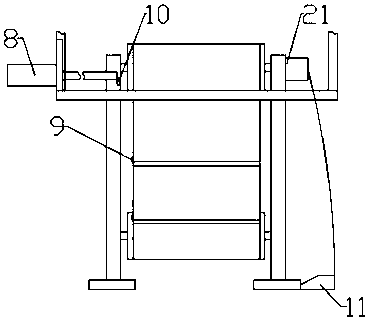

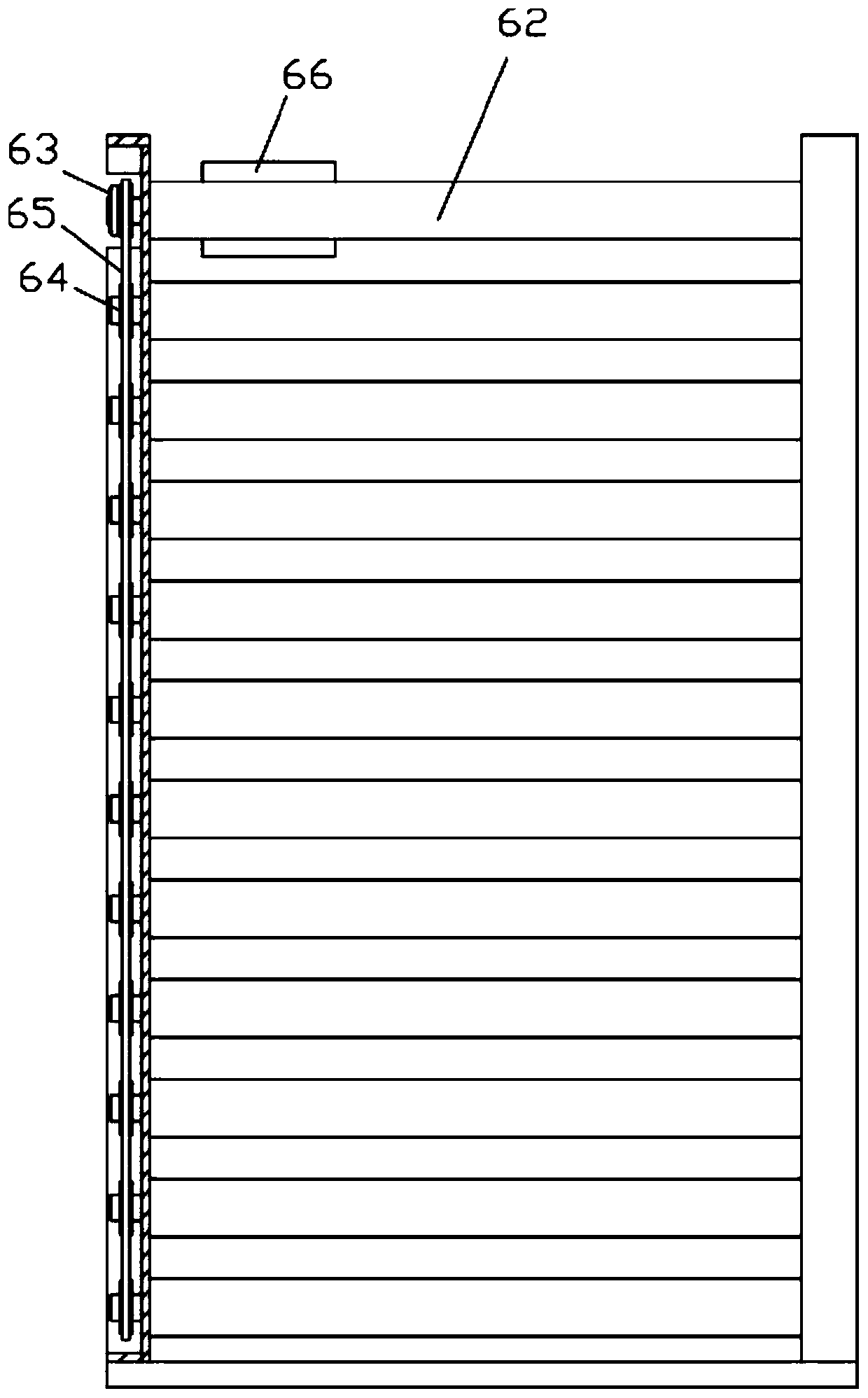

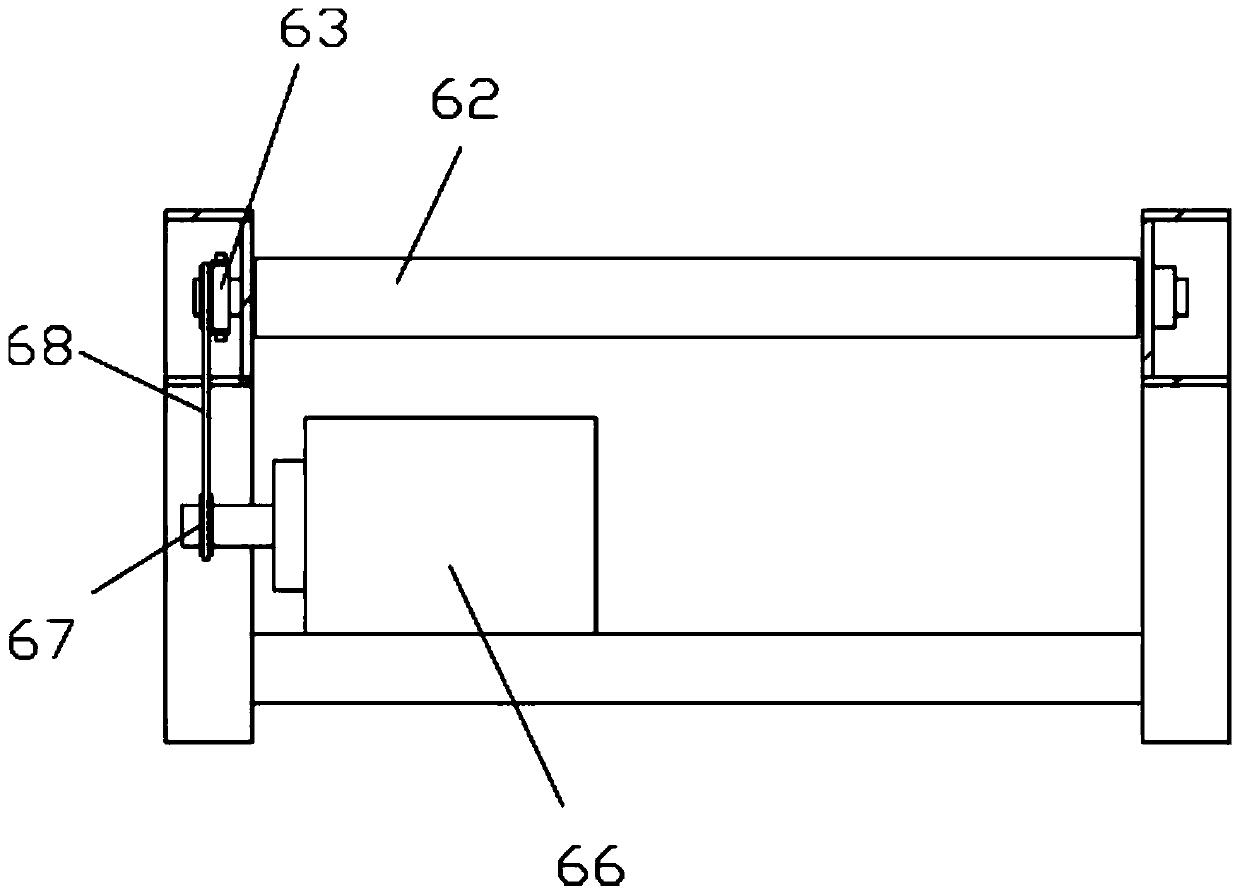

Automatic discharging photoelectric detection lifting frame

InactiveCN109205503ARealize automatic descentEasy to take by handLifting framesConveyor partsEngineering

The invention discloses an automatic discharging photoelectric detection lifting frame. The automatic discharging photoelectric detection lifting frame comprises an upper top plate, supporting columnsare fixed to the front portions and the rear portions of the left side and the right side of the bottom face of the upper top plate, the bottom ends of the supporting columns are fixed to a bottom plate, lower extension connection blocks are fixed to the opposite wall faces of the lower portions of the supporting columns on the left side and the right side, lower infrared receivers are fixed to the rear wall faces of the lower extension connection blocks on the front portion, lower infrared emission heads are fixed to the front wall faces of the lower extension connection blocks on the rear,a middle through groove is formed in the middle of the upper top plate, a receiving plate is inserted in the middle through groove in a sleeved manner, baffles are fixed to the tops of the front and the rear of the receiving plate, and a lifting plate is fixed to the bottom face of the receiving plate. Through objects carried through infrared induction, automatic descending of objects can be achieved, the receiving plate can be automatically pushed and moved out, manual taking is facilitated, manual control and manual receiving from the receiving plate are not needed, manual labor amount is greatly reduced, effect is good, and efficiency is high.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Automatic material collecting device for box-packed bean curds

The invention discloses an automatic material collecting device for box-packed bean curds. The automatic material collecting device comprises a support, a driving roller, a driven roller and a rubberconveying belt. The driving roller and the driven roller are arranged at the upper end and the lower end of a support correspondingly, and the rubber conveying belt is annularly arranged between the driving roller and the driven roller in a sleeving mode for drive connection. A plurality of rows of material collecting plates perpendicular to the surface of the rubber conveying belt are arranged onthe upper surface of the rubber conveying belt. A hoisting platform is arranged at the upper end of the support. A through hole used for allowing the rubber conveying belt to pass through is formed in the center of the hoisting platform. A radial telescopic driving device is arranged on the back face of the hoisting platform. According to the automatic material collecting device for the box-packed bean curds, the rubber conveying belt drives the material collecting plates to rotate annularly, the packaged box-packed bean curds can enter the material collecting plates automatically, then the material collecting plates are driven by the rubber conveying belt onto the upper surface of the hoisting platform, the box-packed bean curds can be automatically pushed onto the hoisting platform through the radial telescopic driving device, manual taking can be facilitated, the characteristics of being capable of achieving temporary storage and convenient to bin are achieved, and labor force is relieved.

Owner:沭阳万和香食品有限公司

Drying and conveying equipment with good effect for plate cutting

PendingCN113967934AEasy accessSimple structureDrying gas arrangementsMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of drying, in particular to drying and conveying equipment with a good effect for plate cutting. The equipment comprises a cutting system and a material collecting system arranged on one side of the cutting system, the material collecting system comprises a collecting box, a discharge port formed in one side of the collecting box and a conveying part arranged in the collecting box, and the conveying part comprises a conveying frame, conveying belts arranged on the two sides of the conveying frame and a driving part for driving the conveying belts to rotate. By arranging the collecting box and the conveying part, plates cut by the cutting system are conveyed into the collecting box and then conveyed out from the discharge port of the collecting box; meanwhile, a lifting part is further arranged, the plates at the bottom of the collecting box can be conveyed to the uppermost end, manual taking is convenient, the structure is simple, and efficiency is high; and the lifting part cooperates with a pressing part so that the plates in the collecting box can be pressed.

Owner:常州市智阳机械设备有限公司

High-precision die stamping device

The invention discloses a high-precision die stamping device. The high-precision die stamping device comprises a rack, the lower portion of the rack is provided with a main bottom plate, main verticalplates are fixed to the left side and the right side of the top face of the main bottom plate, a supporting upper top plate is fixed to the main vertical plates, a main lifting plate is located underthe supporting upper top plate, an upper stamping oil cylinder is fixed to the middle of the top face of the main lifting plate, a pushing rod of the upper stamping oil cylinder penetrates through the bottom face of the main lifting plate and is fixedly provided with an upper installing plate, and an upper die block is fixed to the middle of the bottom face of the upper installing plate. According to the high-precision die stamping device, the height of the upper die block can be fine-adjusted, therefore, when the spacing between an upper die and a lower die plate can not meet the requirement, the spacing can be adjusted by adjusting the upper die, it is guaranteed that stamping molding meets the requirement, and great convenience is achieved; and in addition, after stamping molding is completed, the lower die plate is lifted, manual taking is convenient, great convenience is achieved, and the effect is good.

Owner:嘉兴市六和塑料制品有限公司

System for preventing out-of-control state in industrial machine and control method

InactiveCN112721297AImprove picking efficiencySecurity plusEngineering safety devicesPressesControl engineeringIndustrial machine

The invention discloses a system for preventing an out-of-control state in an industrial machine and a control method. The system comprises a supporting seat, support shafts, connecting line, traction lines, rotating rods, protection rods and lifting rods, wherein support bars are fixedly welded to the upper surface of the supporting seat; a sliding groove is arranged in the outer surface of each support bar; a rotating groove is arranged in each support bar; a fixing frame is fixedly welded to the outer surface of each support bar; a first reset spring is fixedly welded to the interior of each fixing frame; each connecting wire is fixed to the outer surface of the corresponding support shaft; each traction line is fixedly connected to the outer surface of the corresponding support shaft; and a pressing block is fixedly connected to the lower end of each traction line. According to the system for preventing the out-of-control state in the industrial machine and the control method, in the using process, certain safety of the whole device is still guaranteed in the out-of-control state, and a worker can know whether the whole device leaks electricity or not through flickering of a warning lamp and the alarm sound.

Owner:缪建强

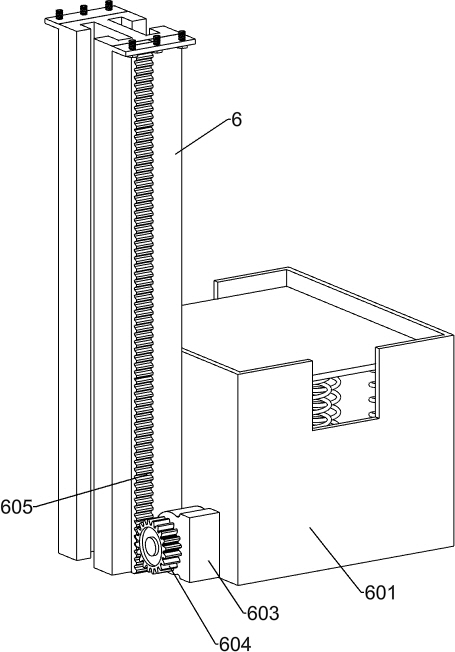

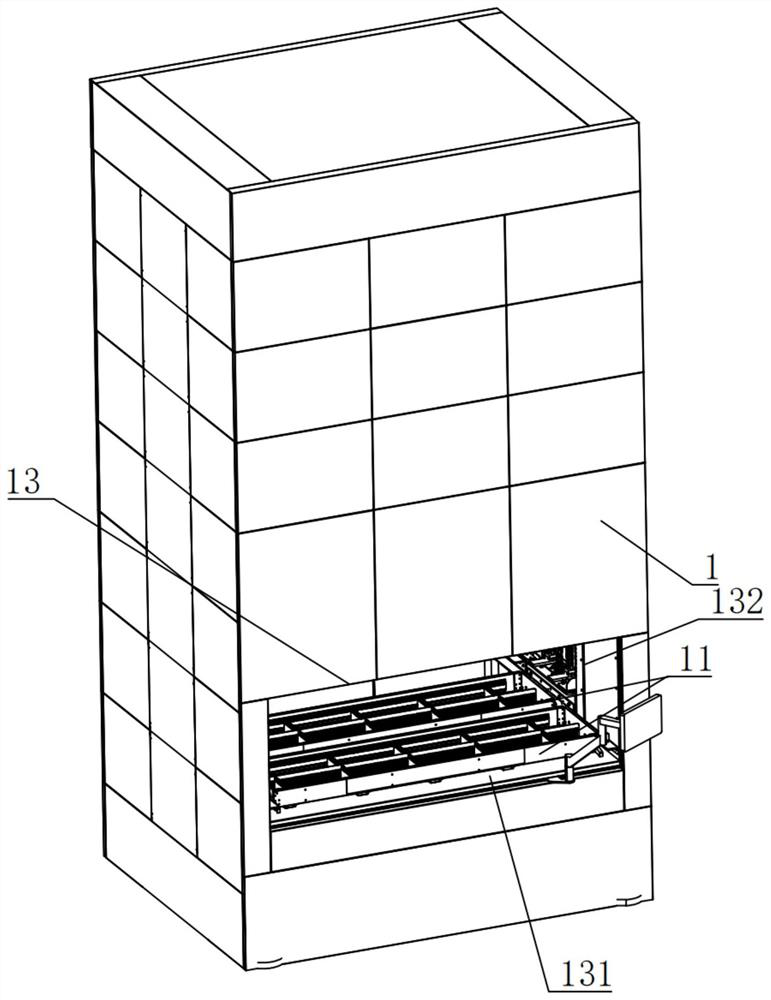

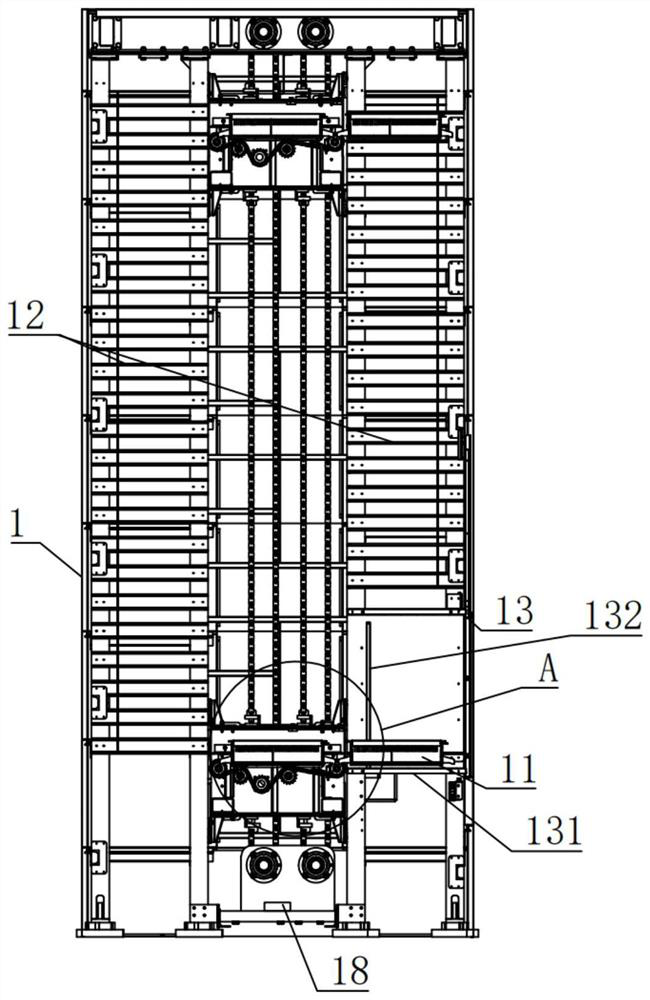

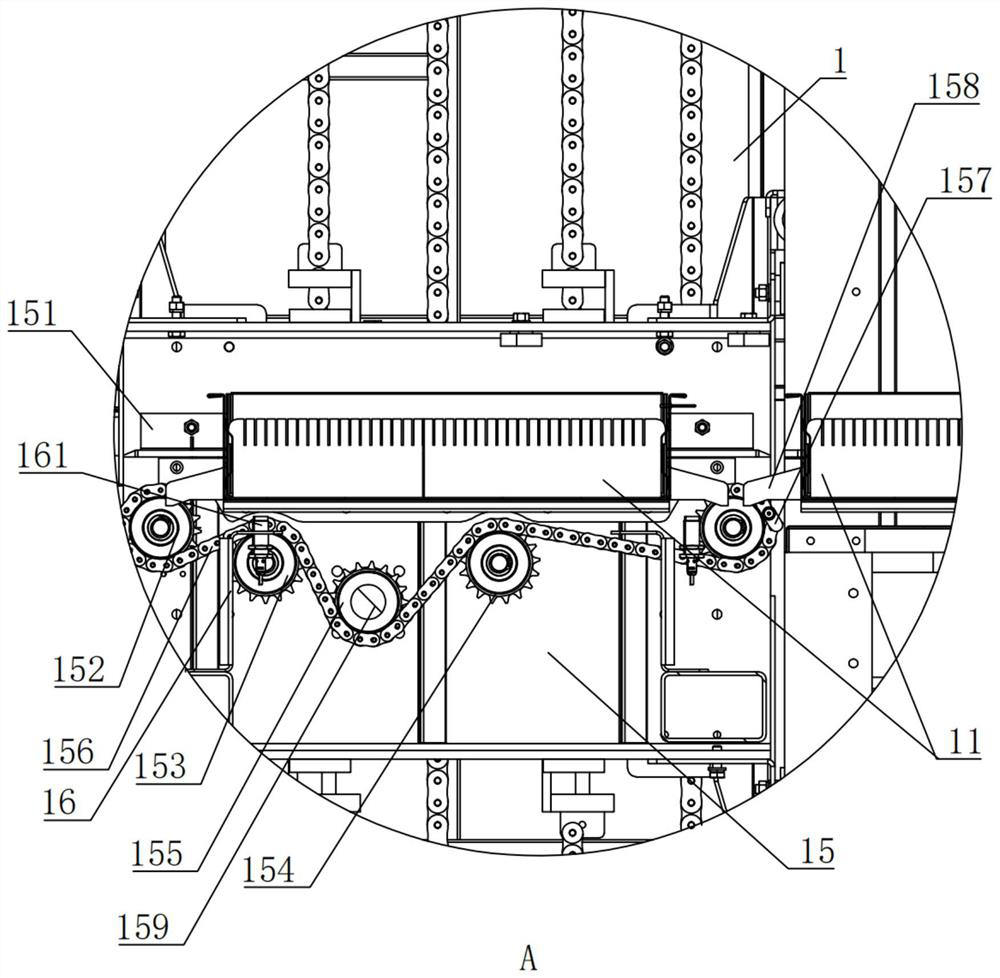

Intelligent lifting warehouse with efficient storage function

PendingCN113844810AEasy to take by handSmall footprintStorage devicesStructural engineeringMechanical engineering

The invention discloses an intelligent lifting warehouse with an efficient storage function, and relates to the technical field of cargo storage. The intelligent lifting warehouse with the efficient storage function has the advantage of reducing the occupied area of cargo storage, and the technical scheme is characterized in that the intelligent lifting warehouse with the efficient storage function comprises a lifting container which is placed on the ground and extends upwards and a tray located in the lifting container; a plurality of opposite first sliding rails are distributed on the inner wall of the lifting container in the height direction of the lifting container; the first sliding rails are in sliding connection with the bottom of the tray; a cargo taking opening is formed in the lower end of the side face of the lifting container; and a lifting device for conveying the tray to the first sliding rails at any height position and a pushing device for conveying the tray to the first sliding rails or the cargo taking opening are arranged in the lifting container.

Owner:安徽乾德智能科技有限公司

A paper cutting device

InactiveCN104875222BAchieve reductionAchieve positioningMetal working apparatusPulp and paper industryPiston rod

The invention discloses a paper cutting device. The paper cutting device is used for cutting energy charge receipt label paper. The upper part of a base is slidably provided with a platform, a first sidesway assembly is arranged between the platform and the base, and the top of the platform is slidably provided with a paper box; a second sidesway assembly is arranged between the paper box and the platform, the base is provided with a vertical column, and the upper side of the base is provided with a cross arm; the vertical column is provided with a lifting assembly used for driving the cross arm to ascend and descend, the cross arm is slidably provided with a tool frame, and the cross arm is provided with a longitudinal driving assembly used for driving the tool frame to reciprocate; t<0}{0><}0{>the lower part of the tool frame is fixedly provided with a first knife shell, the first knife shell is internally provided with a first blade which is obliquely arranged, two sides of the first knife shell are further respectively provided with a vertically-arranged air cylinder, and the free ends of piston rods of the air cylinders are provided with pressure levers used for pressing to-be-cut paper. The paper cutting device is high in automation degree and cutting efficiency, and can be used for greatly liberating the manpower.

Owner:国网山东济南市历城区供电公司 +1

Portable automatic insulin injection device

ActiveCN113908381AEasy extrusionAvoid wastingAutomatic syringesPharmaceutical containersInsulin injectionEngineering

The invention discloses a portable automatic insulin injection device, which comprises a shell; the upper portion, close to the right side, of the shell is connected with an injection mechanism for insulin injection; the interior of the shell is connected with an adjusting mechanism for controlling the insulin injection amount; an insertion needle is fixedly connected with a movable sleeve through a connecting block; the outer wall of the movable sleeve is fixedly connected with a protective cover; one end, far away from the movable sleeve, of the protective cover is fixedly connected with a fixed sleeve; connecting rods are respectively connected between the movable sleeve and a mounting column and between the movable sleeve and the fixed sleeve; and a roller is rotatably mounted on the connecting rod where the mounting column is located through a fixing strip. According to the invention, the two rollers move towards the end close to the fixed sleeve while moving in the opposite directions, so that air at the end of a catheter is conveniently squeezed out, and a large amount of waste caused by squeezing out the air by discharging insulin is effectively avoided.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

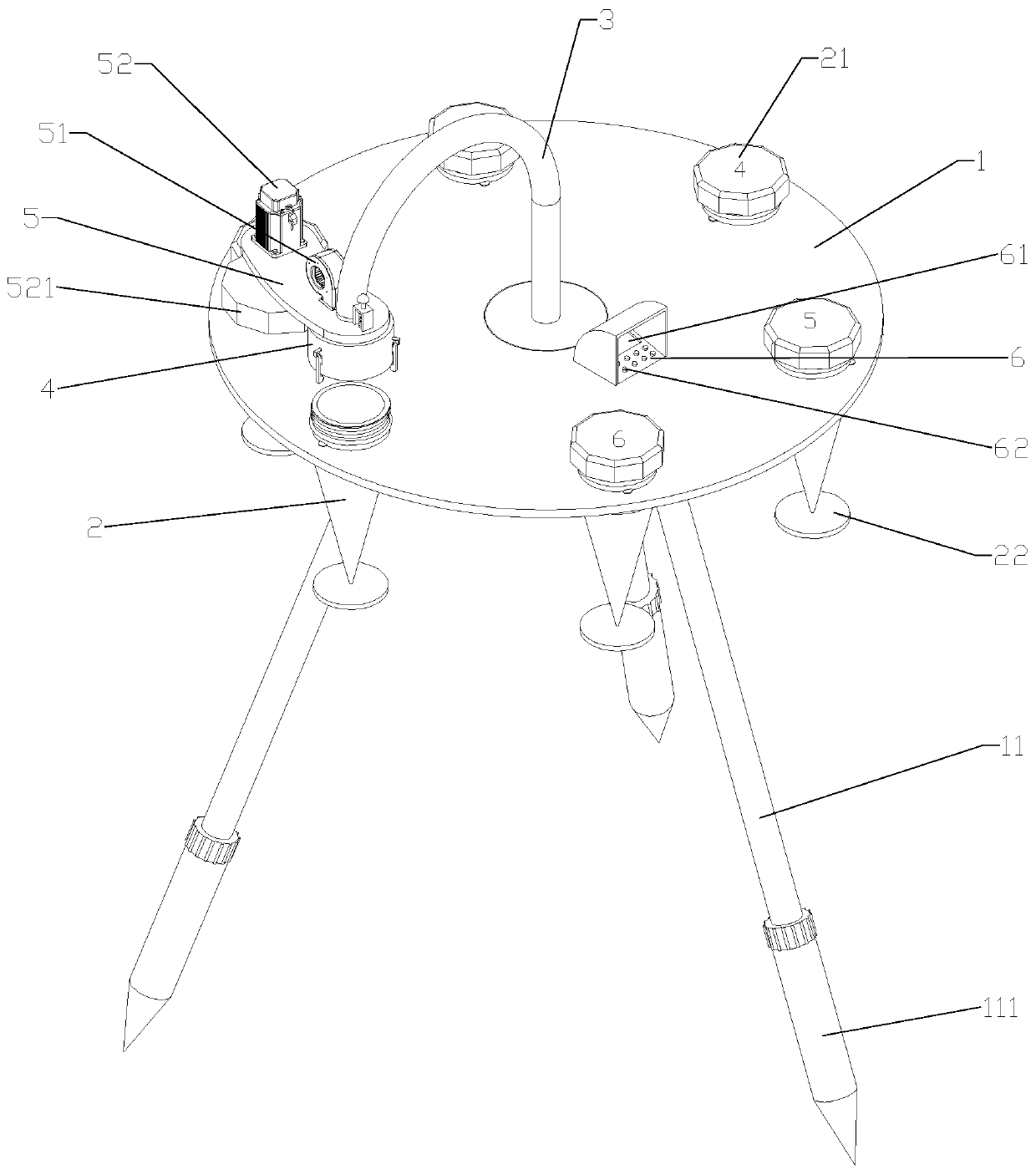

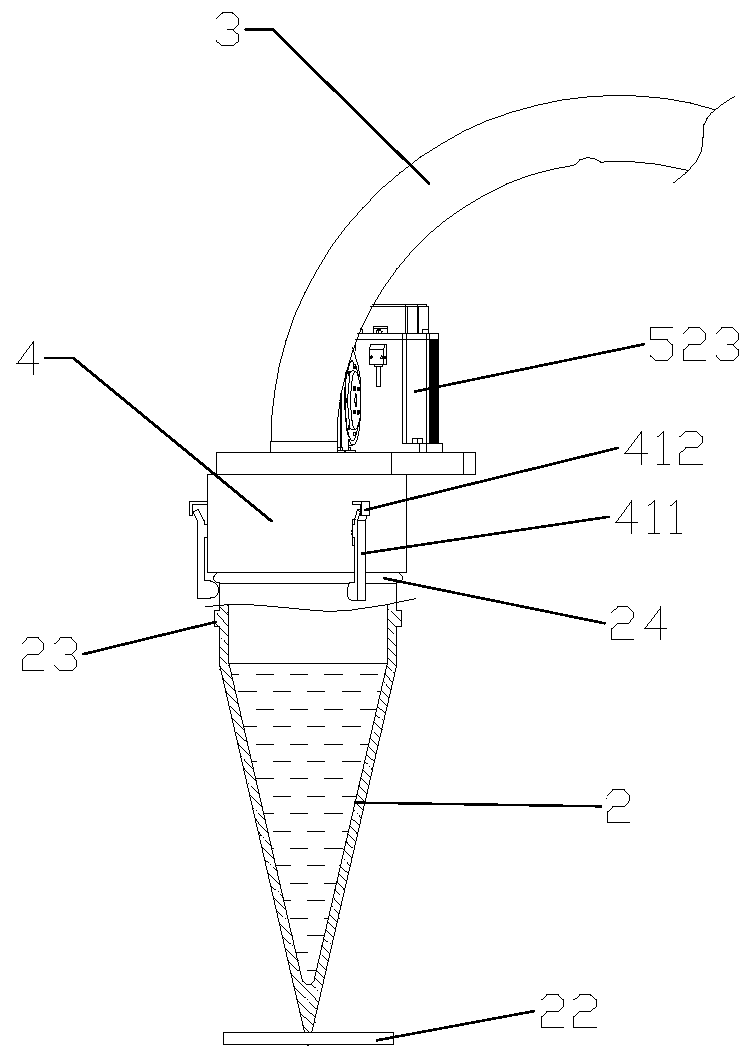

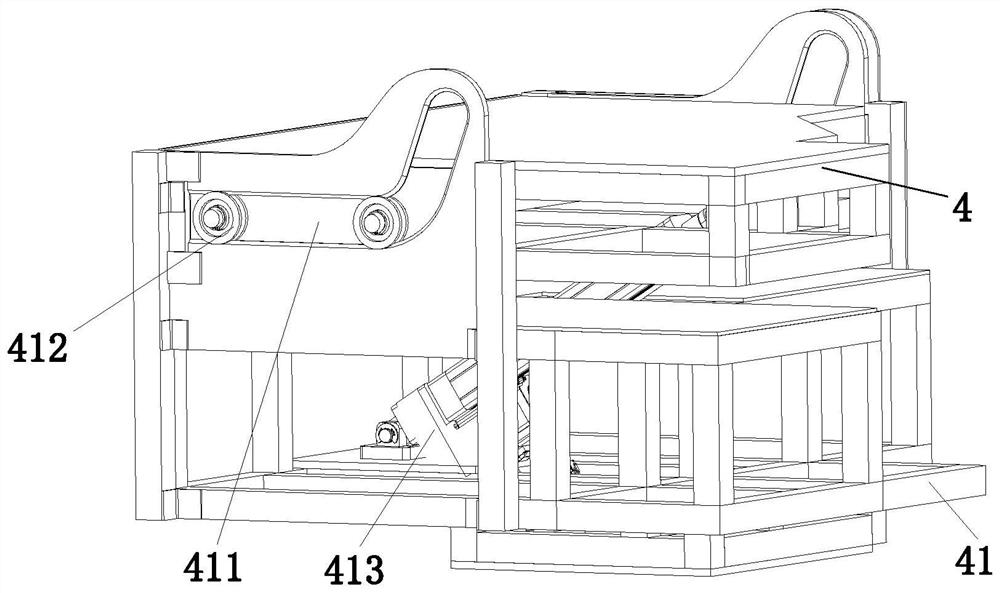

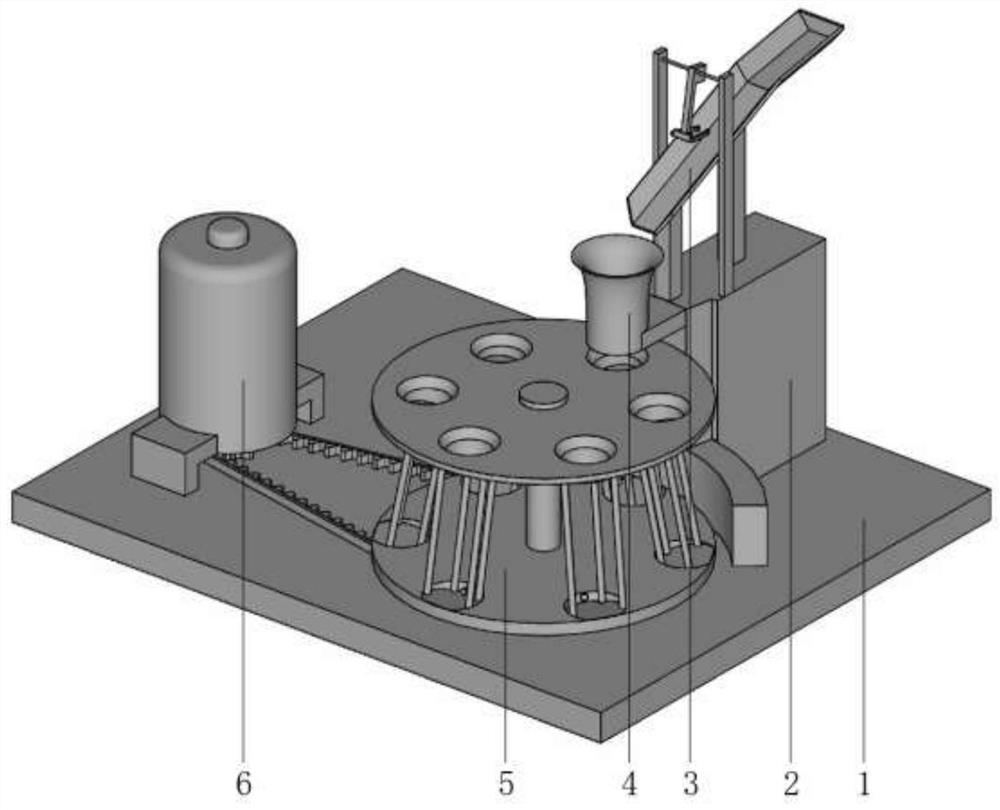

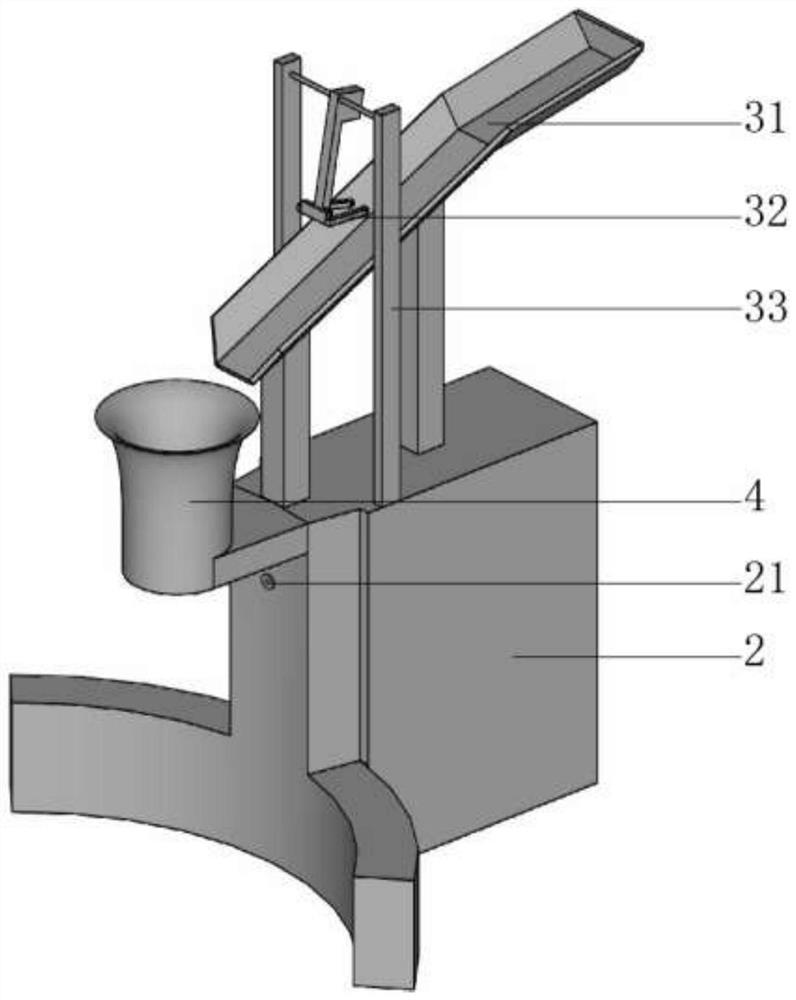

Air sample collecting device

InactiveCN111413159AAvoid breakingReduce manual operationsThreaded caps applicationPower operated devicesAir sampleStructural engineering

The invention discloses an air sample collecting device which comprises a rack, and a plurality of conical collecting bottles containing liquid detachably connected to the rack at equal intervals in the circumferential direction. A plurality of supporting legs are hinged to the bottom end of the rack, a center rod is rotatably arranged in the middle of the rack, the bottom end of the center rod isconnected with a center rod driving mechanism for driving the center rod to ascend, descend and rotate, and the top end of the center rod extends to the position above the collecting bottle and is connected with a blocking cover capable of blocking an opening in the upper end of the collecting bottle. A connecting mechanism connected with the collecting bottle is arranged on the plugging cover; an arc-shaped supporting plate is rotatably arranged on the center rod at the top end of the plugging cover; and a fan, a bottle cover opening device and a supporting plate limiting mechanism are arranged on the supporting plate. The bottle cap opening device comprises an opening head which is arranged at the bottom end of the supporting plate, matched with the bottle cap and provided with a polygonal groove. The device has the characteristics of automatically replacing the collecting bottle, collecting the air sample at regular time and being convenient to take.

Owner:朱晓艳

Conveying equipment for pressing steel ingots into steel plates and using method of conveying equipment

PendingCN114655636AImprove work efficiencyReduce space occupationConveyorsSupporting framesSteel platesStructural engineering

The conveying equipment comprises a bearing table, a crawler belt is arranged on the bearing table, limiting plates are arranged on the two sides of the top of the bearing table, a plurality of first pin shafts are fixedly connected to the bottoms of the opposite sides of the two limiting plates at equal intervals, and the outer walls of the first pin shafts are rotationally and alternately sleeved with flow guide plates; a plurality of sliding holes are formed in one side of the limiting plate at equal intervals, a handle is fixedly connected to one side of the flow guide plate, the outer wall of the handle is slidably connected with inner cavities of the sliding holes in a sleeved mode, a driving device is arranged on one side of the bearing table, and supporting devices are arranged at the four corners of the bottom of the bearing table. According to the steel plate conveying device, the arrangement mode that the crawler belt, the limiting plates and the flow guide plate are matched is utilized, when a steel plate is conveyed on the crawler belt, the two limiting plates can limit the position of the steel plate, the flow guide plate can rotate by lifting a handle, and therefore the steel plate conveyed on the crawler belt is jacked up, the steel plate can be conveniently and manually taken, and the working efficiency of the steel plate conveying device is improved.

Owner:江苏瑞格高合金材料有限公司

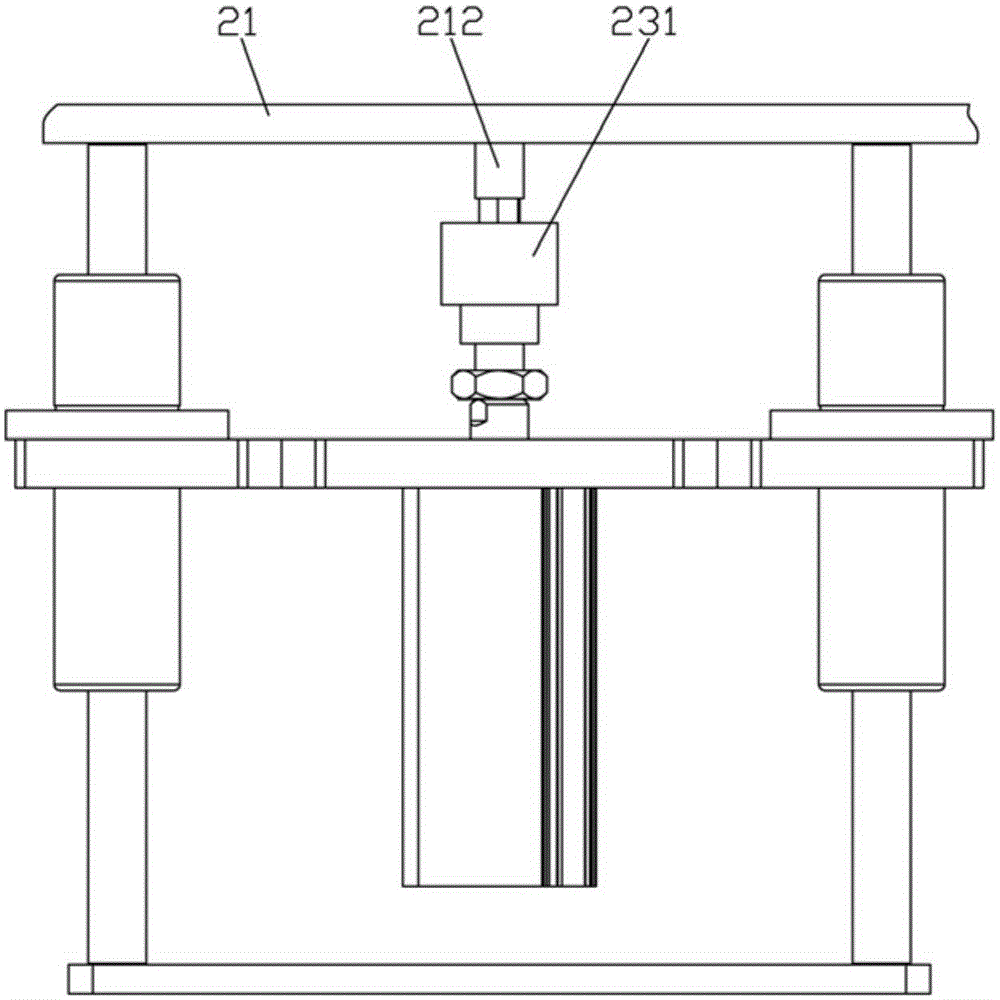

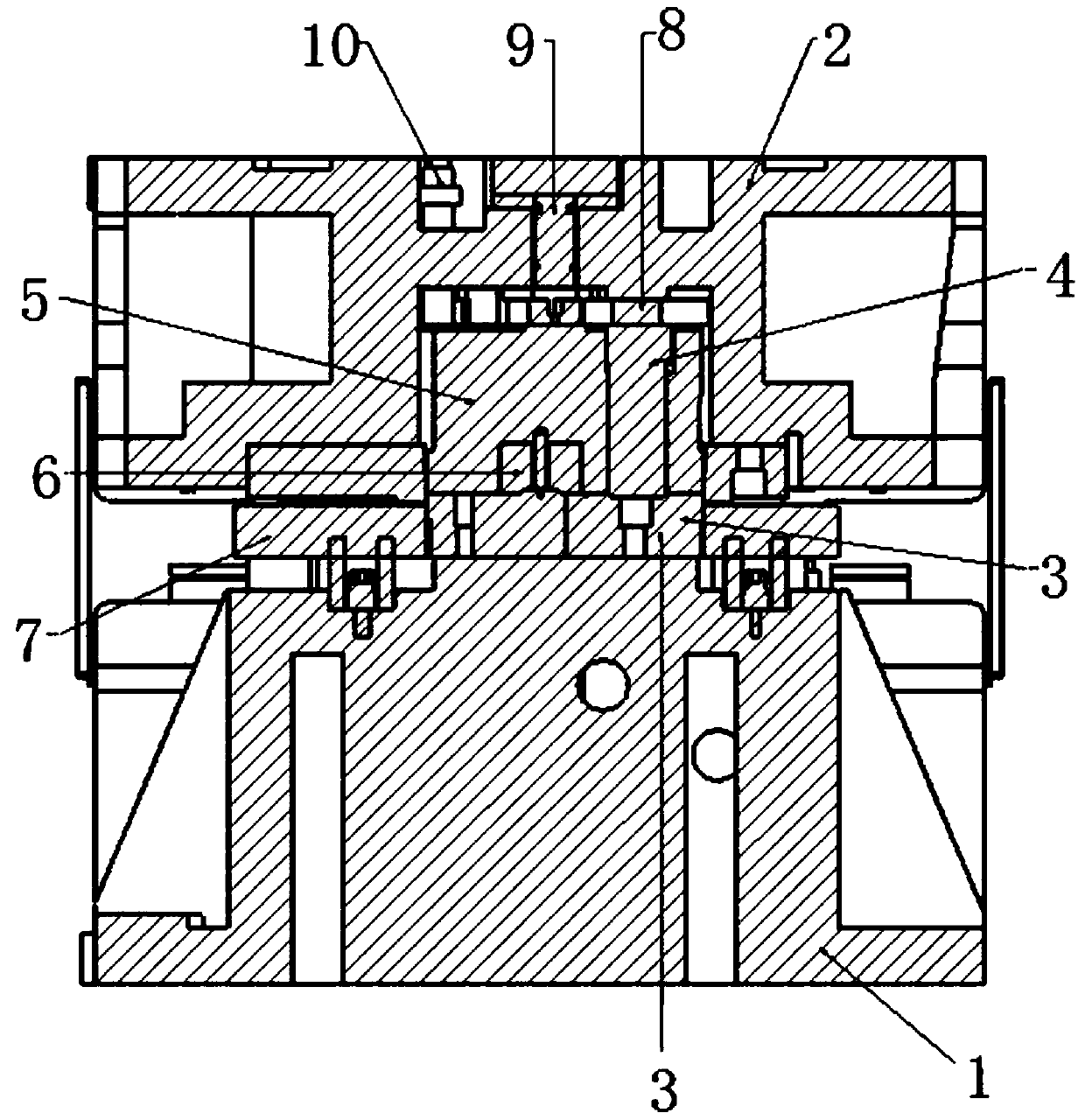

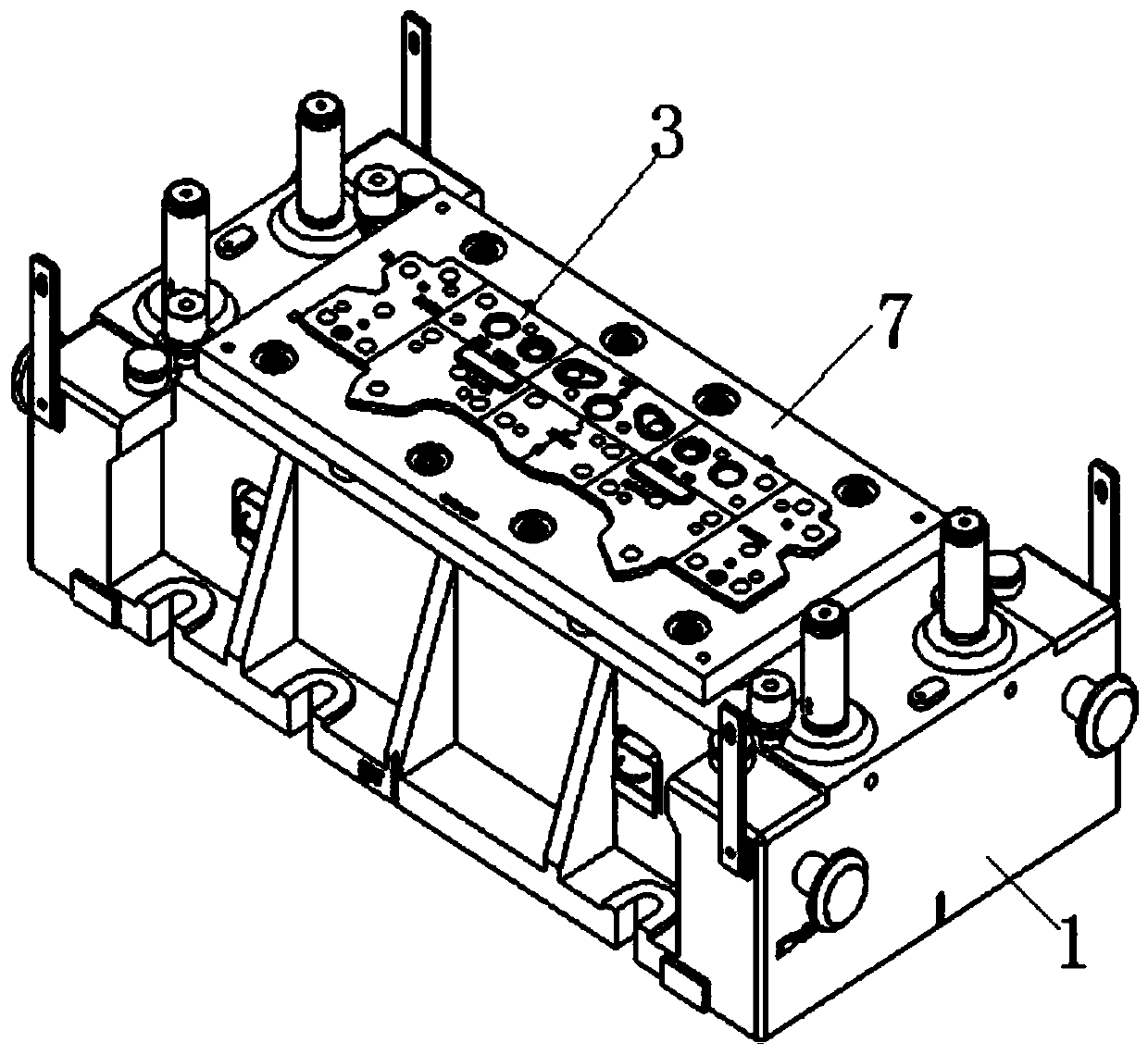

Stiffening beam-rear transverse beam trimming punching and forming combination structure

InactiveCN110405070AReduce production quantityPromote technological developmentShaping toolsLoad-supporting pillarsPunchingNitrogen

The invention provides a stiffening beam-rear transverse beam trimming punching and forming combination structure. The structure comprises a lower mold plate, nitrogen springs and limiting screws. Thelower mold plate and an upper mold plate are buckled together. A material return plate is fixedly installed on the plane of the top of the lower mold plate. According to the stiffening beam-rear transverse beam trimming punching and forming combination structure, a mold structure with the diversified working procedure content is adopted, the outline appearance of the portion of the lower mold plate can be directly fed, trimmed and accomplished by the structure, the material return plate can directly push out blank waste materials, workers conveniently take the blank waste materials, the division of plate materials and product feeding parts is accomplished, and small holes formed in the bottom surface can be punched after trimming is accomplished. In the drawing 2, a small flanging male mold is processed to be a movable part, and the new technological development of the punching mold industry is also promoted. By means of the working procedure, the hole position deformation which is caused by material movement in the punching and forming process is avoided, and the requirement for the precision punching of the hole position in the follow-up process is met. In the current social form, the stiffening beam-rear transverse beam trimming punching and forming combination structure can completely maximize all resources.

Owner:SHIYAN TIANCE MOLD

An automatic coloring machine for round wooden boards

ActiveCN111482319BRealize automatic coloringImprove the efficiency of coloringLiquid surface applicatorsSpraying apparatusRubber ringStructural engineering

The invention relates to a coloring machine, in particular to an automatic coloring machine for circular wooden boards. The technical problem of the present invention is to provide an automatic coloring machine for round wooden boards that can replace manual work and automatically paint wood boards to improve the coloring efficiency. The technical problem of the present invention is: an automatic coloring machine for round wooden boards, comprising: a coloring seat, a mounting plate is installed on the side of the mounting plate, and a deceleration motor is installed on the side of the mounting plate; a support plate is installed on the top of the coloring seat. plate, the placement mechanism is arranged on the top of the support plate; the coloring mechanism is connected to the coloring mechanism on the side of the mounting plate near the side of the support plate. The invention realizes the automatic coloring of the round wooden boards through the coloring mechanism, without manual coloring of the wooden boards, which improves the coloring efficiency, protects the round wooden boards through the rubber ring, and prevents the round boards from being stained by the turntable. Under the action of bevel gears, toothless gears and belts, the automatic rotation of the circular planks is realized, reducing manual operations.

Owner:山东智汇新谷科技企业孵化器有限公司

a panel grabber

ActiveCN106800186BEasy to take by handGreat suctionWork holdersConveyor partsSuction stressEngineering

The invention provides a panel grabber comprising: a suction cup, a U-shaped tube and a piston, wherein the suction cup is provided with a suction cup inner cavity, and comprises a first surface and a second surface which are arranged oppositely; the first surface of the suction cup is provided with at least one first hole communicated with the suction cup inner cavity, and the second surface of the suction cup is provided with a second hole communicated with the suction cup inner cavity; a first end and a second end of the U-shaped tube are arranged on the second surface of the suction cup, and the second end is connected with the second hole to enable the suction cup inner cavity to be communicated with the U-shaped tube; the U-shaped tube comprises a first side tube and a second side tube, the first end is positioned on the first side tube, and the second end is positioned on the second side tube; the other end, opposite to the first end, of the first side tube is provided with a first opening; and one end of the piston is inserted in the first opening, and can move in the first side tube, the width of one end of the piston is matched with the width of the first side tube, and the width of the other end of the piston is matched with the width of the first opening. The magnitude of suction for grabbing a panel can be controlled by controlling the distance of piston movement.

Owner:BOE TECH GRP CO LTD +1

A metal pipe automatic clamping and cutting mechanism with a receiving tank body

ActiveCN109702268BEasy to take by handHigh degree of automationTube shearing machinesMetal working apparatusGear wheelElectric machinery

The invention discloses a metal pipe automatic clamping and cutting mechanism with a receiving tank body. The metal pipe automatic clamping and cutting mechanism comprises a rack; a horizontal plate is arranged above the top face of a top plate of the rack, and lower supporting plates are fixed to the front part and the rear part of the bottom face of the horizontal plate correspondingly; the bottom faces of the lower supporting plates are fixed to the top face of the top plate of the rack; receiving supporting plates are fixed to the left side and the right part of the middle of the top faceof the top plate of the rack correspondingly; a receiving moving screw is hinged to the two receiving supporting plates through bearings; and the right end of the receiving moving screw stretches outof the receiving supporting plate on the right side, a transmission gear is fixed to the right end of the receiving moving screw, and a moving driving motor is fixed to the upper part of the left sidewall of the receiving supporting plate on the right side. A to-be-machined metal pipe can be automatically clamped and fixed and is automatically cut and automatically discharged to fall into the receiving tank body, the receiving tank body can automatically move out of the lower part of the horizontal plate, and thus manual taking is convenient; and the metal pipe automatic clamping and cuttingmechanism is high in automation degree and good in effect, people do not need to be at the cutting position, thus people are not prone to being touched during cutting, and safety is high.

Owner:TAIZHOU FUNAIJIE AUTOMATION CO LTD

Dye container standby conveying and grasping system

The invention discloses a dye container standby conveying and grasping system comprising a stock rack, a transition discharging rack and a gripping mechanism. The stock rack and the transition discharging rack are placed on the ground behind a bottom rail mechanism of the gripping mechanism; a plurality of discharging empty slots are formed in the stock rack, and discharging inserting slots are formed at the positions of the discharging empty slots and in the middle portion of a bottom plate; the transition discharging rack includes a discharging support frame, a plurality of conveying rollersare arranged between two side transverse beams on the left and right of the discharging support frame, and rotating shaft portions at the two ends of each conveying roller are hinged to side plates of the corresponding side transverse beams through bearings; the stock rack, the transition discharging rack and the gripping mechanism are installed at the same place, the grabbing mechanism automatically grabs a basin from the stock rack and places the basin on the transitional discharging rack, and manual taking and placement are facilitated; and meanwhile, the grasping mechanism can also directly take out the basin from the stock rack and then place the basin on other frames nearby, and the dye container standby conveying and grasping system is high in automatic grabbing efficiency and goodin effect.

Owner:浙江绍兴福元科技有限公司

A packaging and conveying metering device for masks

InactiveCN105270675BEasy to take by handIndividual articlesPackaging machinesRespiratorSupport plane

The invention discloses a mask packaging, conveying and metering device which comprises a main supporting frame. A main supporting plate is arranged at the upper portion of the main supporting frame. The front and back sides of the main supporting plate are each fixedly provided with a moving mechanism. Each moving mechanism is structurally characterized in that two supporting plates are fixed to the main supporting plate, the two ends of a rotating screw are hinged to the two supporting plates, a driving motor is fixedly arranged on one supporting plate, moving blocks are in screw connection with the rotating screw, a pushing frame is fixedly arranged on the moving blocks, and at least one pushing air cylinder is fixedly arranged on the pushing frame. Push rods of the pushing air cylinders of the two pushing frames stretch out oppositely and are fixedly provided with receiving frames. A discharging through hole is formed in the left end of the main supporting plate. A conveying frame is fixedly arranged on the ground below the main supporting frame. The lower portion of the discharging through hole is just opposite to a conveying belt of the conveying frame. The mask packaging, conveying and metering device can receive a certain number of packaged masks, automatically convey the masks and place the masks into a box, automatically count the number of the masks and move the masks to the ground, facilitates manual taking for follow-up arrangement and is quite convenient to use.

Owner:贵州中开生物科技有限公司

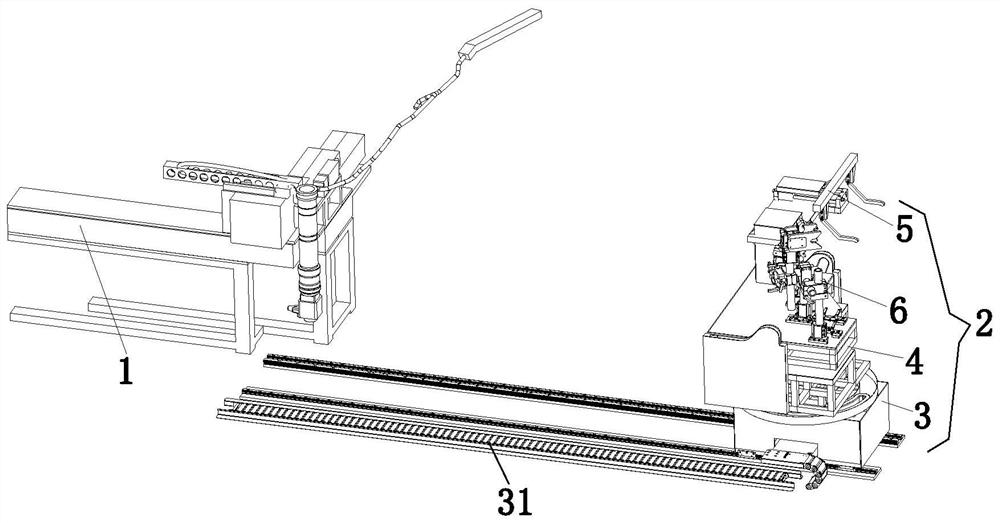

Automatic bent pipe discharging device

PendingCN112045005ARealize automatic discharge operationEasy to take by handStripping-off devicesStructural engineeringMechanical engineering

The invention discloses an automatic bent pipe discharging device and belongs to the technical field of bent pipes. The automatic bent pipe discharging device comprises a bending machine and further comprises a discharging device. The discharging device is arranged on one side of the bending machine, and the discharging device comprises a moving assembly, a bearing table, an inserting and supporting assembly and two clamping assemblies. A sliding way is arranged at the bottom of the moving assembly, the moving assembly is erected on a sliding way, the bearing table is located over the moving assembly and is in transmission fit with the moving assembly, the two clamping assemblies are arranged in a spaced mode, and the inserting and supporting assembly is located beside one clamping assembly. The two clamping assemblies and the inserting and supporting assembly are installed on the top of the bearing table. The automatic bent pipe discharging device has the advantages that in the bent aluminum pipe discharging process, the steps of moving, rotating, clamping, inserting and supporting and resetting can be sequentially achieved, manual labor is reduced, the full-automatic step of aluminum pipe discharging is improved, and bent aluminum pipe discharging is convenient to popularize.

Owner:惠州启动工业科技有限公司

Paper cup collecting and stacking system

The paper cup collecting and stacking system comprises a main base, a main support is arranged on one side of the top face of the main base, a falling mechanism is arranged on the upper portion of the support, a falling stabilizing opening is formed in one side of the main support, a stacking mechanism is arranged on the other side of the main base, and the lower portion of the stacking mechanism is connected with a driving mechanism in an engaged mode. According to the paper cup stacking device, inverted paper cups are aligned through the inverted aligning unit, the falling paper cups are stacked through the stacking unit in the stacking mechanism, when the stacking height reaches the set height, an inductor is triggered, and therefore the driving mechanism is started to drive the stacking mechanism to rotate, and the paper cups are stacked through the stacking unit in the stacking mechanism. According to the paper cup stacking device, the next stacking unit continues to conduct stacking, it is guaranteed that the number of each pile of paper cups is the same, meanwhile, the paper cups stacked in the previous stacking unit are pushed out through cooperation of the cam shaft and the stacking base, manual taking is convenient, and the manual discharging efficiency is greatly improved.

Owner:怀宁鑫辰纸塑有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com