Air sample collecting device

A sample collection and air technology, applied in the direction of sampling devices, measuring devices, electric operating devices, etc., can solve the problems of air particle number deviation, increased labor costs, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

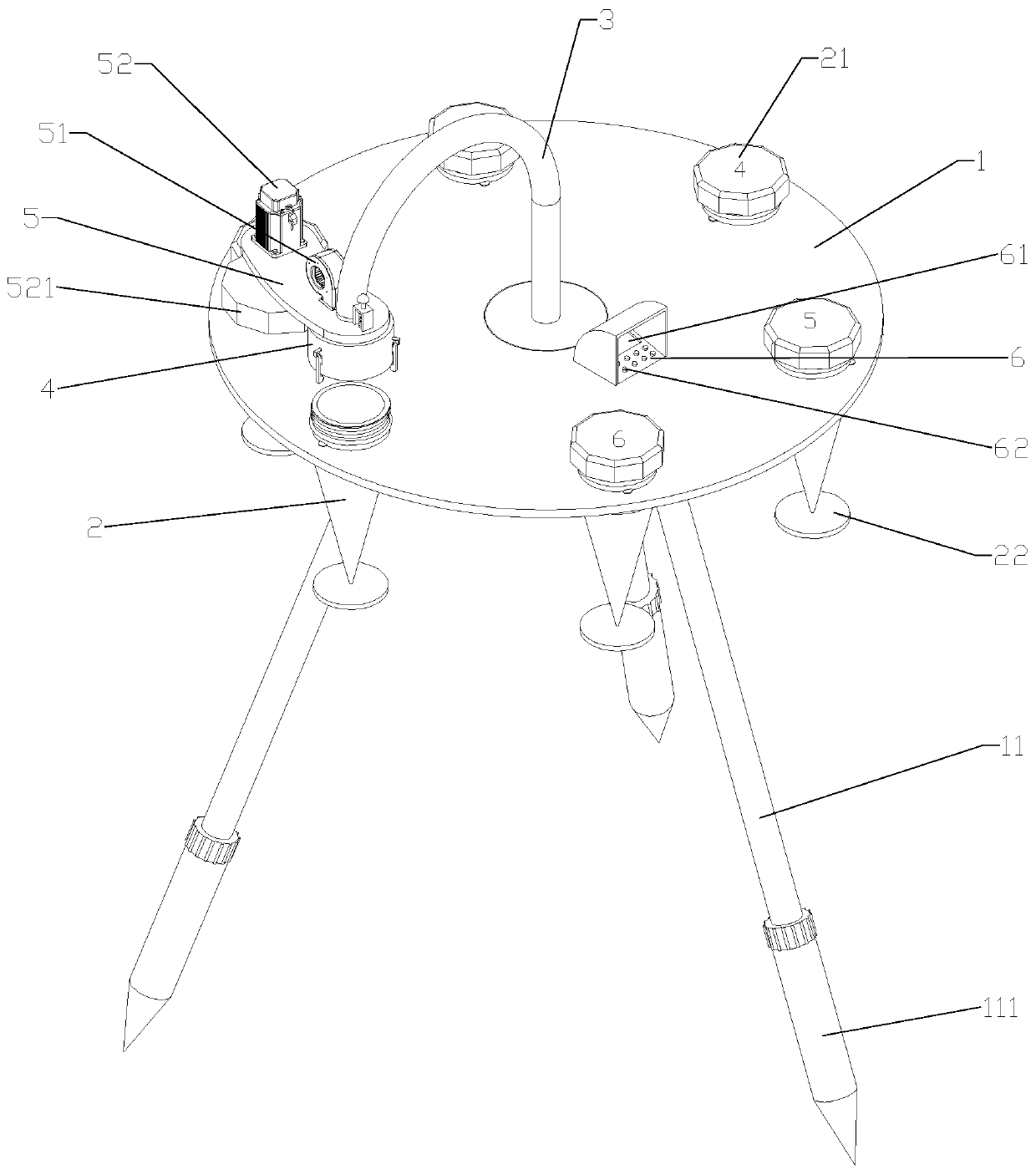

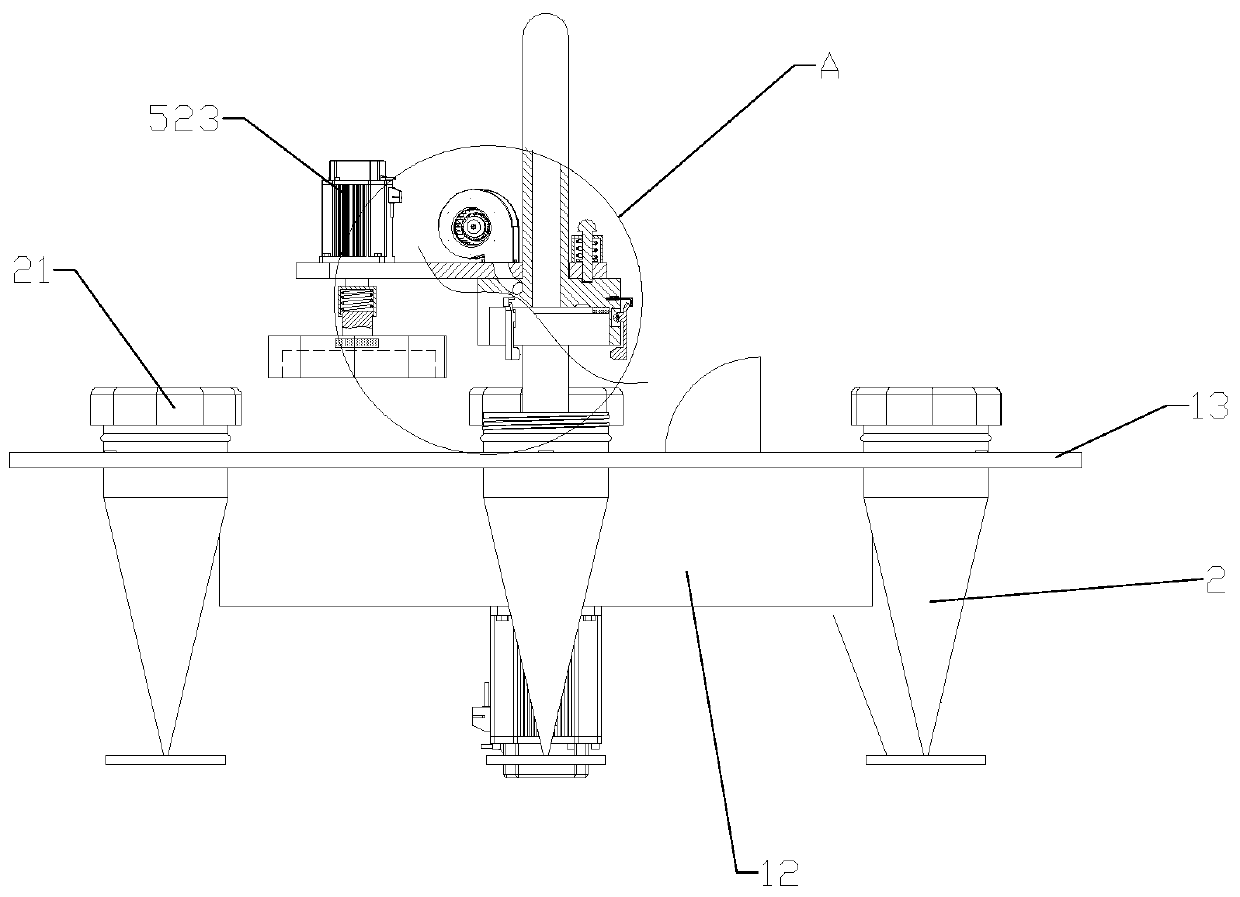

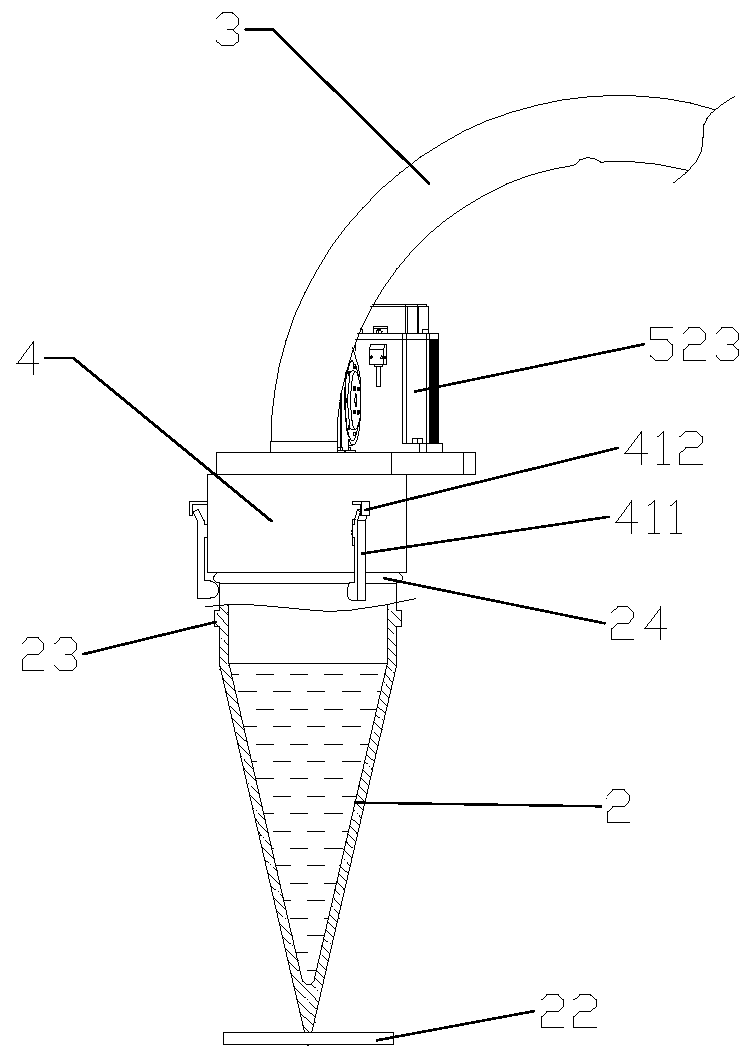

[0026] as attached figure 1 to attach Figure 9 The shown air sample collection device includes a frame 1, on which a plurality of through holes 131 are arranged at equal intervals around the circumference, and a collection bottle 2 with a tapered cavity inside is placed in each through hole 131. The specific implementation is as follows: the bottom end of the frame 1 is a cylinder 12 , and the top end is a flat plate 13 with a through hole 131 . A limiting block 23 is provided on the side wall of the collection bottle 2 , and a card slot 131 a is provided on the side wall of the through hole 131 of the plate 13 . When in use, it is enough to insert the conical collection bottle 2 into the through hole 131 of the plate 13 . The upper end of each collection bottle 2 is threadedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com