Mask packaging, conveying and metering device

A metering device and mask technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of increased labor load, troublesome material collection, etc., and achieve the effect of convenient follow-up arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

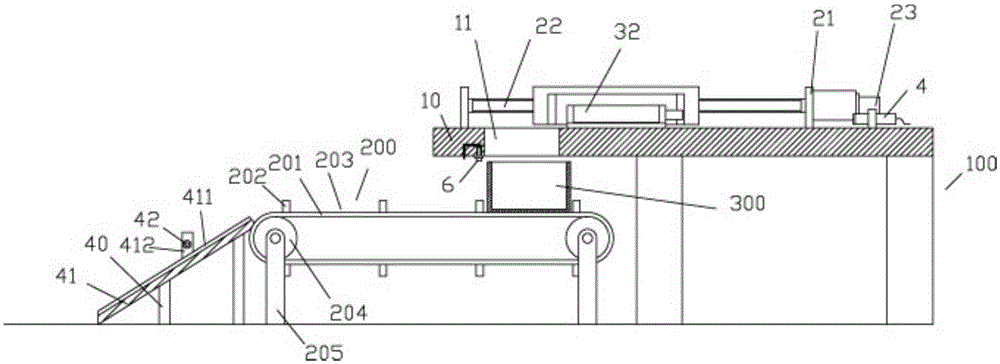

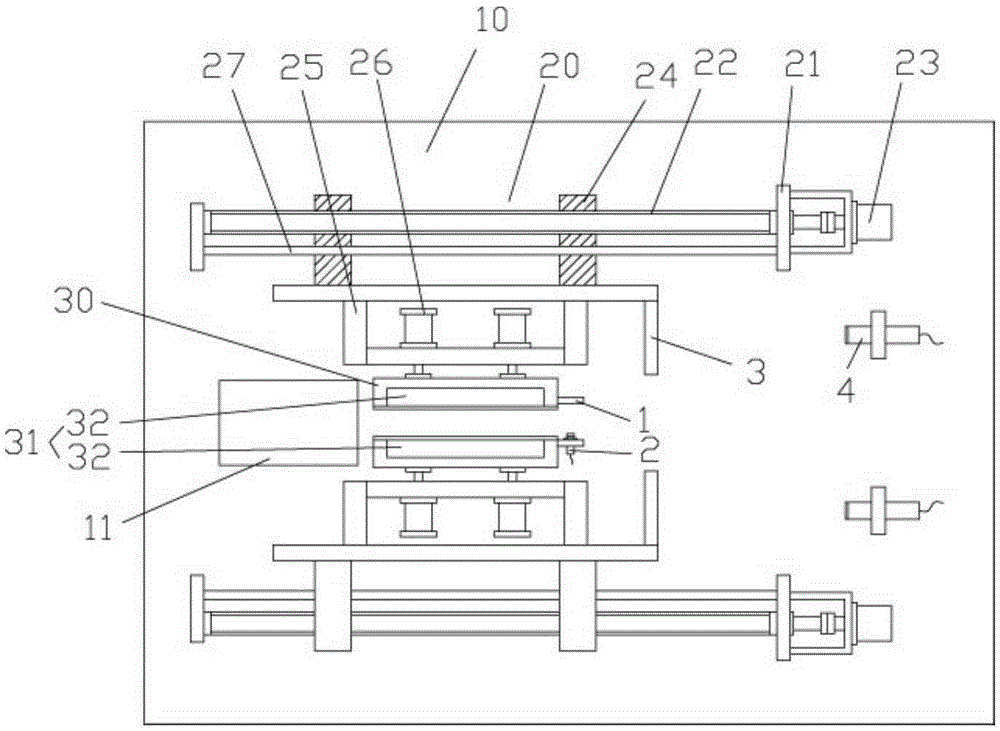

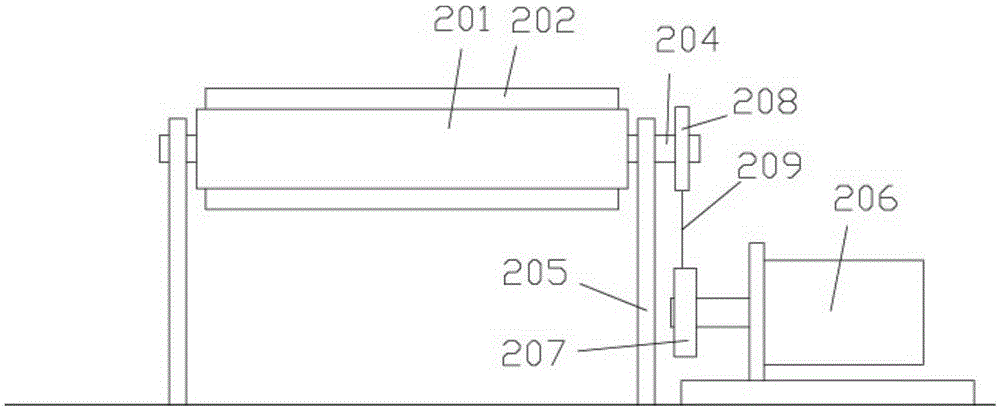

[0021] Examples, see e.g. Figure 1 to Figure 4 As shown, a mask packaging delivery metering device includes a main support frame 100, the upper part of the main support frame 100 is a main support plate 10, and the front and rear sides of the main support plate 10 are fixed with moving mechanisms 20;

[0022] The structure of the moving mechanism 20 is that two support plates 21 are fixed on the main support plate 10, and the two ends of the rotating screw rod 22 are hinged on the two support plates 21, and a drive motor 23 is fixed on one of the support plates 21, and the drive motor 23 The output shaft is connected with an end of the supporting plate 21 that stretches out correspondingly with the rotating screw rod 22 through a coupling, the moving block 24 is screwed on the rotating screw rod 22, the moving block 24 is fixed with a push frame 25, and the push frame 25 is fixed with At least one push cylinder 26, the push rods of the push cylinders 26 of the two push frames...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com