Dye container standby conveying and grasping system

A dye and conveying roller technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of large manual labor, troublesome process, inconvenient, etc., and achieve good effect, convenient picking and placing, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

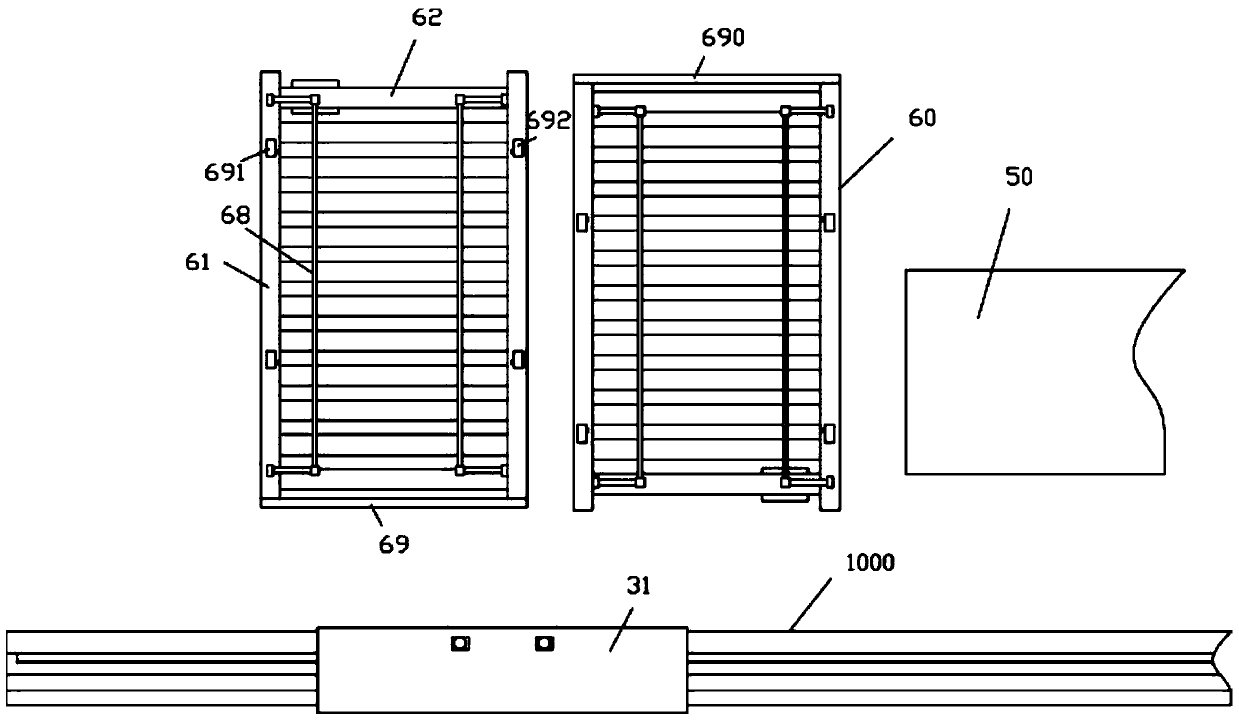

[0039] Examples, see e.g. Figure 1 to Figure 12 As shown, a kind of conveying and grabbing system for dyestuff storage includes a stocking rack 50, a transitional feeding rack 60 and a grabbing mechanism 1000, and a stocking rack is placed on the ground behind the bottom track mechanism 10 of the grabbing mechanism 1000. 50 and transition rack 60;

[0040] A plurality of empty slots 51 are formed on the stock rack 50, and a slot 52 is formed in the middle of the bottom plate at the empty slots 51;

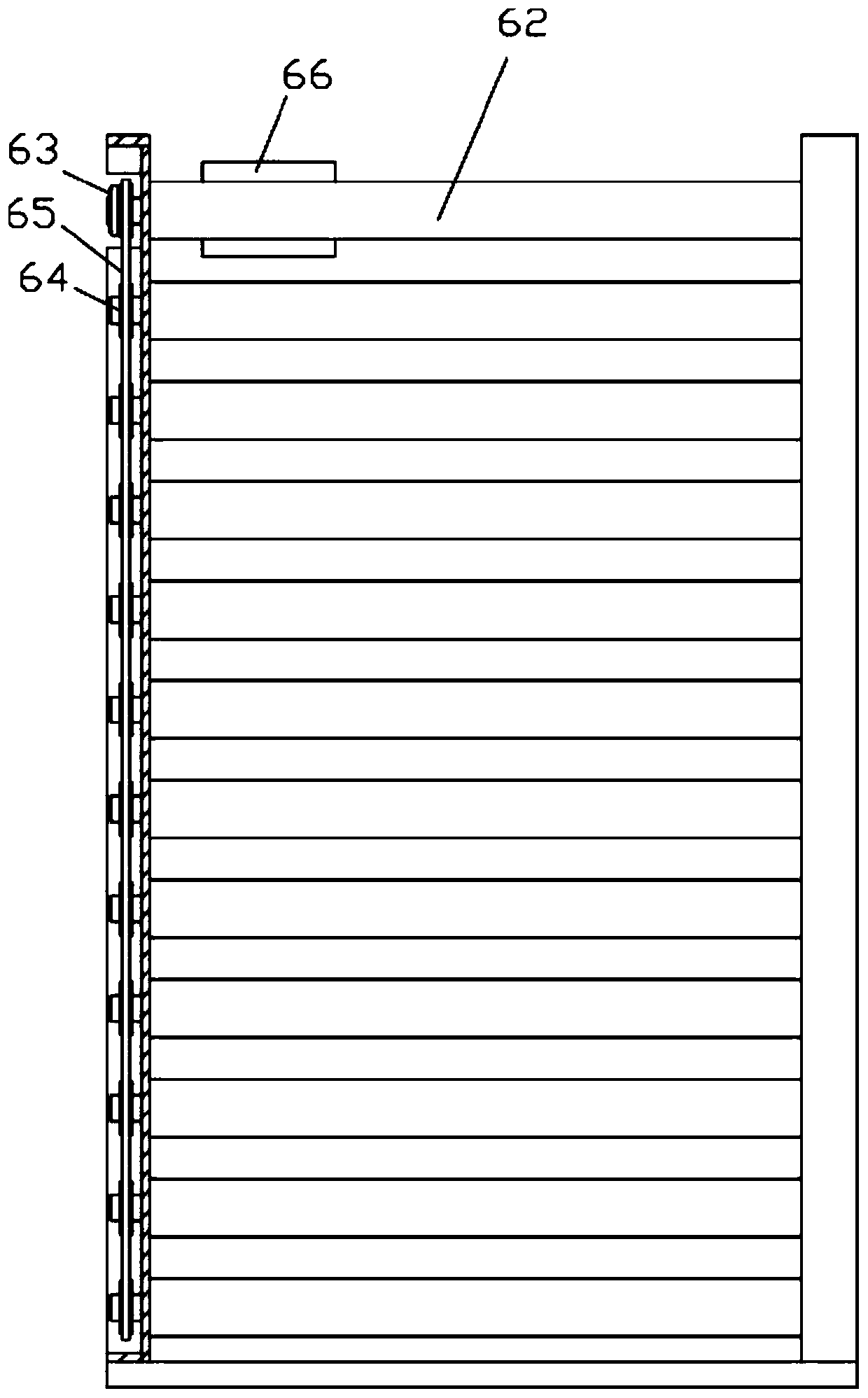

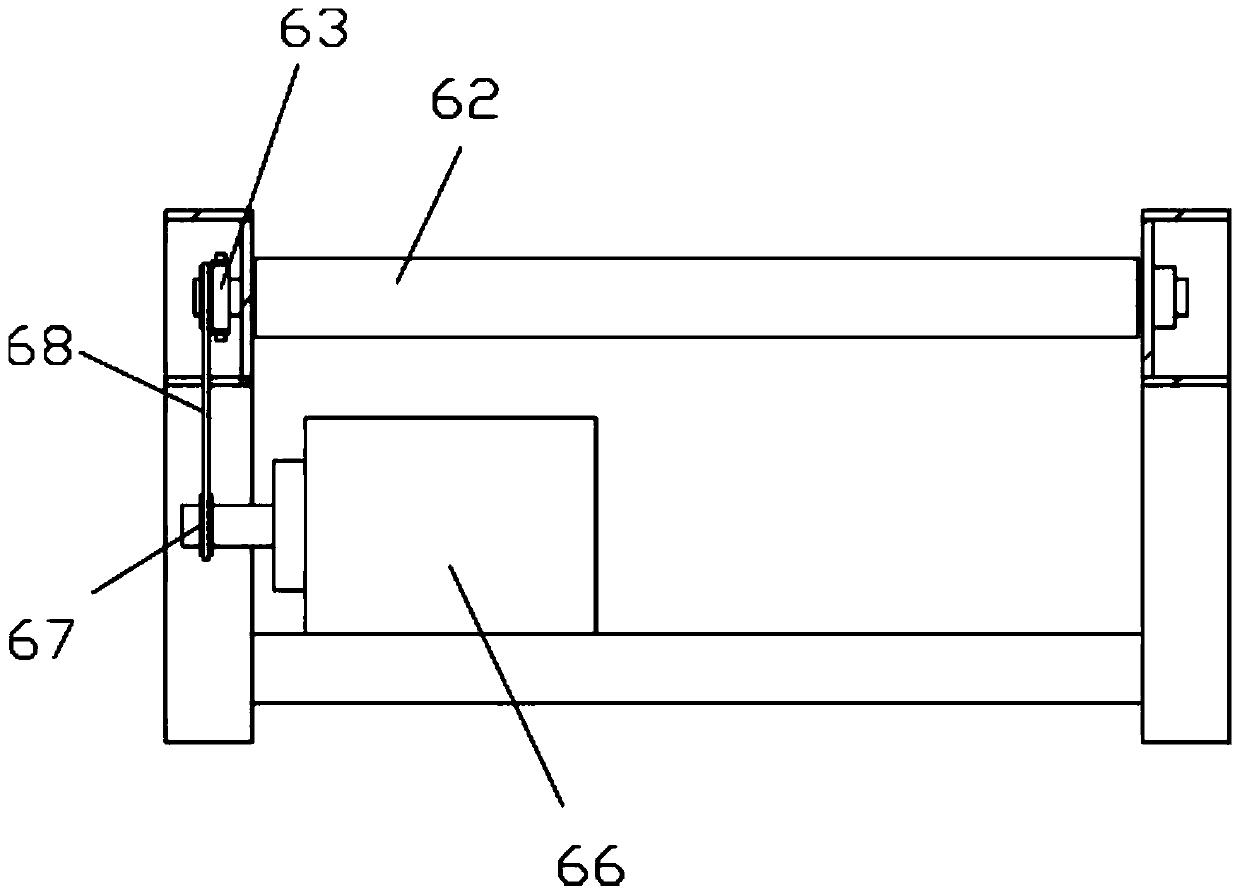

[0041]The transitional discharge frame 60 includes a discharge support frame 61, a plurality of conveying roller bodies 62 are arranged between the left and right side beams of the discharge support frame 61, and the rotating shafts at both ends of the conveying roller bodies 62 are hinged on the corresponding On the side plate body of the side beam, the shafts on the same side of all conveying rollers 62 stretch out from the side plate of the side beam, and one of the shafts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com