A metal pipe automatic clamping and cutting mechanism with a receiving tank body

A technology of cutting mechanism and receiving chute, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of troublesome disassembly and installation of clamping blocks, easy contact with people, and low cutting efficiency, so as to achieve automation High degree, good effect, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

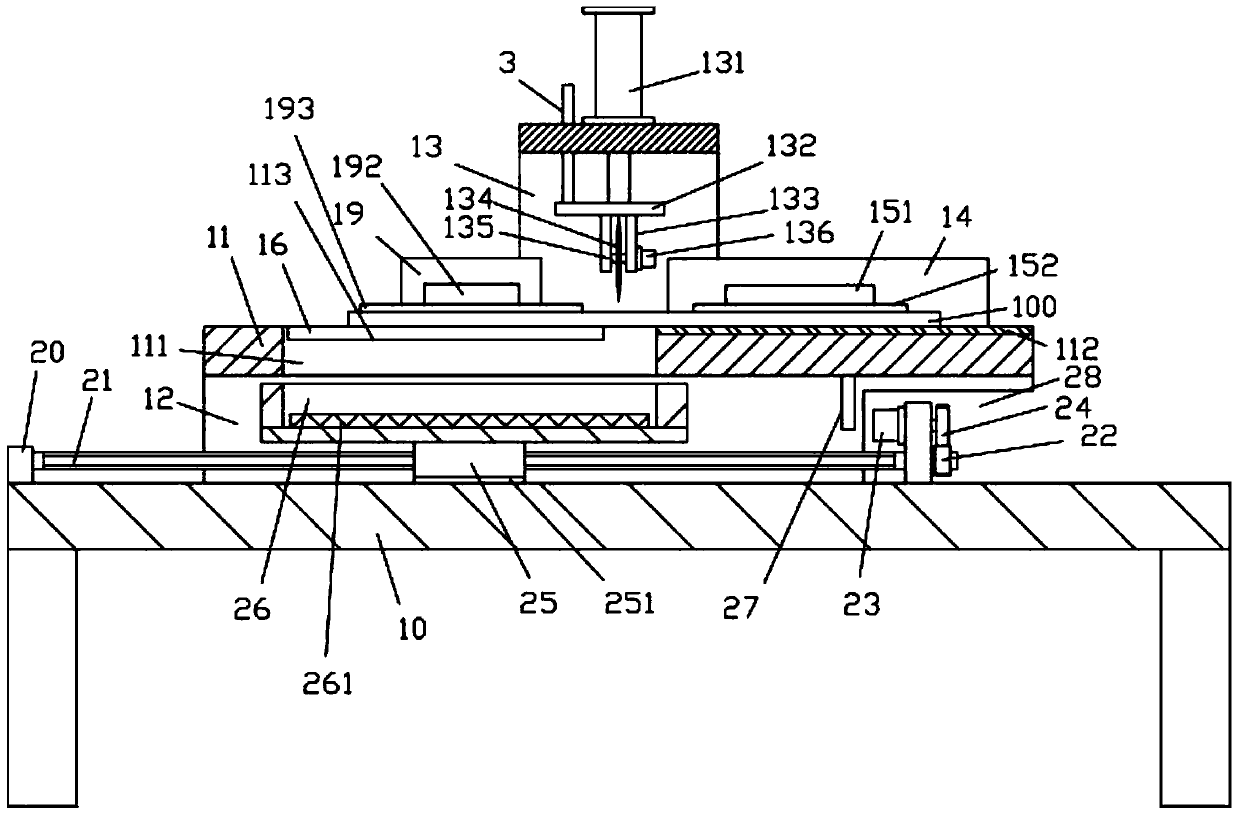

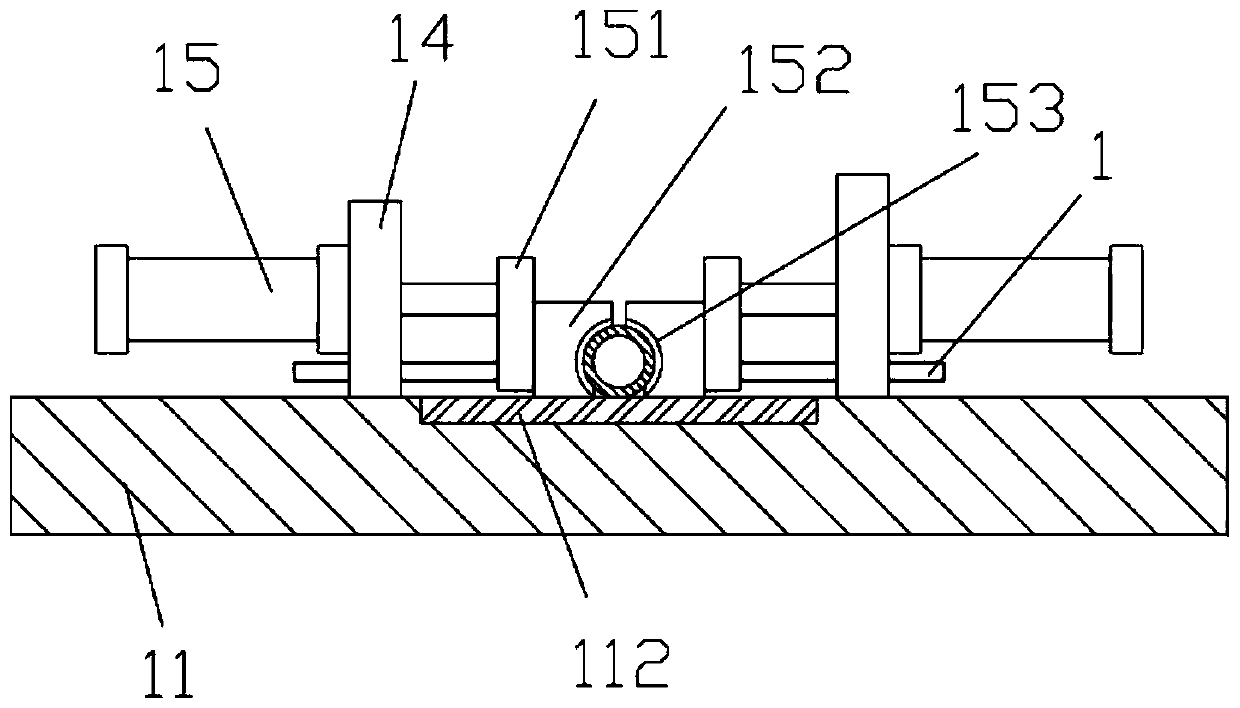

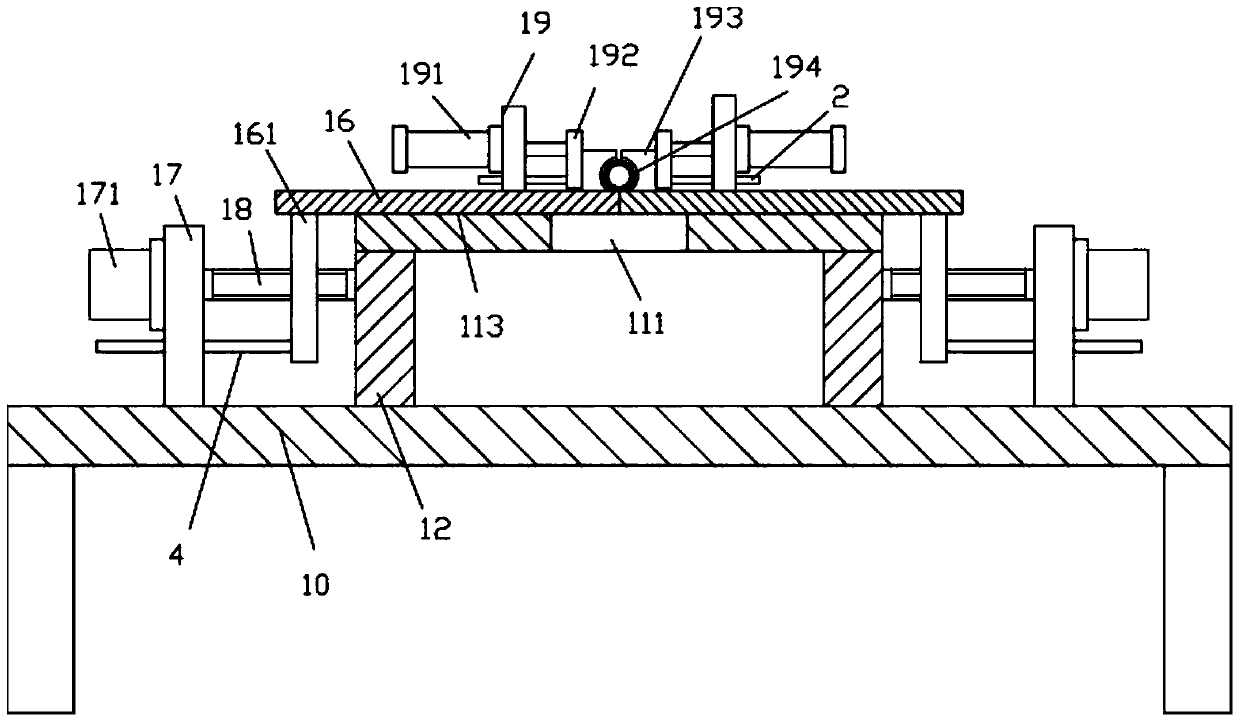

[0023] Examples, see e.g. figure 1 with image 3 As shown, a metal pipe automatic clamping and cutting mechanism with a material receiving tank body includes a frame 10, a horizontal plate 11 is provided above the top surface of the top plate of the frame 10, and the front part of the bottom surface of the horizontal plate 11 and The rear portion is fixed with a lower support plate 12, and the bottom surface of the lower support plate 12 is fixed on the top surface of the top plate of the frame 10;

[0024] The left side and the right part of the top surface middle part of the top plate of the frame 10 are all fixed with a material receiving support plate 20, and the material receiving moving screw rod 21 is hinged on the two material receiving supporting plates 20 through bearings, and the material receiving moving screw rod 21 The right end stretches out the material receiving support plate 20 on the right side and is fixed with transmission gear 22, and the top of the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com