Telescopic heavy building pipe clamping and lifting mechanism

A telescopic and heavy-duty technology, applied in the direction of cranes, load hanging components, transportation and packaging, etc., can solve the problems of energy consumption, low efficiency, high crane handling costs, etc., to achieve easy access, improve efficiency, and reduce manual labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

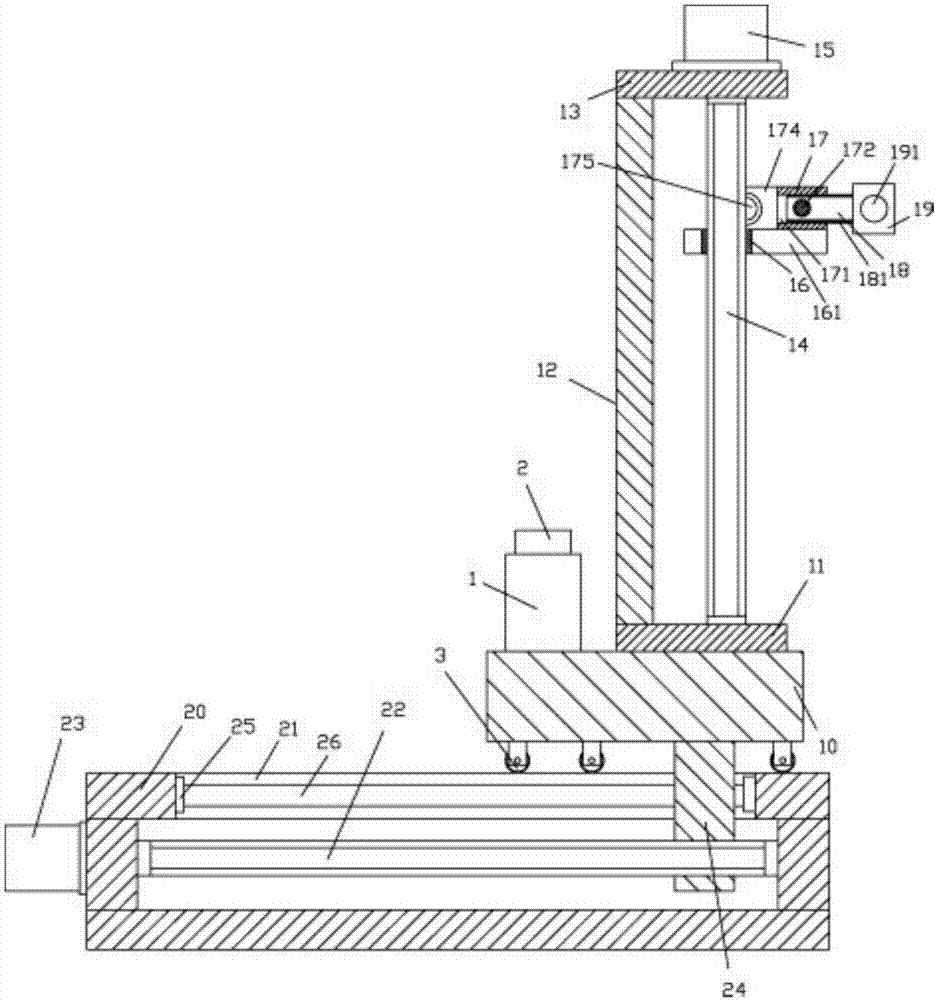

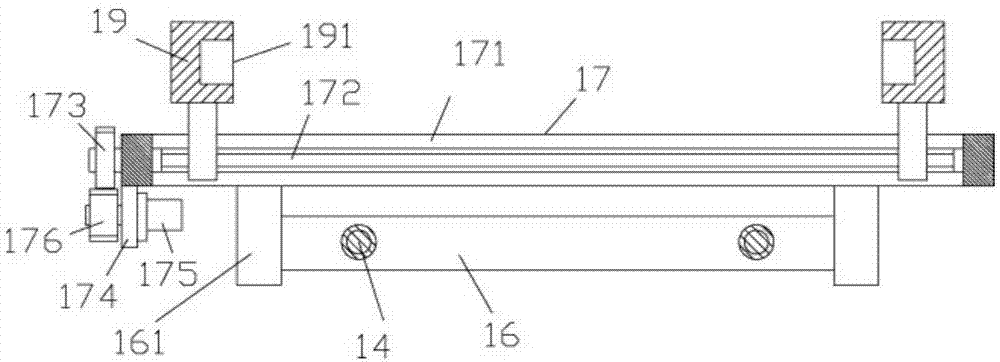

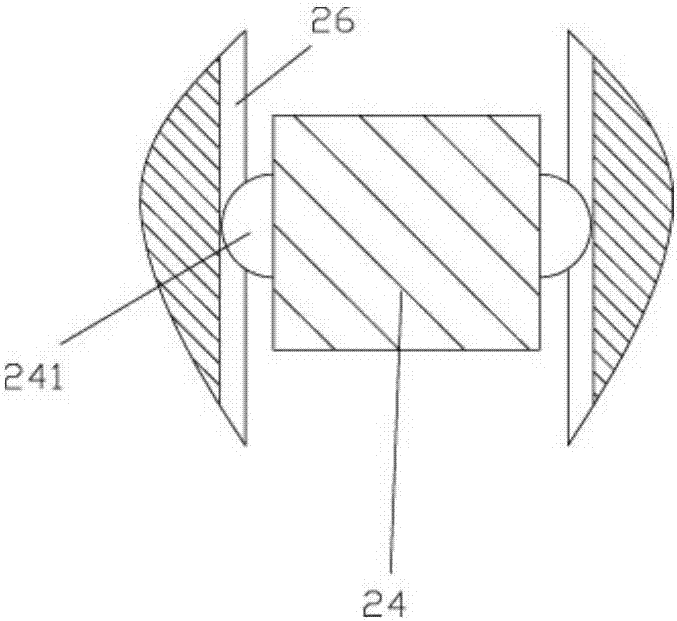

[0018] Examples, see e.g. Figure 1 to Figure 3 As shown, a telescopic heavy-duty construction pipe material clamping and lifting mechanism includes a base 10 and a moving main frame body 20. The middle part of the top plate of the moving main frame body 20 has a transverse moving channel 21, and the middle part of the moving main frame body 20 Be provided with main transverse transmission screw rod 22, the two ends of main transverse transmission screw rod 22 are hinged on two side plates of mobile main frame body 20, and the lateral main drive motor 23 is fixed on the outer wall of one of them side plate, and transverse main drive motor The output shaft of 23 is a spline shaft, and the spline shaft is inserted into the spline hole at one end of the main transverse transmission screw 22, and the push block 24 is screwed in the main transverse drive screw 22, and the top of the push block 24 extends out of the transverse direction. Move the slot 21 and fix it on the bottom sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com