Automatic conveying mechanism of illuminating fluorescent tubes with automatic adjustment mechanism

A fluorescent tube and automatic conveying technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of low efficiency and poor effect, and achieve the effect of high efficiency, good effect and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

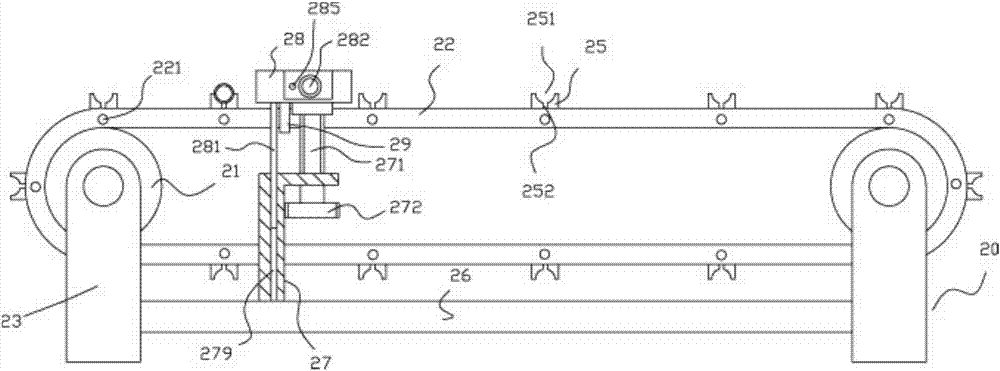

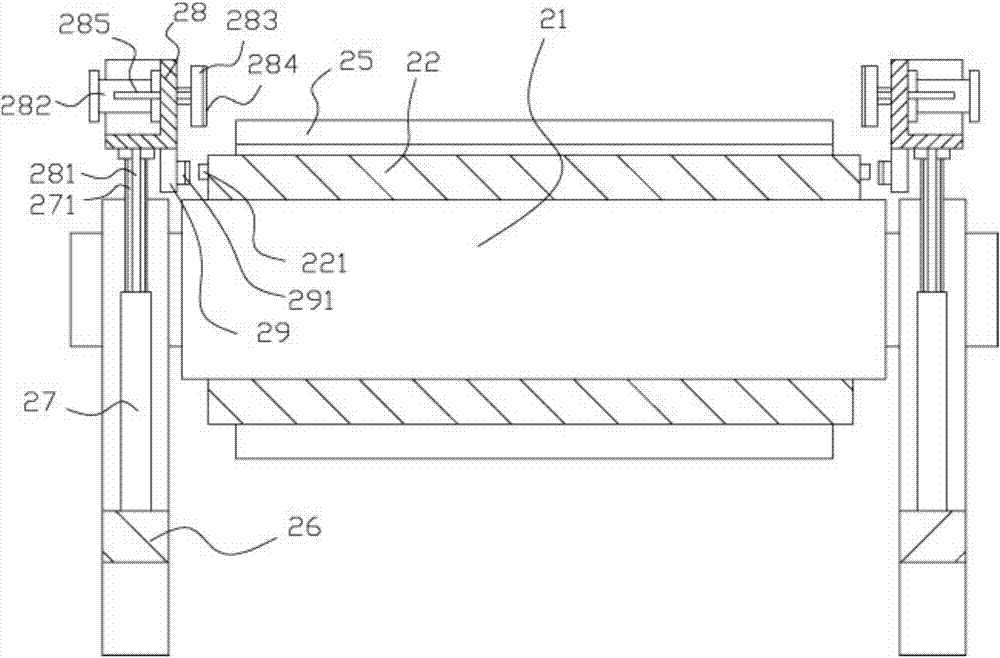

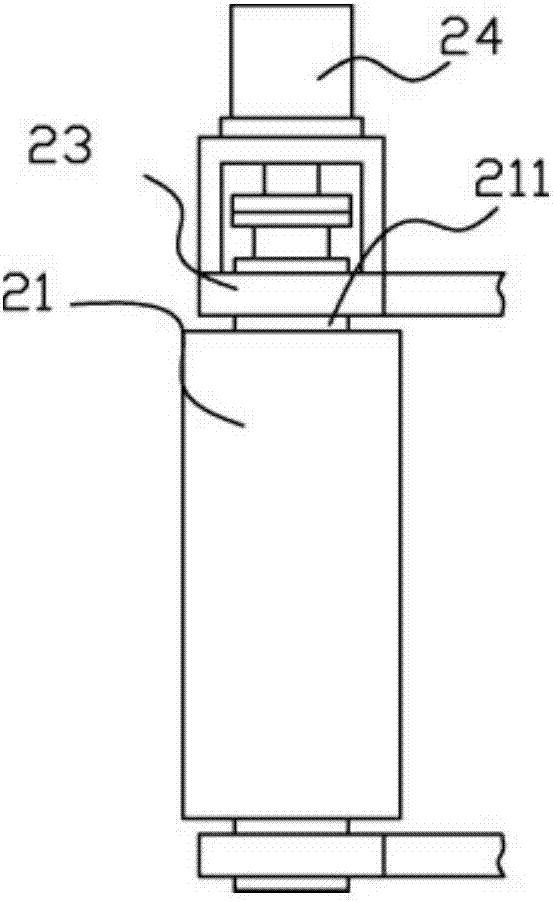

[0017] Example: see Figure 1 to Figure 3 As shown, an automatic conveying mechanism for lighting fluorescent tubes with an automatic adjustment mechanism includes a conveying frame 20, the left and right ends of the conveying frame 20 are hinged with transmission rollers 21, and the conveyor belt 22 is tensioned on the two transmission rollers 21, wherein One end of a transmission roller 21 is formed with a raised column 211, and the raised column 211 stretches out from the support leg 23 of the conveyor frame 20 and is connected with the output shaft of the transmission motor 24 fixed on the support leg 23 through a coupling. A plurality of lamp tube placement blocks 25 are fixed on the outer wall surface of 22, and a mounting groove 251 is formed on the outer wall surface of the lamp tube placement block 25;

[0018] Described delivery frame 20 comprises four supporting legs 23, is provided with intermediate beam 26 between two supporting legs 23 on the same side, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com