Drying and conveying equipment with good effect for plate cutting

A technology for conveying equipment and plates, which is applied in the directions of wood drying, drying gas arrangement, lighting and heating equipment, etc. It can solve the problems of slow cutting efficiency, wet plates, and blackening of the cutting parts of the plates, so as to improve the sealing effect and improve the drying efficiency , The effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

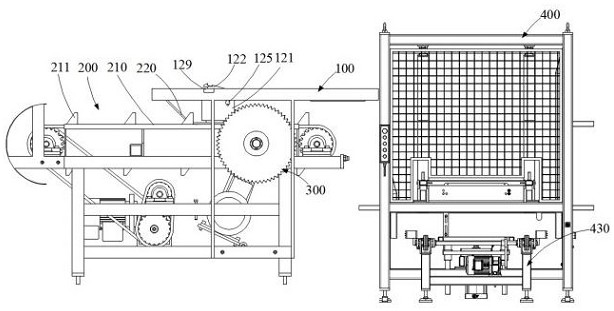

[0047] Such as Figure 1~6 As shown, a kind of dry conveying equipment for plate cutting with good effect, including,

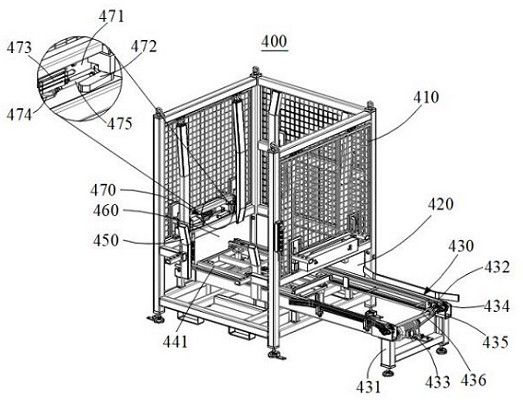

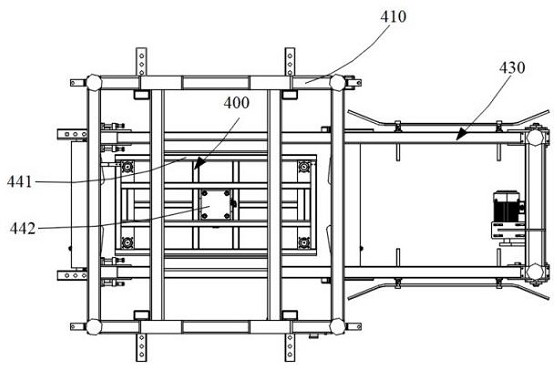

[0048]The cutting system and the receiving system 400 arranged on one side of the cutting system, the receiving system 400 includes a collection box 410, a discharge port 420 provided on one side of the collection box 410 and a collection box 410 within the transfer section 430, and

[0049] The transmission part 430 includes a transmission frame 431, a transmission belt 432 arranged on both sides of the transmission frame 431, and a driving part for driving the transmission belt 432 to rotate; a lifting part 440 is also provided between the transmission frames 431, and the lifting The part 440 is adapted to lift the sheets in the collection box 410 to the top of the collection box 410;

[0050] The cutting system includes a first conveying unit 100, the first conveying unit 100 includes a support 110, a cooling unit 120 arranged on the support 110 and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com