Carrier capable of horizontally moving and rotating fabric reels

A technology for moving horizontally and transporting vehicles, applied in the direction of motor vehicles, trolleys, multi-axis trolleys, etc., can solve the problems of increased labor, unsatisfactory results, and manual handling consumes physical strength, etc., to achieve good results, reduce manual labor, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

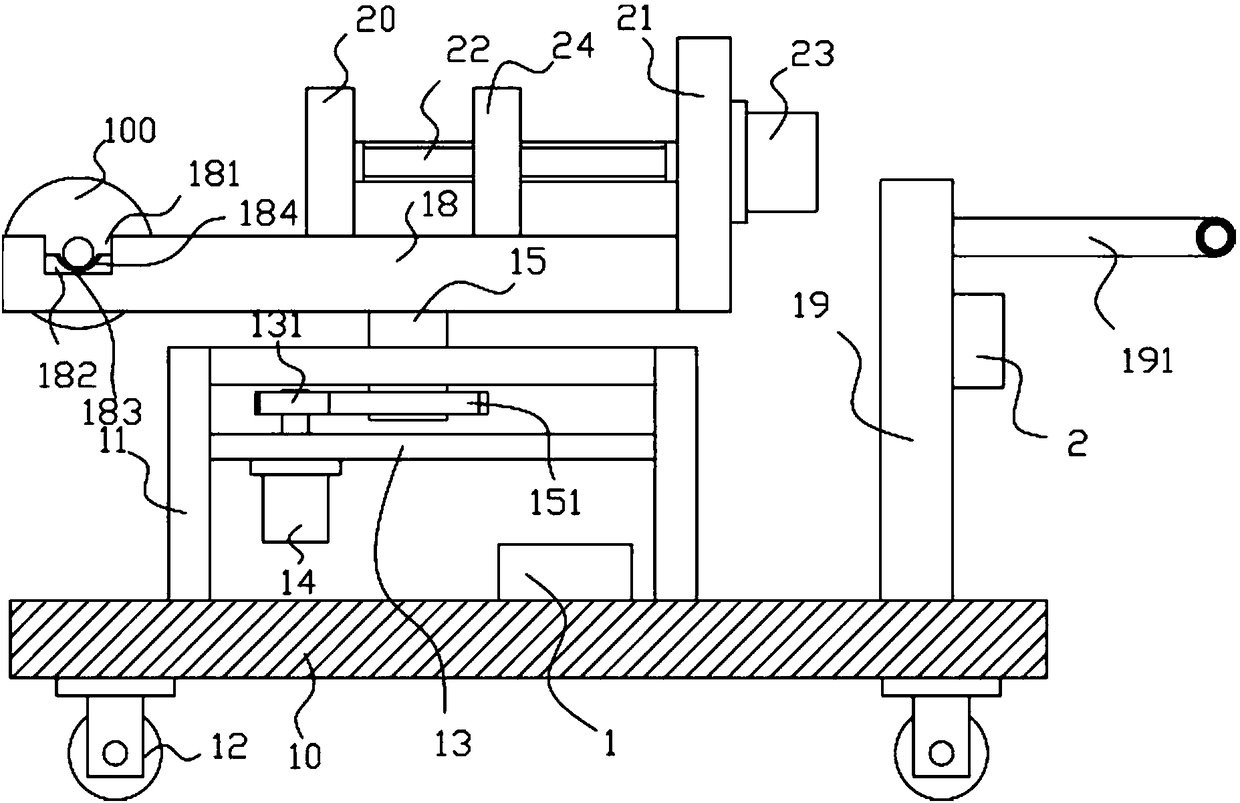

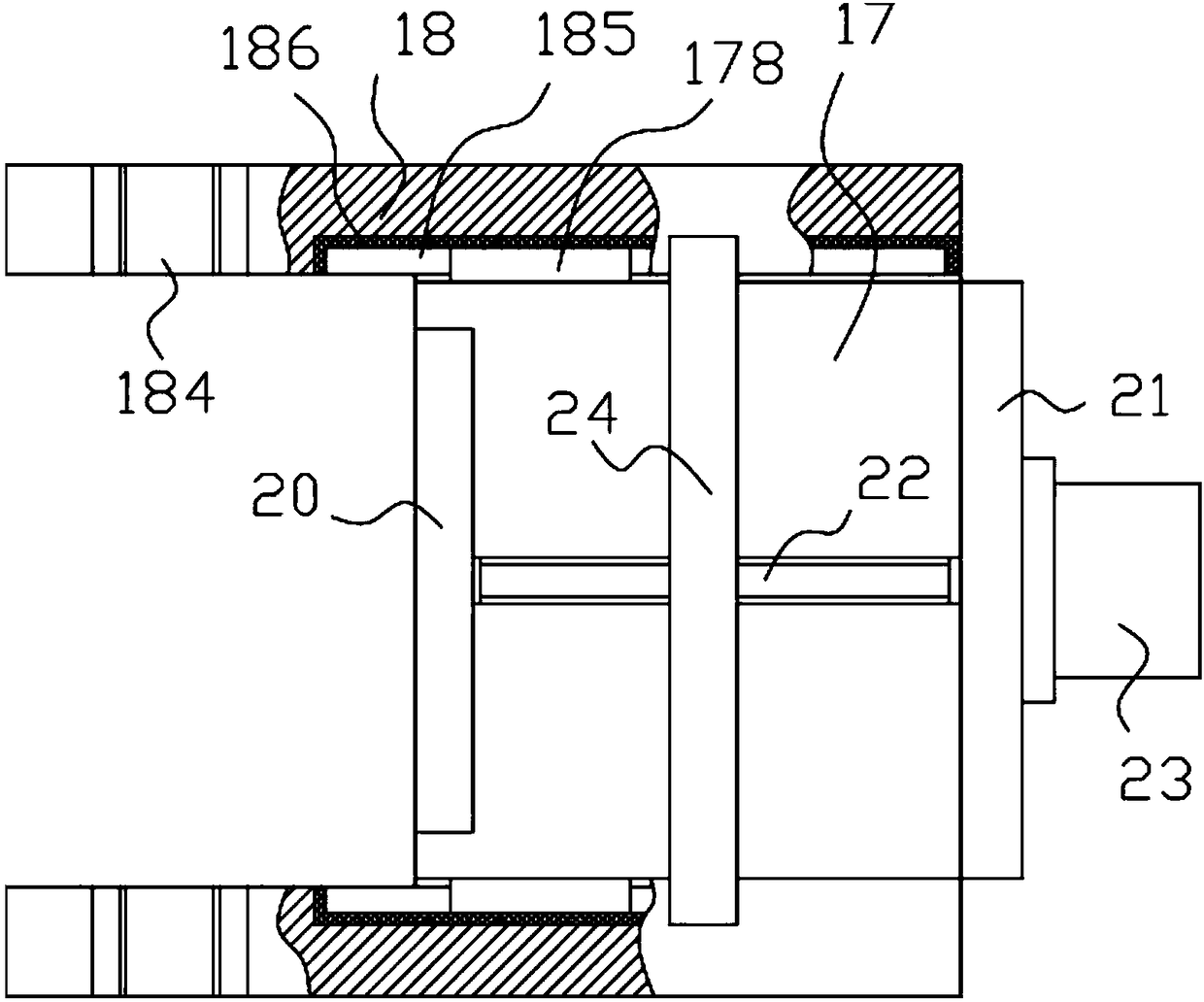

[0016] Example: see Figure 1 to Figure 2 Shown, a kind of material reel horizontally moves rotary transfer vehicle, comprises vehicle floor 10, and the top surface of described vehicle floor 10 is fixed with support frame 11, and the bottom surface of vehicle floor 10 is fixed with a plurality of wheels 12, and support frame 11 is provided with There is a transverse plate 13, the side wall of the transverse plate 13 is fixed on the inner side wall of the support frame 11, the bottom surface of the transverse plate 13 is fixed with an adjusting rotating motor 14, and the output shaft of the adjusting rotating motor 14 passes through the transverse plate 13 and is fixed with a driving gear 131, the transmission shaft 15 is hinged on the top plate of the support frame 11, the bottom end of the transmission shaft 15 is below the top plate of the support frame 11 and is fixed with a transmission gear 151, the transmission gear 151 is meshed with the drive gear 131, and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com