Material tray bottom lifting mechanism with detecting device

A detection device and material tray technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as safety, hidden dangers, inconvenient refueling, etc., and achieve good safety, high degree of automation, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

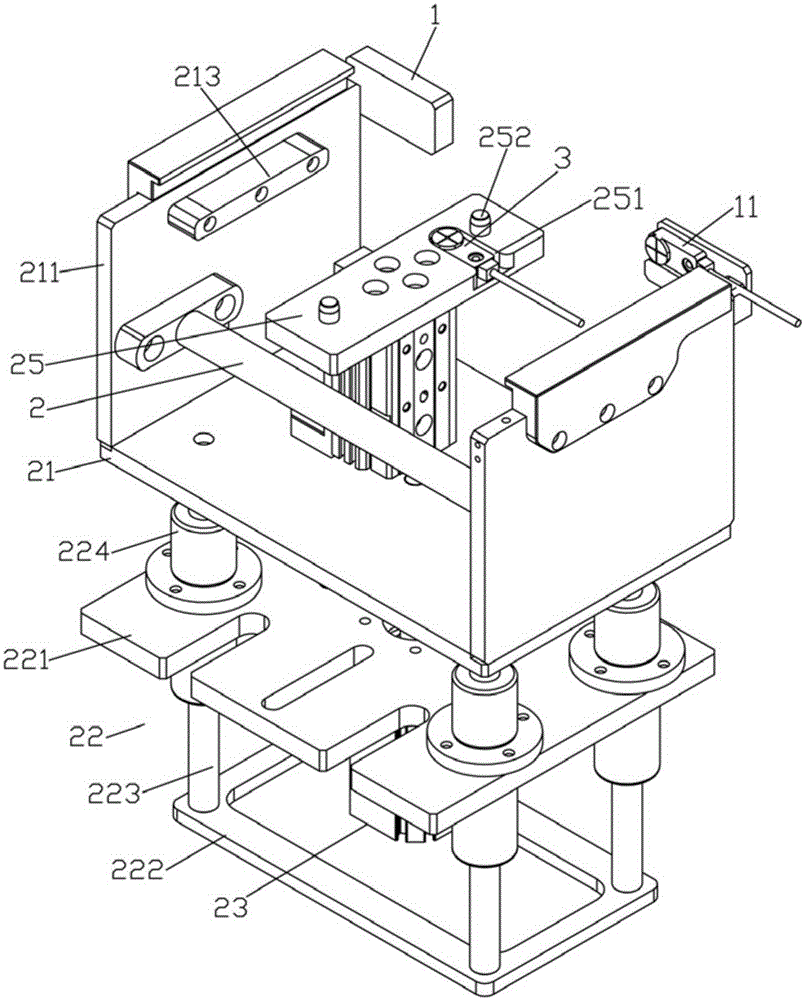

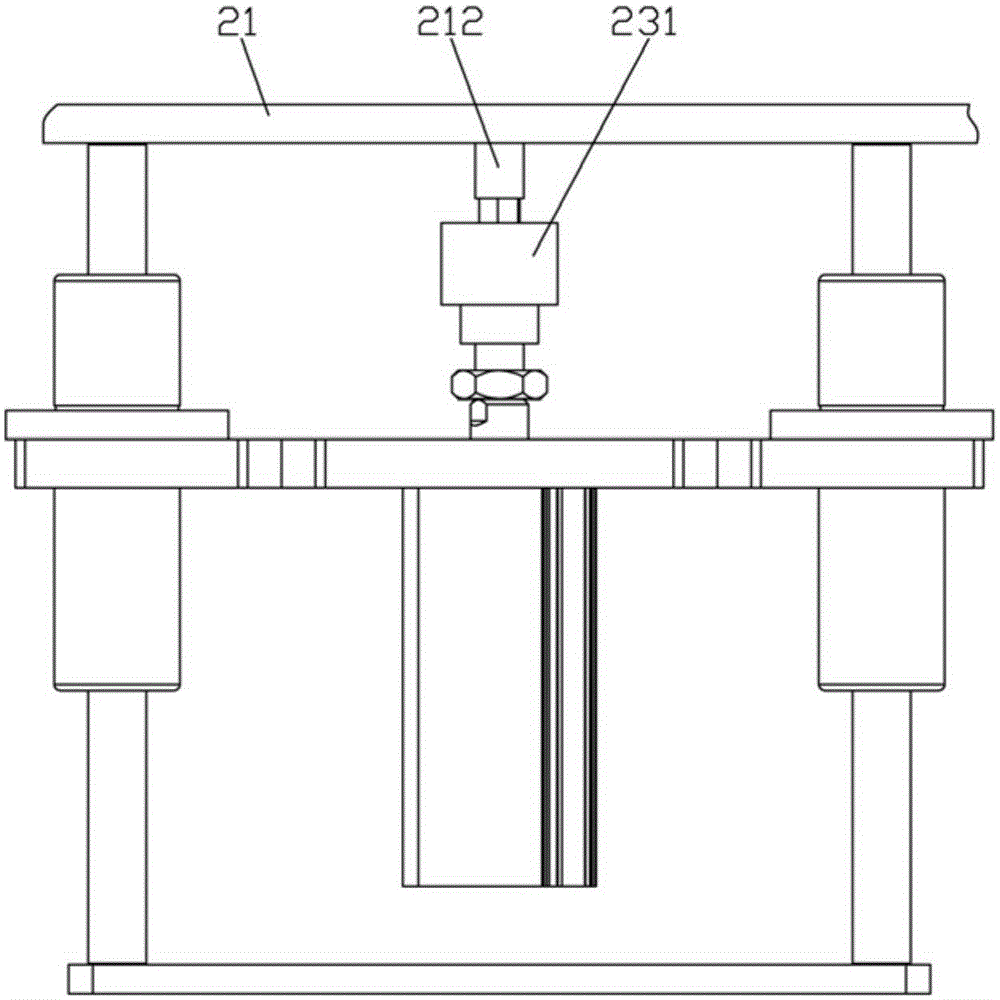

[0016] Examples, see e.g. Figures 1 to 2 As shown, a lifting mechanism at the bottom of a material tray with a detection device includes a base 22, a lifting cylinder 23 is fixed in the base 22, and the push rod of the lifting cylinder 23 passes through the base top plate 221 of the base 22 vertically upwards and is fixed on the lifting cylinder 22. On the bottom surface of the frame 21, a jacking cylinder 24 is fixed on the bottom plate of the lifting frame 21, and a jacking block 25 is fixed on the push rod of the jacking cylinder 24;

[0017] Two baffle plates 1 are fixed on the upper rear end of the lifting side plate 211, and the baffle plate 1 is located between the two lifting side plates 211, and a baffle plate proximity switch 11 is fixed on one of the baffle plate 1;

[0018] A jacking proximity switch 3 is fixed on the jacking block 25 , and the jacking proximity switch 3 is located in the groove 251 of the jacking block 25 , and two positioning columns 252 are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com