Patents

Literature

49results about How to "Free fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

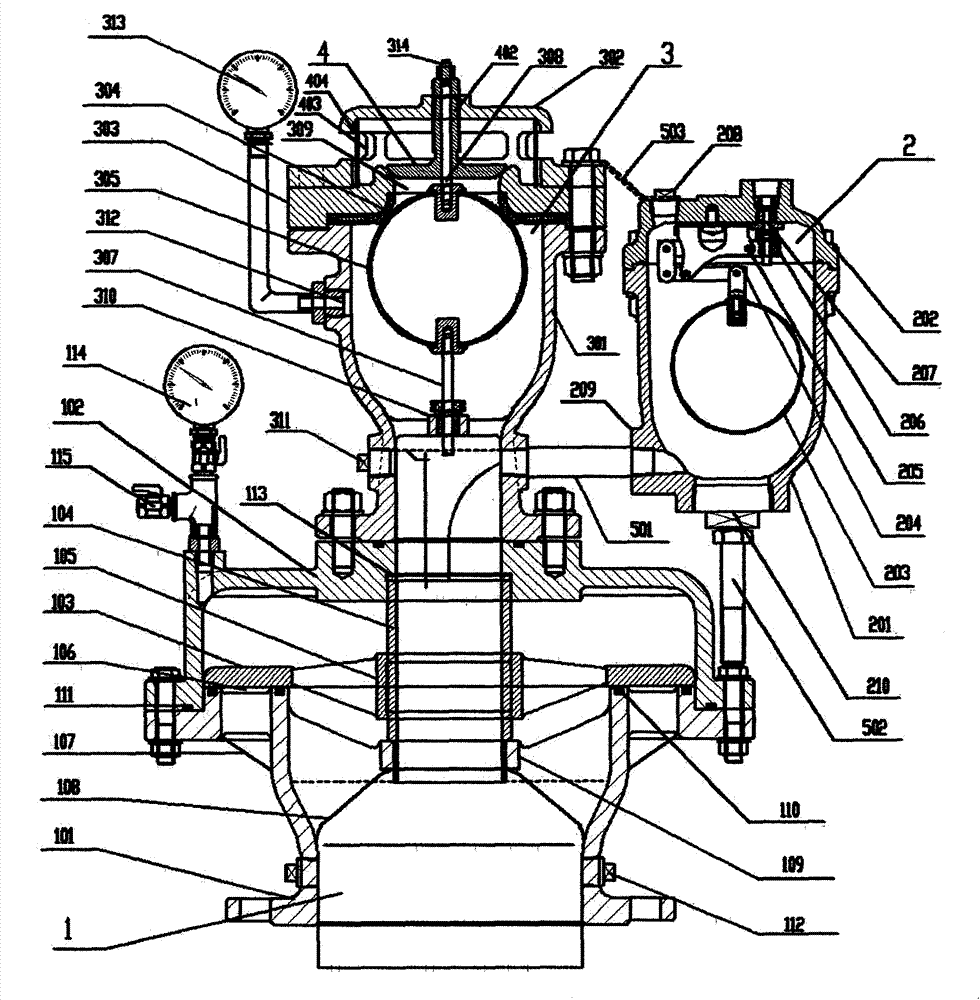

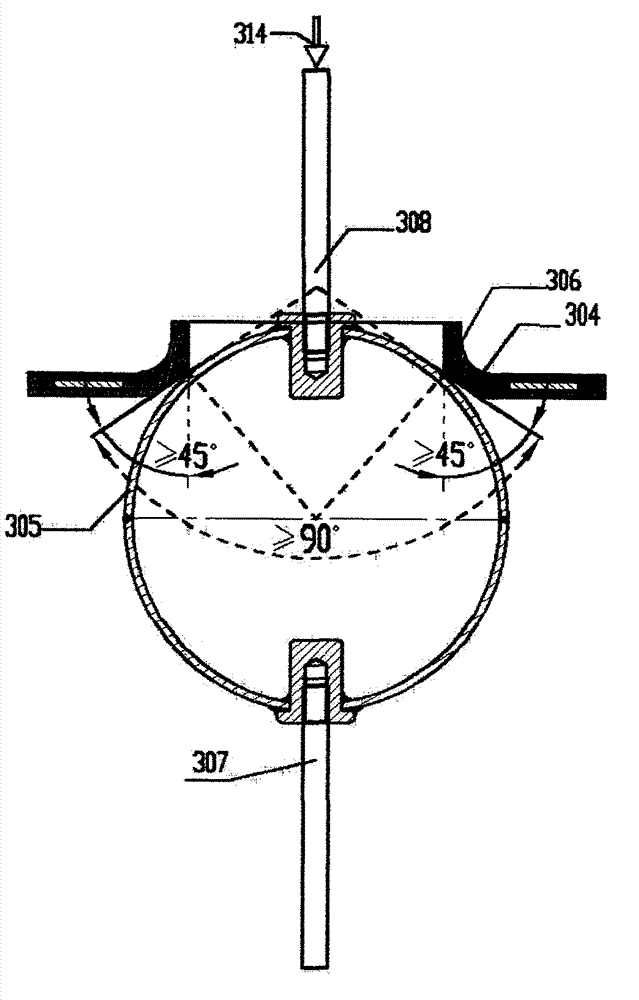

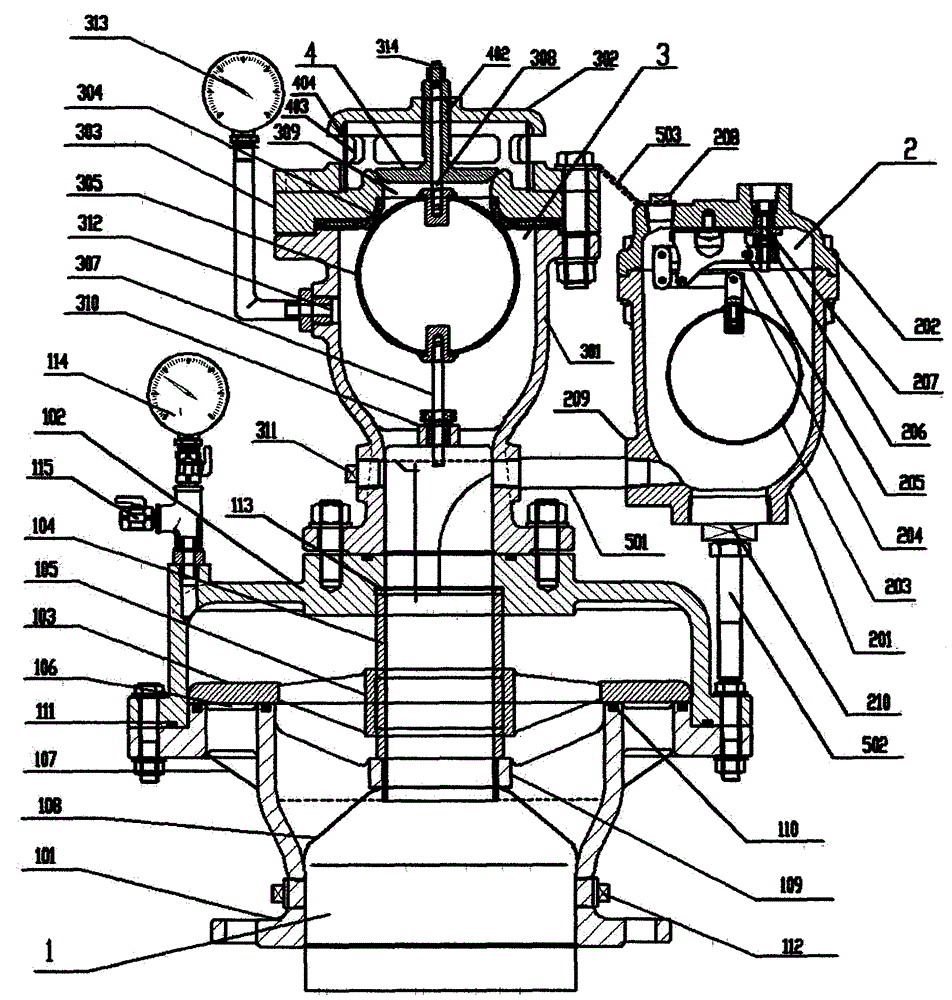

Rear adjustable three-hole composite type waterproof hammer air group valve

ActiveCN103672042ASmall sizeFilling speed reducedValve members for absorbing fluid energyMultiple way valvesSite monitoringAnti freezing

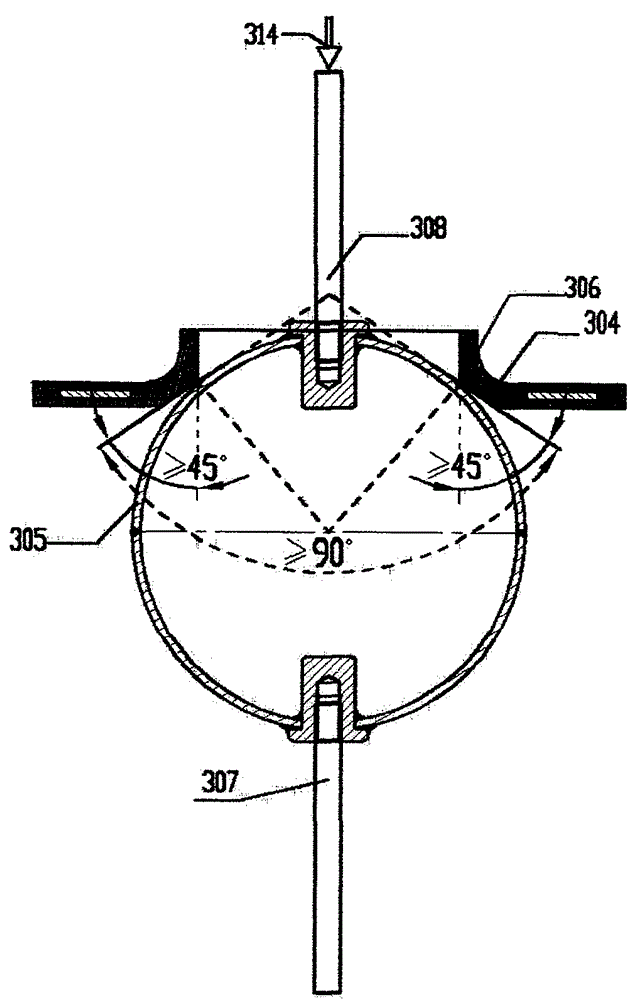

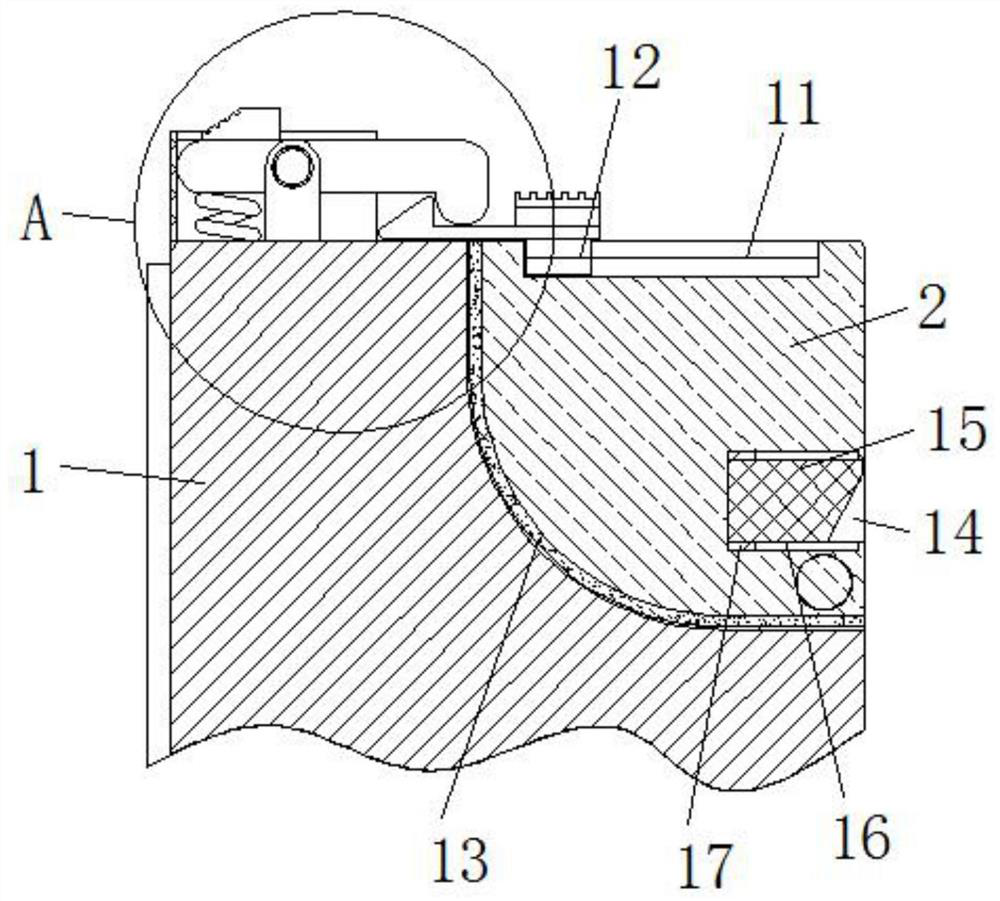

The invention discloses a rear adjustable three-hole composite type waterproof hammer air group valve. The air group valve is integrally or separately arranged on a liquid conveying pipeline or a container system, a high-speed exhaust hole of the air group valve can be adjusted and controlled, is arranged alone, and is generally smaller than suction holes, the high-speed exhaust hole and the high-speed suction holes are formed separately and are not shared for use, independent model selection and adjustment can be conducted, the requirements of high-speed exhaust and high-speed gas suction for two different quantities of flow or two different diameters or two proportions are met, and meanwhile two built-in type gas bags are formed quite ingeniously. The group valve combines independent intermediate-speed exhaust, independent high-speed gas suction and trace amount exhaust, and has a dozen of functions, namely, the independent intermediate-speed exhaust function, the independent high-speed gas suction function, the trace amount exhaust function, the function of a high-suction and intermediate-exhaust waterproof hammer, the function of a high-suction and trace-exhaust waterproof hammer, the function of a built-in gas bag waterproof hammer, the built-in gas bag anti-freezing function, the function of a rear adjusting control valve and the function of monitoring the hole pressure difference and the total pressure difference on site in the empty pipe liquid filling process through two pressure meters. The various ventilation and safety protection requirements of a liquid path system can be met.

Owner:ANHUI REDSTAR VALVE

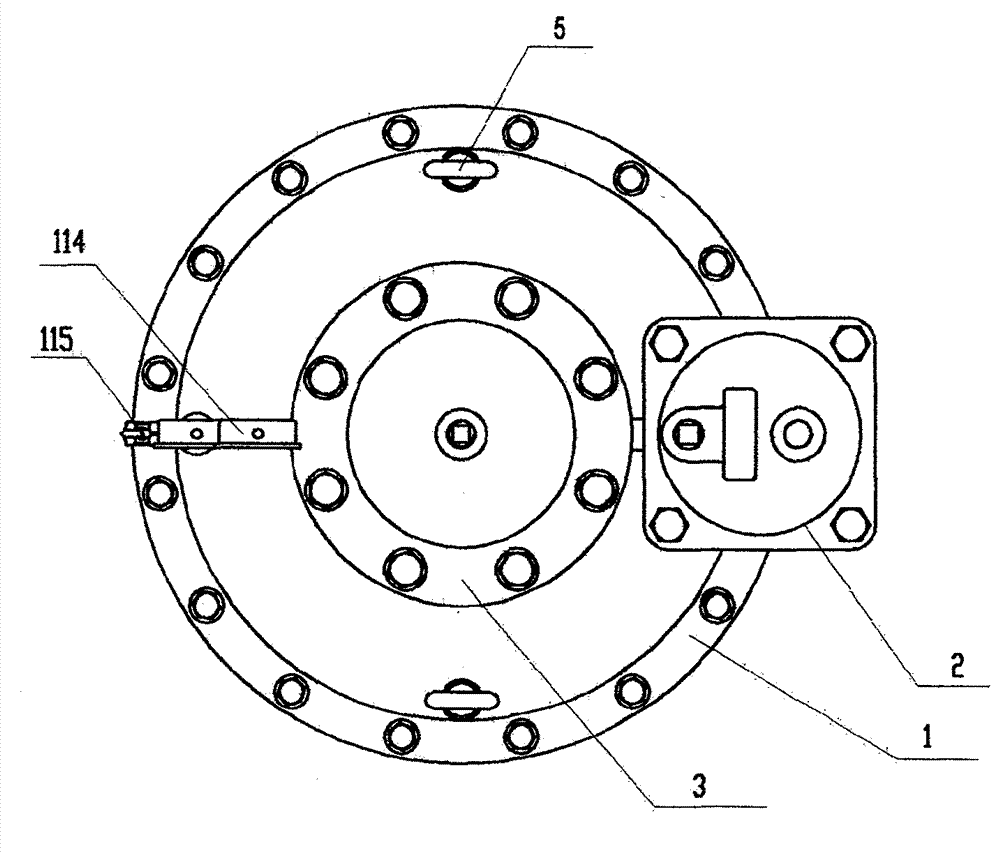

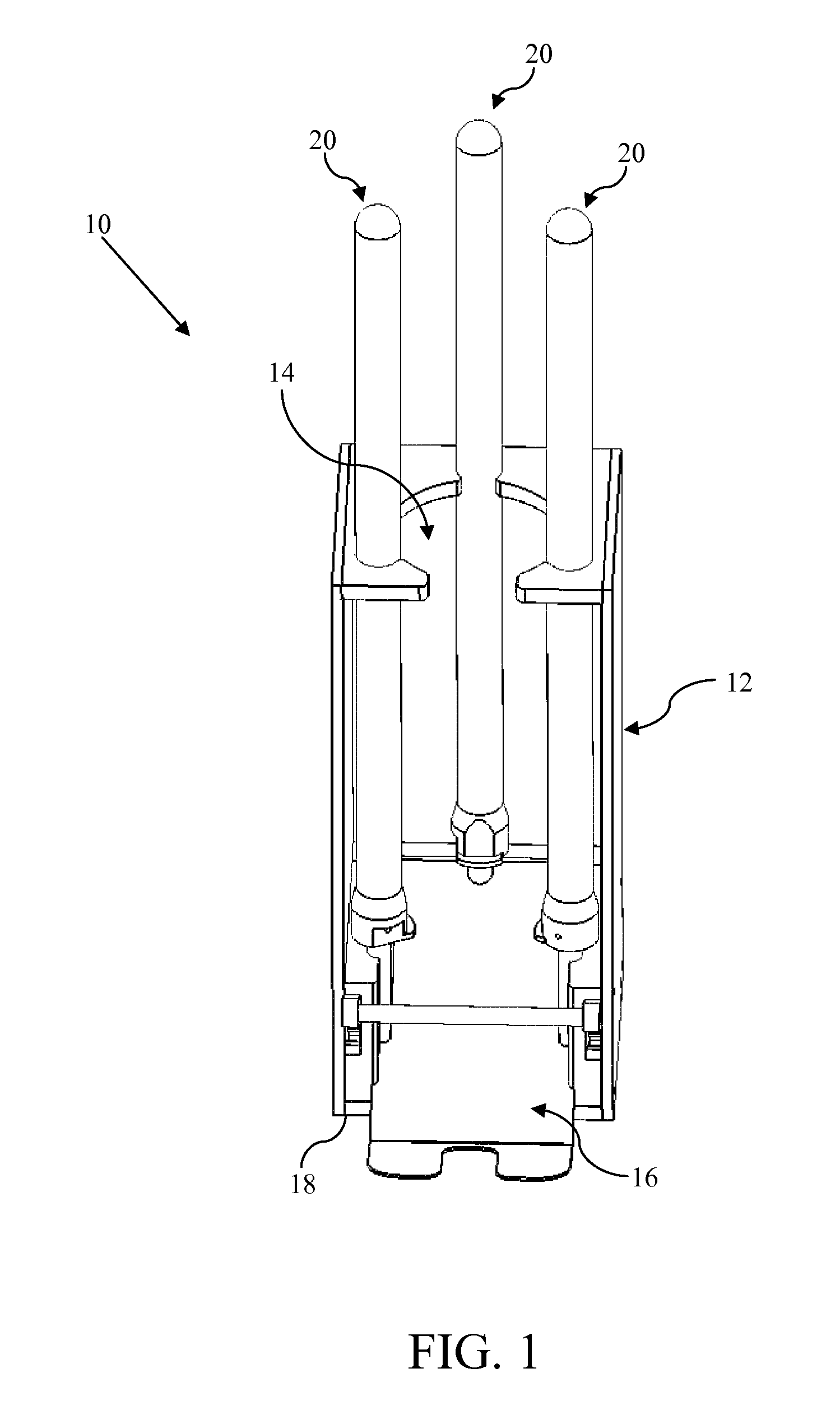

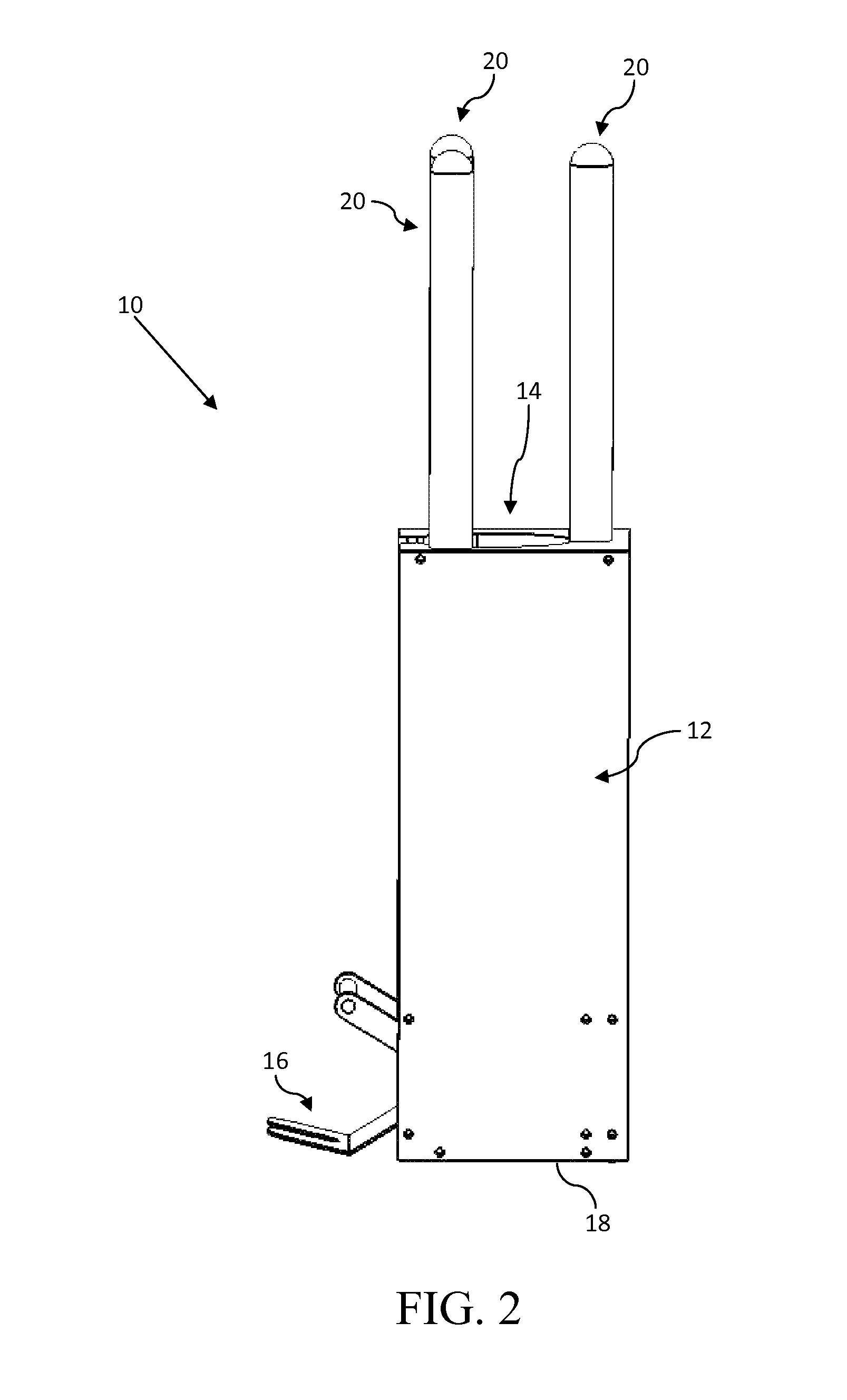

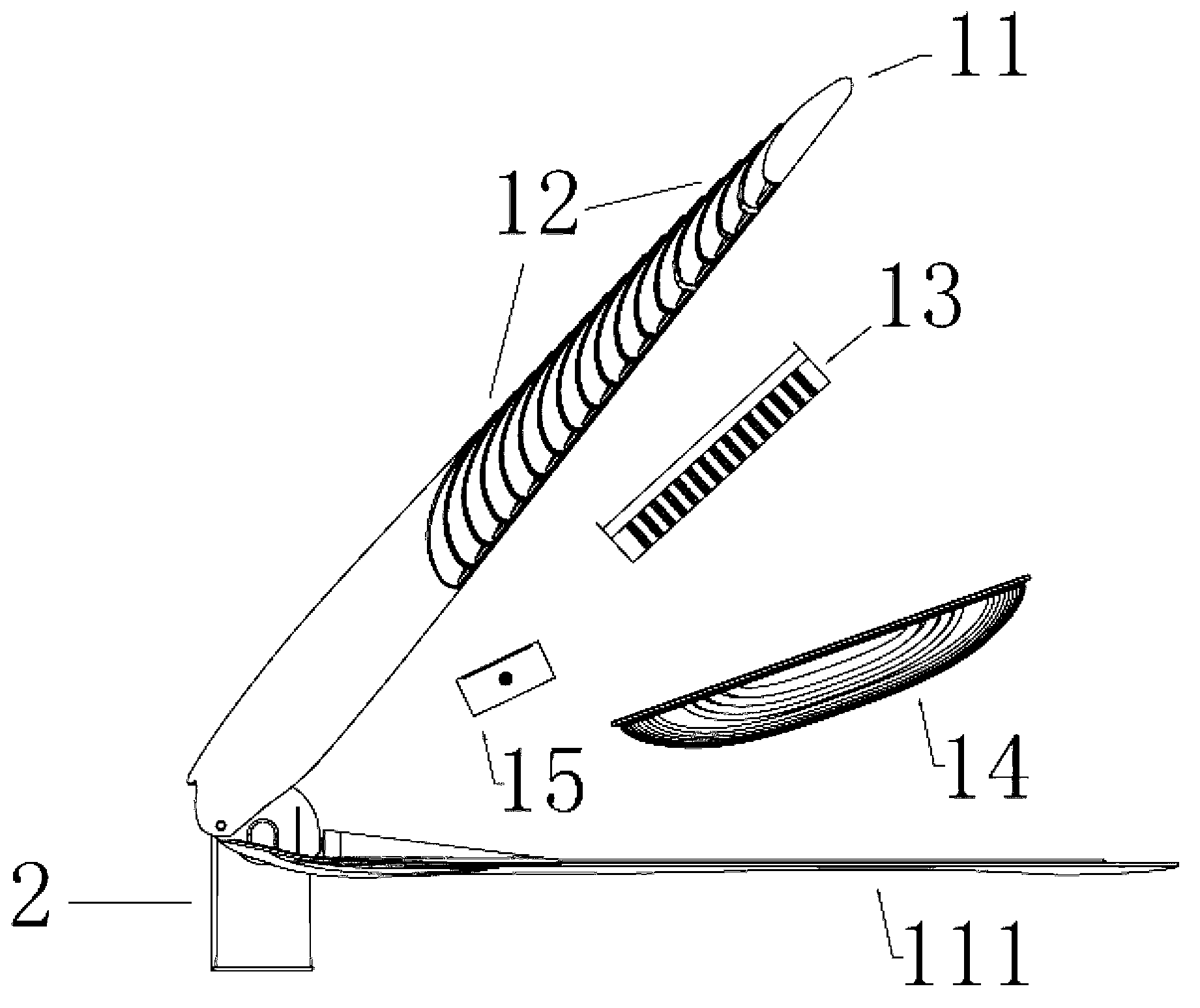

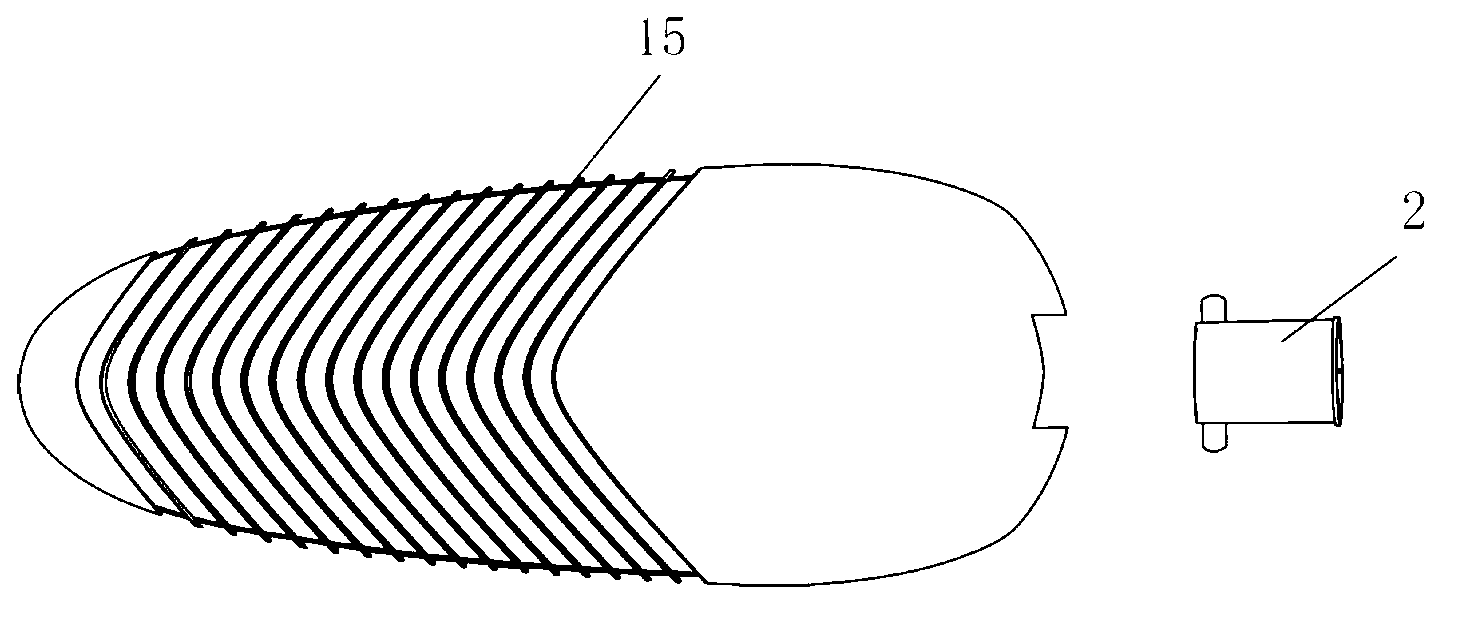

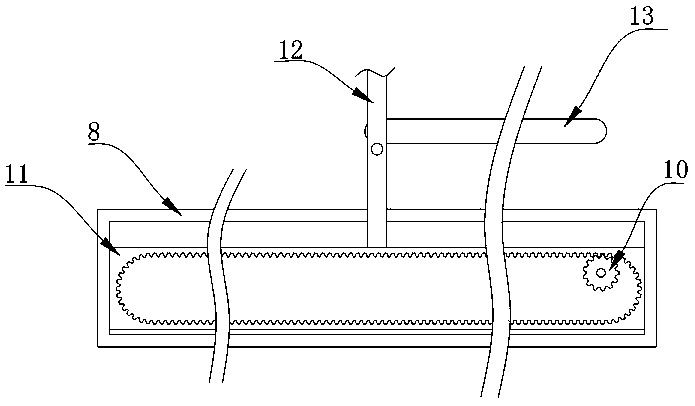

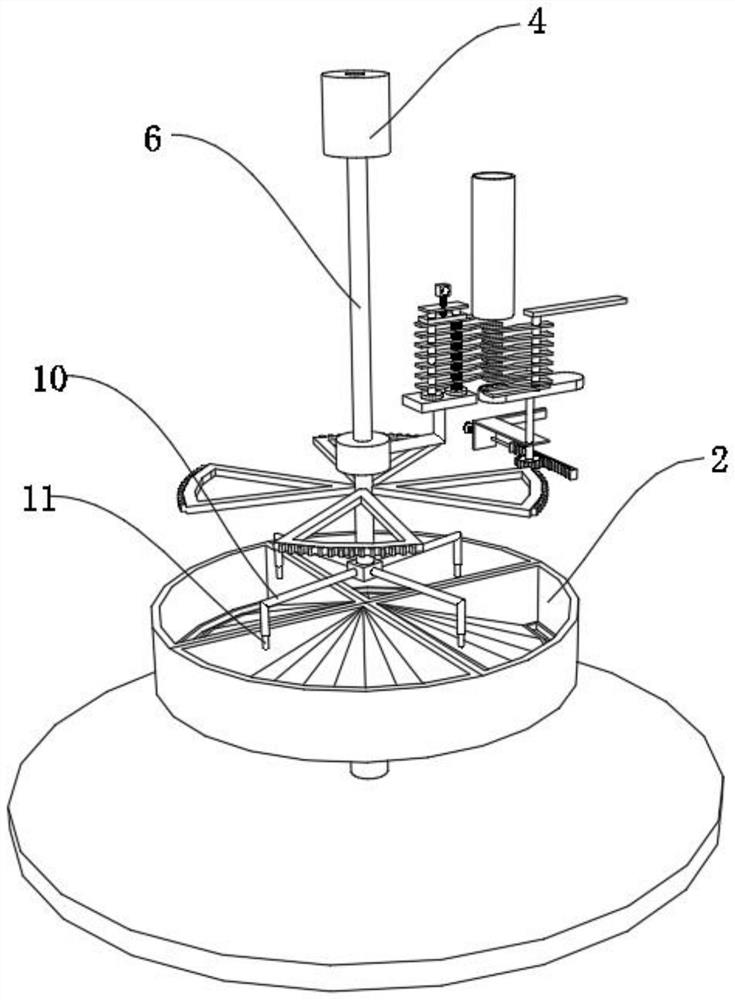

Dispenser for soft pliable lids

InactiveUS20110101017A1Easy to stackConducive to diversificationCoin-freed apparatus detailsFlat article dispensingGear wheelEngineering

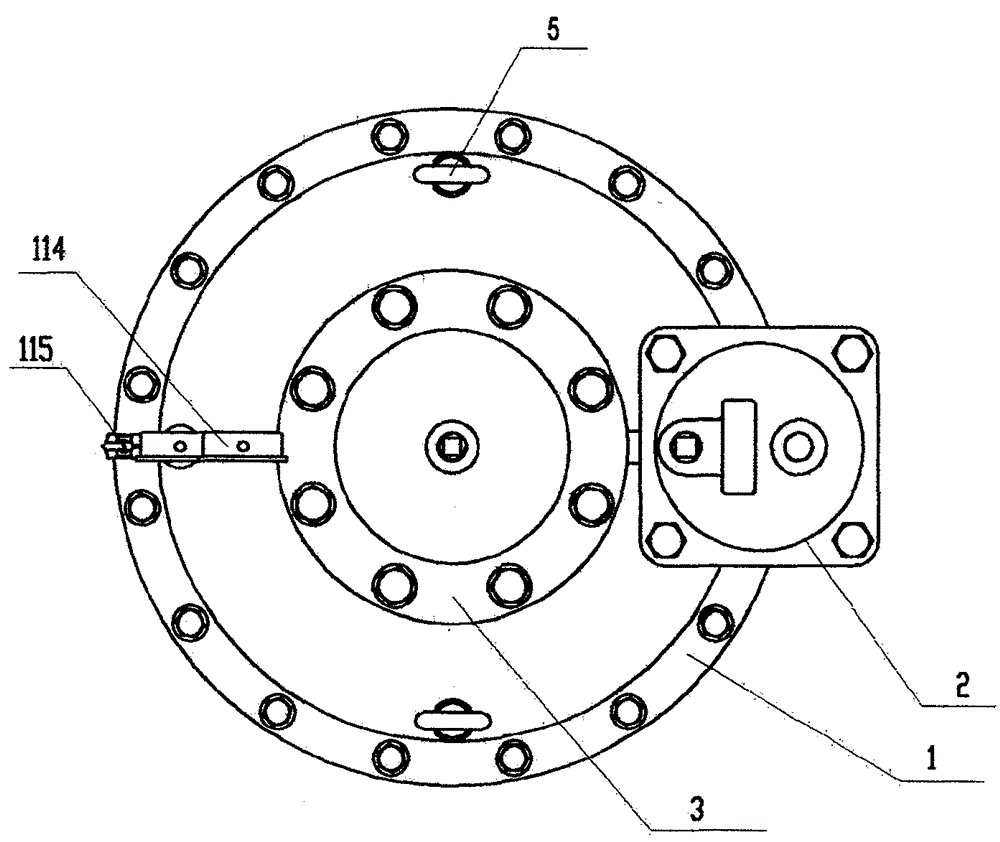

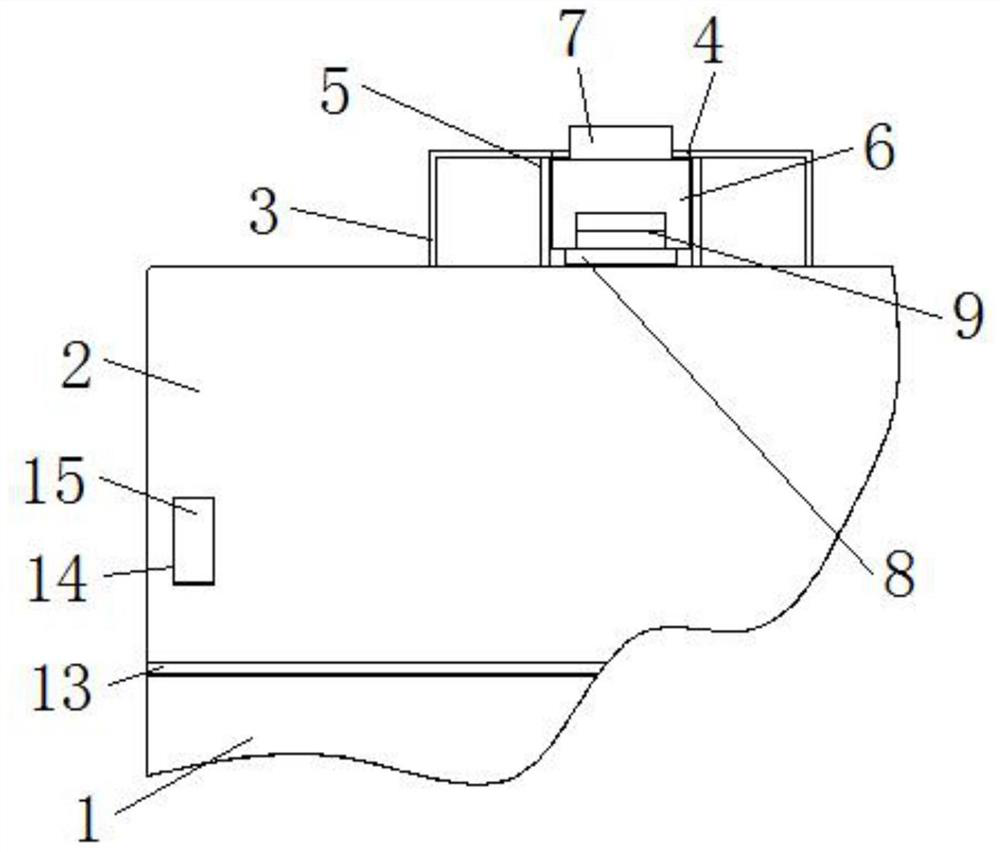

A lid dispenser includes a housing, shaft assemblies and a lid dispensing mechanism. Each shaft assembly includes a shaft that extends from a base of the housing, a lid shelf that supports at least a bottom-most lid in the lid stack area and a drive gear about its shaft so that rotation of the drive gear causes rotation of the associated shaft and lid shelf. A common gear is positioned so as to mesh with each of the drive gears such that rotation of the common gear causes corresponding rotation of each of the drive gears. Manual operation of the lid dispensing mechanism causes the common gear to rotate each of the shafts sufficient to allow the lid shelves to dispense the bottom-most lid. Release of the lid dispensing mechanism rotates the common gear back to a default position, rotating each of the shaft assemblies back to their default position.

Owner:SCHROEDER ROY D +1

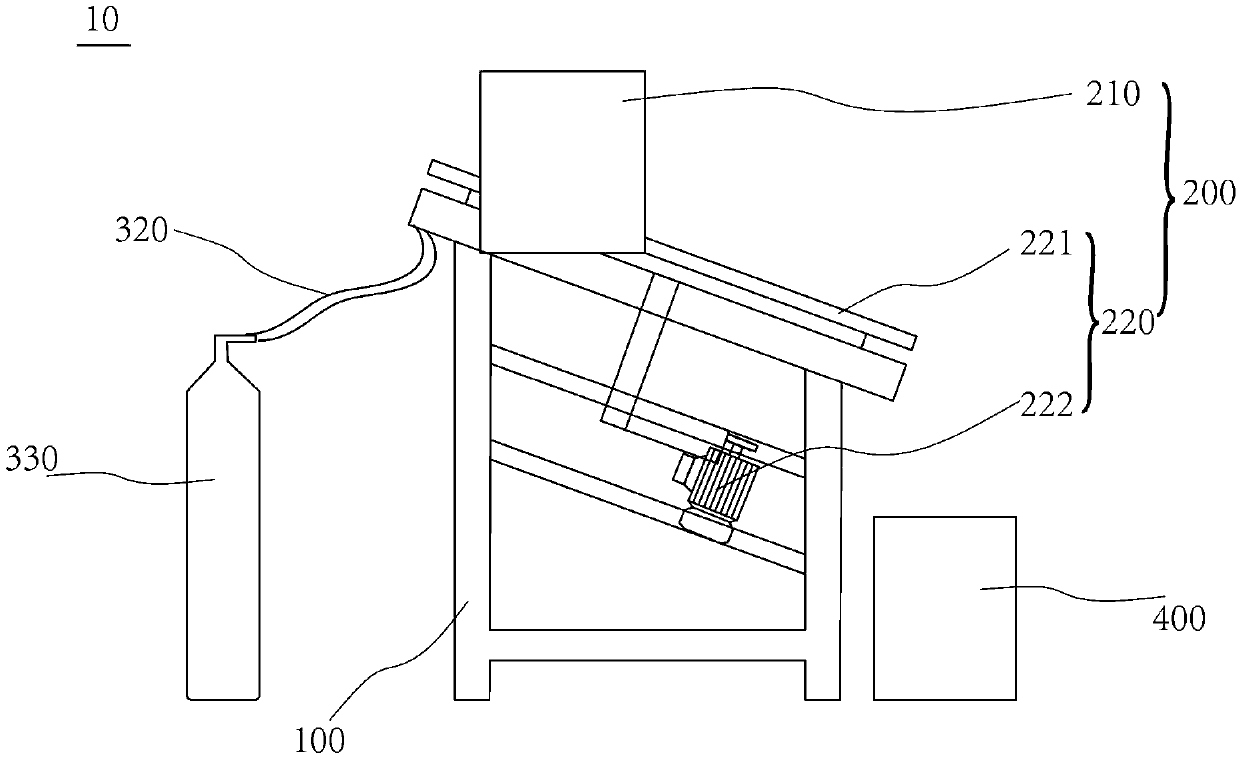

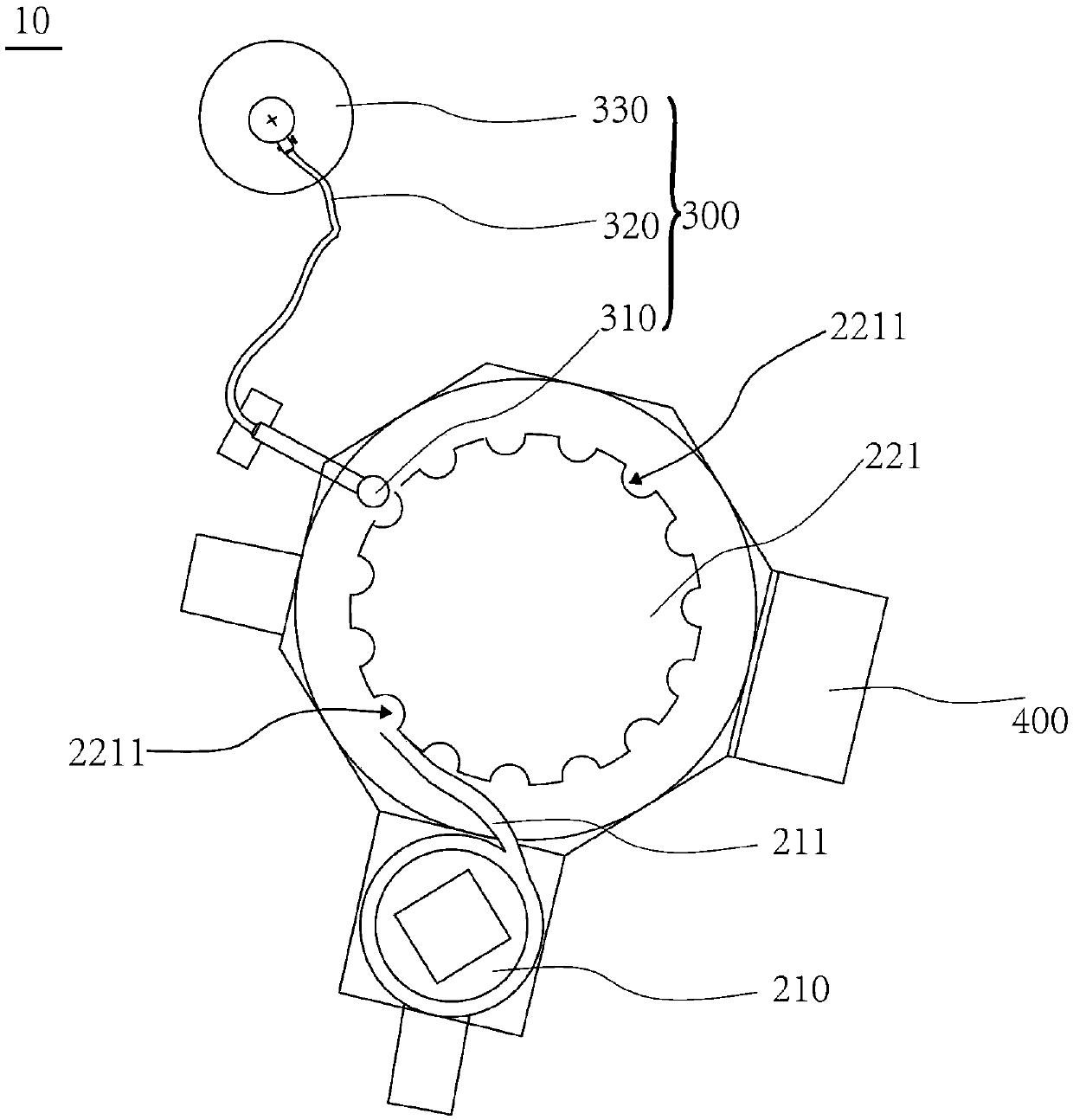

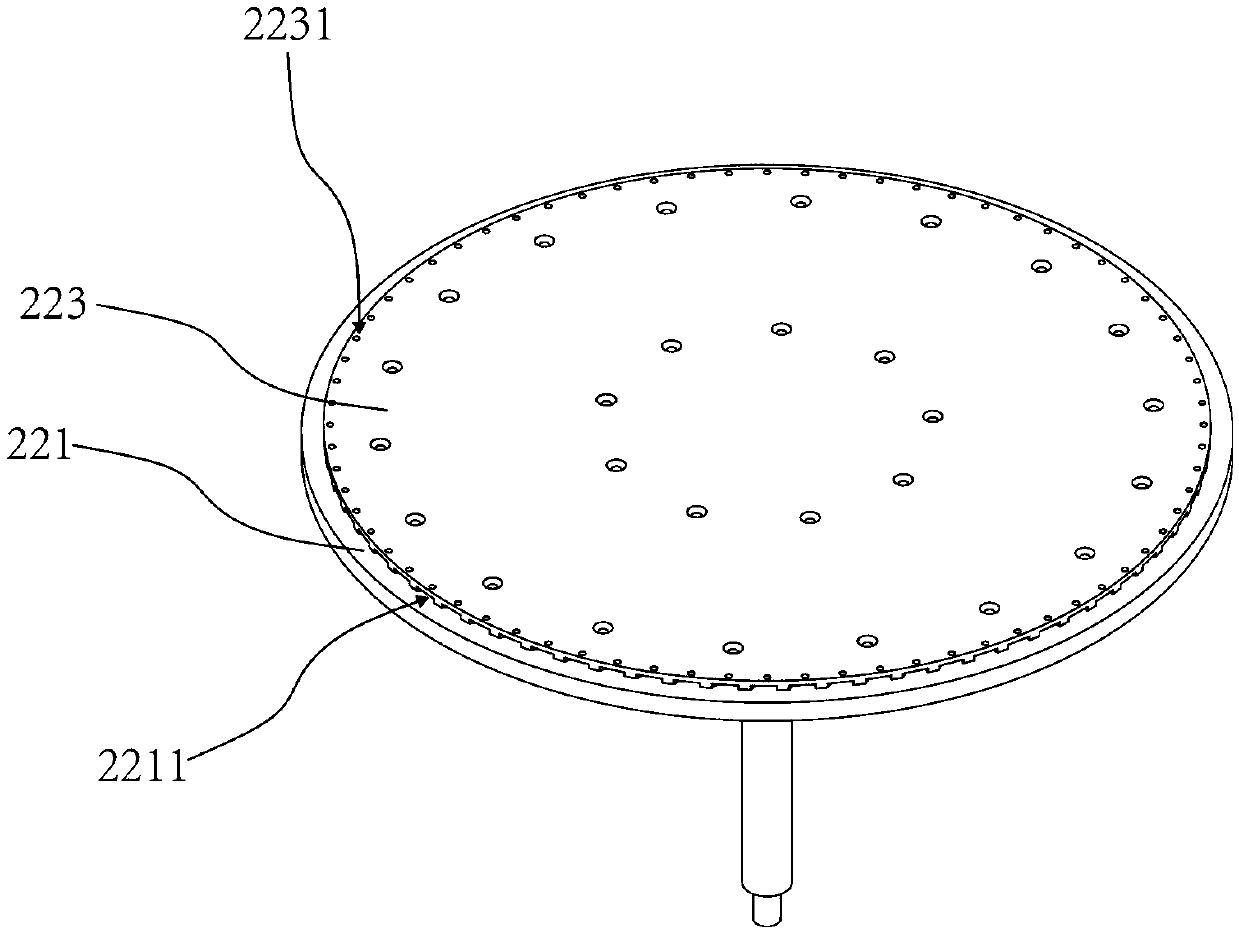

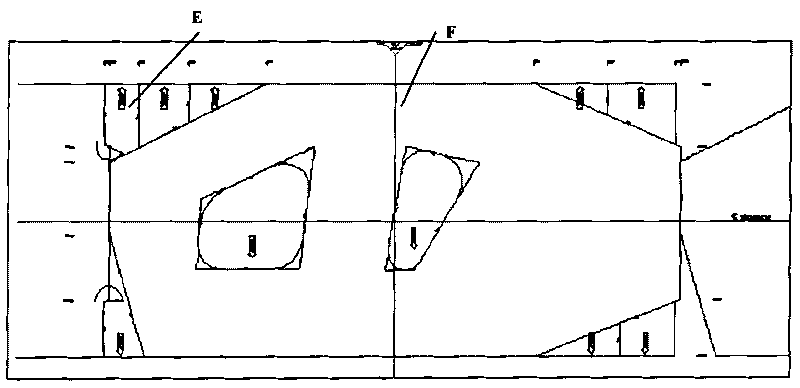

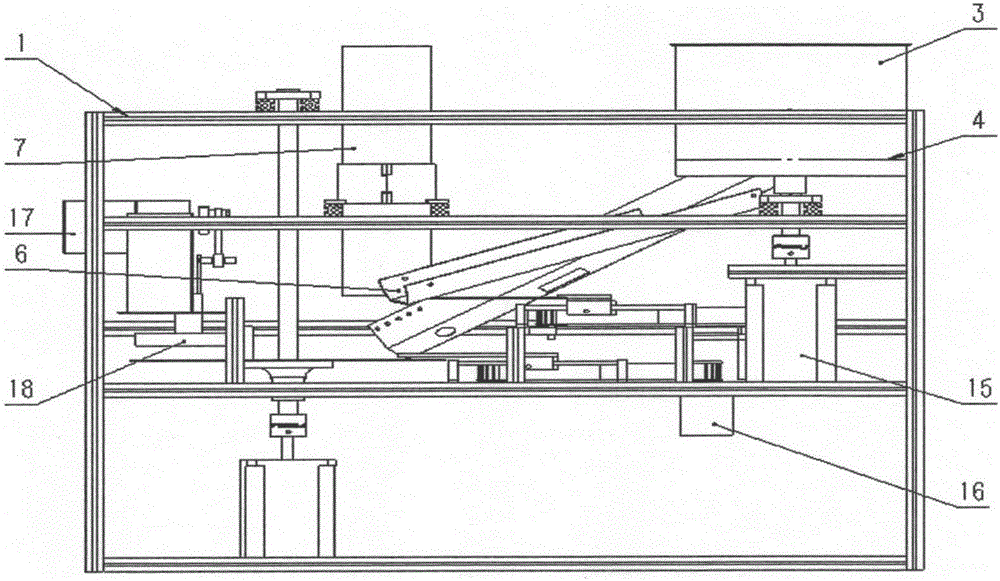

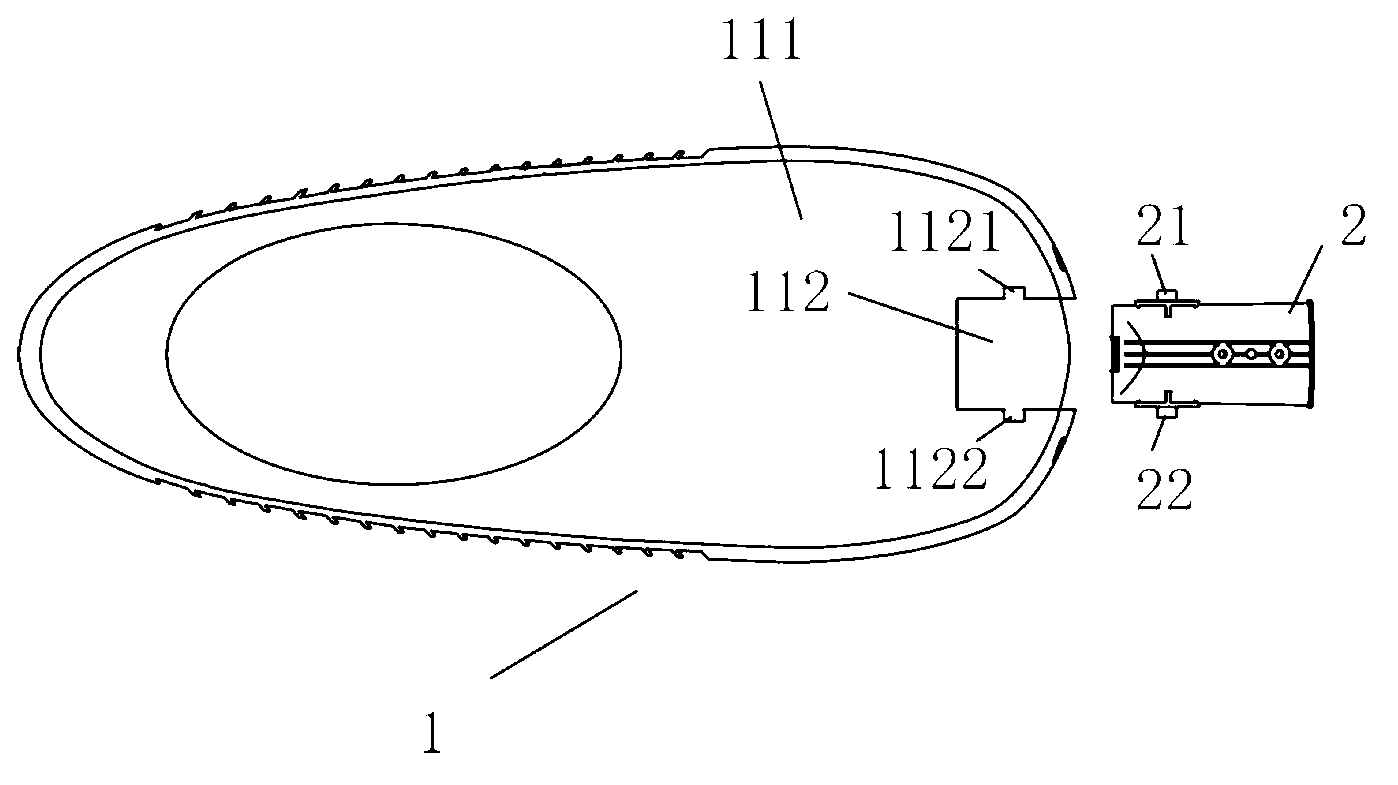

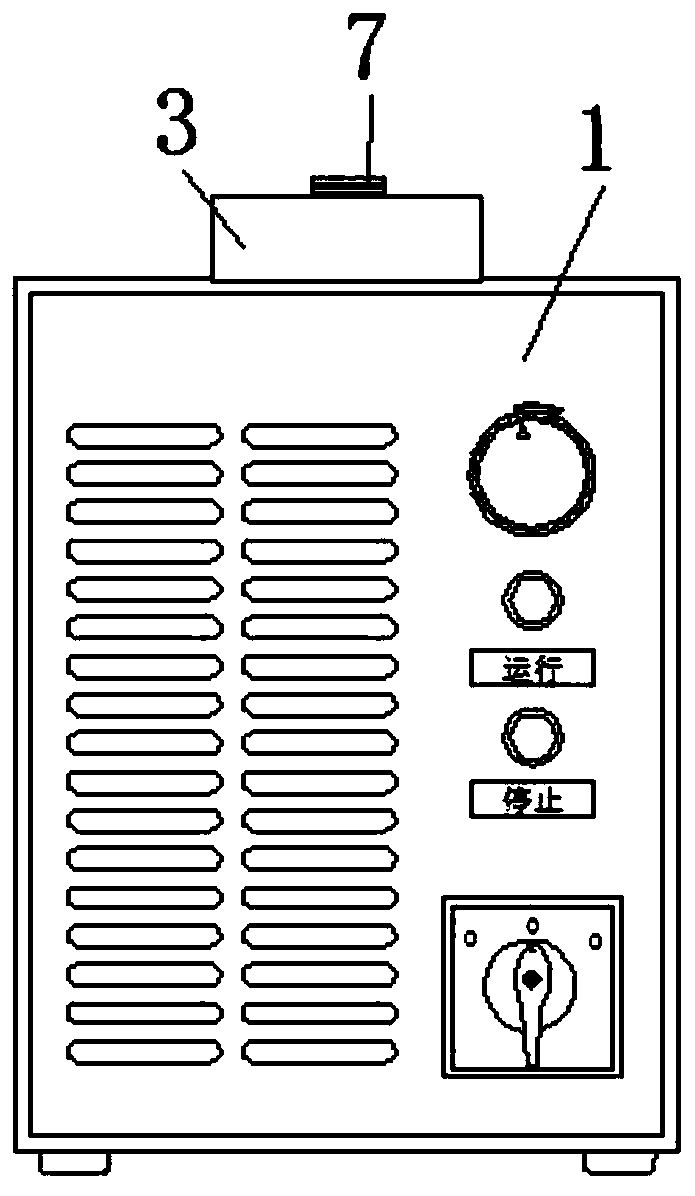

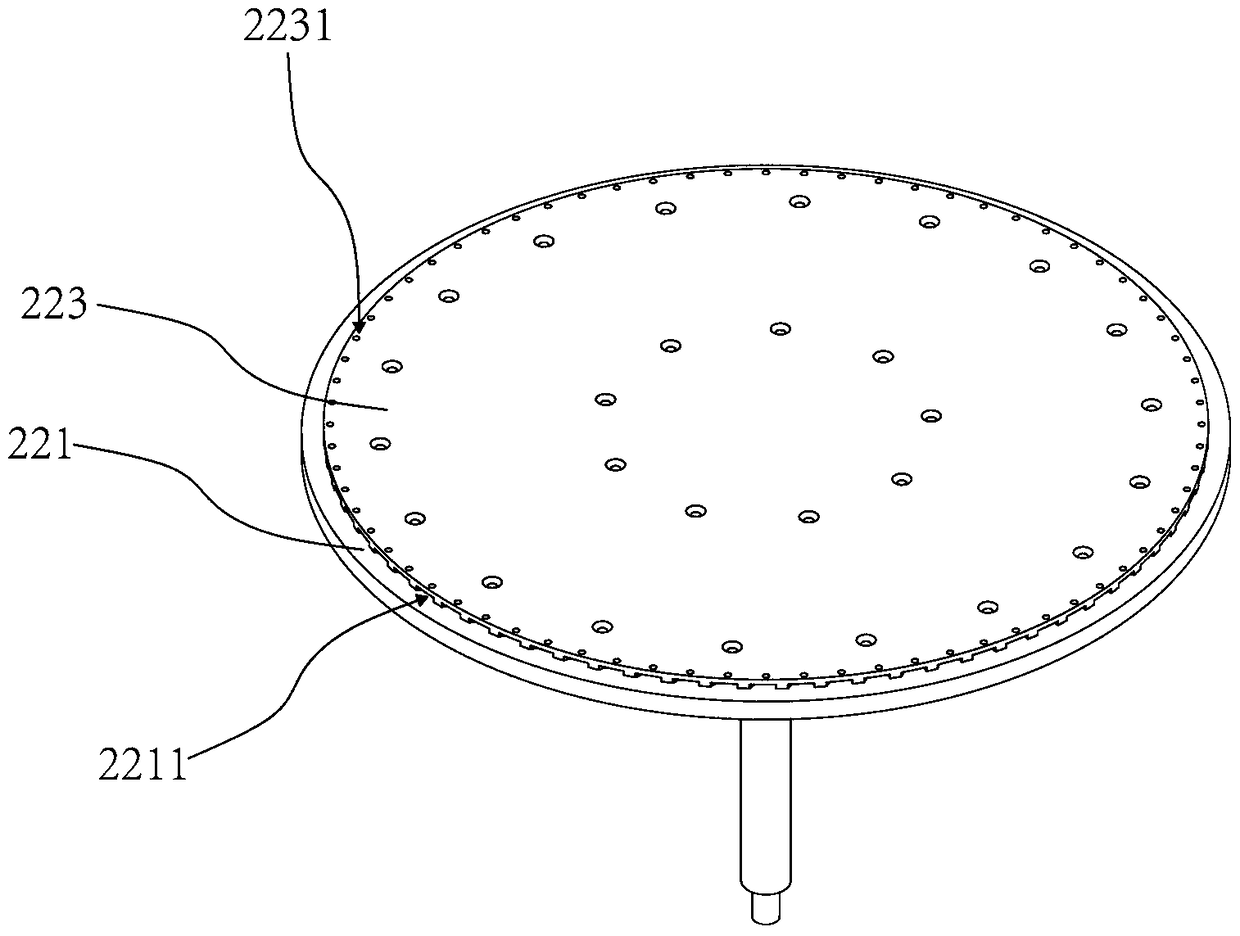

Button flaming machine

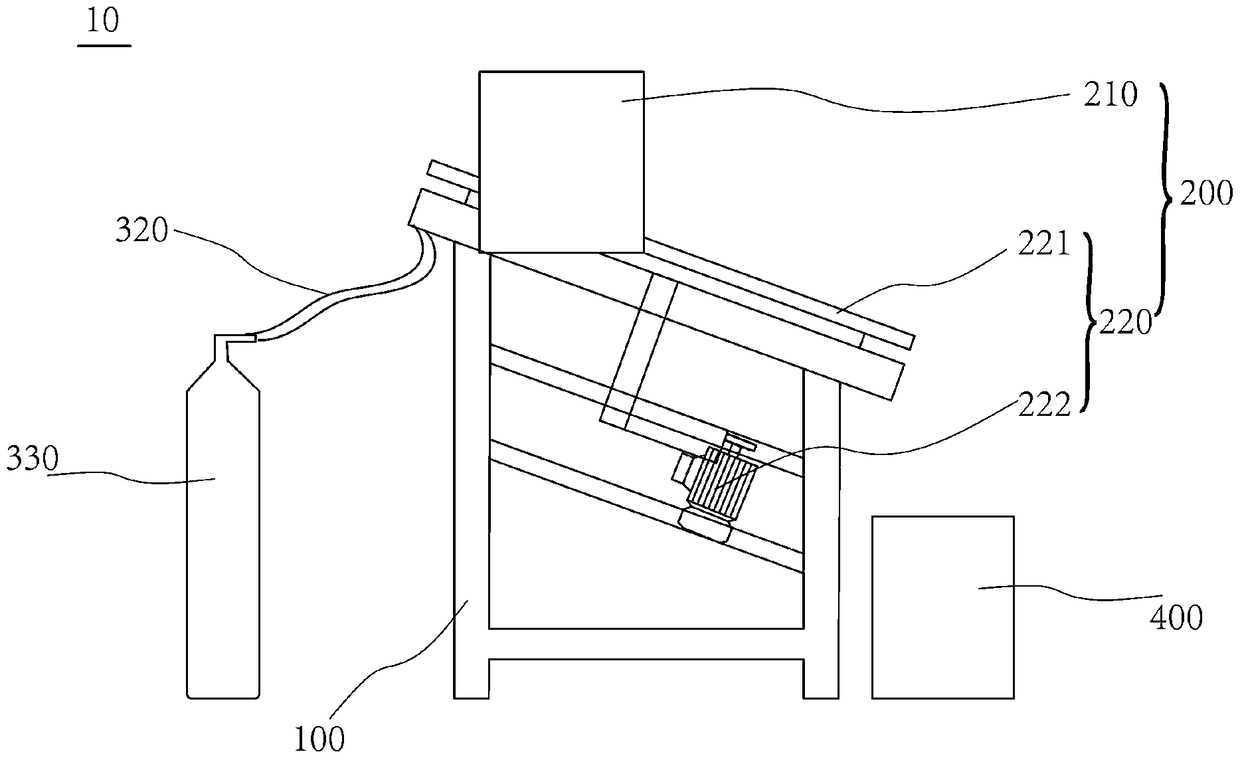

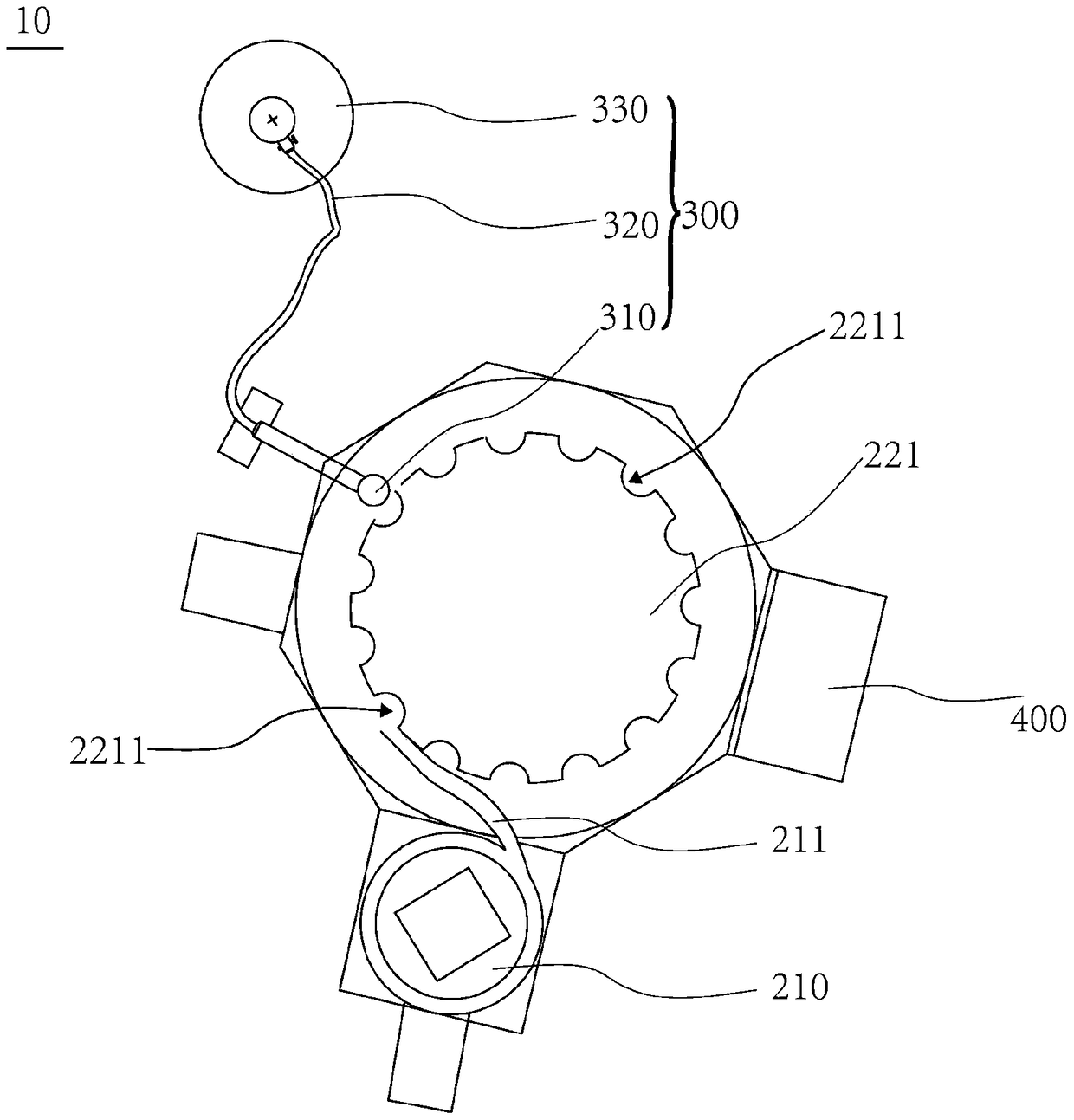

ActiveCN105495870ABurning edge effect is goodIncrease productivityClothes buttonsEngineeringFlame treatment

The invention discloses a button flaming machine which comprises a machine table, a button feeding device and a flame jetting device. The button feeding device comprises a vibrating part and a rotating part; the vibrating part is provided with a vibrating plate and a vibrating drive element, the vibrating plate is arranged on the machine table, used for carrying a button and provided with a discharge port, and the vibrating drive element is connected to the vibrating plate and used for driving the vibrating plate to vibrate to drive the button to vibrate to be discharged from the discharge port; the rotating part is provided with a rotating plate and a rotating drive element; the rotating plate is arranged on the machine table and located under the discharge port to be used for receiving the button discharged from the discharge port, and the rotating drive element is connected to the rotating plate to be used for driving the rotating plate to rotate. The flame jetting device is arranged on the machine table, and a flame jetting port of the flame jetting device faces the rotating plate to be used for performing flame treatment on the button located on the rotating plate. The button flaming machine is high in production efficiency and low in cost.

Owner:广东康派环创科技有限公司

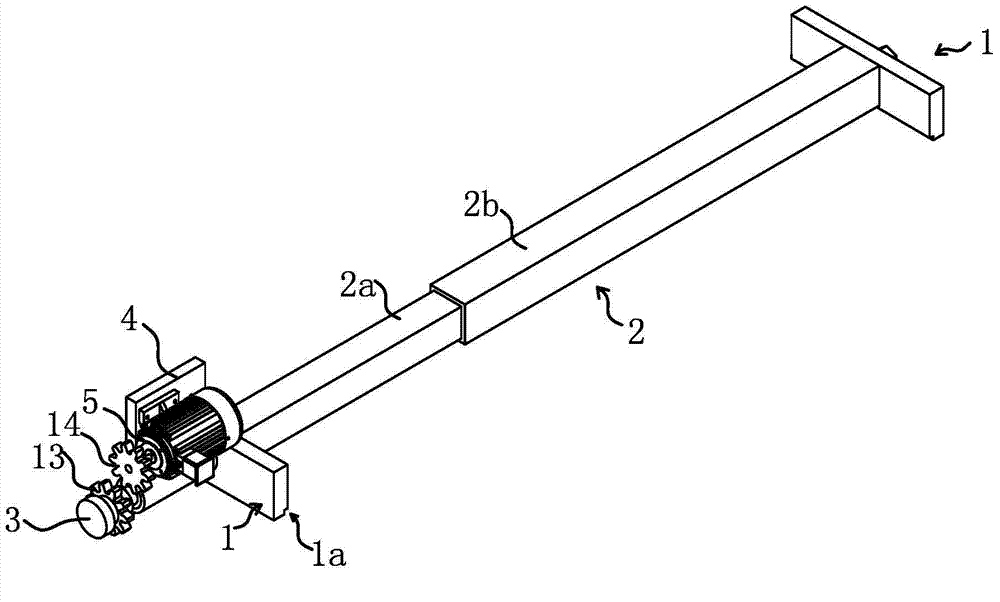

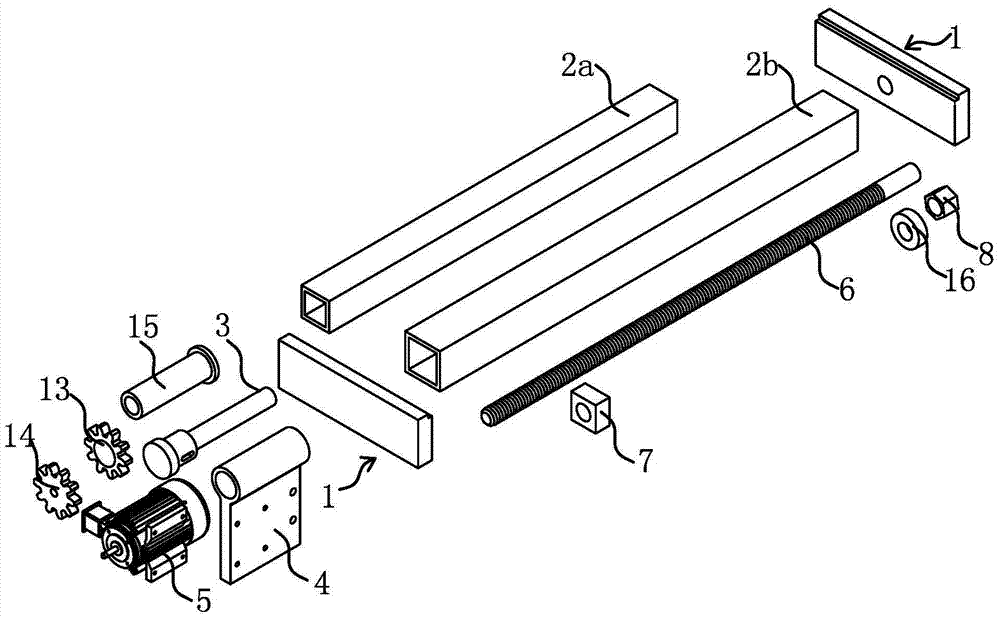

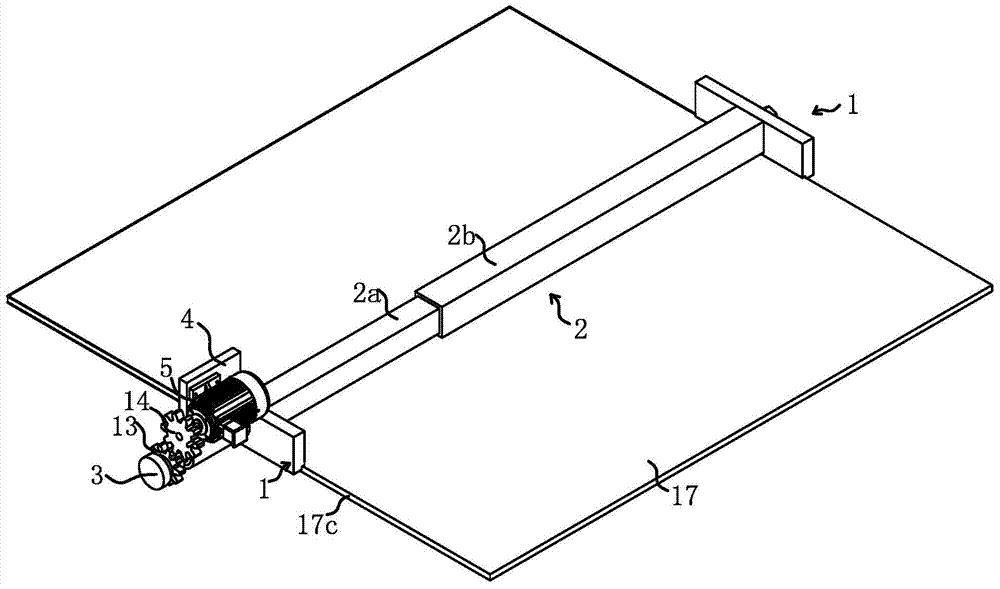

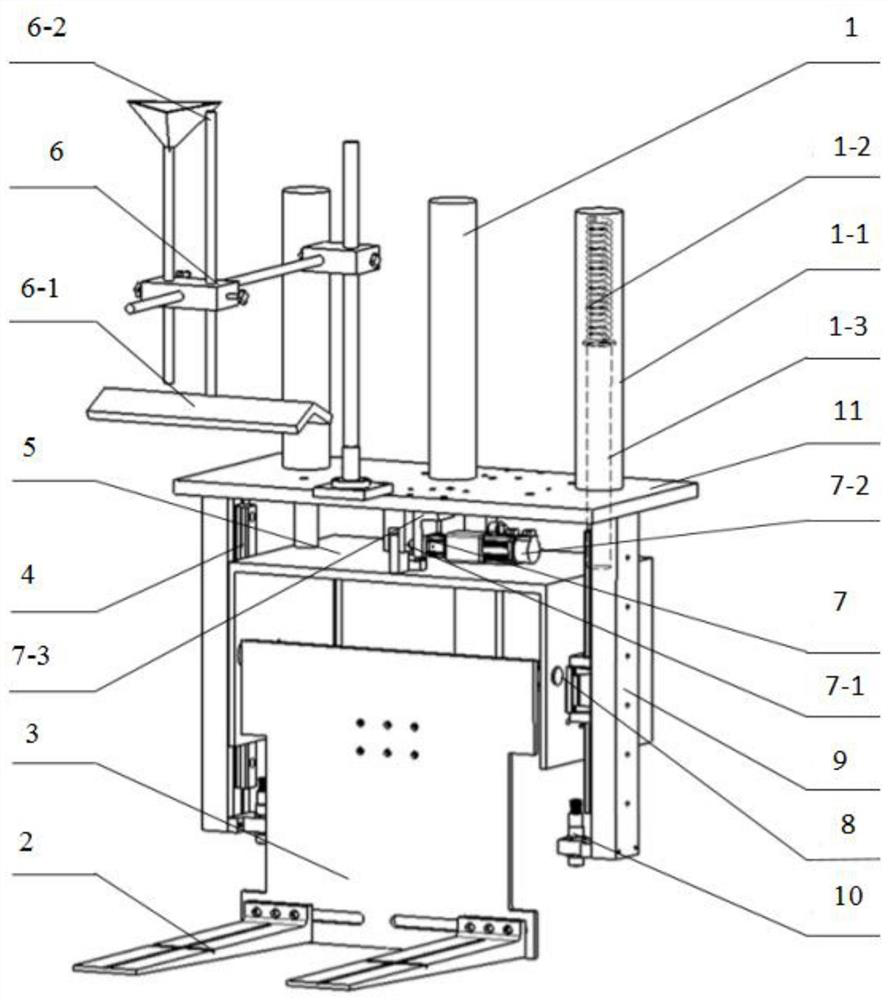

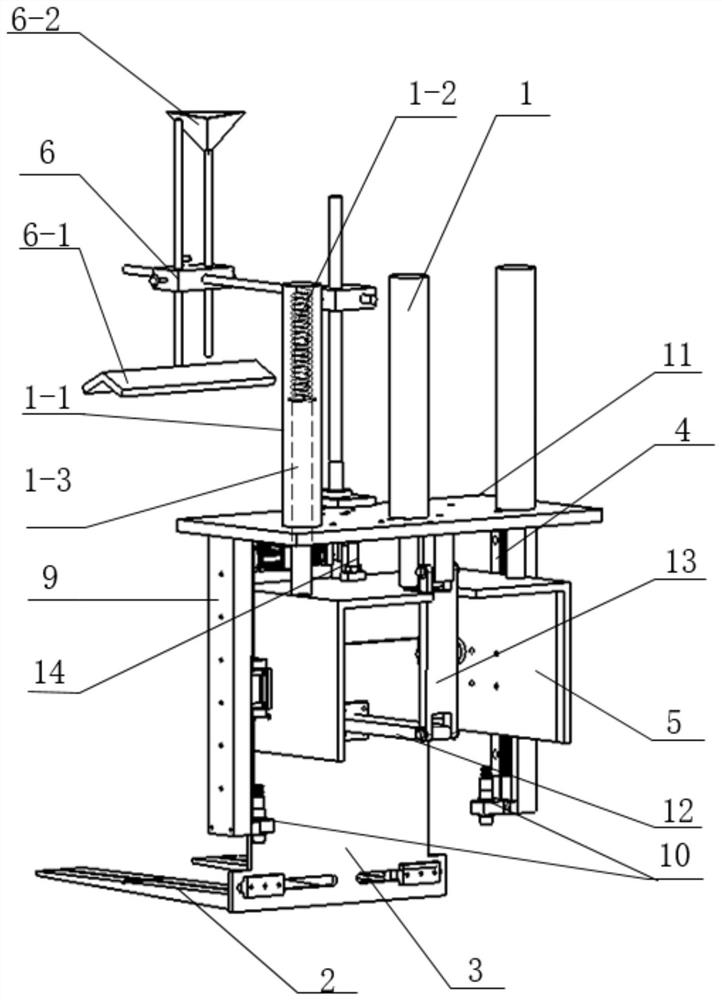

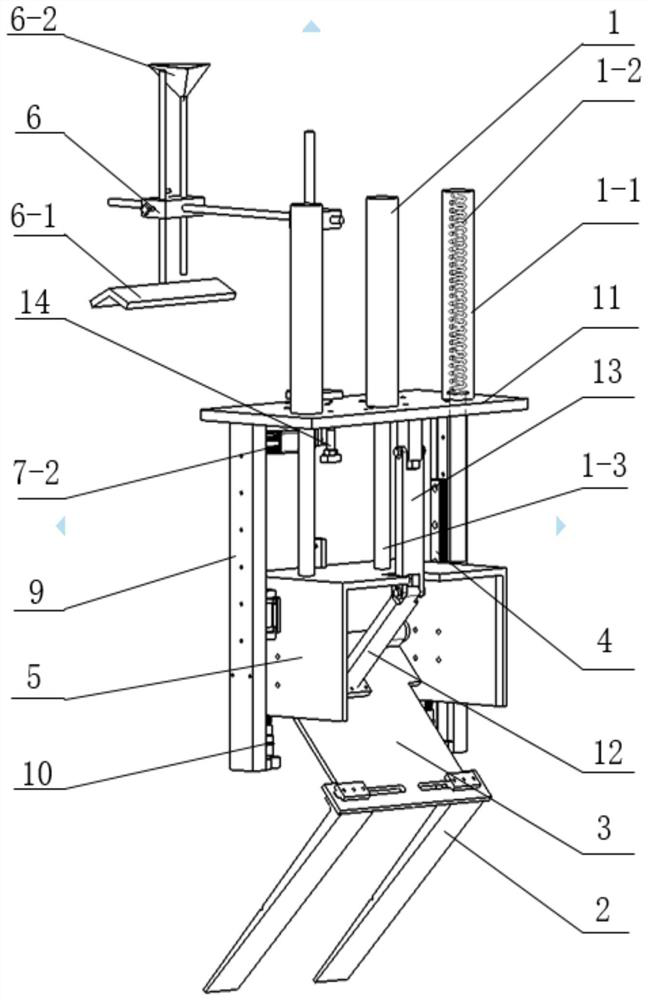

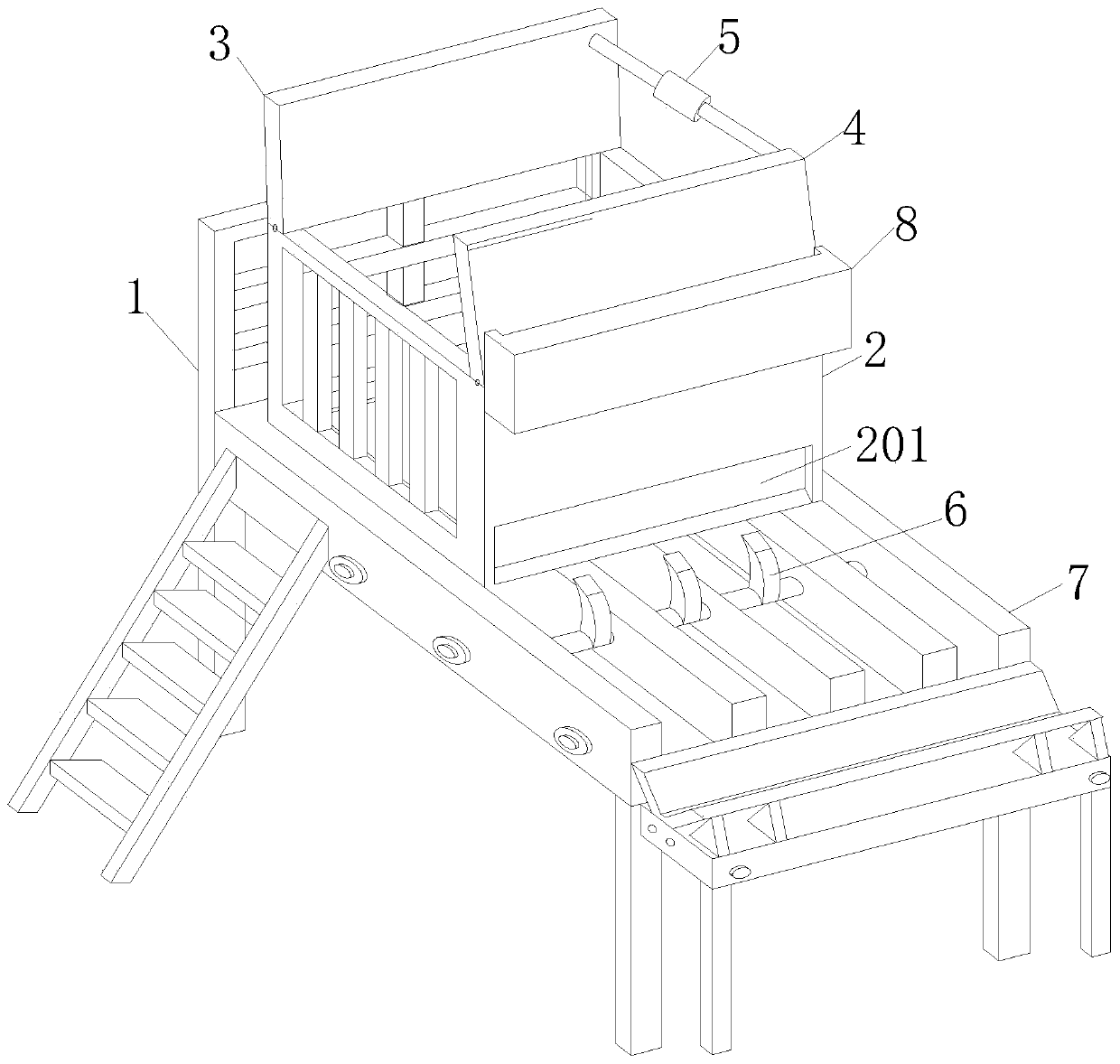

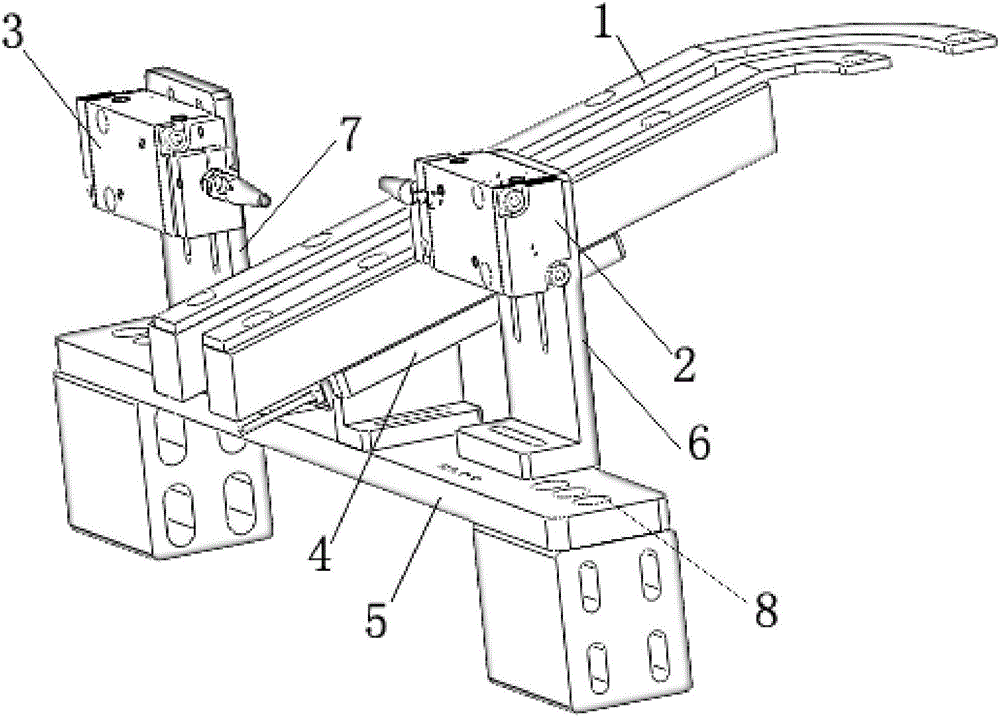

Tile clamping device of tile fixing machine

InactiveCN104234398ASave spaceImprove smoothnessBuilding constructionsBiochemical engineeringLocking mechanism

The invention provides a tile clamping device of a tile fixing machine, and belongs to the field of building decoration machines. The tile clamping device solves the problems that an existing tile clamping device of the tile fixing machine is large in occupied area and high in manufacturing cost. The clamping device of the improved structure comprises two clamping plates which are symmetrically arranged. Supporting rods are arranged between the two clamping plates. One end of each supporting rod is fixedly connected with one clamping plate, and the other end of each supporting rod is fixedly connected with the other clamping plate. The supporting rods can be stretched out and drawn back. Locking mechanisms which can lock the length of the supporting rods are arranged on the supporting rods. The tile clamping device of the improved structure is simple in structure, high in use reliability and quite suitable for popularization.

Owner:台州八鑫工贸股份有限公司

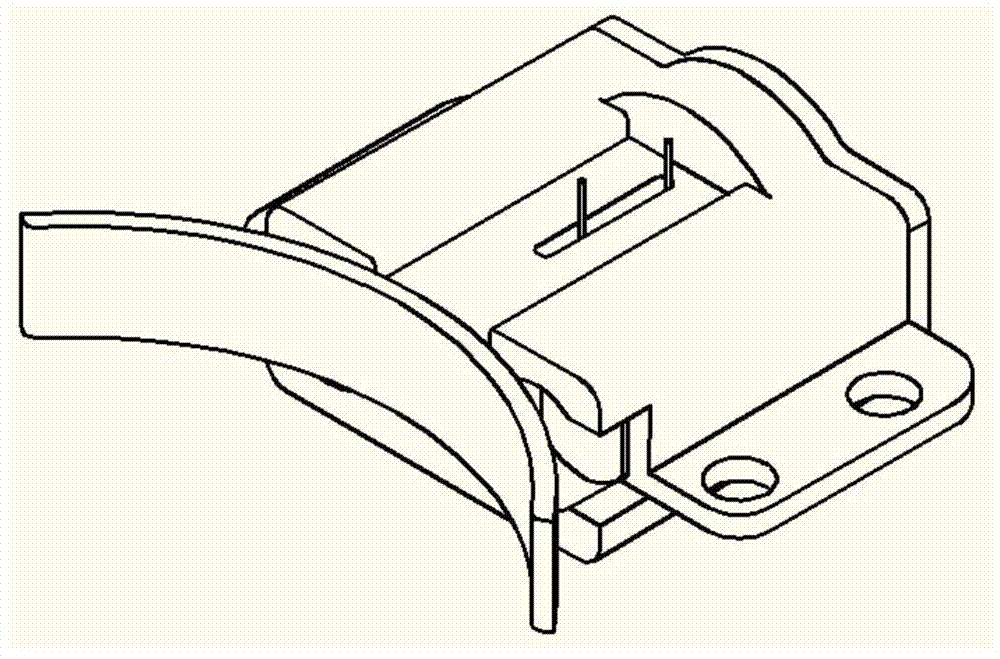

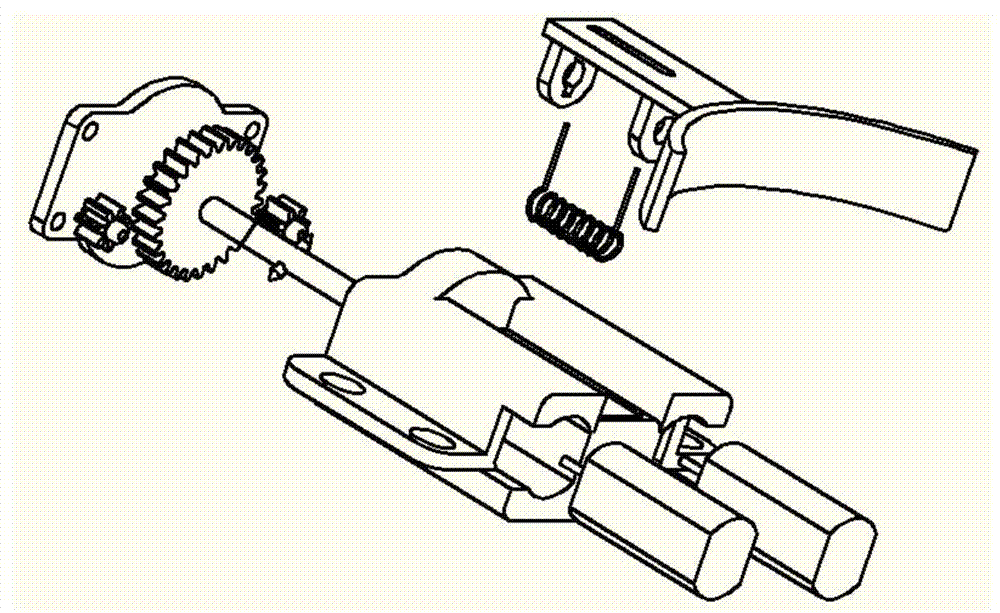

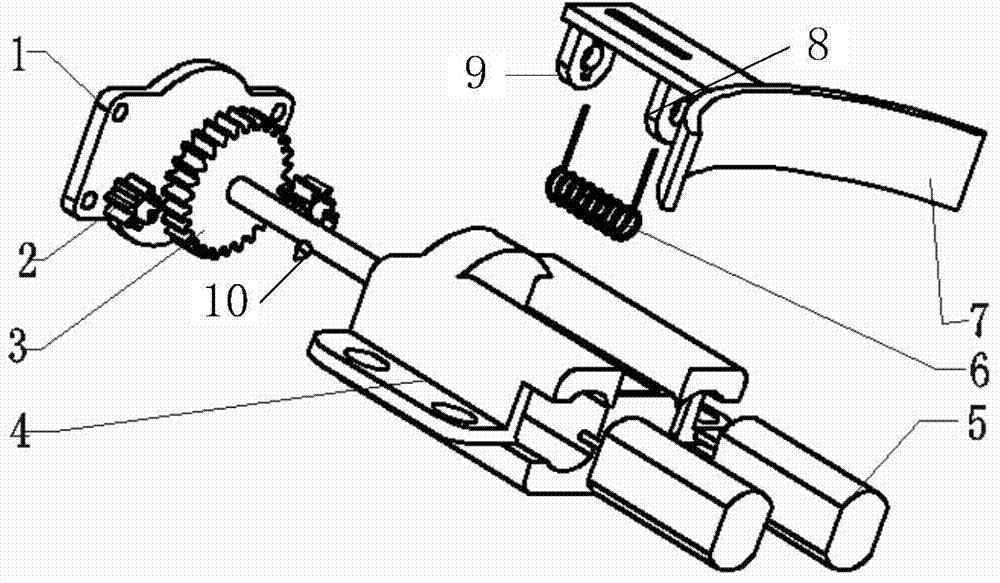

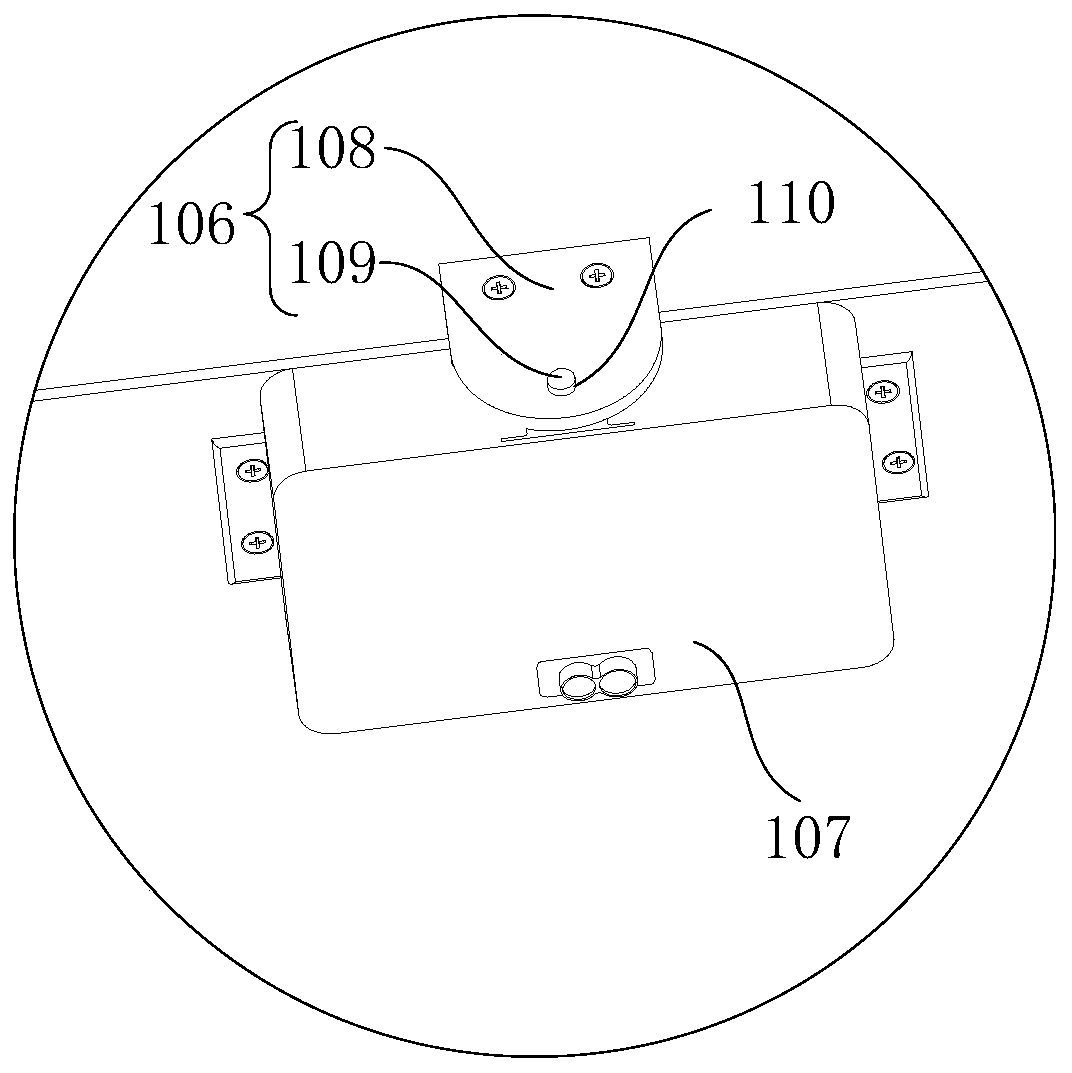

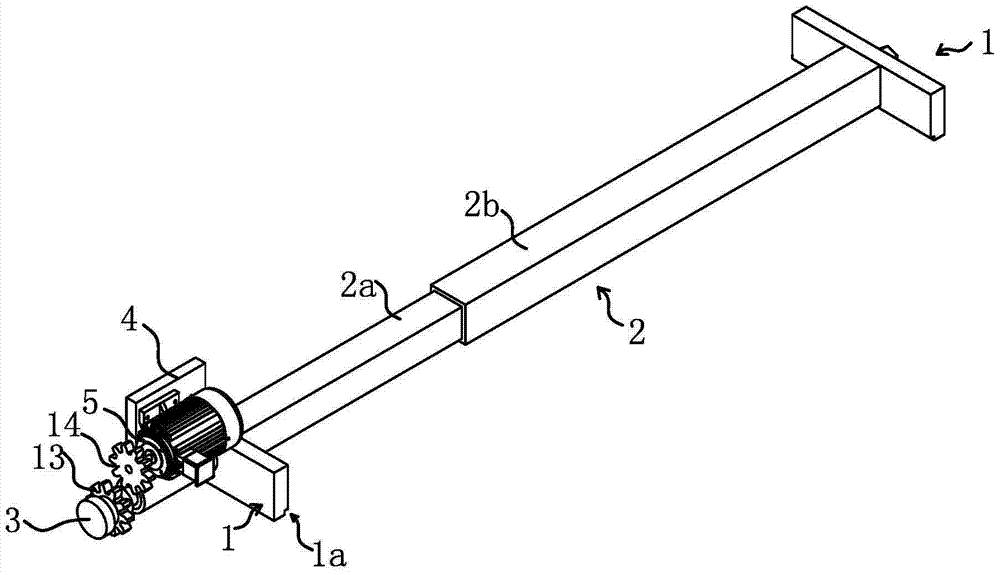

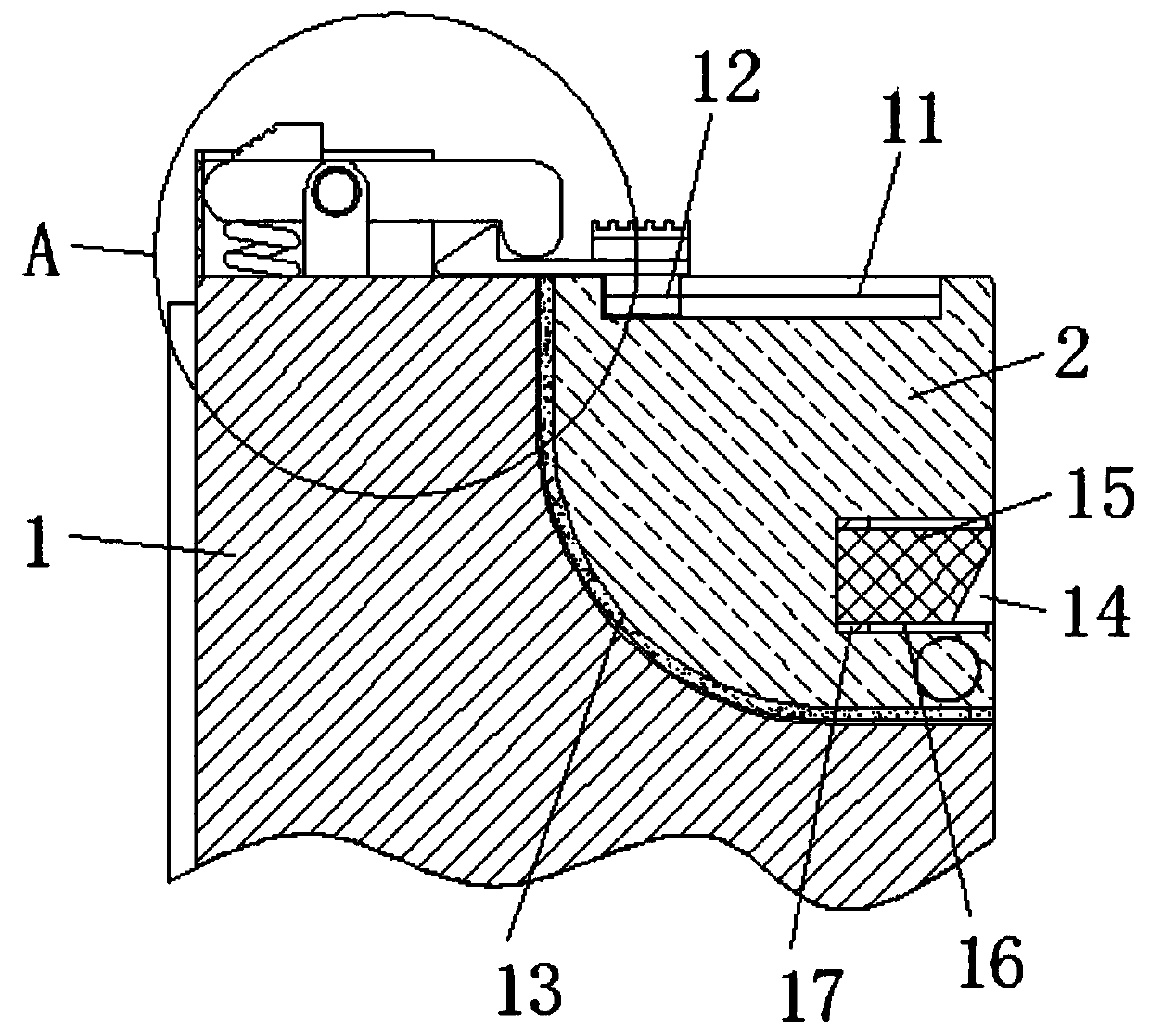

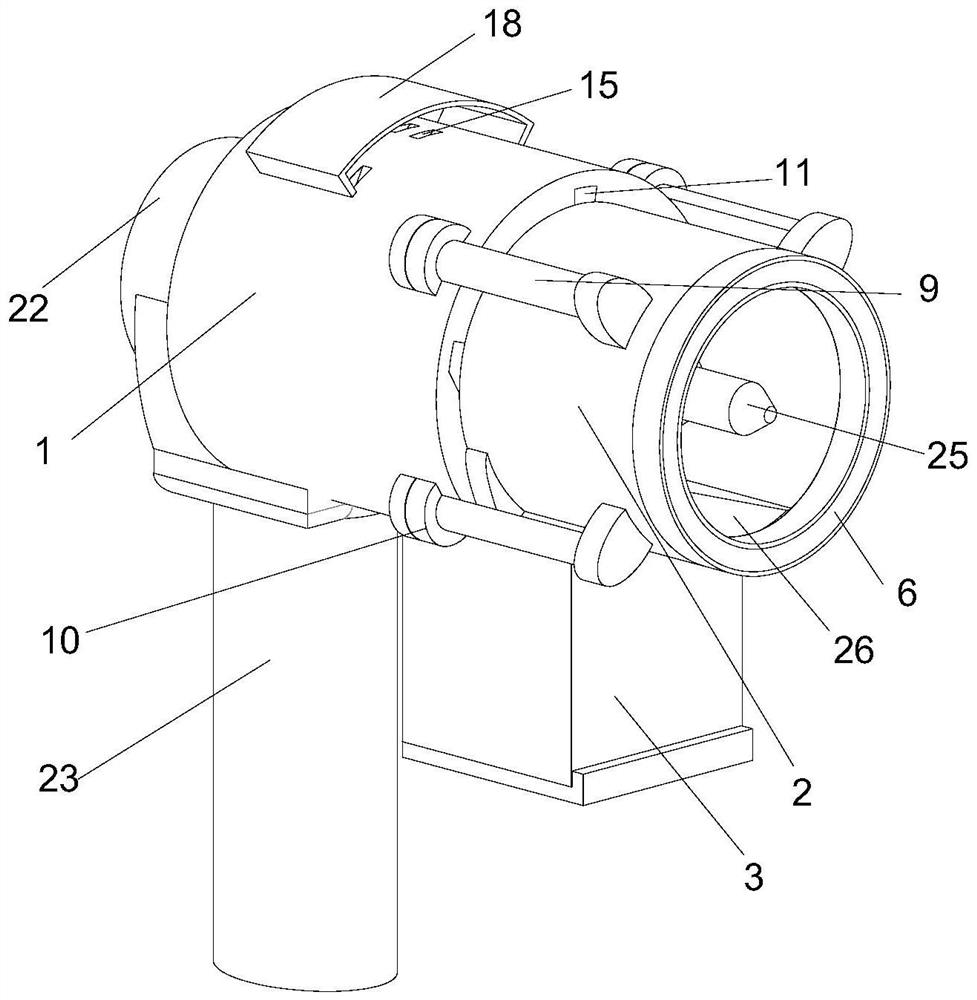

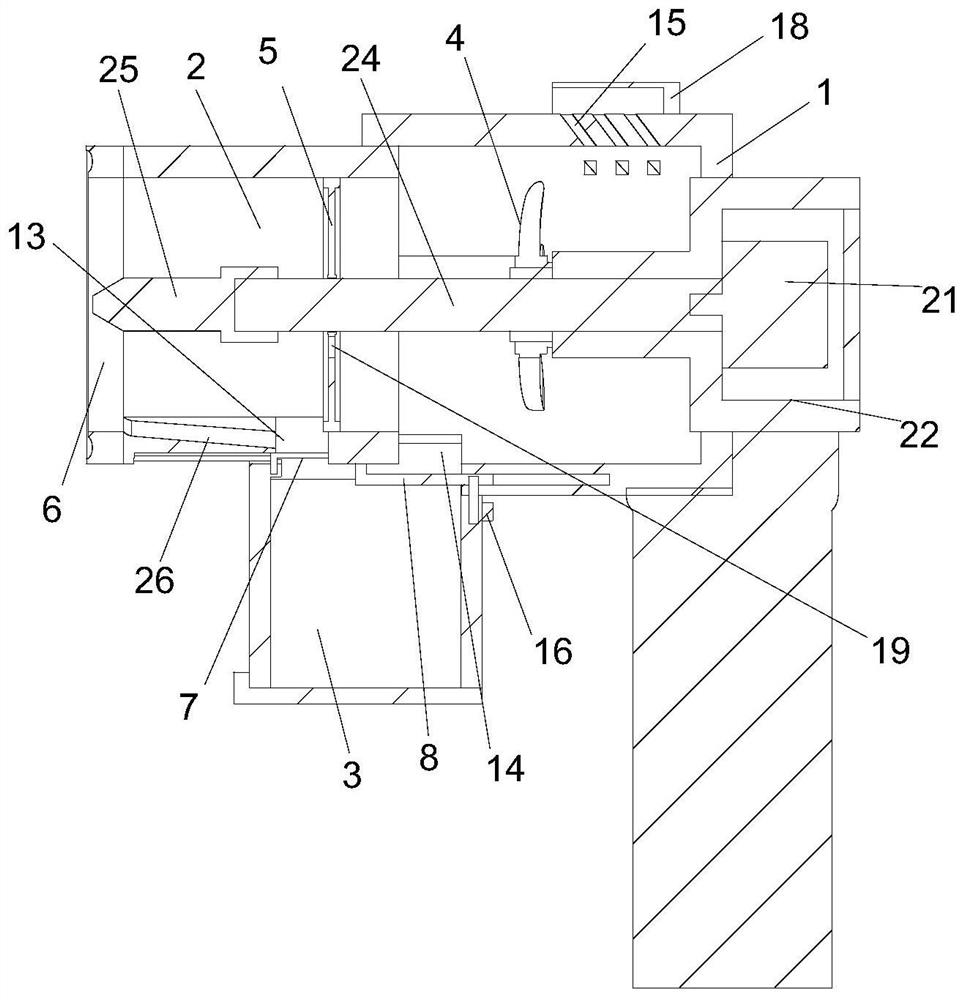

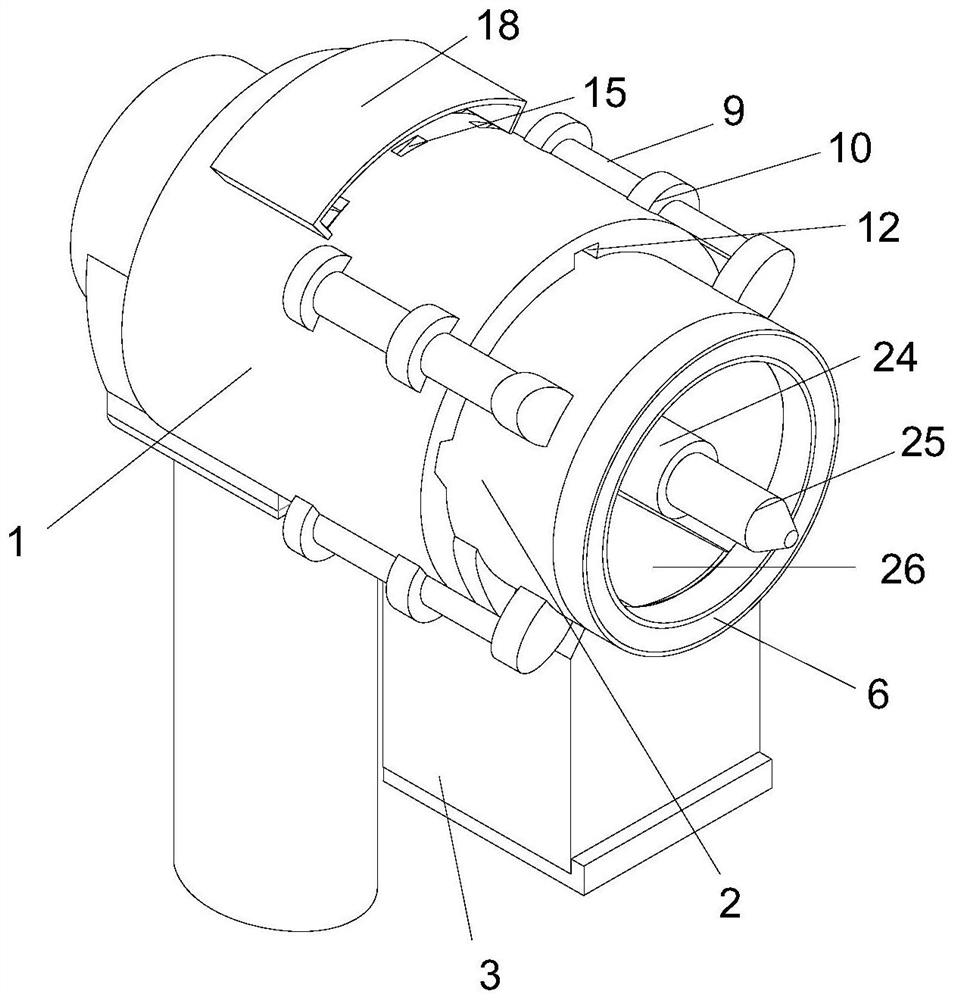

Motor assembly for intelligent electronic door lock

InactiveCN104727652AReduce the risk of stopping workFree fallNon-mechanical controlsElectric machineCircular cone

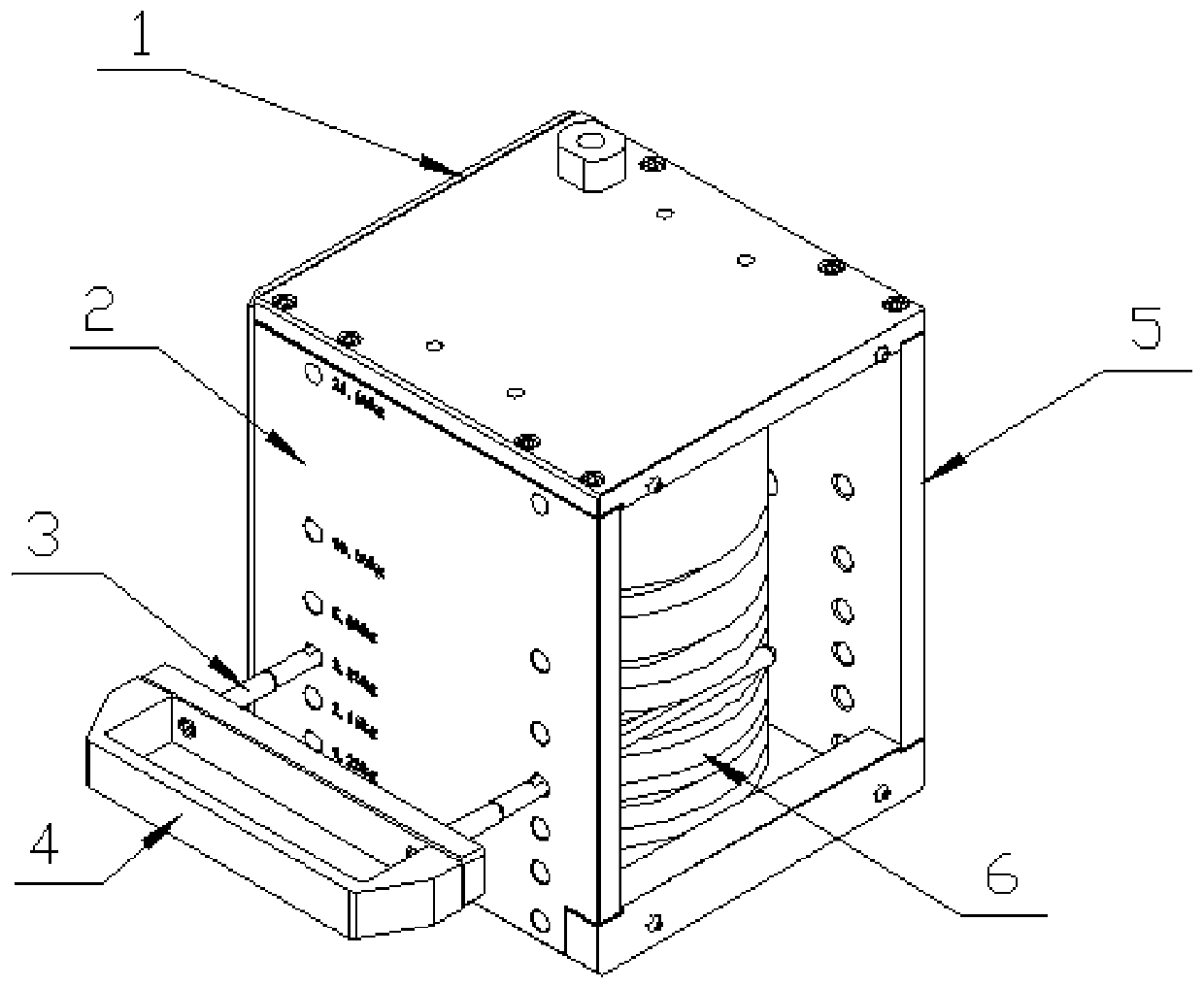

The invention provides a motor assembly for an intelligent electronic door lock. According to the motor assembly, structures of a cover plate (1), two small gears (2), a gear shaft (3), a motor shell (4), two same motors (5), a torsion spring (6), an arc push plate (7), a front push plate (8), a rear push plate (9) and a transverse rod (10) are designed cleverly, especially the two same motors work independently, and the risk caused by working stop of the motor assembly due to damage of the motors can be lowered through the redundant design that one motor is available, and the other motor is standby. Besides, the top end of the transverse rod of the gear shaft is designed to be in a circular cone shape, due to the profile of the transverse rod of the gear shaft, the top face of the transverse rod is a point and makes less contact with a spring wire, the spring wire can slide off freely when the transverse rod penetrates through the spring wire alternately, the situation that the spring wire of the torsion spring is stuck by the transverse rod is avoided, and the normal state is achieved.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

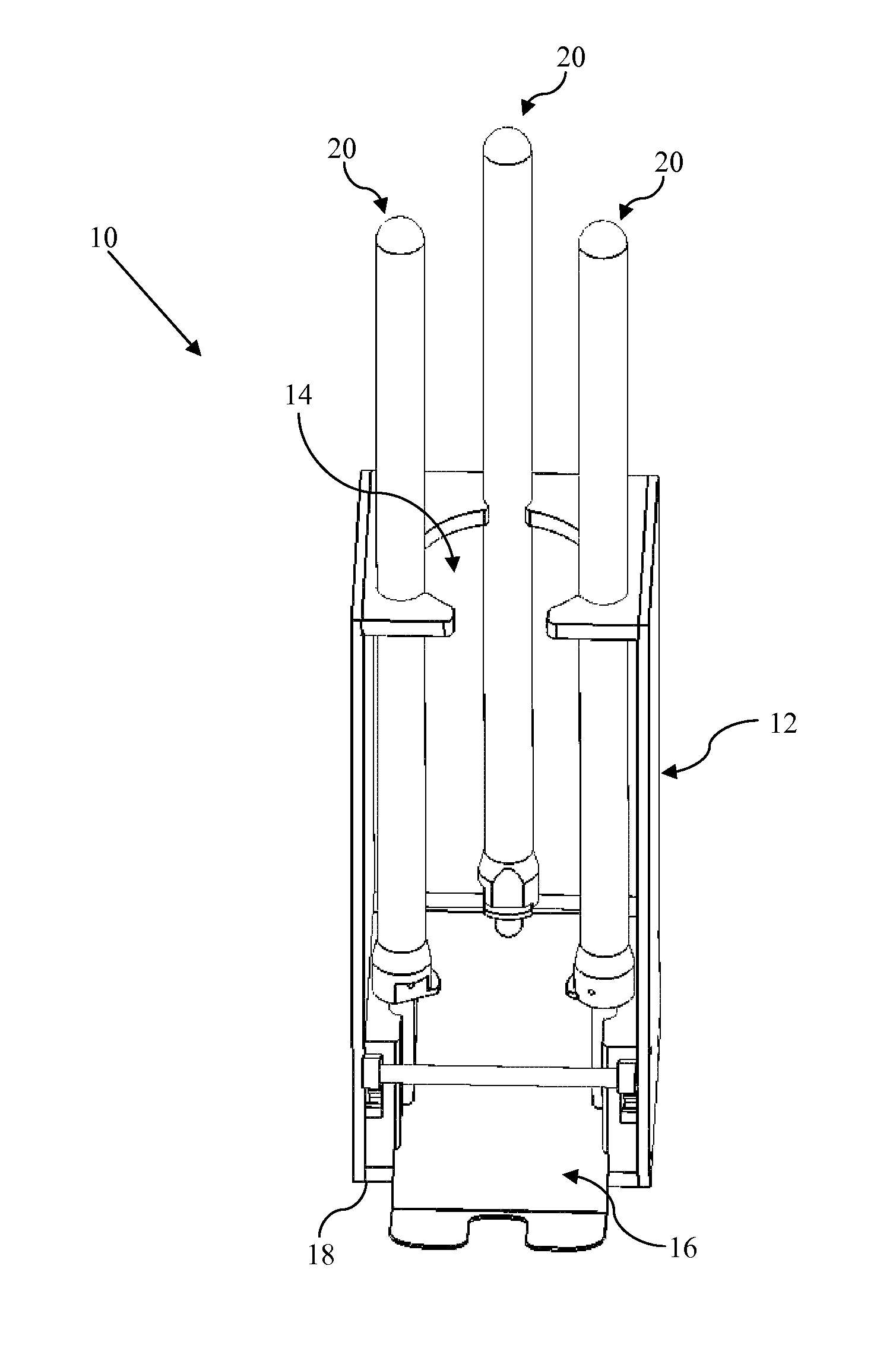

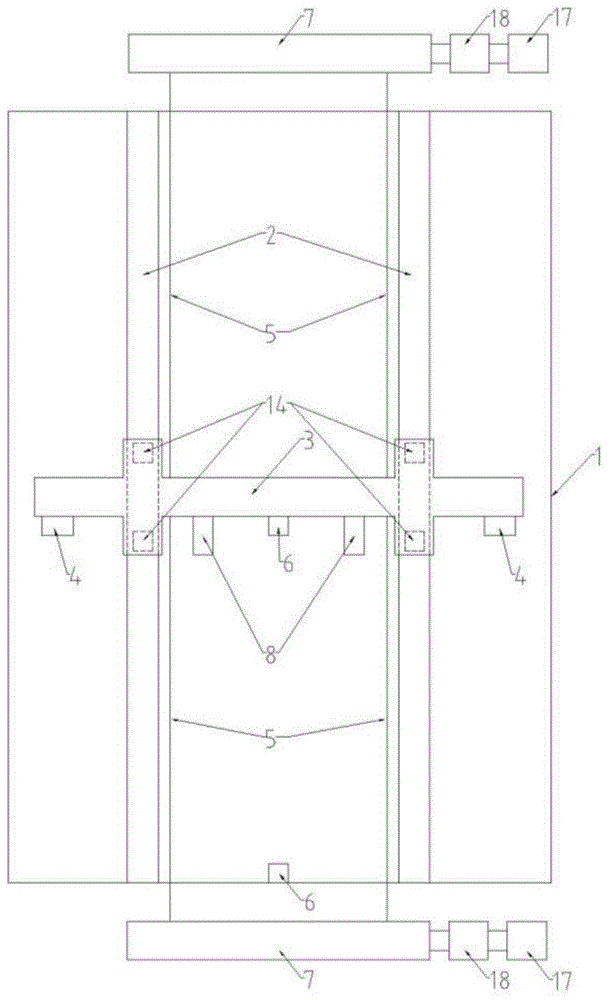

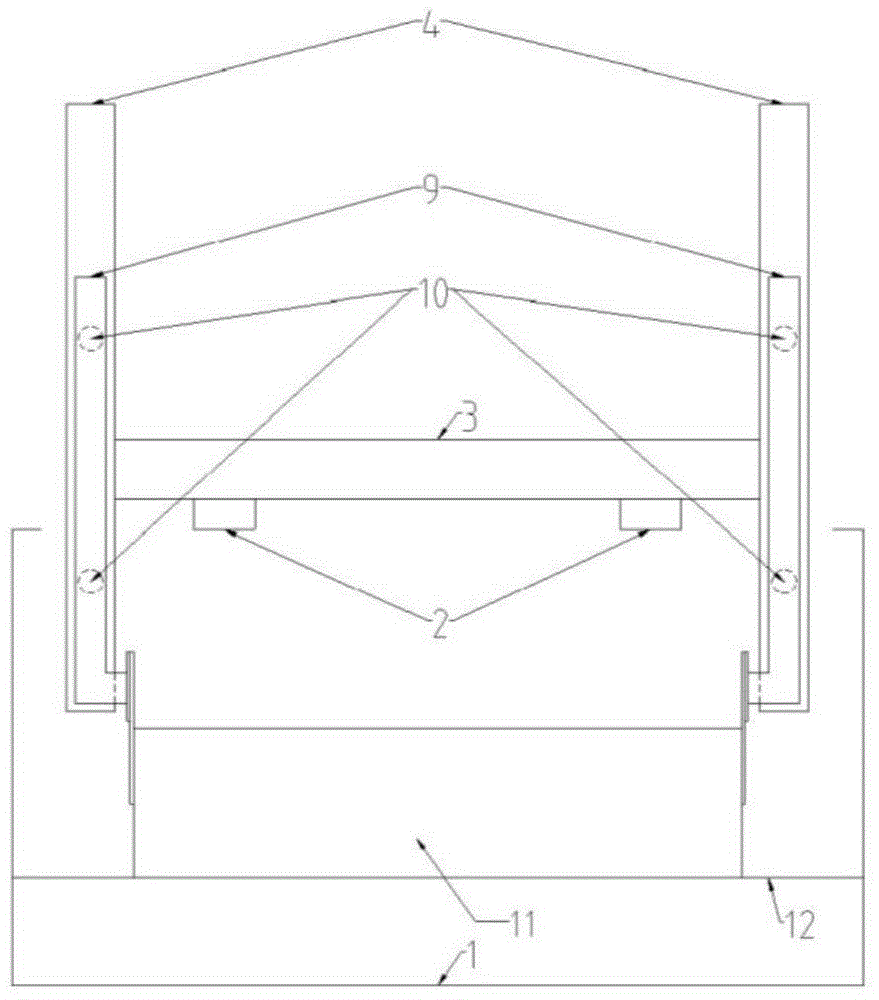

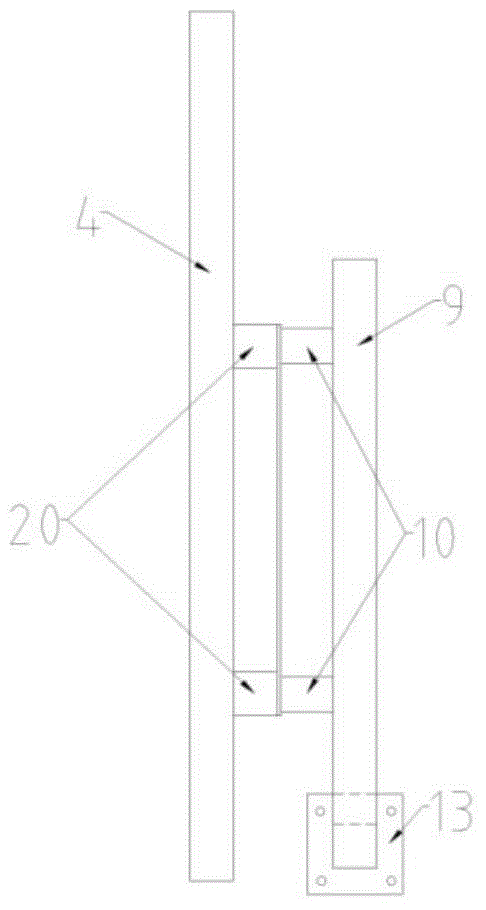

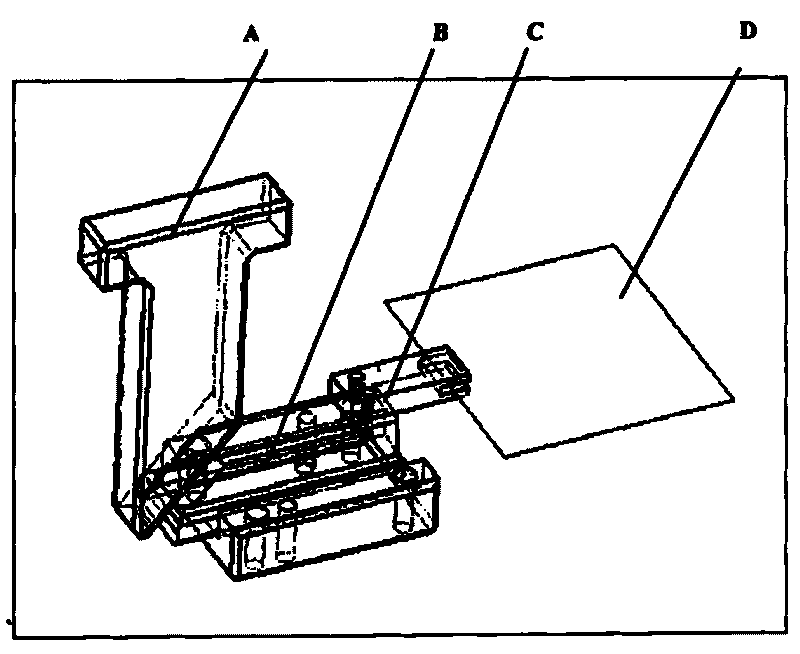

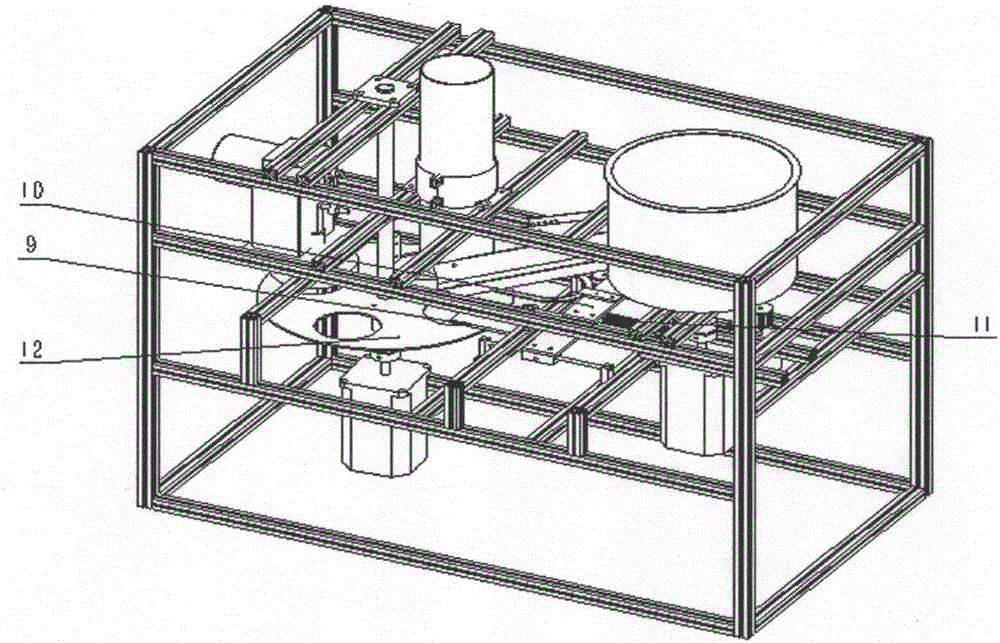

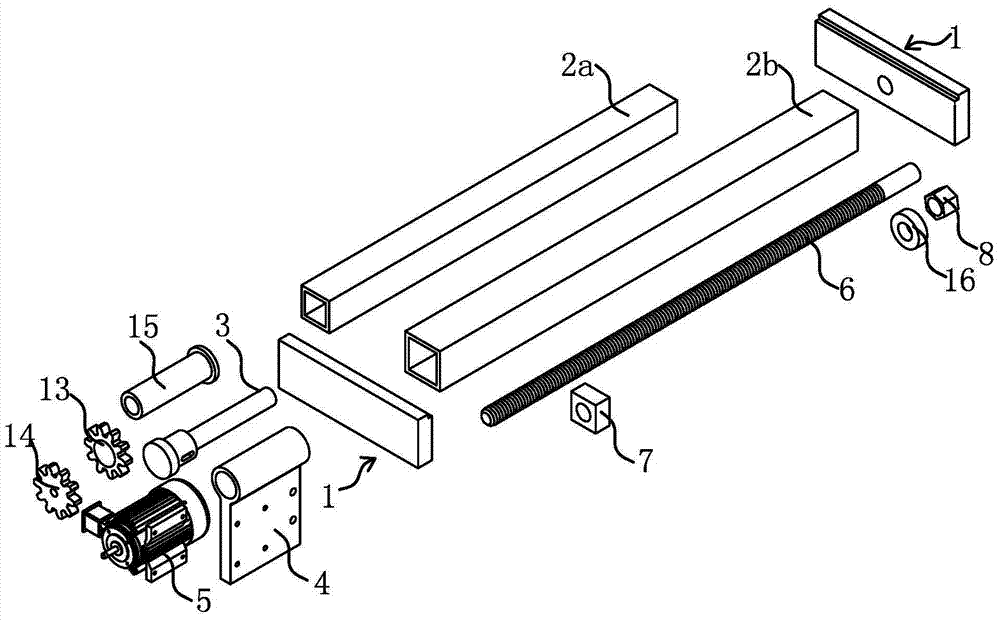

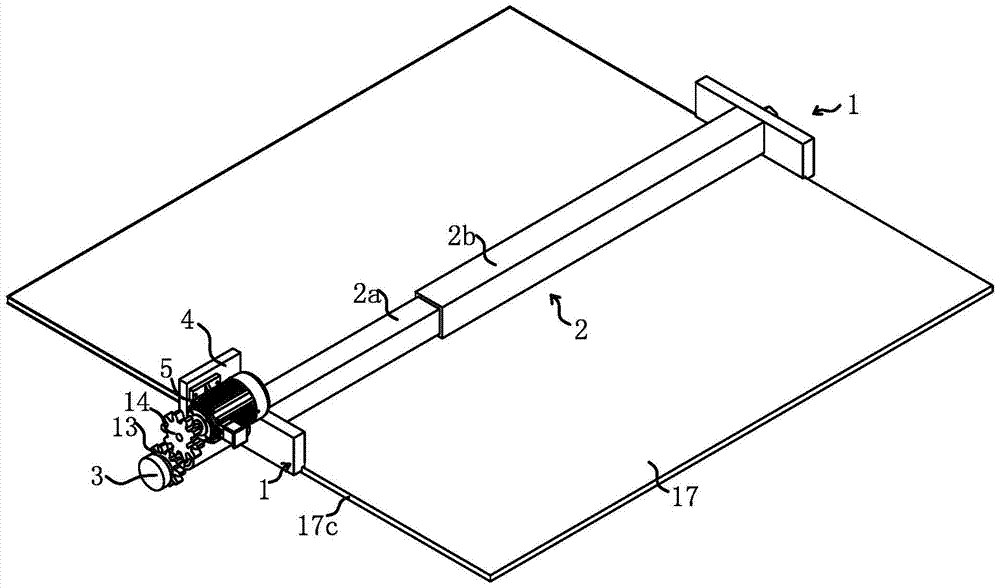

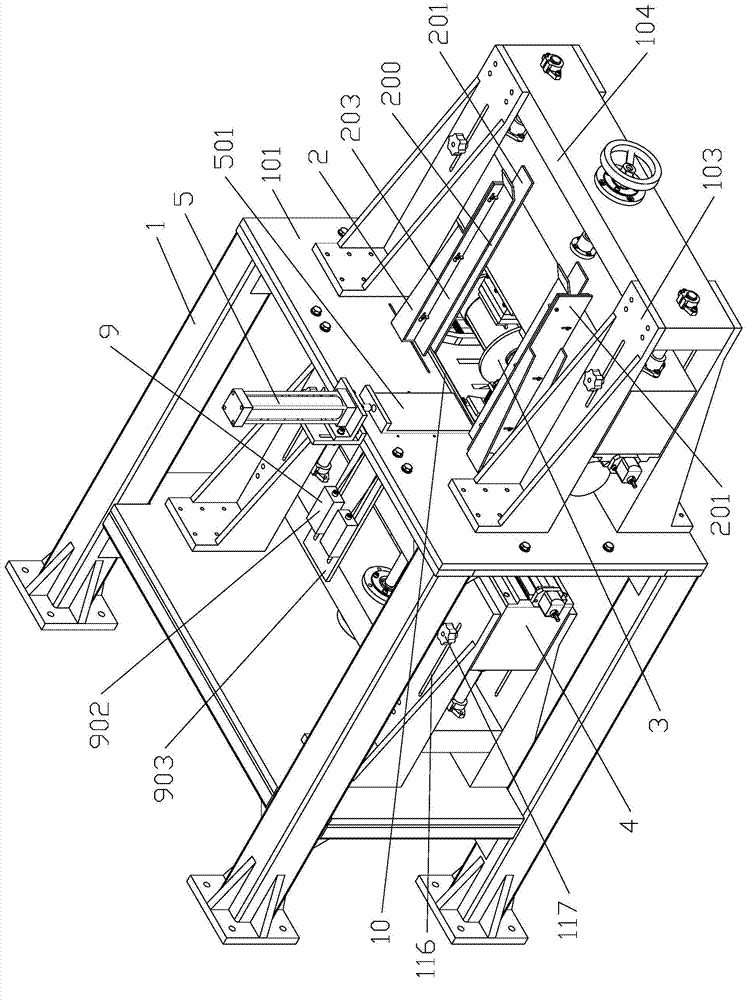

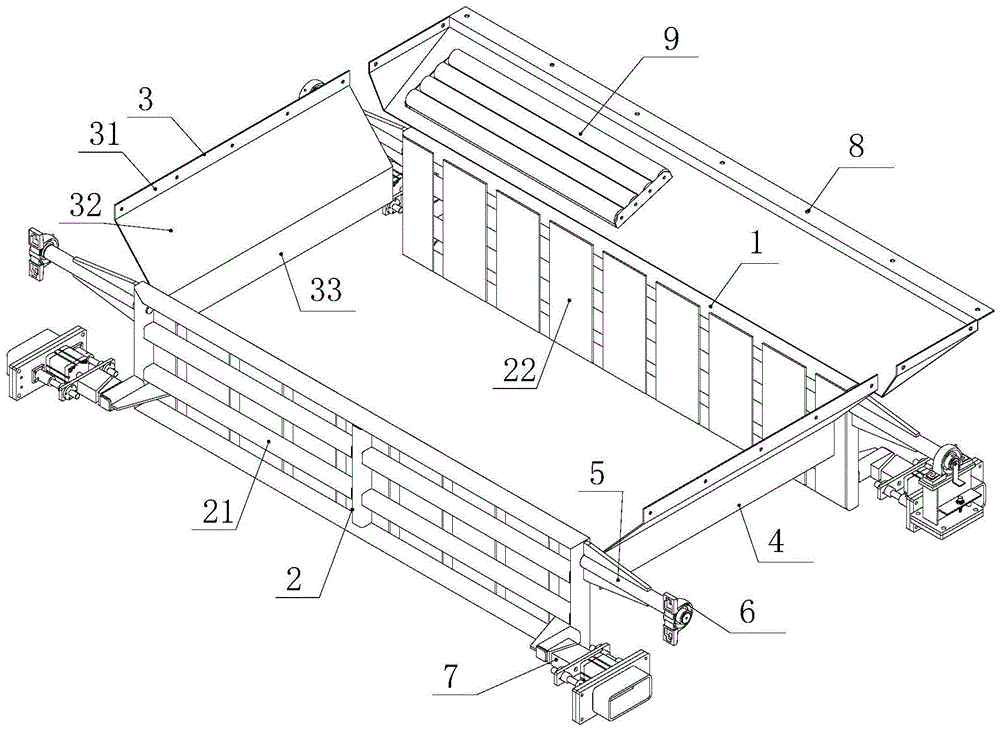

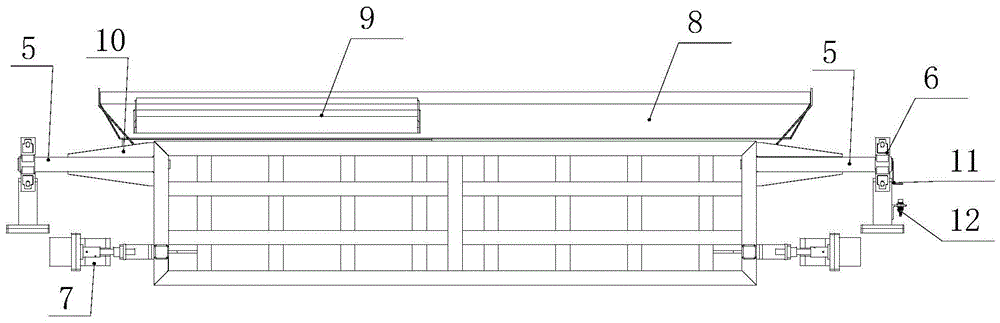

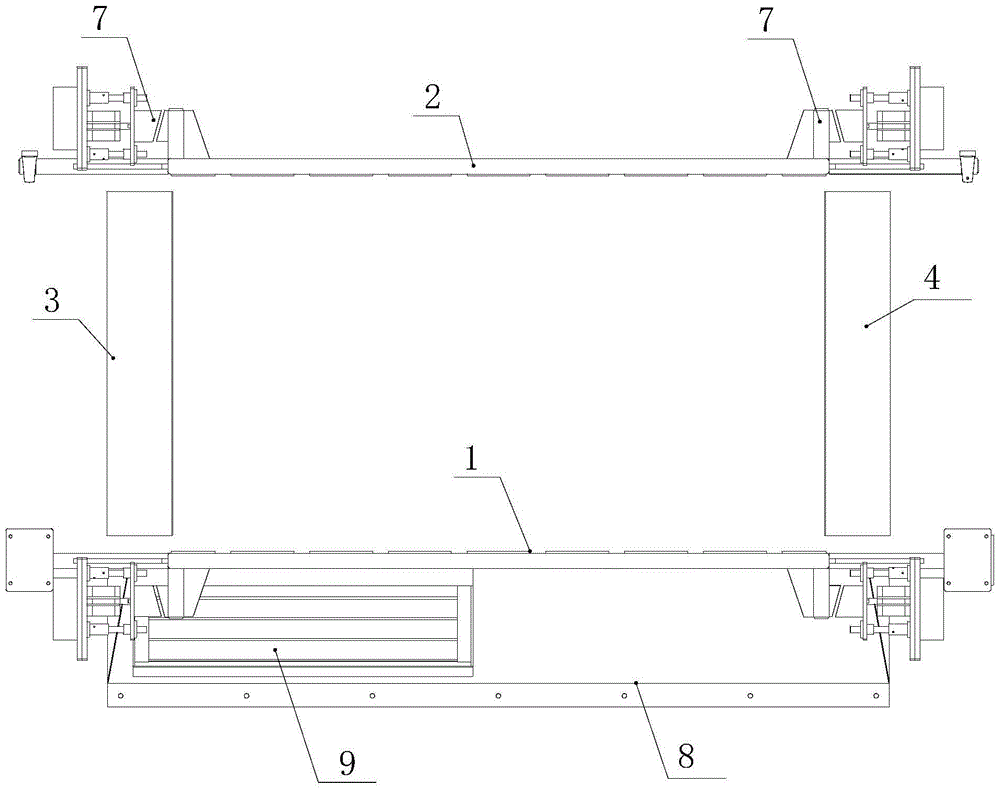

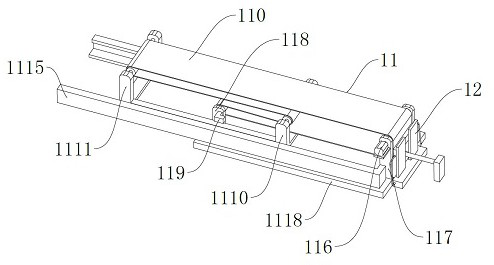

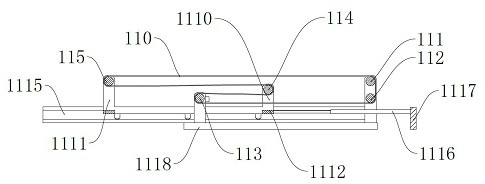

Testing device for measuring lateral soil resistance of pipeline

InactiveCN104677540AFree riseFree fallApparatus for force/torque/work measurementEngineeringSoil resistance

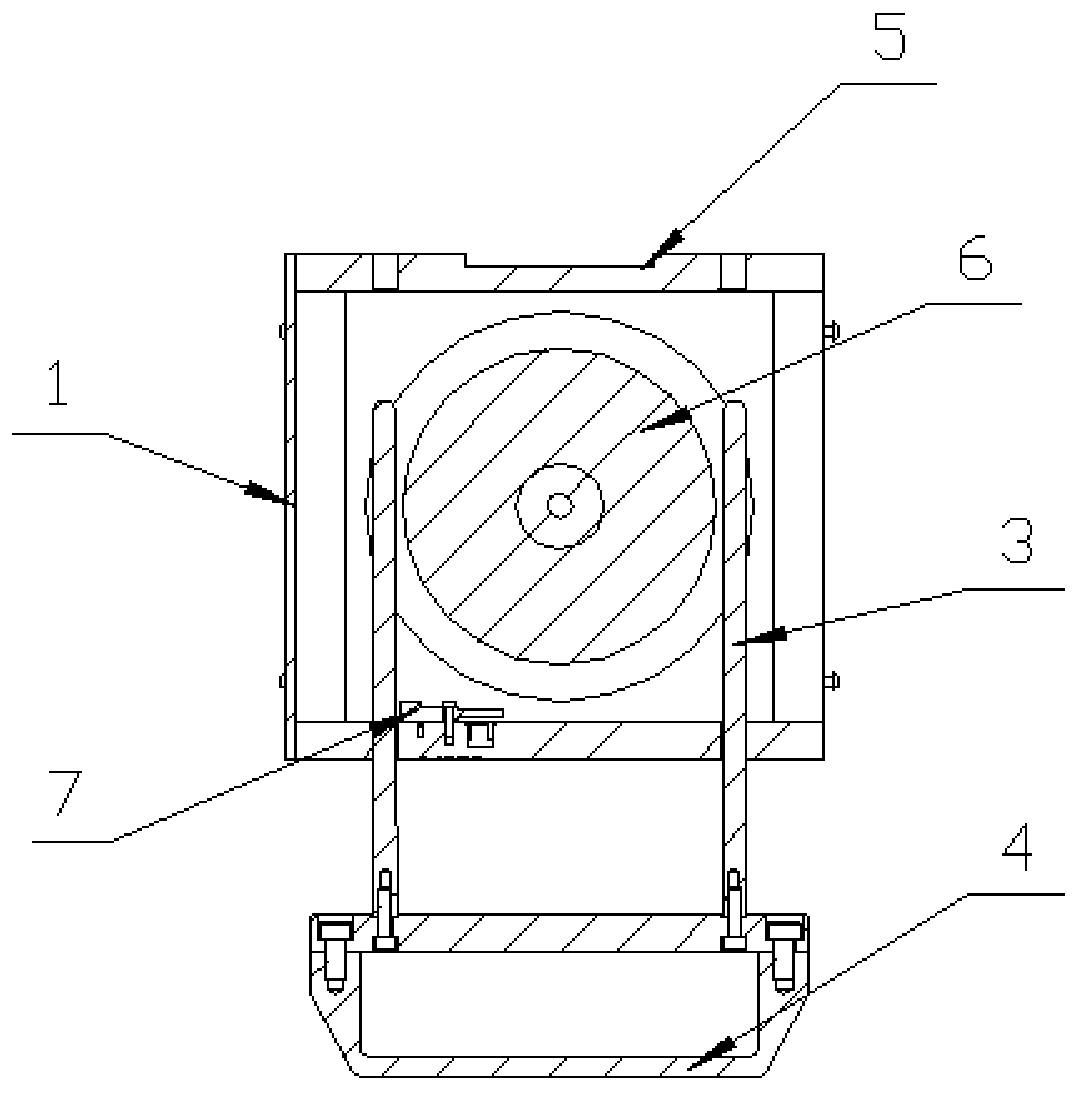

The invention relates to a testing device for measuring lateral soil resistance of a pipeline. The testing device comprises a soil groove (1), two horizontal linear guide rails (2), a horizontal trolley (3), vertical linear guide rails (4), two vertical rods (9), a force measuring system, a displacement measuring system, a pipeline weight regulating system and a power system, wherein the horizontal linear guide rails (2) are arranged along the length direction of the soil groove (1); sliding blocks (14) which are used for fixing the horizontal trolley (3) are arranged on the horizontal linear guide rails (2); the horizontal trolley (3) is fixedly provided with the two vertical linear guide rails (4) which are respectively provided with two sliding blocks, each sliding block (20) is provided with a tension and pressure sensor (10), and the tension and pressure sensors (10) are fixedly connected with the vertical rods (9); the bottom ends of the two vertical rods (9) are respectively and fixedly connected with the two ends of a test pipeline (11). According to the testing device disclosed by the invention, the measured soil resistance is enabled to more approach the stress of a seabed pipeline under a real state.

Owner:TIANJIN UNIV

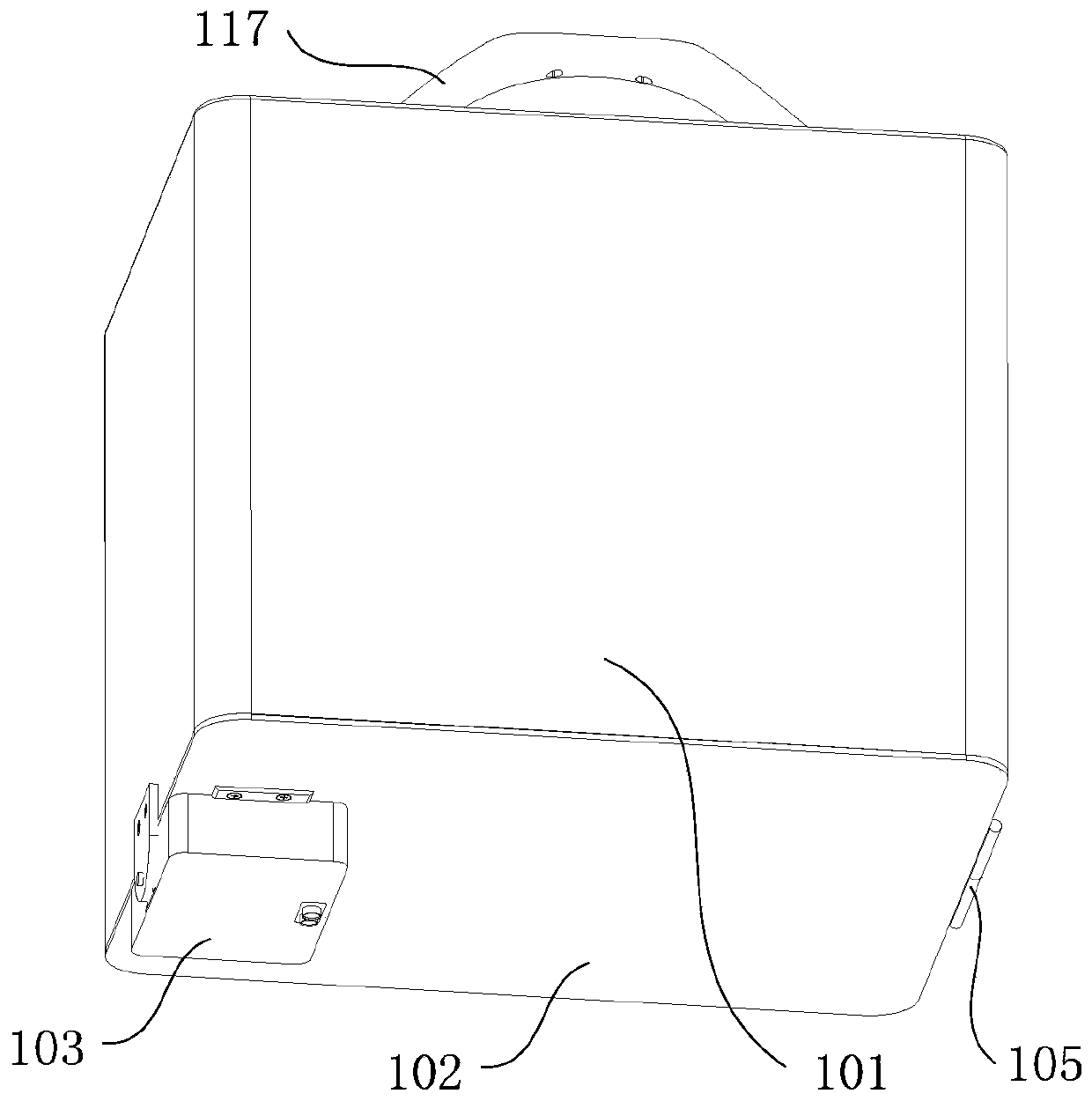

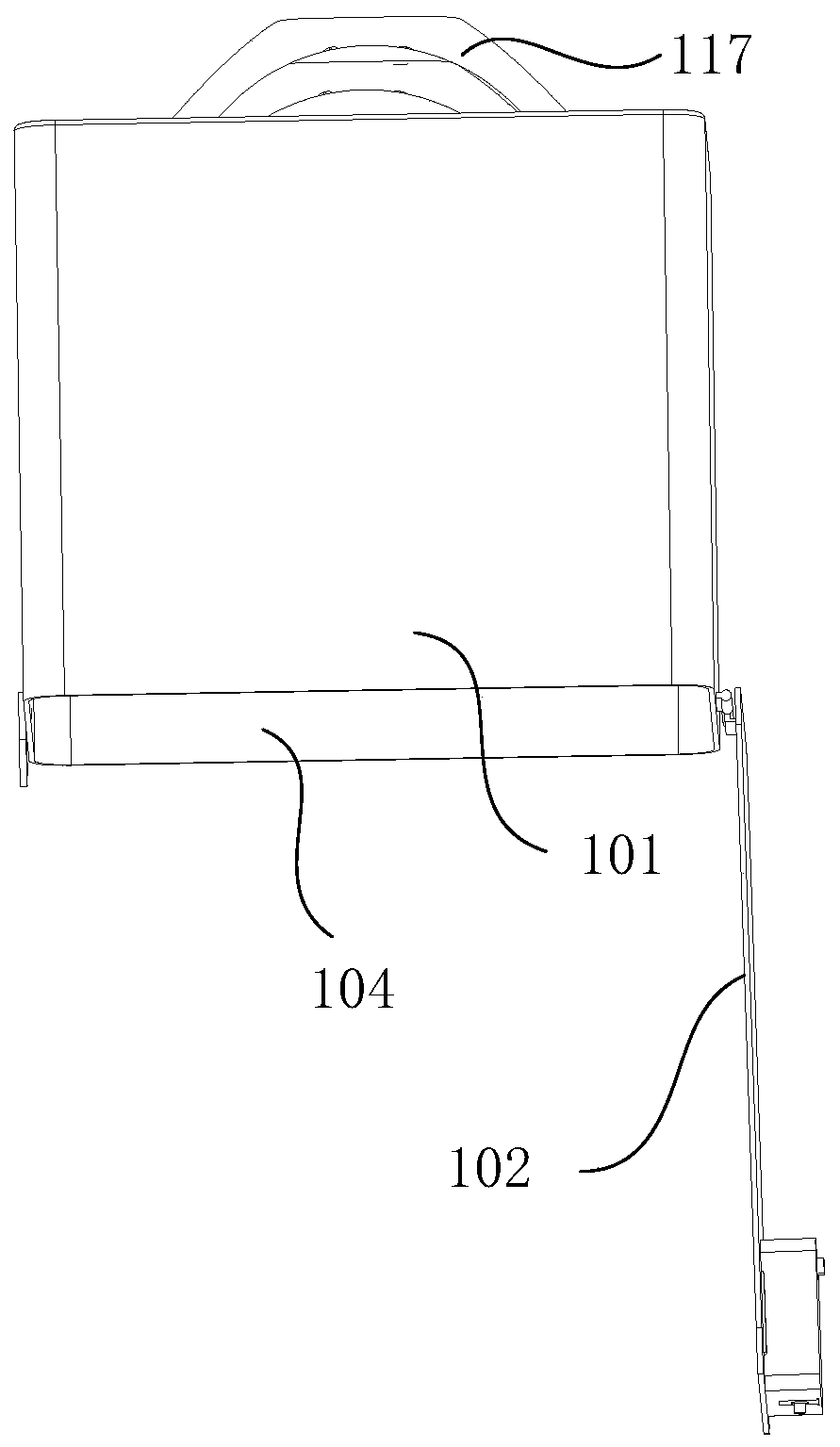

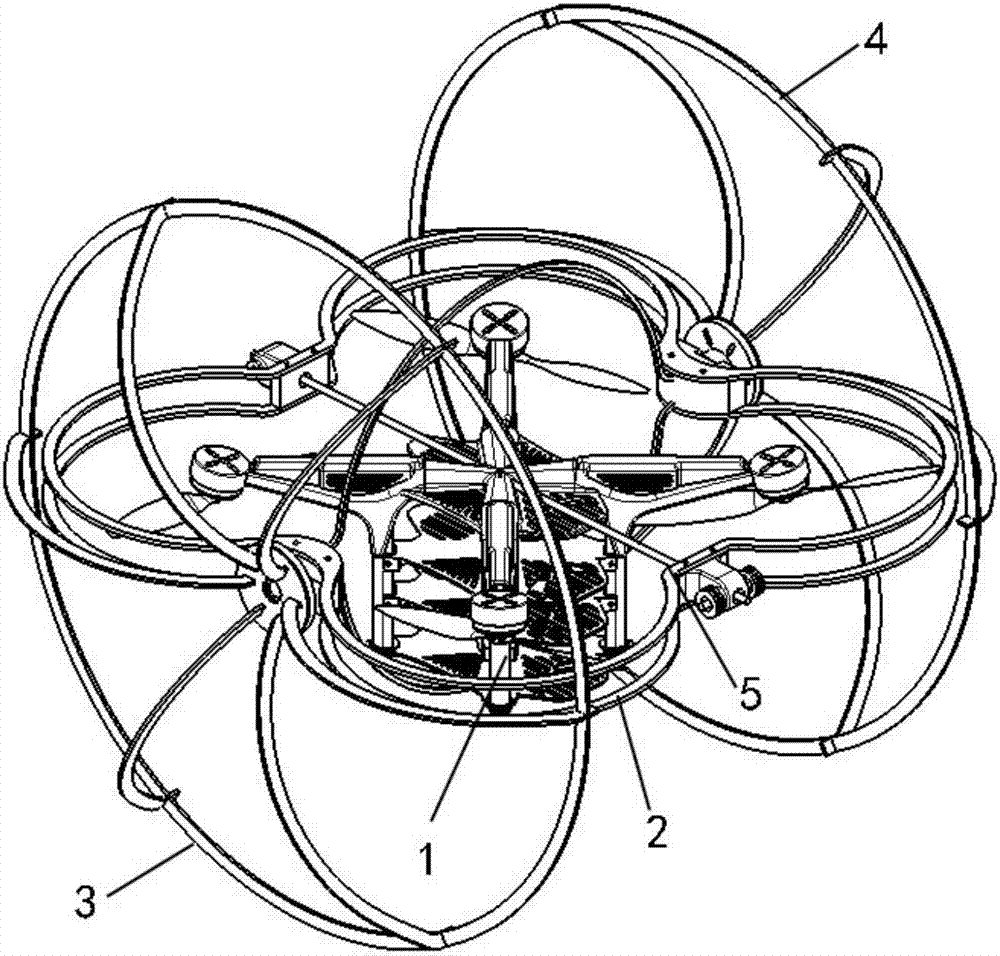

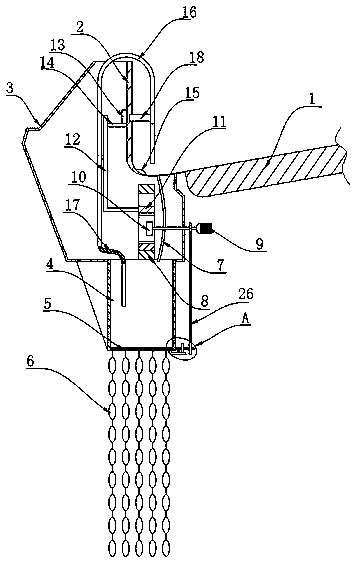

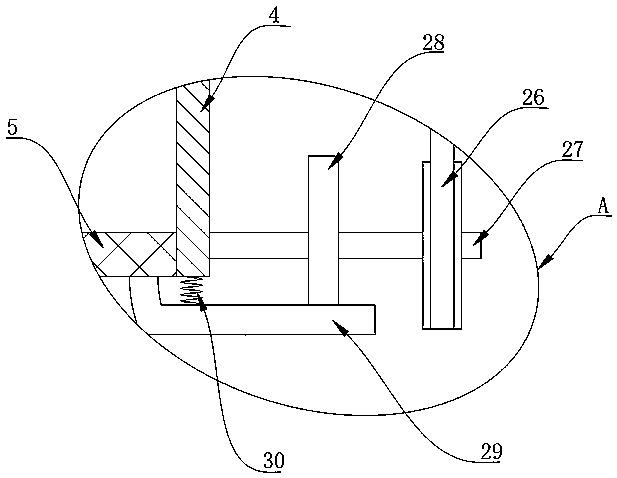

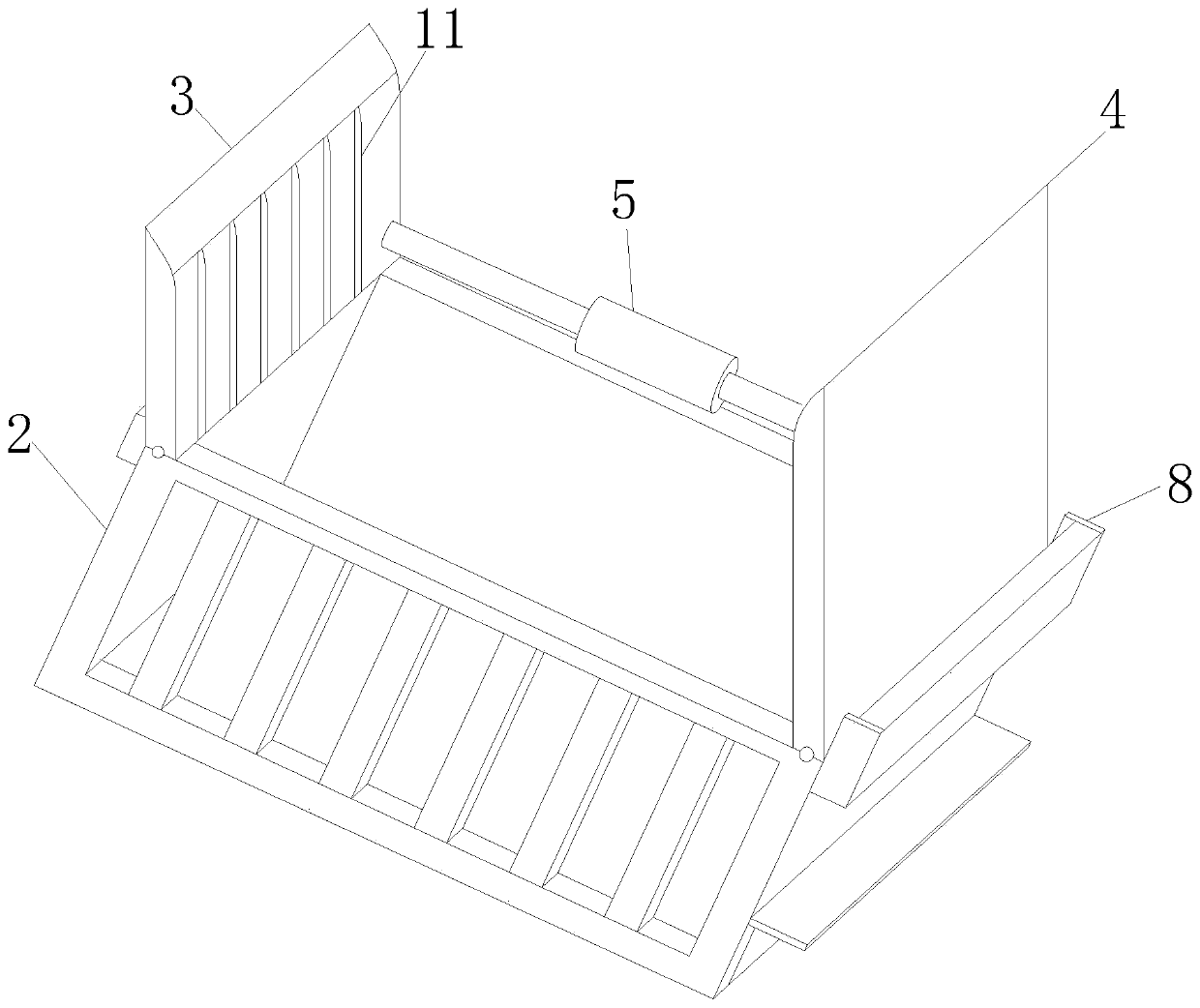

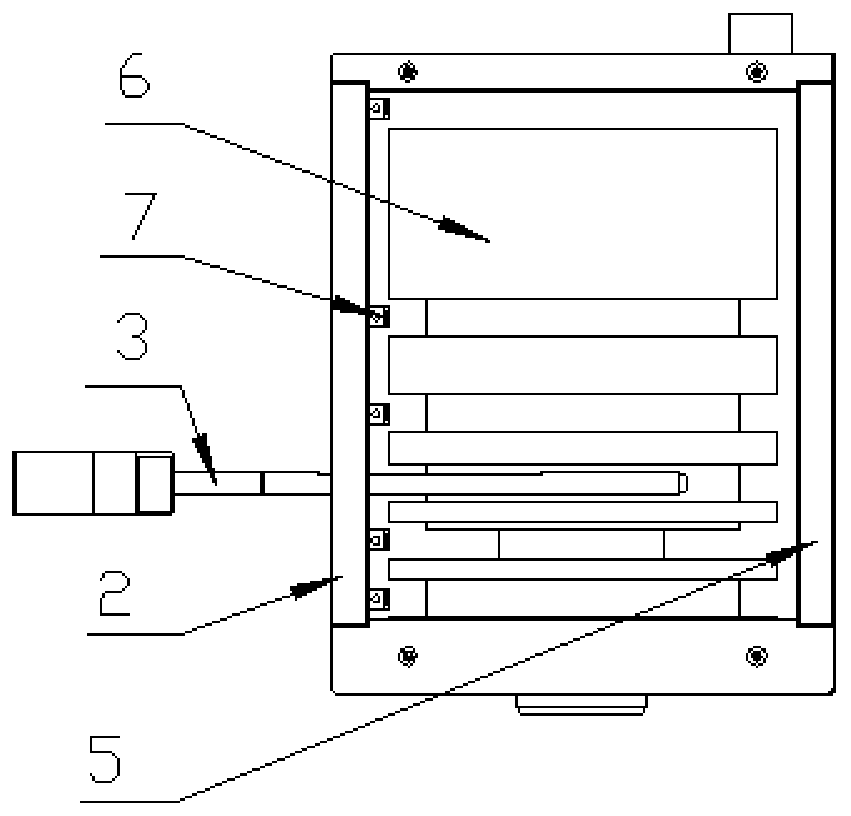

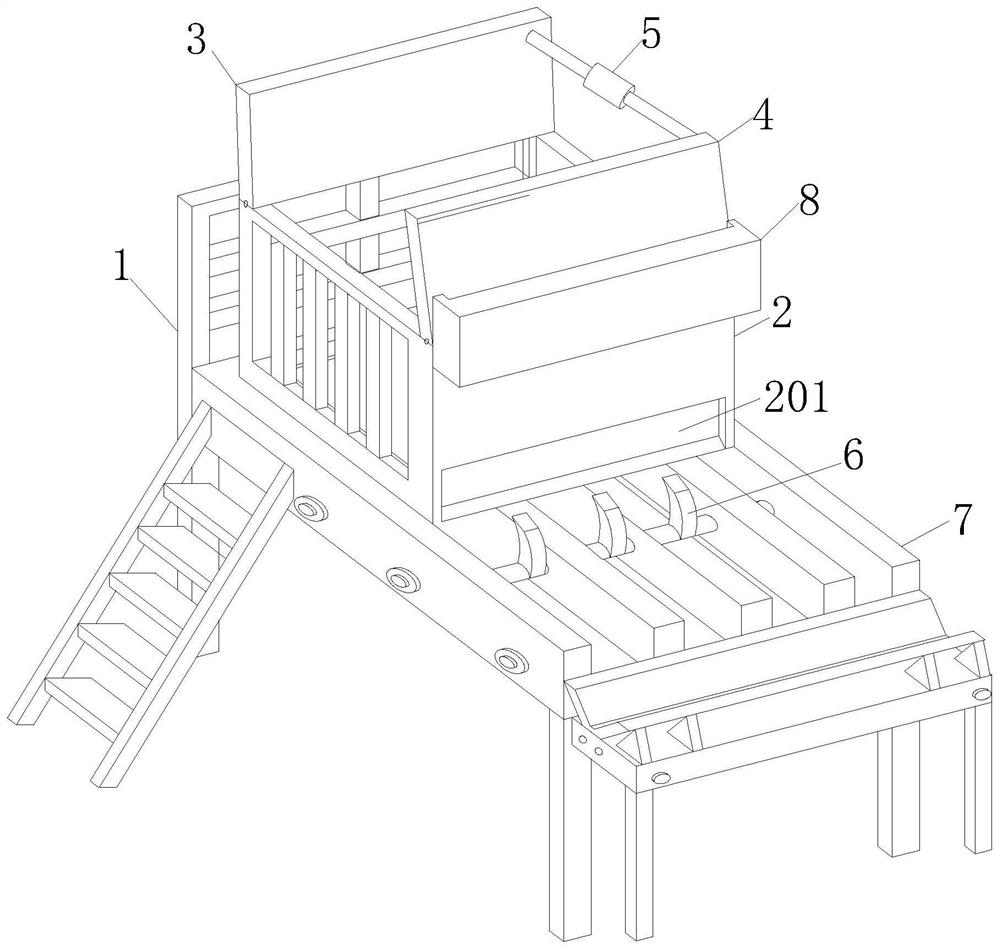

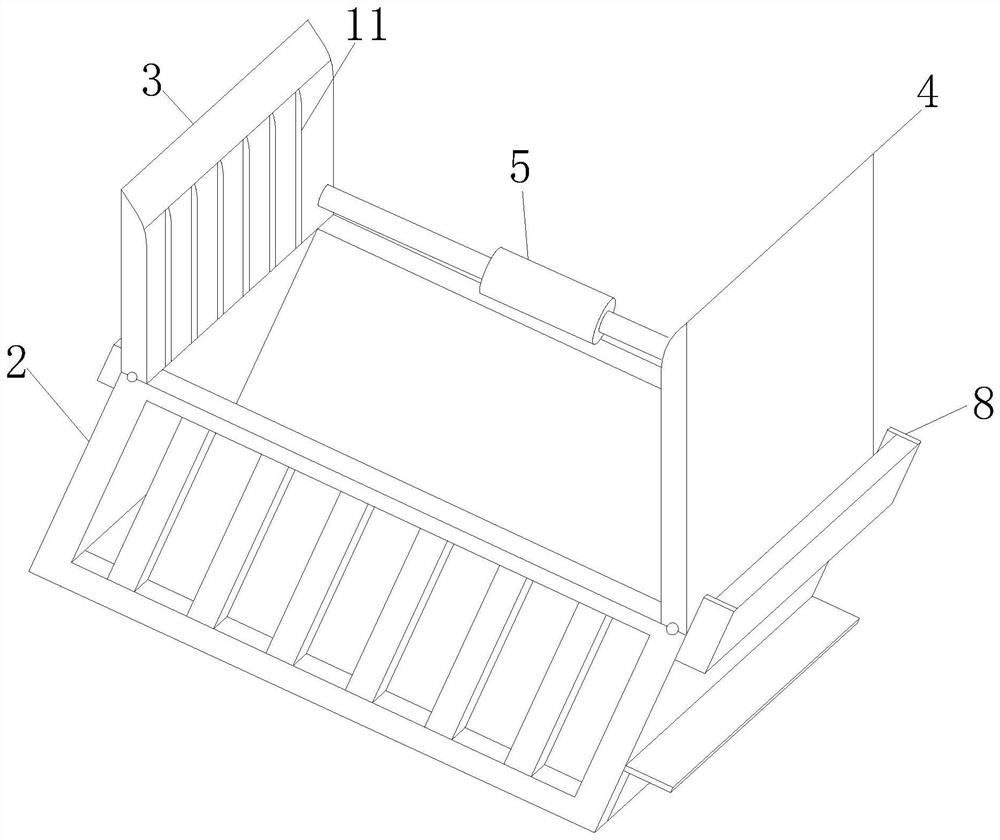

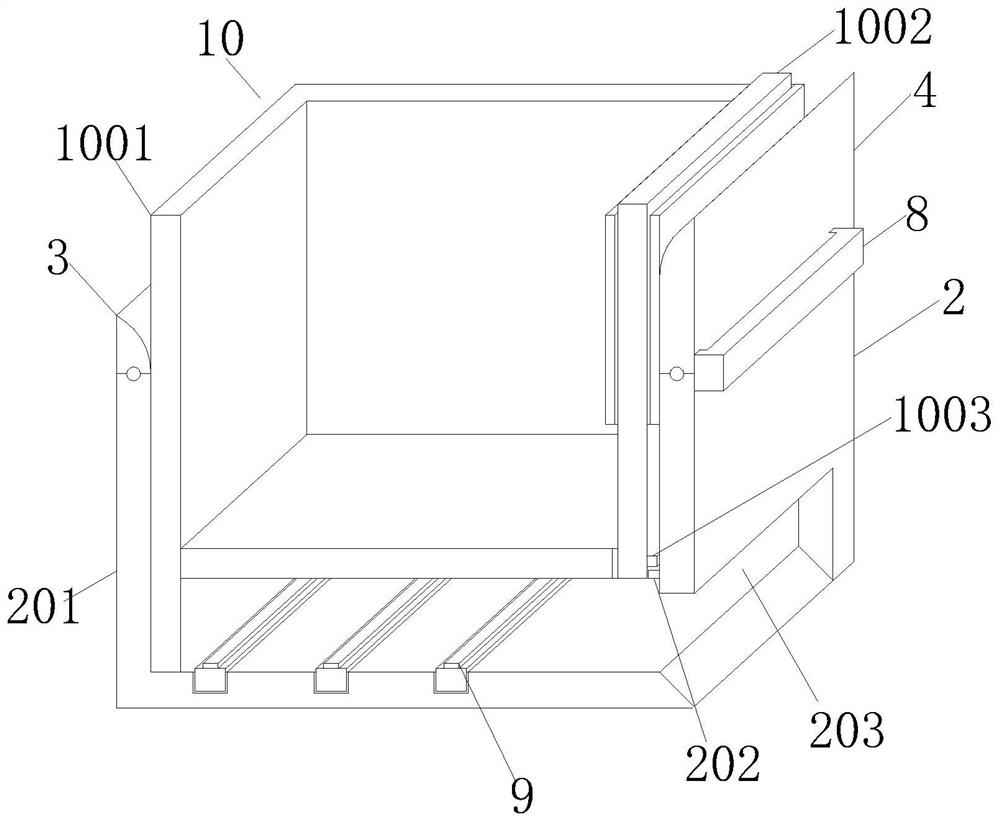

Goods delivery box, unmanned aerial vehicle and control method of box door

PendingCN110091992AAvoiding the problem of reloading cargoRealize deliveryAircraft componentsLaunching weaponsElectrical connectionEngineering

The invention relates to the technical field of unmanned aerial vehicles, in particular to a goods delivery box, an unmanned aerial vehicle and a control method of a box door. The goods delivery box is used for the unmanned aerial vehicle and comprises a box main body, a box door and a control switch. A delivery opening is formed in the bottom of the box main body, and the box door is connected with the bottom of the box main body. The control switch is arranged between the box main body and the box door and is used for opening or closing the box door. According to the invention, the box dooris arranged at the bottom of the box main body; the box door is opened through the control switch, the goods transported in the box body fall to the ground under the influence of gravity, and the goods delivery box completely and independently works without electrical connection or information exchange with the unmanned aerial vehicle; automatic delivery of the goods can be achieved autonomously;and the problem that the unmanned aerial vehicle needs to unload the goods after landing is solved.

Owner:CHENGDU TECHCAL UNIV

Mold structure

Owner:CHERY AUTOMOBILE CO LTD

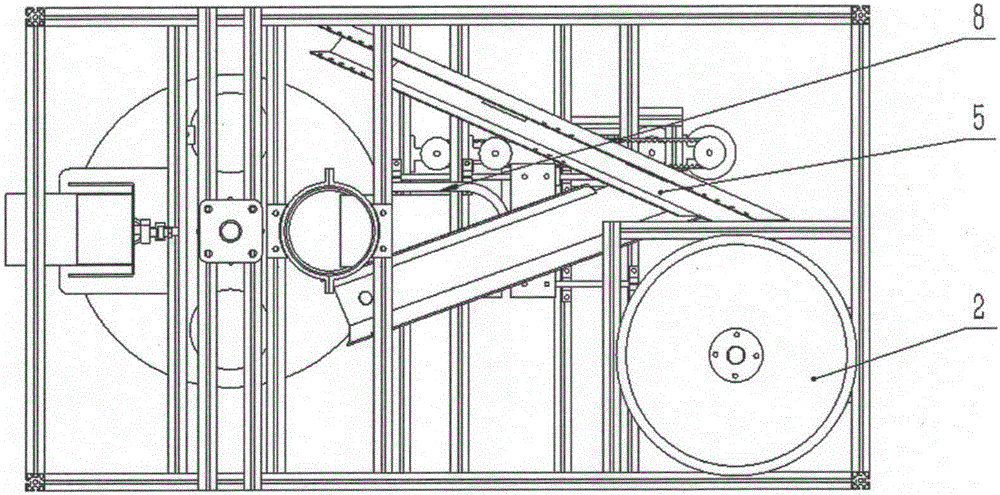

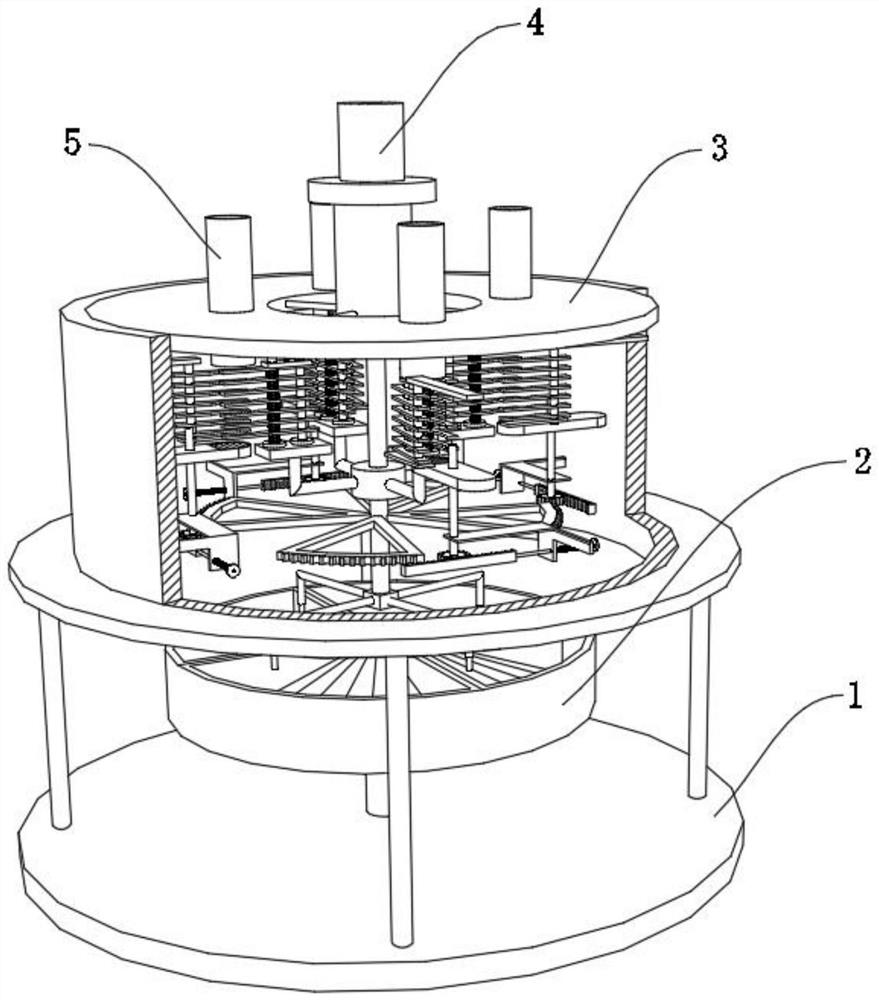

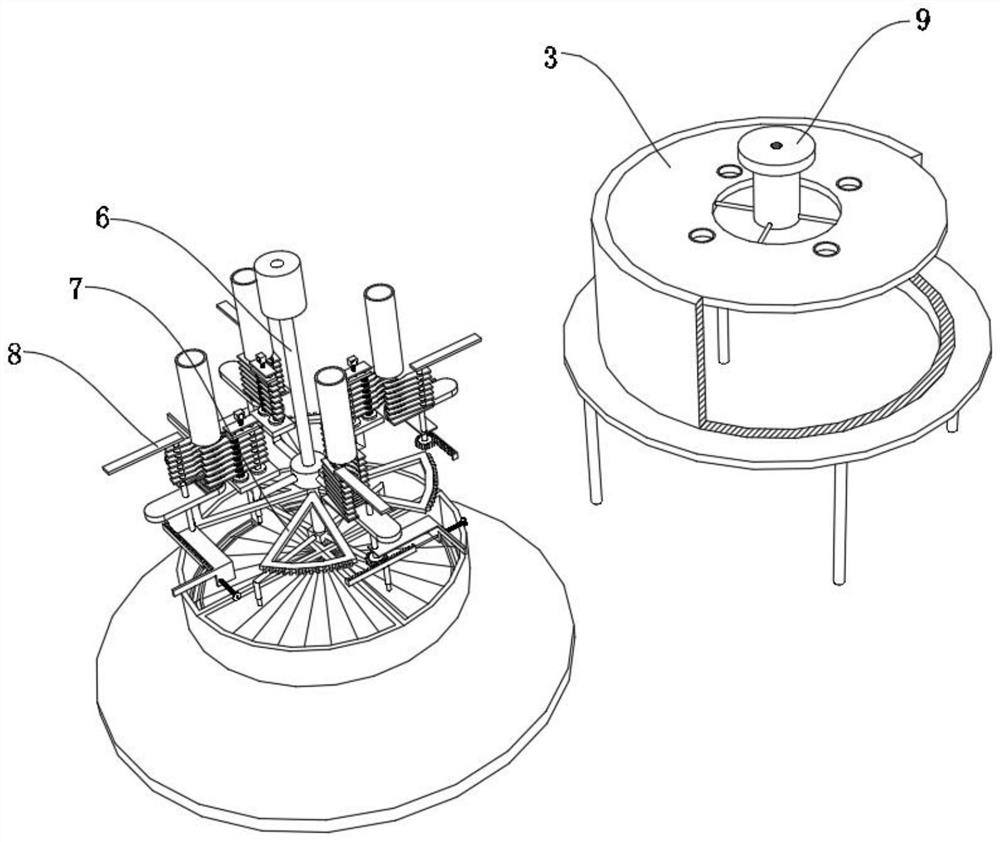

Coin sorting and collating machine

InactiveCN106127920AEasy to controlEasy to implementCoin countersSmall holeElectrical and Electronics engineering

The invention provides a coin sorting and collating machine comprising a sorting mechanism which is used for classifying, counting and collecting all the mixed coins; a cup dropping mechanism which is used for conveying cups used for packaging the sorted coins to the designated positions one by one; and a packaging mechanism which quantitatively packages the sorted coins through the cups. The coins enter a speed-adjustable disc through a funnel, the coins having circumferential velocity continuously pass through small holes beside the disc to enter a sorting track and fall from different slot ports to be counted and packaged. The device is adjustable in separation speed, convenient to control and implementable in function; the counting accuracy is high and the result is accurate; the packaging part can realize free falling of the packaging cups so as to be high in degree of automation and efficient and convenient; the packaged and sealed coins can be automatically transmitted out of the device so that the degree of automation is high and manpower can be saved; and the whole device is integrated in sorting, counting and packaging so as to be low in cost, high in reliability and high in adaptability.

Owner:DONGHUA UNIV

Tile clamping device for tiling machine

The invention provides a ceramic tile clamping device of a tile tiling machine, which belongs to the field of construction and decoration machinery. The utility model solves the problems that the clamping device of the existing tile tiling machine occupies a large area and is expensive. The clamping device of the improved structure includes two clamping plates arranged symmetrically; a support rod is arranged between the two clamping plates; one end of the support rod is fixedly connected with a clamping plate, and the other end is connected with The other clamping plate is fixedly connected; the support rod can be stretched, and the support rod is provided with a locking mechanism capable of locking the length of the support rod. The ceramic tile clamping device of the tile tiling machine with the improved structure is simple in structure and high in use reliability, and is very suitable for popularization.

Owner:台州八鑫工贸股份有限公司

Novel LED street lamp

InactiveCN103256529AEasy to maintain laterRealize the goal of energy savingLighting heating/cooling arrangementsGlobesIlluminanceEffect light

The invention relates to the field of lighting, in particular to a novel LED street lamp. The novel LED street lamp comprises a lamp body and a lamp stem. The tail end of the lamp body is connected with the lamp stem. The lamp body comprises a lamp shell. Radiating fins are mounted on the surface of the lamp shell. An LED module is fixed in the lamp shell and connected with a power supply. A lampshade which covers the LED module is fixed to the lamp shell. A lower lamp shell is fixed to the lower end of the lamp shell. A method of 'once light distribution' is used, LED lamp beads are embedded on the LED module, light emitted by the LED module is reflected by the lampshade and then uniformly irradiates from a high position to the ground, and lighting uniformity of the novel LED street lamp is increased by 20% compared with modularized street lamps with same power. The novel LED lamp changes traditional light distribution and LED lighting, and is high in lighting effect, high-power, simple, high in reliability and the like.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

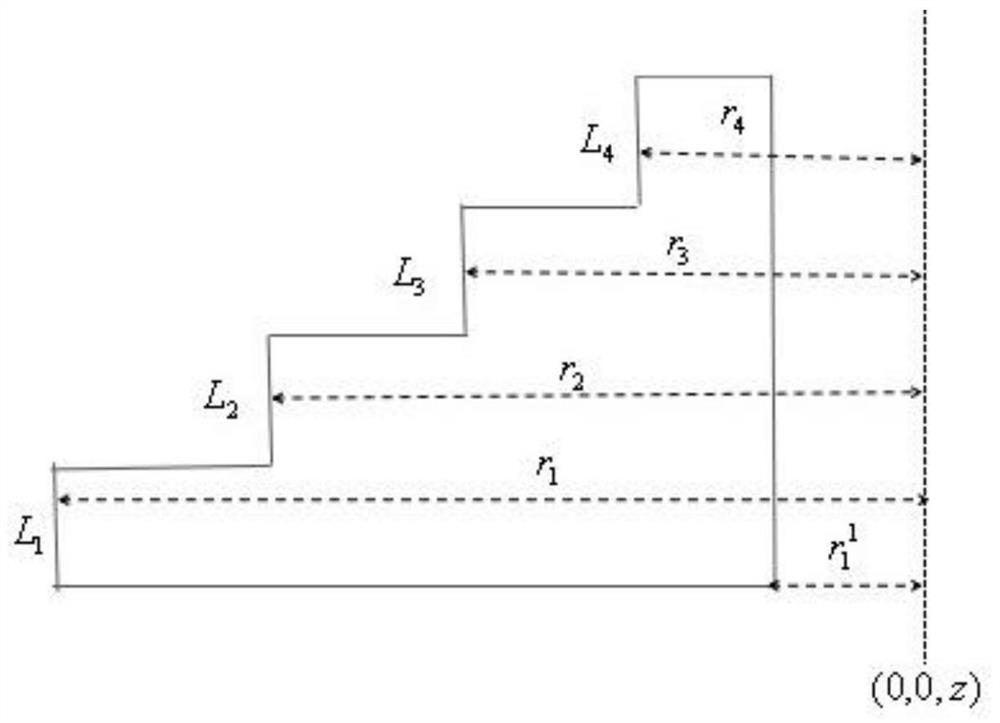

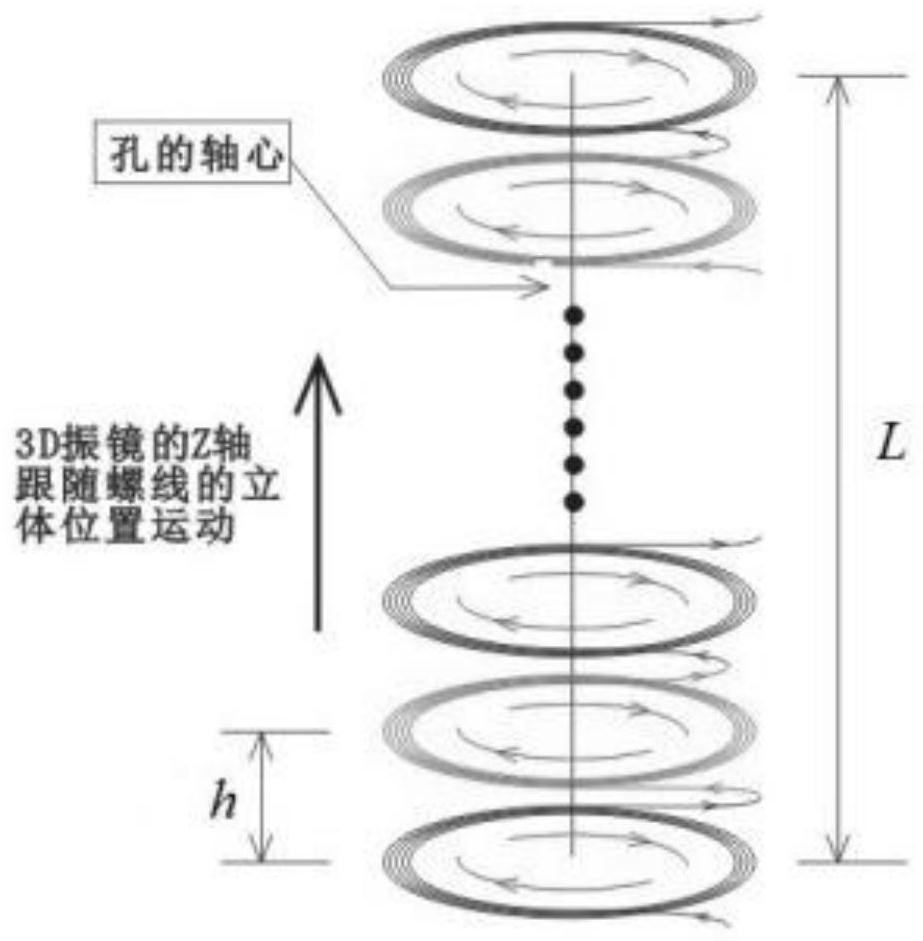

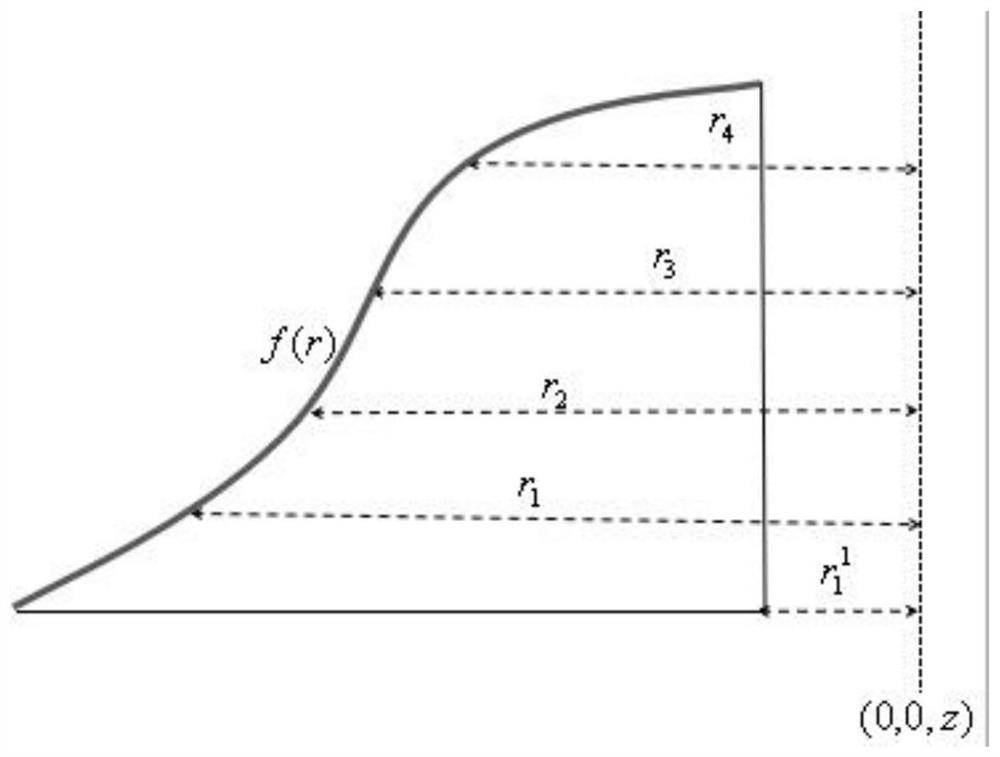

Method for improving punching stability of photovoltaic glass stepped holes

PendingCN112171089AImprove stabilityImprove punch stabilityLaser beam welding apparatusGalvanometerMachining

The invention discloses a method for improving the punching stability of photovoltaic glass stepped holes. The method includes the following steps that the starting point position of a focus of a 3D galvanometer is adjusted, laser is focused to the lower surface of a to-be-machined material, the coordinate positions of the point are defined as (0, 0, 0), and the hole axis coordinates of the to-be-machined material are defined as (0, 0, z); the laser starting point moves to the (r1, 0, 0) position and moves in a spiral line manner with the (0, 0, 0) used as the circle center and the r1 used asthe outer radius; after the laser starting point passes through a layer of spiral line, the focus Z axis controlled by the 3D galvanometer is lifted, and then machining is continued; when the Z axis reaches the second layer, the laser starting point moves to the (r11, 0, h) position and moves in a spiral line manner with the (0, 0, h) used as the circle center and the r11 used as the inner radius,and the advancing direction is changed into a spiral line from inside to outside until the laser passes through the spiral line of the layer; and after the focus Z axis controlled by the 3D galvanometer is lifted, machining is continued, when the Z axis reaches the third layer, the laser starting point moves to the (r1, 0, 2 h) position, and the (0, 0, 2 h) is used as the circle center. Accordingto the method, a product with the smooth hole wall, the high machining precision and the good stability can be obtained.

Owner:SHENZHEN JIXIANGYUN TECH CO LTD

Automatic unloading device of drop test machine

An automatic unloading device of a drop test machine belongs to the technical field of drop impact test, and aims to solve the problems in the prior art, three groups of spring accumulators are equidistantly arranged on a top plate, the lower part of the top plate is connected with a support frame, two sides in the support frame are respectively provided with a slide rail, and a slide block on the slide rail is connected with a box body; the lower portions of the three spring force accumulators make contact with the top of the box body, the two buffers are installed at the bottom ends of the two sides in the supporting frame respectively, and a tested object bracket is installed on the overturning plate and connected through a hinge; the box body and the overturning plate are connected through two rotating shafts; a posture fixing frame is mounted in front of the top plate; the top plate and the box body are locked through a lock pin mechanism; one end of the pull rod is fixed on the turnover plate, and the other end is connected with the connecting rod through a rotating shaft; the connecting rod is connected with the top plate through a shaft; and the limiting nut is fixed below the top plate and located above the box body to limit the rising position of the box body along the sliding rail, and after the limiting position is reached, the lock pin mechanism is locked through a plug pin. The tested object can freely fall without posture change.

Owner:CHANGCHUN UNIV OF SCI & TECH

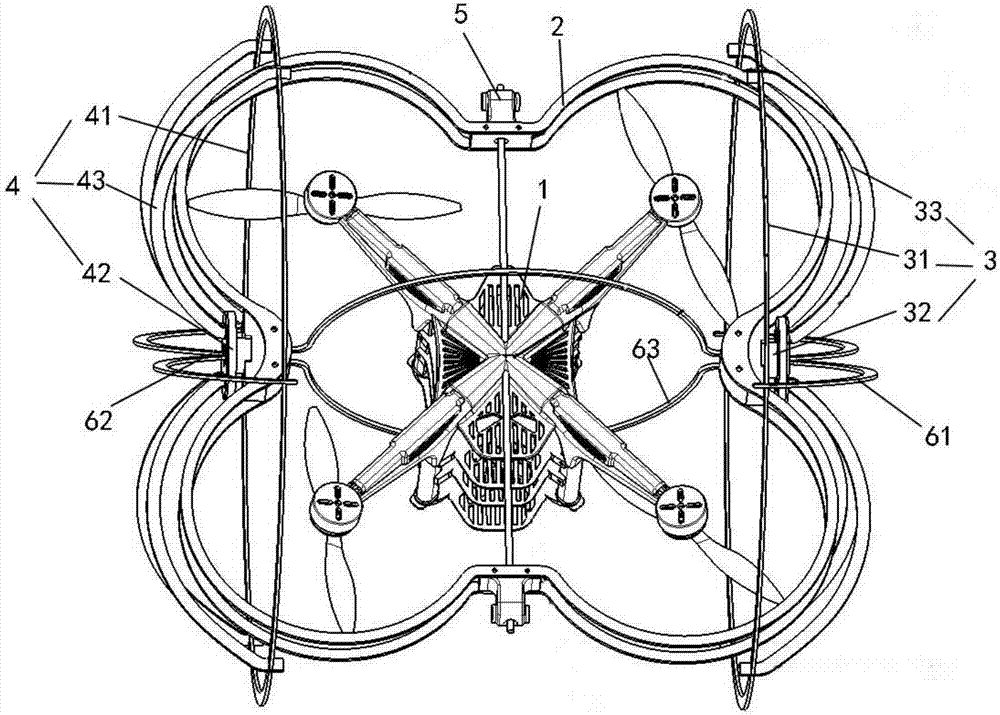

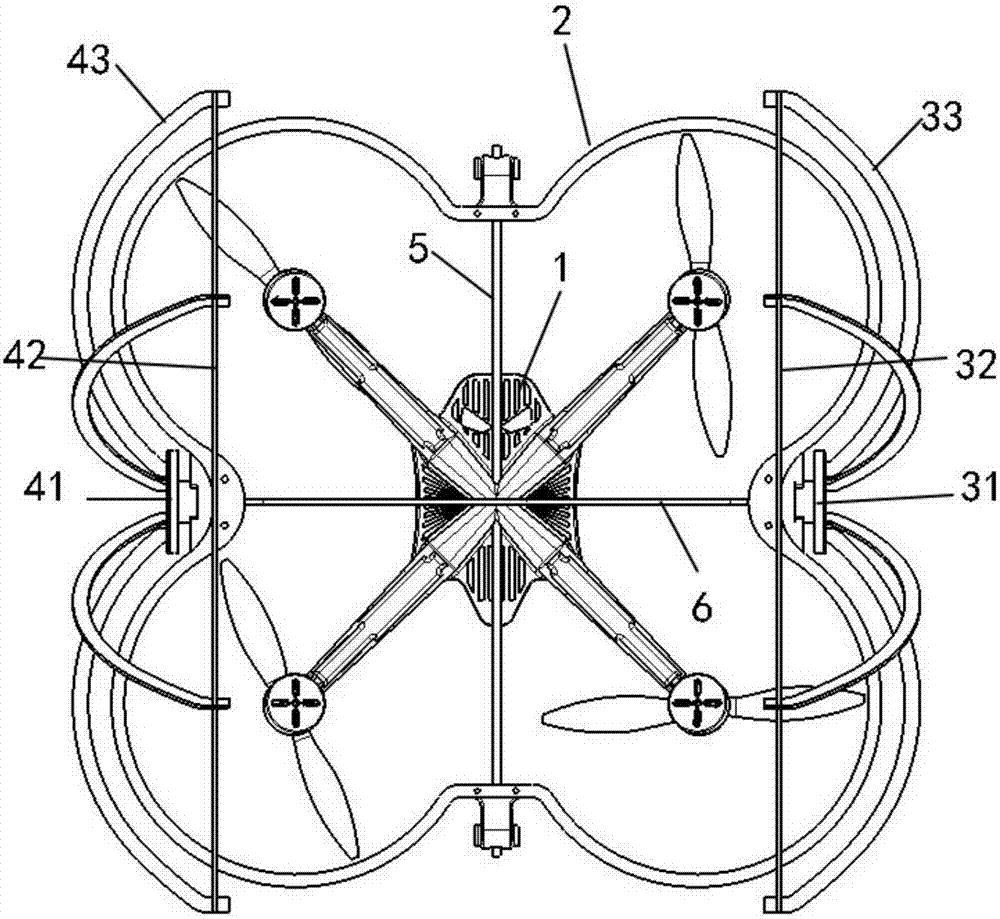

Aircraft

Owner:瑞电恩吉能源技术(深圳)有限公司

Novel metal building roof free water falling device

The invention discloses a novel metal building roof free water falling device. The novel metal building roof free water falling device comprises an eave arranged at the edge of a roof, wherein the eave is vertically arranged at the edge of the roof; a gutter is fixed to the eave; the lower wall of the gutter communicates with a rain dividing groove; the lower part of the rain dividing groove communicates with and is fixedly connected with a flow guiding net; a plurality of vertical rain guiding curtains are fixed to the lower end face of the flow guiding net; and a plurality of rainwater pipesfixedly communicate with the bottom of the eave in a penetrating mode. The novel metal building roof free water falling device has the advantages that during raining, rainwater can be gathered to theeave and flows out downwards through the rainwater pipes and the flow guiding net, and free water falling is achieved; the multiple rain guiding curtains are arranged, the rain guiding curtains formthe flow guiding effect on the rainwater, and thus free water falling is more attractive; and when the rainwater amount is large, a servo motor drives a gear to rotate, the gear is engaged with an inner toothed plate to drive the inner toothed plate to move, a connecting rod moves in the horizontal direction along with a square sleeve, and the stirring effect on accumulated water in the eave is achieved.

Owner:康慧英

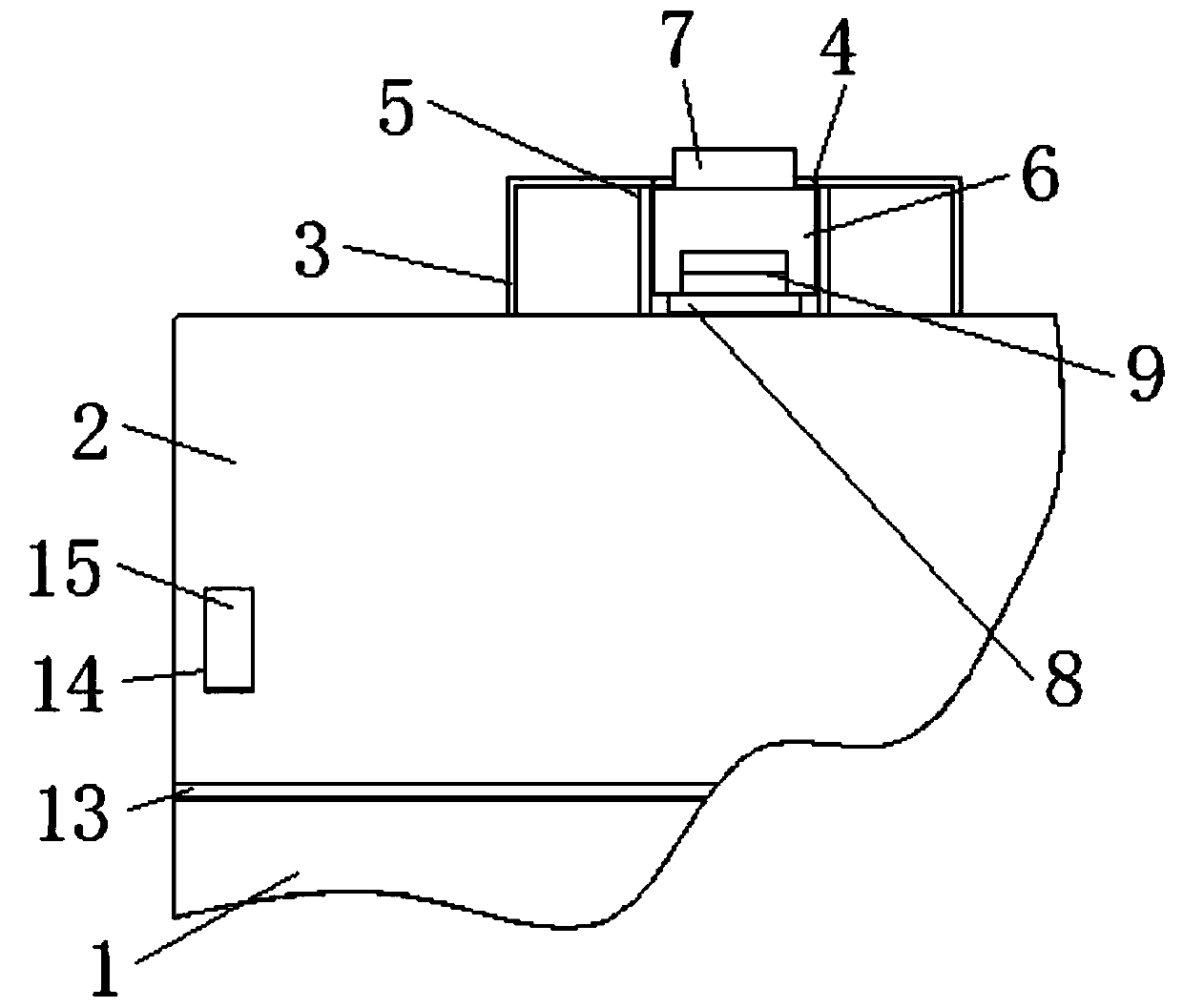

Indoor air treatment recycling treatment device

ActiveCN110715367AEasy to openImprove sealingMechanical apparatusLighting and heating apparatusAir treatmentStructural engineering

The invention discloses an indoor air treatment recycling treatment device. The indoor air treatment recycling treatment device comprises a treatment device body, wherein the back surface of the treatment device body is movably connected with a cover plate body through a pin shaft; the top of the treatment device body is fixedly connected with a transmission box; an opening is formed in the top ofthe transmission box; the left side and the right side of the top of the treatment device body are fixedly connected with connecting plates positioned inside the transmission box; the inner sides ofthe connecting plates are movably connected with clamping jaws through pin shafts; the tops of the clamping jaws are fixedly connected with pressing blocks positioned inside the opening; and the pressing blocks are in sliding connection with the opening. The indoor air treatment recycling treatment device solves the problems that a rear cover of an existing indoor air treatment device is mostly fixed through bolts, a user cannot conveniently and quickly open the rear cover and disassemble a filter screen, and the cleaning efficiency of the filter screen is reduced; and the indoor air treatmentrecycling treatment device has the advantages of being convenient to open the rear cover and the like.

Owner:杭州三夏环保科技有限公司

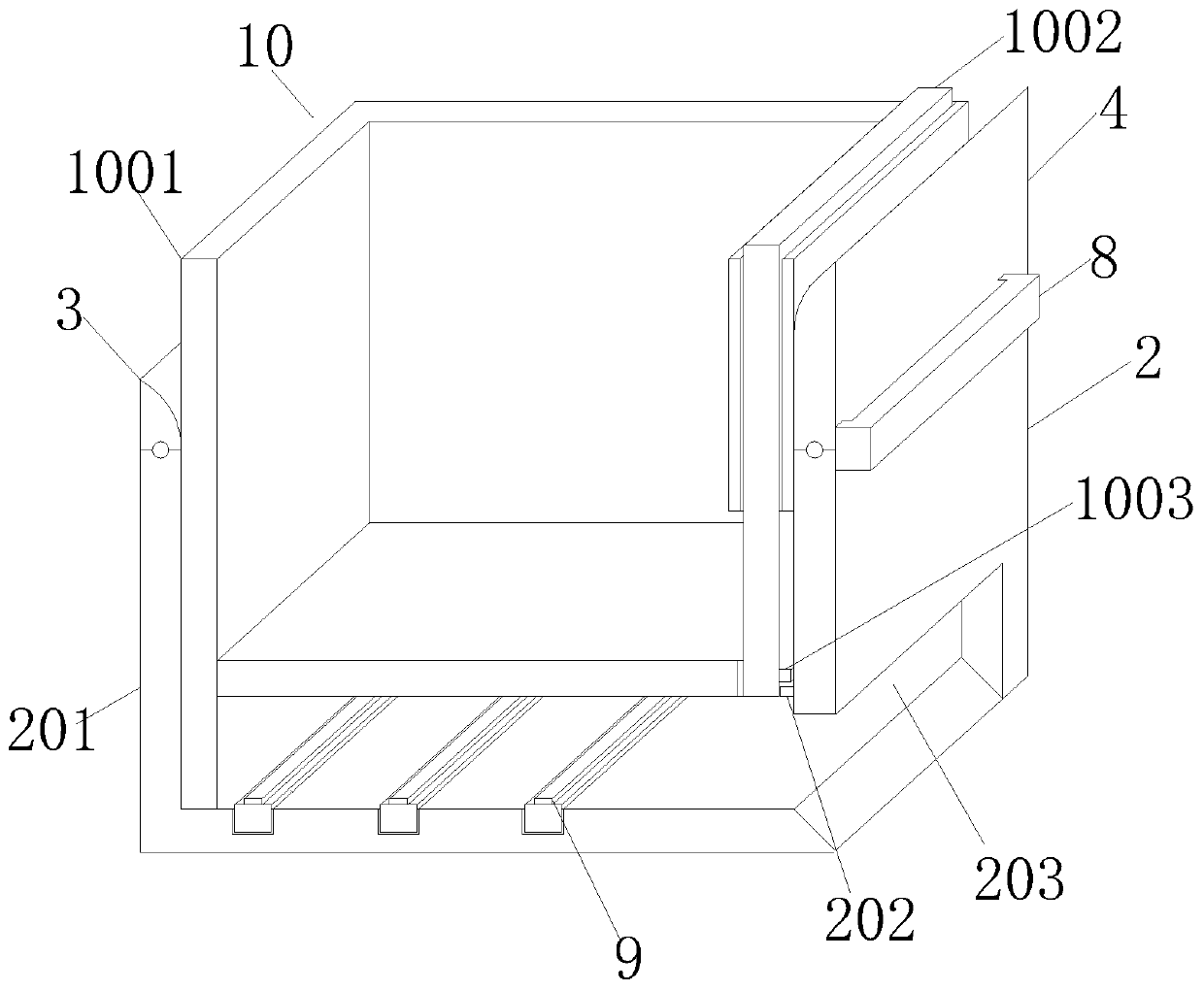

Auxiliary material feeding device for automobile front shaft forging part intermediate-frequency heating furnace

ActiveCN110595212ASmooth entryFree fallCharge manipulationProtection mechanismIntermediate frequency

The invention discloses an auxiliary material feeding device for an automobile front shaft forging part intermediate-frequency heating furnace. The auxiliary material feeding device comprises an auxiliary mechanism body and a plurality of fixed rods arranged on the auxiliary mechanism body, wherein the multiple fixed rods are connected with one same blocking device, and the auxiliary mechanism body is fixedly connected with a placing frame and a first protection plate and a second protection plate which are connected on the placing frame. According to the auxiliary material feeding device forthe automobile front shaft forging part intermediate-frequency heating furnace, by means of the matching arrangements of the placing frame and a containing frame, the containing frame can be made to enter the placing frame smoothly, meanwhile, the containing frame can be opened to make a whole cylinder be capable of being discharged out freely, in the process of the containing frame entering the placing frame, the containing frame can enter the placing frame under guiding of the first protection plate and the second protection plate, a protection mechanism can play a role of protecting the second protection plate, the second protection plate will not perform excessive rotation because of the lateral pressure applied by the containing frame, and in this way, the fact that the containing frame enters the placing frame smoothly is facilitated.

Owner:ANHUI HEFEI AUTO FORGING

A post-adjustable three-orifice compound anti-hammer air valve group

ActiveCN103672042BSmall sizeFilling speed reducedValve members for absorbing fluid energyMultiple way valvesSite monitoringAnti freezing

The invention discloses a rear adjustable three-hole composite type waterproof hammer air group valve. The air group valve is integrally or separately arranged on a liquid conveying pipeline or a container system, a high-speed exhaust hole of the air group valve can be adjusted and controlled, is arranged alone, and is generally smaller than suction holes, the high-speed exhaust hole and the high-speed suction holes are formed separately and are not shared for use, independent model selection and adjustment can be conducted, the requirements of high-speed exhaust and high-speed gas suction for two different quantities of flow or two different diameters or two proportions are met, and meanwhile two built-in type gas bags are formed quite ingeniously. The group valve combines independent intermediate-speed exhaust, independent high-speed gas suction and trace amount exhaust, and has a dozen of functions, namely, the independent intermediate-speed exhaust function, the independent high-speed gas suction function, the trace amount exhaust function, the function of a high-suction and intermediate-exhaust waterproof hammer, the function of a high-suction and trace-exhaust waterproof hammer, the function of a built-in gas bag waterproof hammer, the built-in gas bag anti-freezing function, the function of a rear adjusting control valve and the function of monitoring the hole pressure difference and the total pressure difference on site in the empty pipe liquid filling process through two pressure meters. The various ventilation and safety protection requirements of a liquid path system can be met.

Owner:ANHUI REDSTAR VALVE

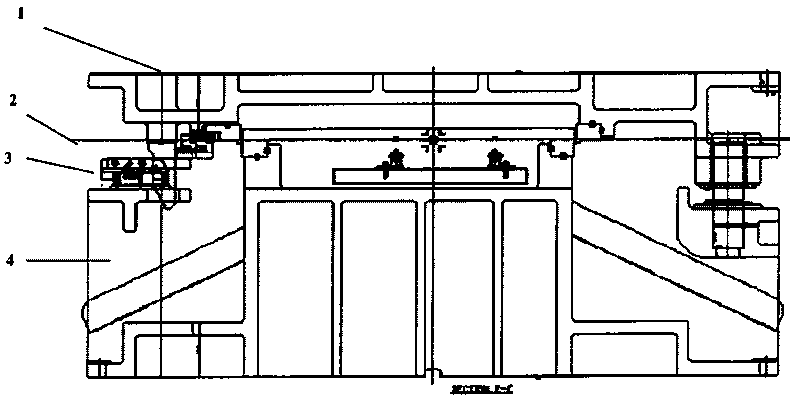

Load selection device and automatic melt index instrument

Owner:深圳万测试验设备有限公司

Workpiece sliding-down device

The invention belongs to the technical field of logistics equipment and relates to a workpiece sliding-down device which comprises a base. A supporting base is installed on the base. An installing face of the supporting base is arranged in an inclined manner. A track is fixed to the installing face of the supporting base. A first air cylinder base is arranged on the portion, corresponding to one side of the track, of the top face of the base, and a second air cylinder base is arranged on the portion, corresponding to the other side of the track, of the top face of the base. A first blocking air cylinder is installed on the first air cylinder base, and a second blocking air cylinder is installed on the second air cylinder base. A piston rod of the first blocking air cylinder and a piston rod of the second blocking air cylinder face one side of the track. The sliding-down device utilizes the self-weight of workpieces to achieve the transferring effect, and the workpiece collecting effect is good.

Owner:WUXI TEHENG TECH CO LTD

Anti-deformation slicing device for kiwi fruit processing

The invention discloses an anti-deformation slicing device for kiwi fruit processing, and relates to the technical field of kiwi fruit processing and slicing. In order to improve the slicing rate of kiwi fruits, the anti-deformation slicing device comprises a base and a slicing mechanism, a protective shell is arranged on the outer wall of the top of the base, a guide frame is arranged on the circumferential inner wall of the protective shell, a cylinder is movably connected to the inner wall of the guide frame, a placement piece is arranged on the circumferential outer wall of the cylinder, and guide-out columns are welded to the inner walls of the two sides of the placement piece; a circular gear is connected to the outer wall of the cylinder circumference through a spline, a convex rod is movably connected to the outer wall of one side of the guide frame, and the same second spring is clamped to the inner wall of one side of the convex rod and the outer wall of one side of the guide frame. According to the kiwi fruit slicing device, kiwi fruits can be placed through the arrangement of the placement piece; after the kiwi fruits are sliced, the kiwi fruits can slide down in time along the guide-out columns through the arrangement of the guide-out columns, and therefore it can be guaranteed that the surface of the placement piece is clean and tidy.

Owner:六安鑫隆果业股份有限公司

Dust collection device for indoor decoration punching

PendingCN113997439AGood punch qualityAvoid wall damageWorking accessoriesStone-like material working toolsDrill holeEnvironmental geology

The invention discloses a dust collection device for indoor decoration punching, which belongs to the technical field of decoration environmental protection and comprises a fixed sleeve, a movable sleeve, fan blades, a sealing suction ring, an annular baffle, a dust collection box, wherein the fixed sleeve and the movable sleeve are coaxially arranged and slidably connected with a drilling head, and the fan blades are mounted on a rotating shaft and are arranged in the fixed sleeve; the sealing suction ring is coaxially mounted at one end, far away from the fixed sleeve, of the movable sleeve, the annular baffle is coaxially installed at the end, away from the sealing suction ring, of the inner circumferential face of the movable sleeve, an annular gap is formed between the inner circumferential face of the annular baffle and the outer circumferential face of the rotating shaft, and the dust collection box is arranged at the bottom of the movable sleeve and the bottom of the fixed sleeve and is in sliding connection with the movable sleeve and fixedly connected with the fixed sleeve. The fixed sleeve is fixedly installed on the shell, and a plurality of filtering through openings are formed in the middle of the annular baffle. The device is small in size, convenient to hold for working, simple in structure and convenient to operate; the device can be tightly adsorbed on a wall body, so that the drilling head is vertical to the wall body and does not deviate; dust in the atmospheric environment is reduced, and the environment quality is improved.

Owner:丰县鲁班工程机械有限公司

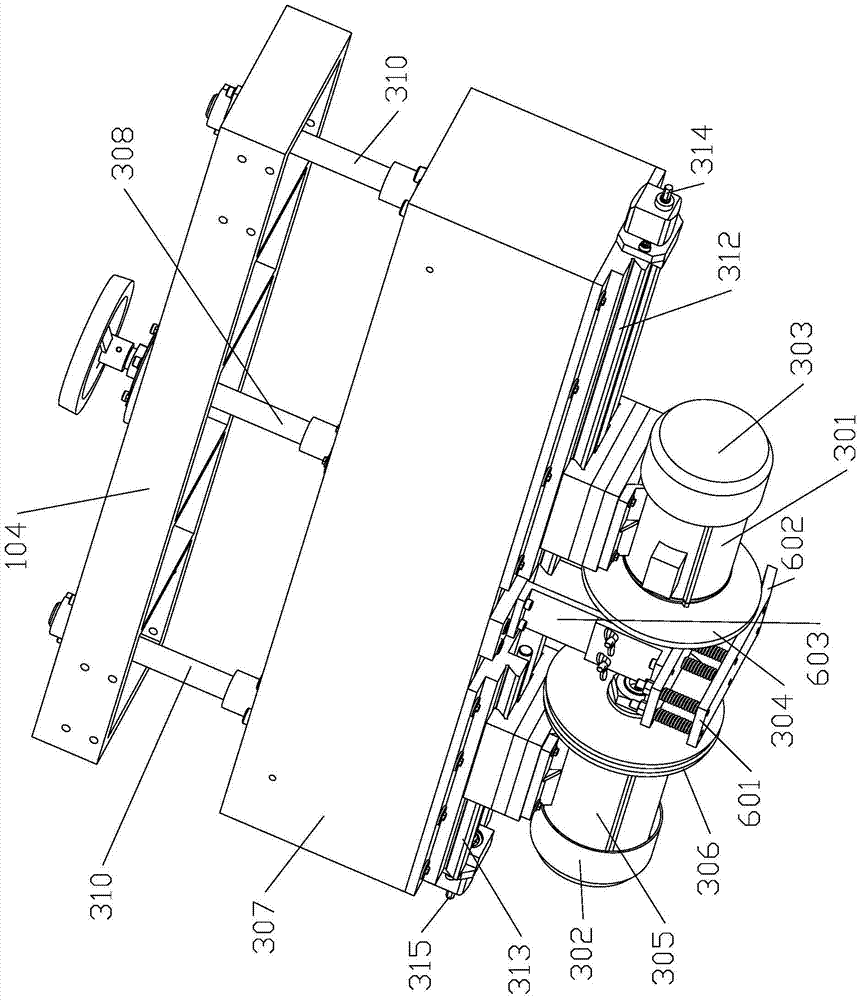

Clamping width-adjustable mandrel grinder

InactiveCN104759966AFree fallSlipping won't stopGrinding machinesGrinding feedersEngineeringGrinding wheel

The invention provides a clamping width-adjustable mandrel grinder, which is capable of automatically grinding a groove in a mandrel and has higher grinding precision and processing efficiency. The clamping width-adjustable mandrel grinder comprises a machine body, a feeding box, a feeding mechanism, an upper grinding mechanism and a lower grinding mechanism, wherein a discharge outlet for the mandrel to get in or out is formed between the feeding box and the workbench; the mandrel is pushed to the upper part of an upper grinding wheel and the upper part of a lower grinding wheel through a push plate of the feeding mechanism; a transition plate connected on the push plate penetrates a clamping plate groove in the workbench; a clamping width adjusting plate is connected to the transition plate; a turnplate is connected to the clamping width adjusting plate in a turning manner; a clamping plate is fixedly arranged on the turnplate; a limiting block is arranged on the transition plate; when the turnplate turns upward to come into contact with the limiting block, the clamping plate is protruded on the upper surface of the workbench; the push surface of the push plate is parallel with the clamping surface of the clamping plate and a distance between the push surface and the clamping surface is equal to the width of the mandrel; when the turnplate turns downward, the clamping plate is lower than the upper surface of the workbench; a turnover state keeping device enables the turnplate to turn upward to come into contact with the limiting block.

Owner:NANJING LIN HENG MACHINERY MFG

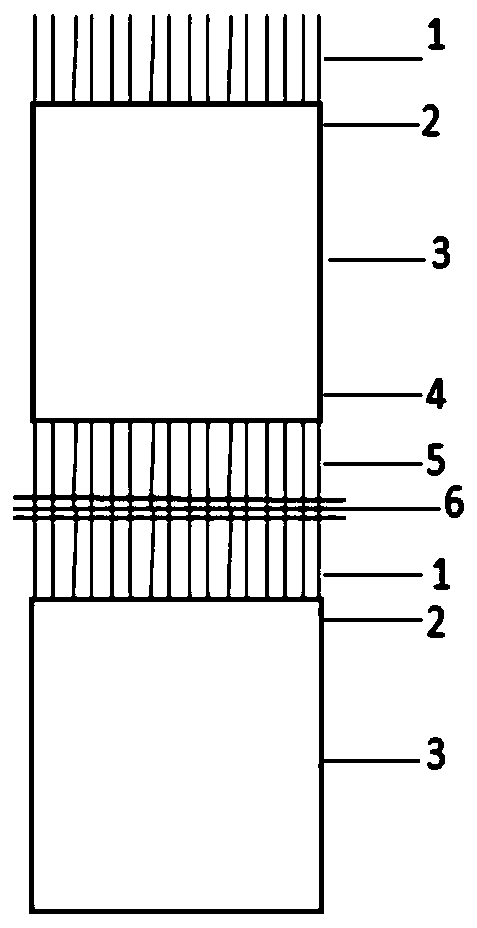

Weaving method of woven tassel fabric

ActiveCN111575874AImprove weaving efficiencyReduce the beating strengthOrnamental textile articlesSwivel-woven fabricsWoven fabricYarn

The invention belongs to the technical field of textile weaving, and particularly relates to a weaving method of a woven tassel fabric. The weaving method is used for weaving the tassel woven fabric which is positioned on the two sides of a plain-color or yarn-dyed fabric and used for decoration. The weaving method comprises a tassel weaving method, a tassel and fabric body front section junctionweaving method, a tassel and fabric body rear section junction weaving method and a tassel center line weaving method. According to the tassel woven fabric woven through the weaving method, a fabric body is effectively prevented from sliding towards tassels, the quality and efficiency of the cutting procedure are greatly improved, the tassels are exquisite in appearance, firm and durable, and theweaving method is suitable for weaving the woven tassel fabric for decoration.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

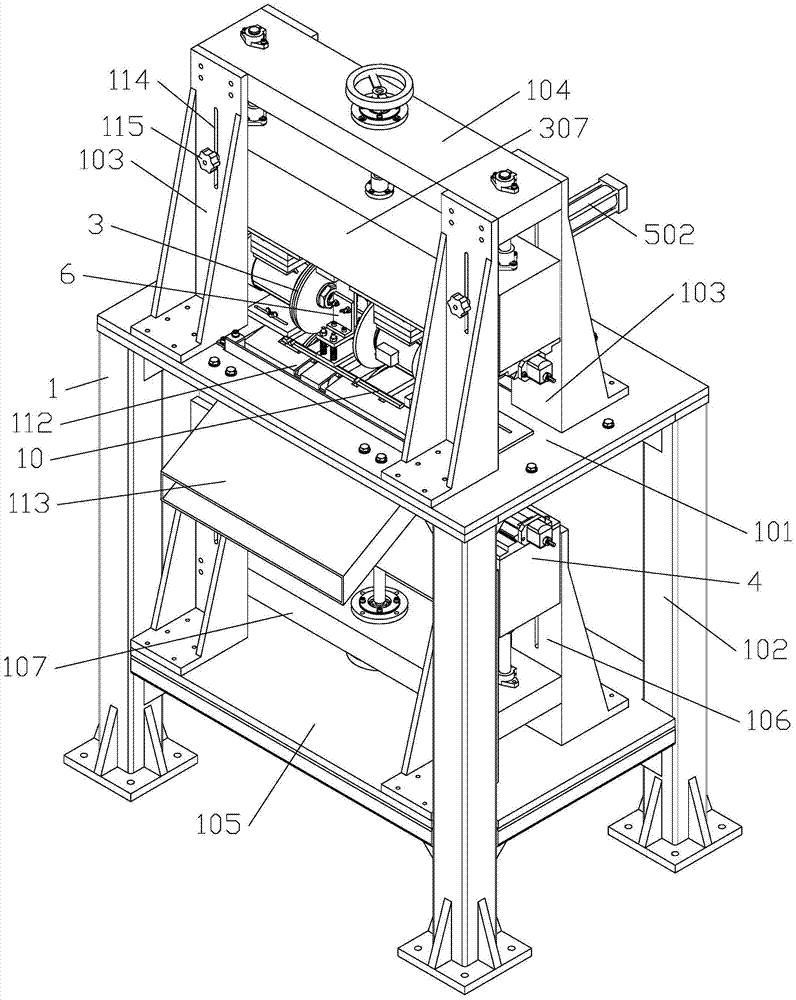

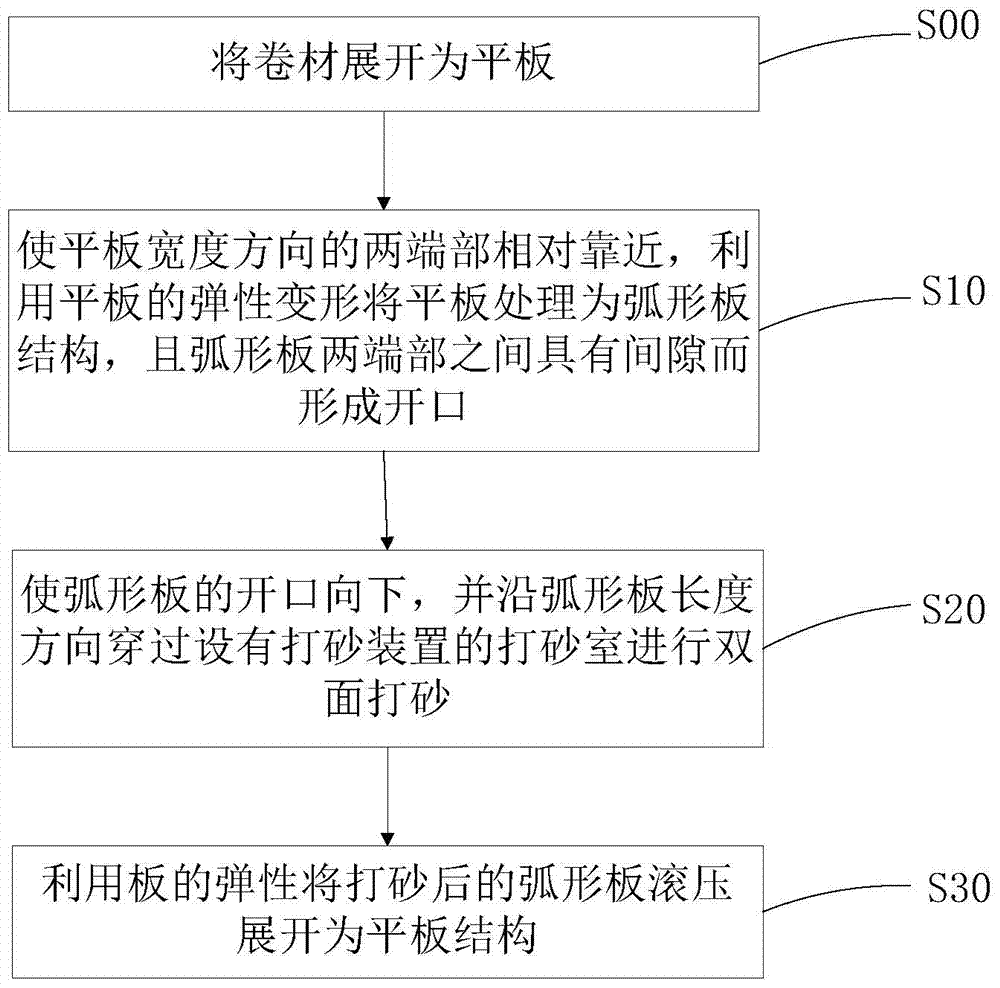

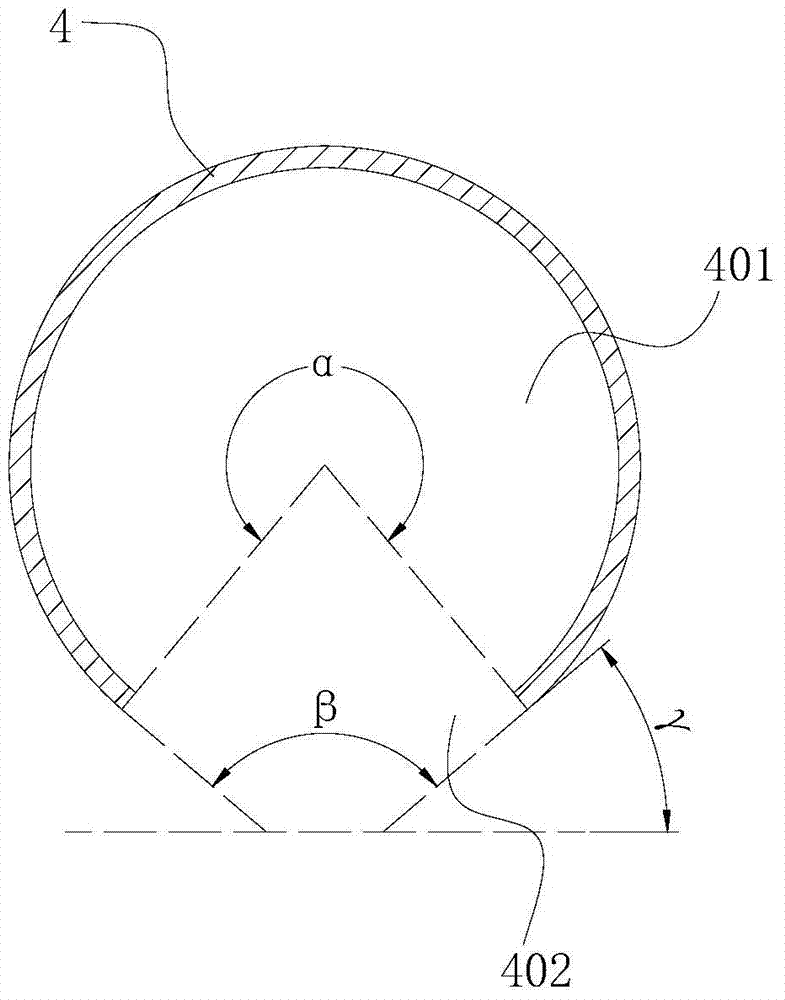

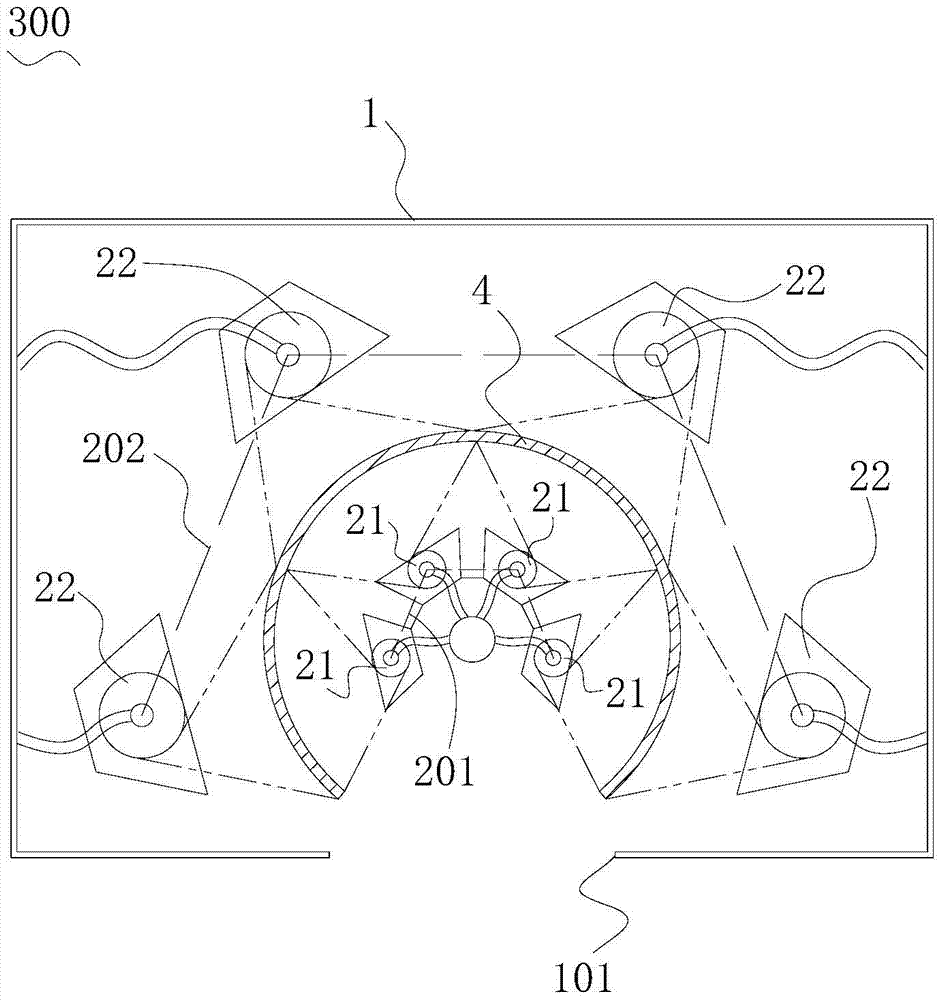

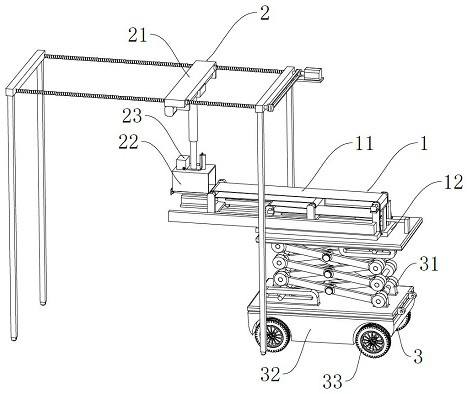

Flat sanding method, arc sanding machine and flat sanding line

ActiveCN104875124BReduce widthFree fallAbrasive machine appurtenancesAbrasive blasting machinesProduction lineEngineering

The invention provides a flat plate sanding method, an arc plate sanding machine and a flat plate sanding production line. The sanding method includes steps of: S10, enabling two end parts of a flat plate in the width direction to get close to each other, and treating the flat plate into an arc plate structure, and a gap between the two end parts of the arc plate forming an opening; and S20, enabling the opening of the arc plate to face downward, and enabling the arc plate to pass through a sanding chamber provided with a sanding device in the length direction of the arc plate for double-face sanding. The sanding treatment of the flat plate with greater width can be realized in the sanding machine of the invention approximately as wide as a conventional common sanding machine, and after sanding, all the sand on both surfaces of the plate can free slide down, and the sanding effect is ensured.

Owner:GUANGDONG XINHUI CIMC SPECIAL TRANSPORT EQUIPS

An indoor air treatment recycling treatment device

ActiveCN110715367BEasy to openImprove sealingMechanical apparatusLighting and heating apparatusAir treatmentMechanical engineering

Owner:杭州三夏环保科技有限公司

Burning button machine

ActiveCN105495870BBurning edge effect is goodIncrease productivityClothes buttonsFlame treatmentMechanical engineering

The invention discloses a button flaming machine which comprises a machine table, a button feeding device and a flame jetting device. The button feeding device comprises a vibrating part and a rotating part; the vibrating part is provided with a vibrating plate and a vibrating drive element, the vibrating plate is arranged on the machine table, used for carrying a button and provided with a discharge port, and the vibrating drive element is connected to the vibrating plate and used for driving the vibrating plate to vibrate to drive the button to vibrate to be discharged from the discharge port; the rotating part is provided with a rotating plate and a rotating drive element; the rotating plate is arranged on the machine table and located under the discharge port to be used for receiving the button discharged from the discharge port, and the rotating drive element is connected to the rotating plate to be used for driving the rotating plate to rotate. The flame jetting device is arranged on the machine table, and a flame jetting port of the flame jetting device faces the rotating plate to be used for performing flame treatment on the button located on the rotating plate. The button flaming machine is high in production efficiency and low in cost.

Owner:广东康派环创科技有限公司

Auxiliary feeding device for intermediate frequency heating furnace of automobile front axle forging

The invention discloses an auxiliary material feeding device for an automobile front shaft forging part intermediate-frequency heating furnace. The auxiliary material feeding device comprises an auxiliary mechanism body and a plurality of fixed rods arranged on the auxiliary mechanism body, wherein the multiple fixed rods are connected with one same blocking device, and the auxiliary mechanism body is fixedly connected with a placing frame and a first protection plate and a second protection plate which are connected on the placing frame. According to the auxiliary material feeding device forthe automobile front shaft forging part intermediate-frequency heating furnace, by means of the matching arrangements of the placing frame and a containing frame, the containing frame can be made to enter the placing frame smoothly, meanwhile, the containing frame can be opened to make a whole cylinder be capable of being discharged out freely, in the process of the containing frame entering the placing frame, the containing frame can enter the placing frame under guiding of the first protection plate and the second protection plate, a protection mechanism can play a role of protecting the second protection plate, the second protection plate will not perform excessive rotation because of the lateral pressure applied by the containing frame, and in this way, the fact that the containing frame enters the placing frame smoothly is facilitated.

Owner:ANHUI HEFEI AUTO FORGING

A roller rubber baffle device for an open mill

Owner:HANGZHOU CHAOYANG RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com