Flat sanding method, arc sanding machine and flat sanding line

A curved plate and assembly line technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., to achieve the effect of ensuring the sanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

[0033] The flat plate sanding method, curved plate sanding machine and flat plate sanding assembly line of the present invention are applicable to steel plates or other similar plates that need to be sanded, and are introduced one by one as follows.

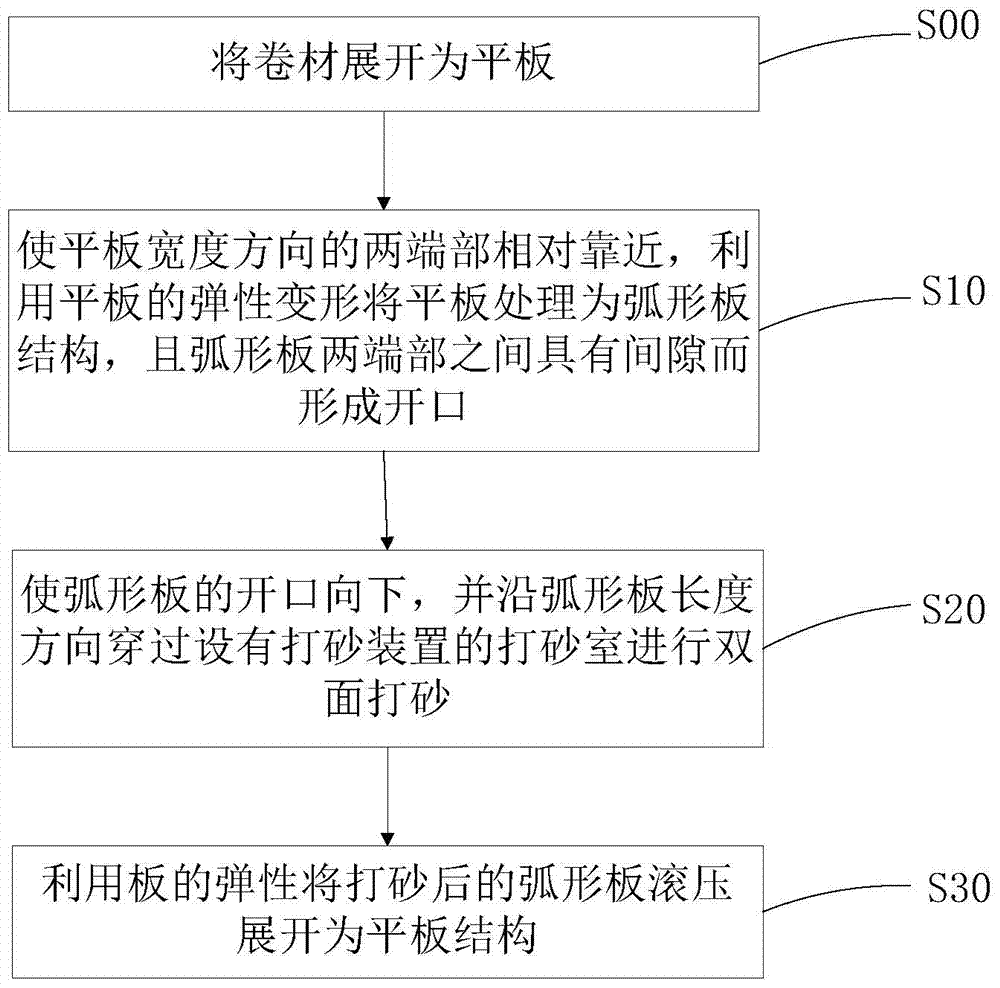

[0034] Embodiment of flat sand blasting method

[0035] refer to figure 1 , the present invention at first provides a kind of flat sanding method, comprises steps:

[0036] S00: Unfold the coiled material into a flat plate; this step is applicable to the case where the raw material is a coiled material, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com