Testing device for measuring lateral soil resistance of pipeline

A technology for measuring pipelines and test devices, used in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of complex operation, large axial friction of bearing housing, and non-repeatability of force measuring system. The effect of saving test materials and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

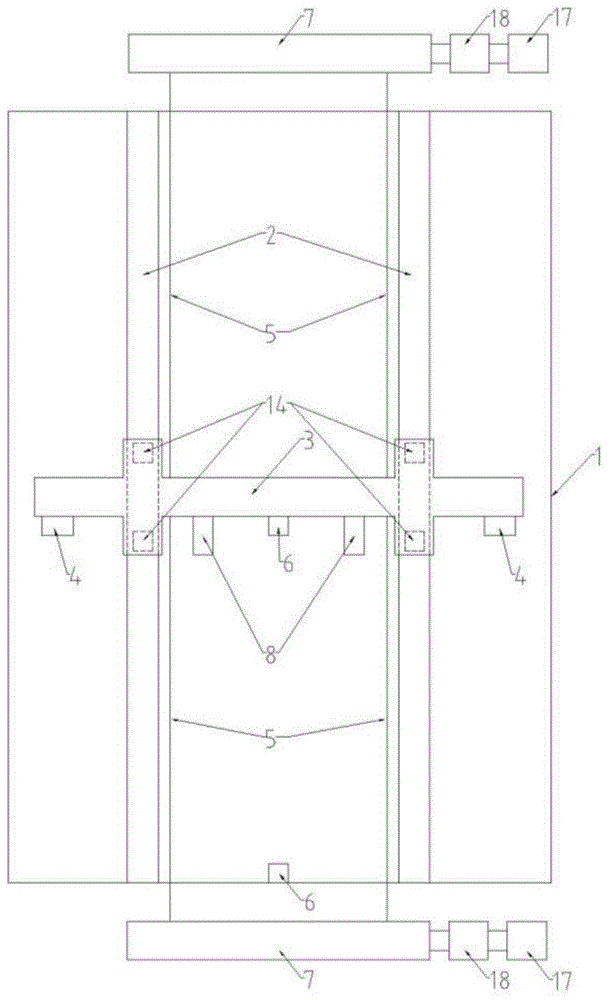

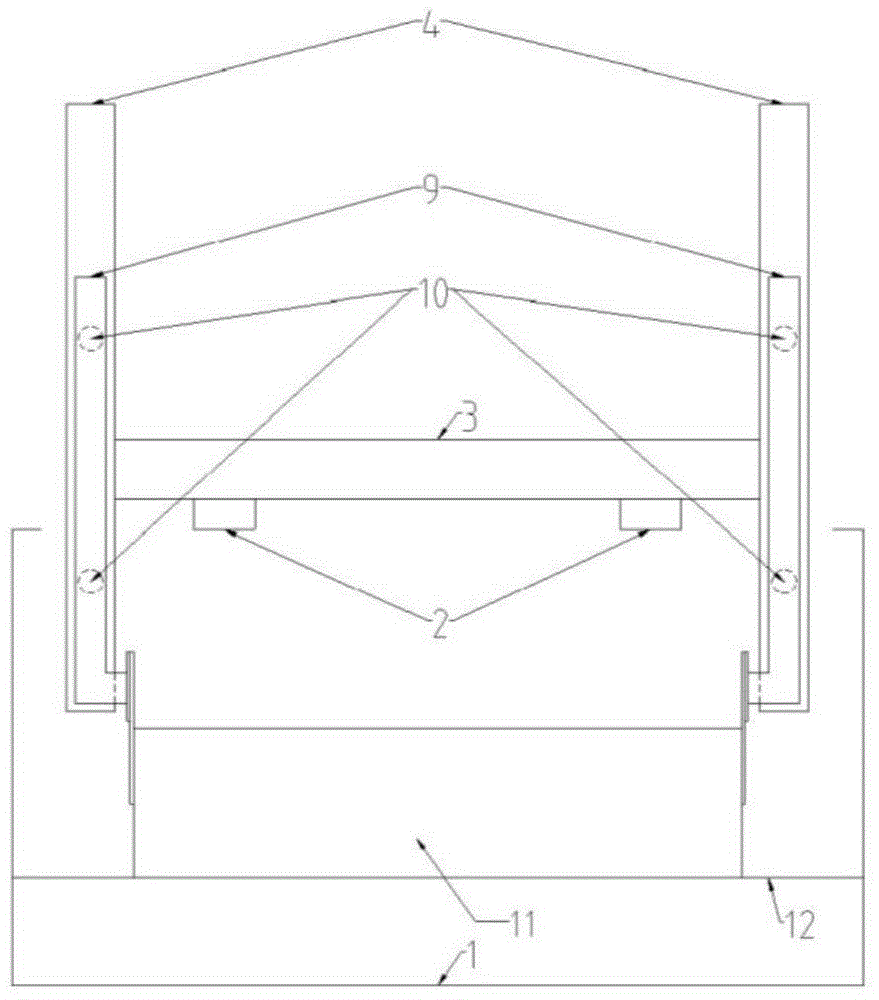

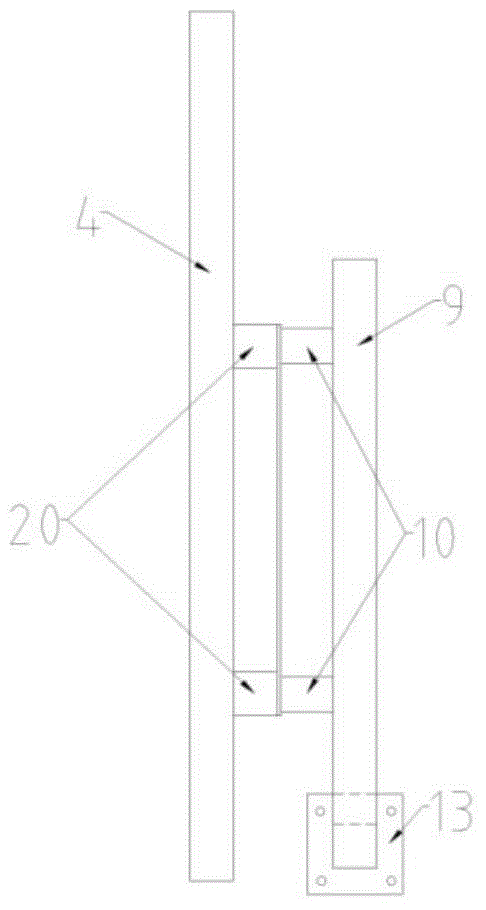

[0030] 1. The pipeline-soil interaction test device of the present invention mainly includes: soil tank 1, horizontal trolley 3, vertical trolley, force measuring system, displacement measuring system, pipeline weight adjustment system, test pipeline 11 and vertical bar 9 connection system , several parts of the power system.

[0031] 2. The soil tank 1 is a cuboid hollow structure with its surroundings closed and its top open. Planks of a certain thickness are laid on the side walls around the soil tank, and the top of the soil tank 1 is open. Two parallel horizontal linear guide rails 2 are arranged along the length direction of the soil tank 1 , and two sliders 14 are arranged on each horizontal linear guide rail 2 . The soil tank 1 is preset with a certain depth of horizontal soil for simulating a flat seabed, or preset with a certain depth of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com