Patents

Literature

35results about How to "Save test material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

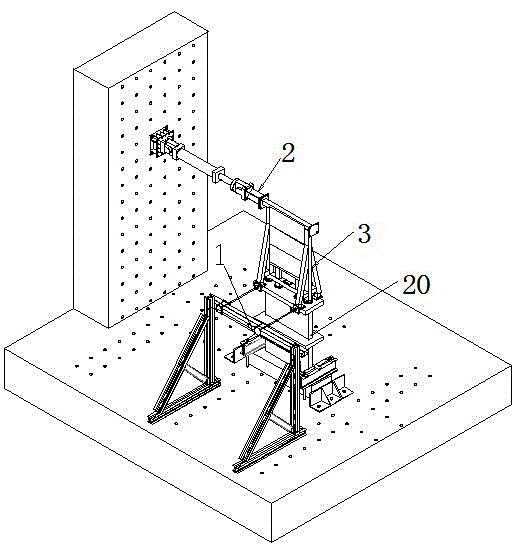

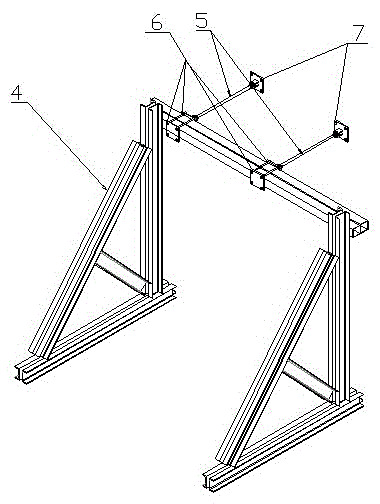

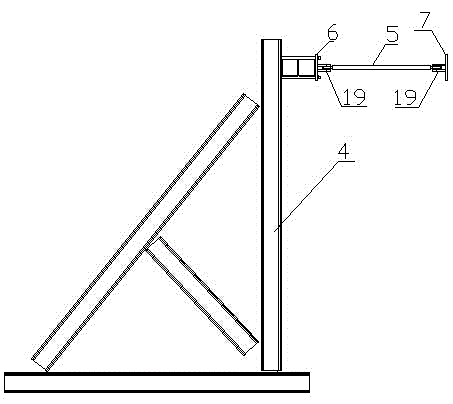

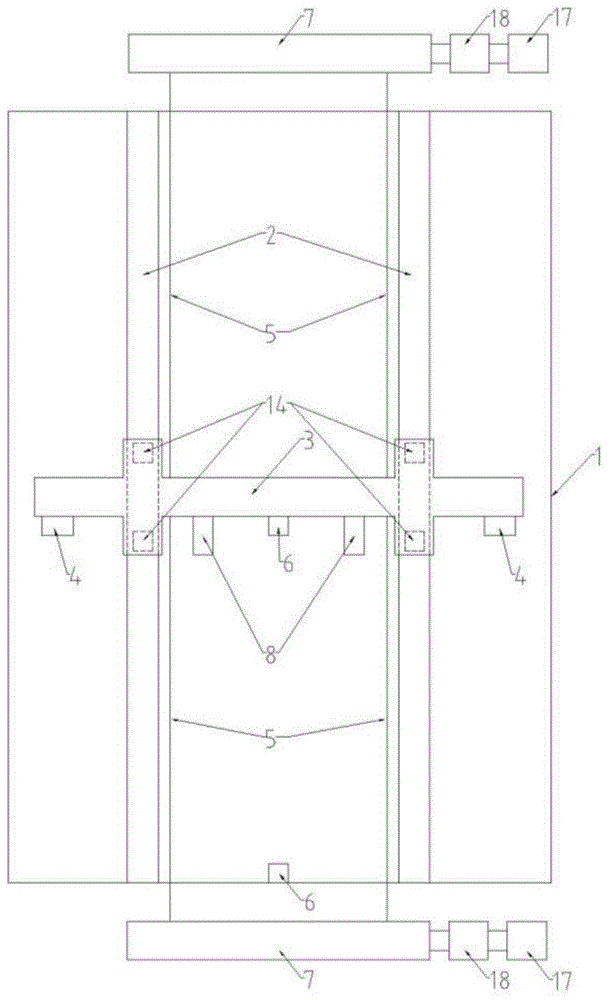

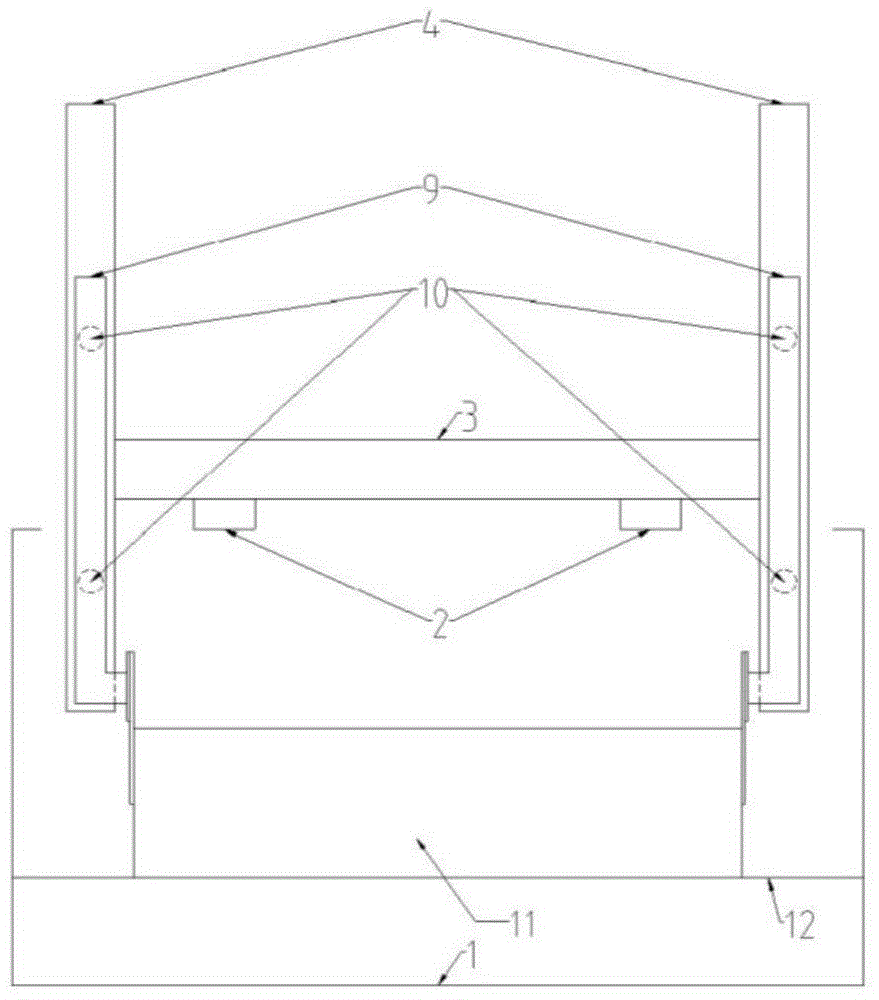

Detachable and reusable shear wall earthquake-proof performance test loading rack and test method

InactiveCN105067211AReduce design heightLight in massVibration testingAxial pressureAxial compression

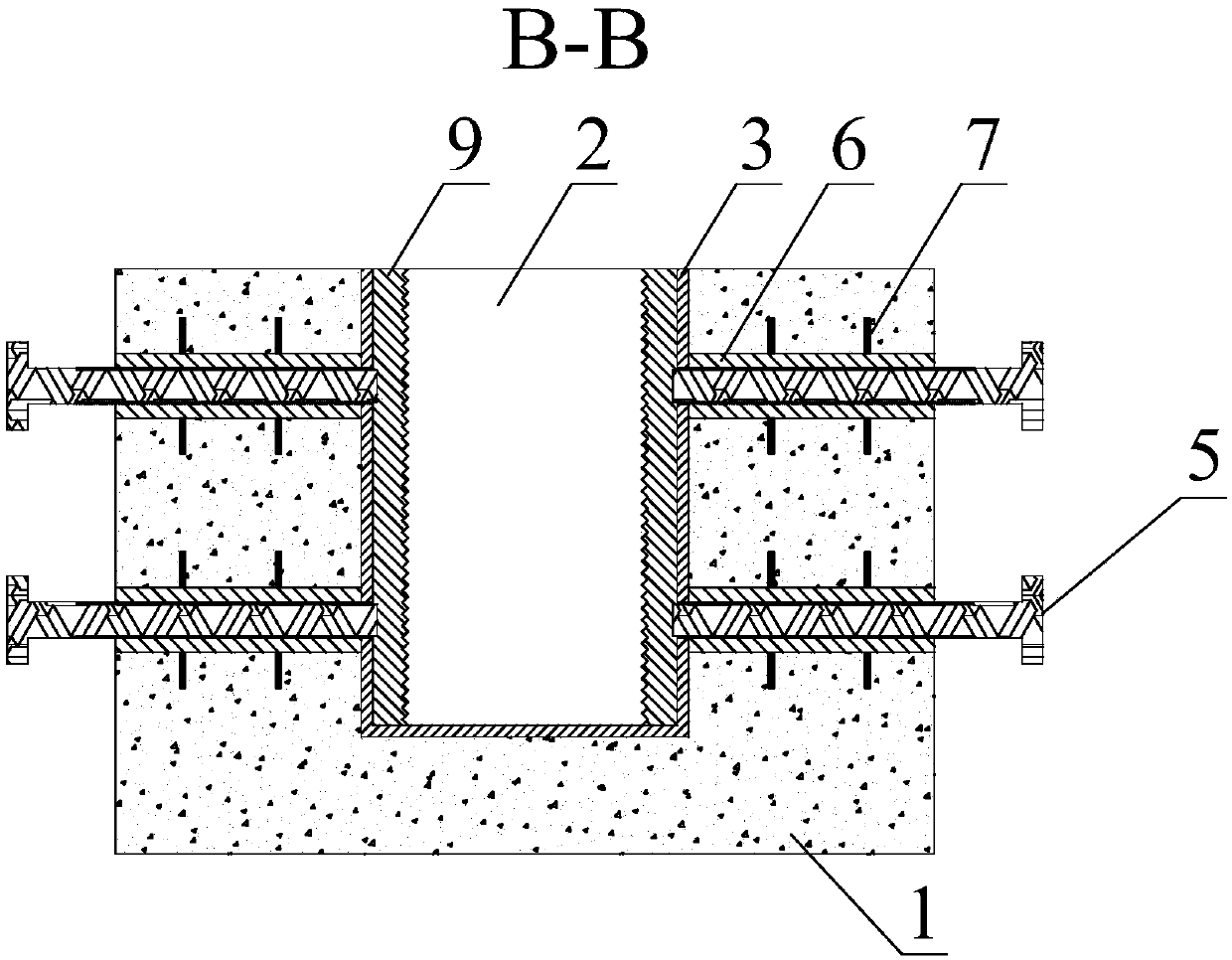

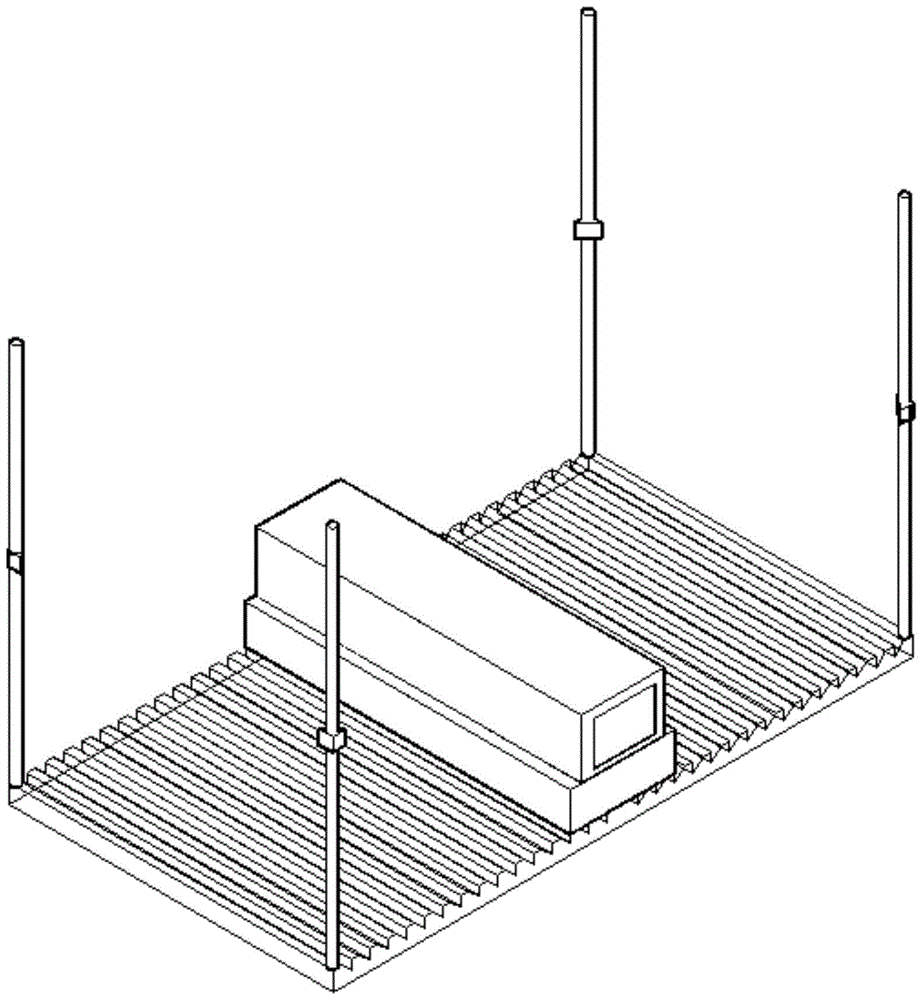

The invention relates to a detachable and reusable shear wall earthquake-proof performance test loading rack and a test method. The test loading rack comprises a wall steel frame apparatus, a loading connecting apparatus, and an anti-sidesway module, wherein the wall steel frame apparatus comprises a loading beam, a steel frame wall, and steel frame wall fulcrum bars; two sides of the steel frame wall are provided with inclined strut type wall fulcrum bars; the wall fulcrum bars are in fixed connection with the bottom of the steel frame wall and a shear wall test piece floor; a jack is arranged on the square steel tube frame of a hollow part on the steel frame wall; the loading beam is fixed on the upper part of the steel frame wall, and is in connection with the loading connecting apparatus through loading terminals at ends of the loading beam; the anti-sidesway module comprises fixed steel frames and anti-sidesway pull rods; two ends of the anti-sidesway pull rods are respectively hinged to the fixed steel frames and the steel frame wall fulcrum bars in the wall steel frame apparatus. The loading rack can increase the shear span ratio of a shear wall test piece, meet the requirement that the shear span ratio is greater than 3 in an earthquake-proof performance test, apply axial pressure to the shear wall test piece, and meet requirements for different axial compression ratios required by a shear wall test.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

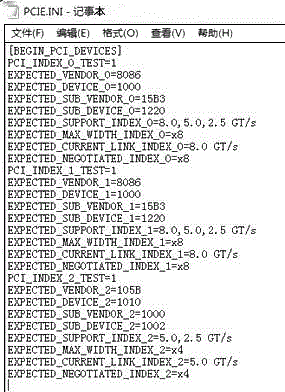

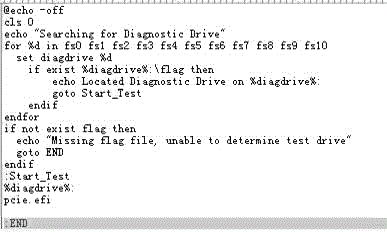

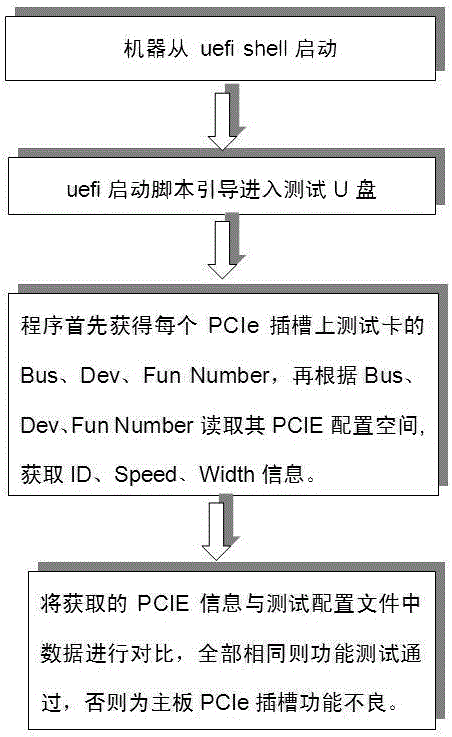

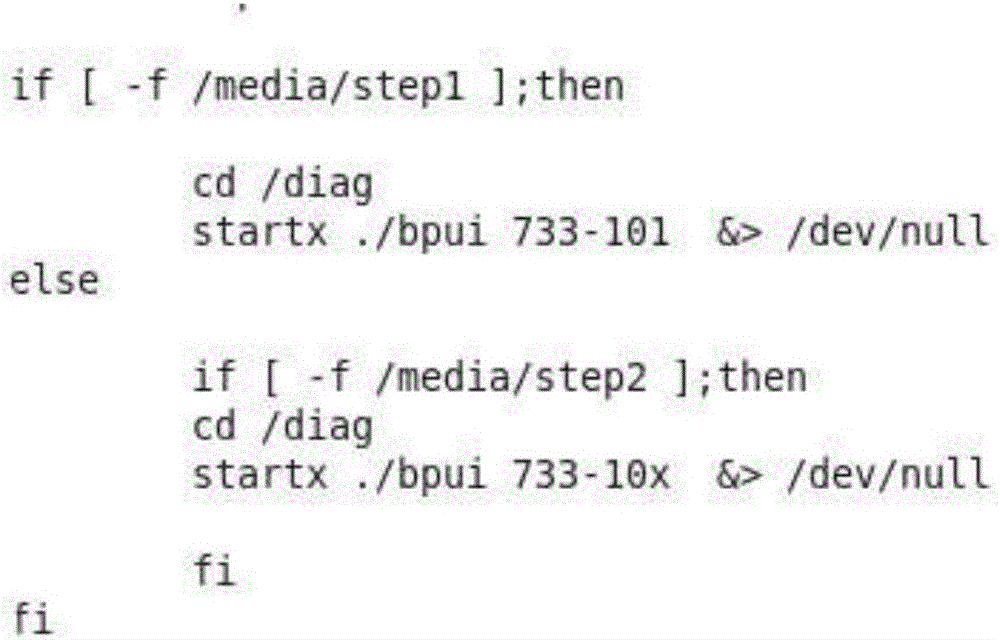

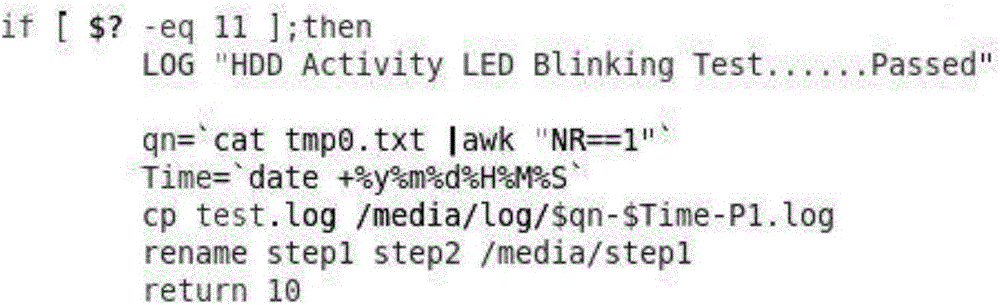

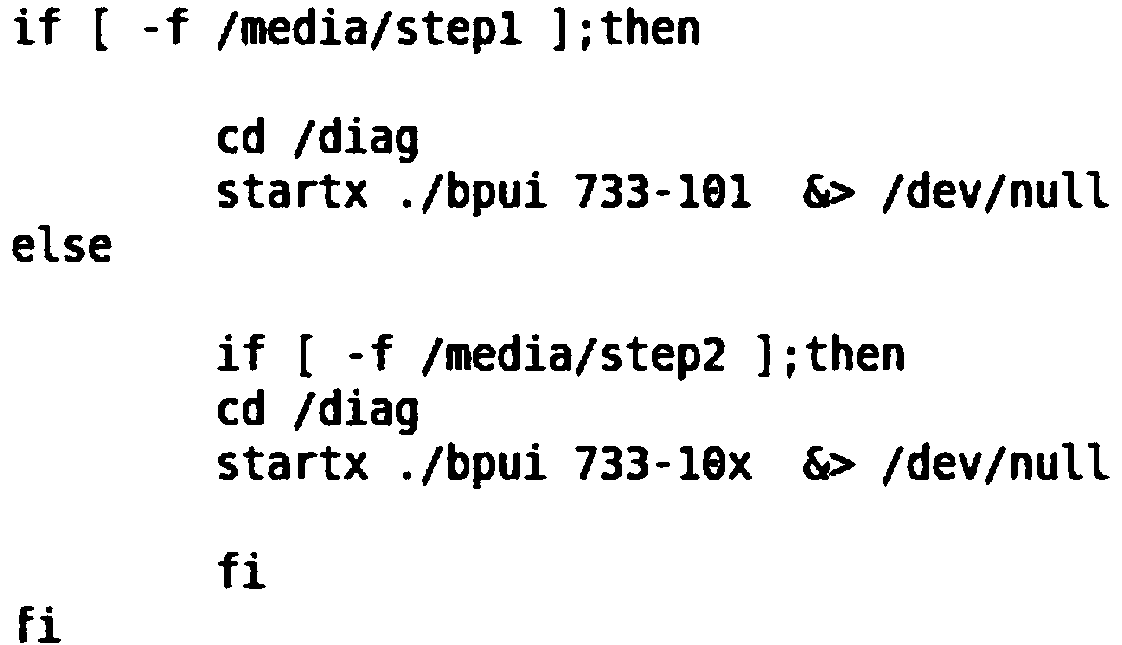

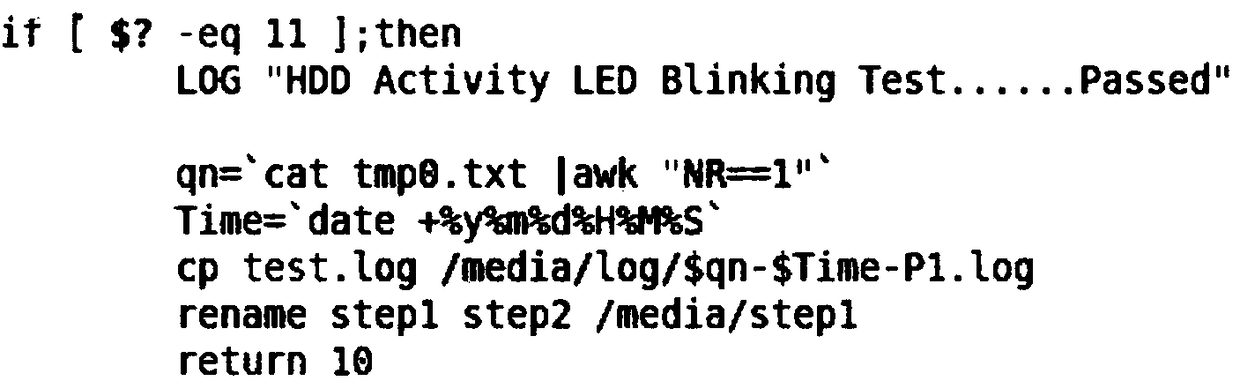

Computer mainboard PCIe slot function test method based on UEFI

InactiveCN105718346AShorten test timeImprove test efficiencyDetecting faulty hardware by power-on testTest efficiencyFunctional testing

The invention provides a computer mainboard PCIe slot function test method based on a UEFI, and relates to the field of large-scale factory tests on computer mainboard PCIe slots. The computer mainboard PCIe slot function test method comprises the following steps: on the basis of a build-in uefi shell, firstly, confirming that a first start item of a machine is boot from build-in shell; according to a mainboard specification, inserting matched PCIe cards into corresponding PCIe slots in a mainboard; writing a test PCIe configuration file, and listing information of each slot; powering on the machine from uefi shell to enter a test U-disc automatically and operate a test program, thereby acquiring information of all PCIe cards in the PCIe slots; comparing grasped data with data in PCIe configuration files PCIE.INI, wherein the test is qualified if the files are completely identical, or else the test is unqualified. By adopting the computer mainboard PCIe slot function test method, no operating system needs to be started for test, so that the test time can be shortened, and the test efficiency can be improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

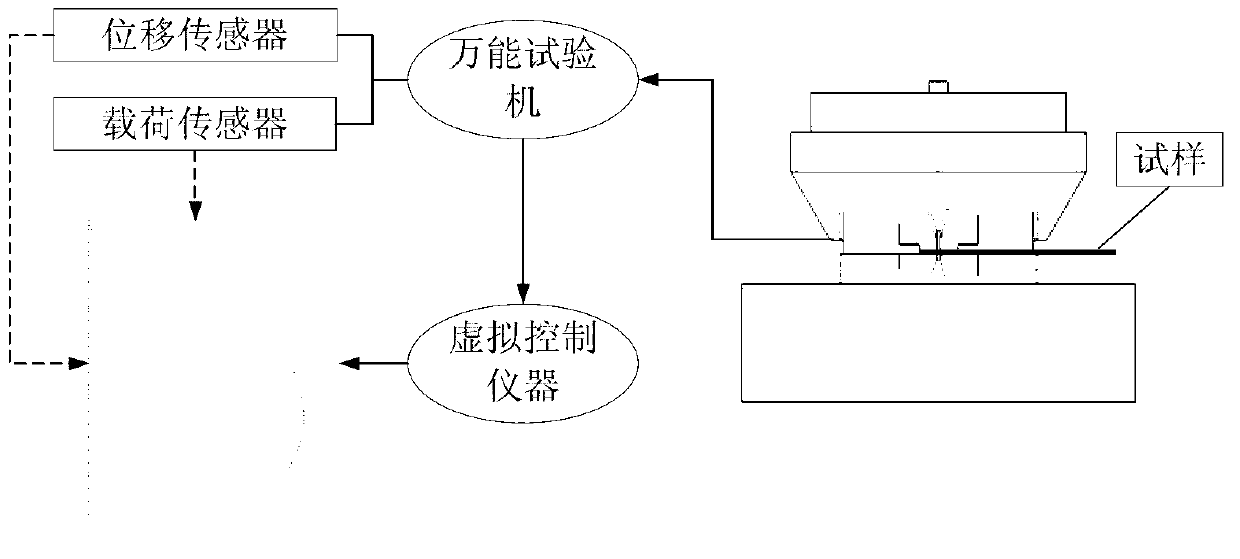

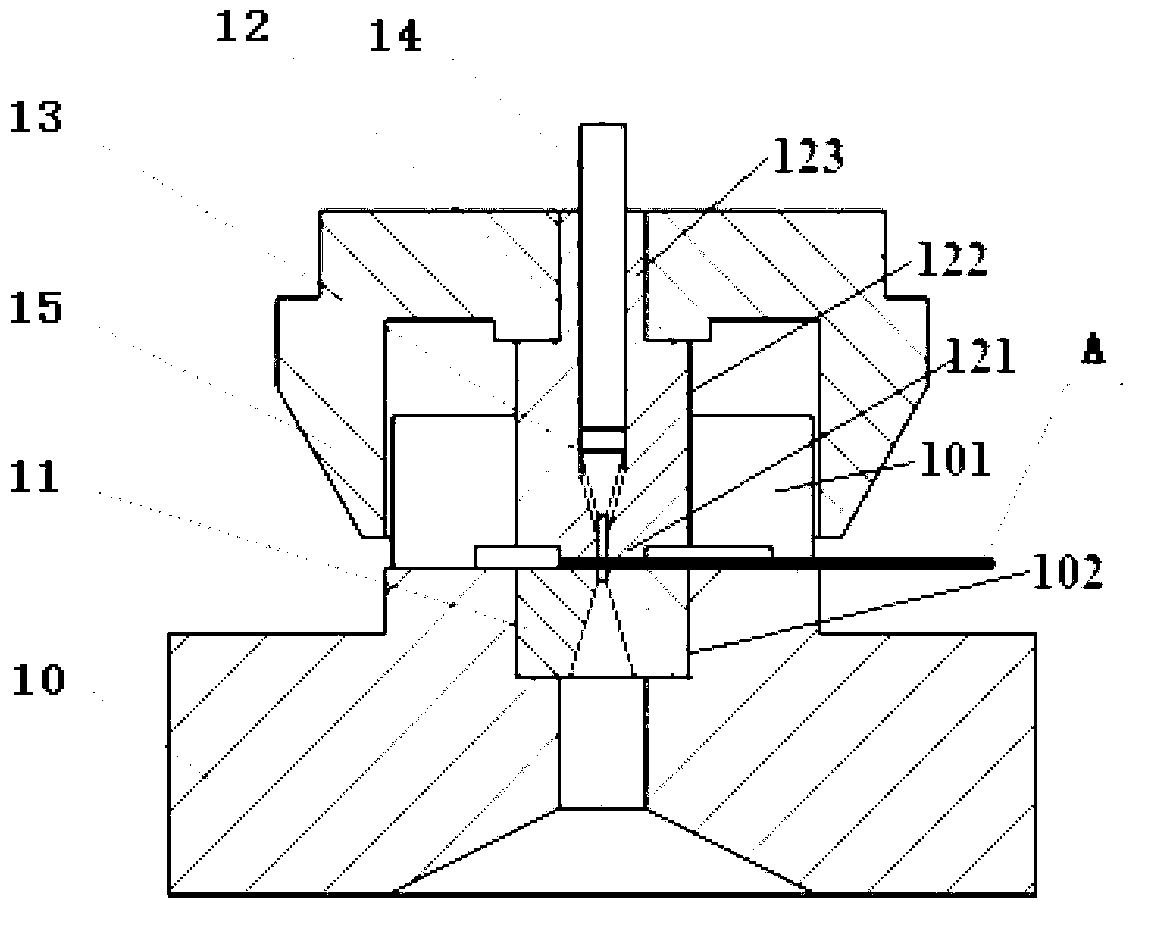

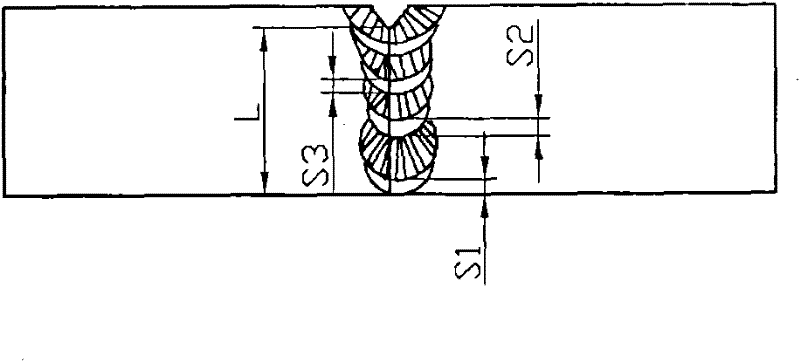

Micro pressure shear experimental device and testing method of mechanical property of fusion welding microcell

InactiveCN102759485AAchieve pure shear actionSmall blanking gapMaterial strength using steady shearing forcesShear stressStress–strain curve

The invention provides a micro pressure shear experimental device and a testing method of mechanical property of a fusion welding microcell. The experimental device comprises a base, a lower die, a guide pressure head, a pressure head and a pressure rod, wherein the center of the base is provided with a concave table; the upper part of the base is provided with two guide posts, a groove is formed between the two guide posts, and the groove is communicated with a concave table; the lower die is installed in the concave table, and the top surface of the lower die is in flush with the bottom of the groove; a cylindrical hole is arranged between the two guide posts, and the guide pressure head is installed in the cylindrical hole; the center of the guide pressure head is provided with a guide hole; and the pressure head and the pressure rod are installed in the guide hole. The micro pressure shear experimental device provided by the invention is reasonable in design, can guarantee the loading precision and accuracy, is reliable in data collection, and is accurate in obtained load-displacement curve of each cell; and through testing, shear strength and an engineering shear stress-strain curve of a welding joint parent metal joint are obtained, and can be expanded to each cell of the joint, thus a microcell heterogenous mechanical property of the joint can be obtained.

Owner:XI AN JIAOTONG UNIV

Method for measuring deformation condition of bulk material interfacial effect of material distribution model of blast furnace

InactiveCN102808052AEasy to operateAccurate measurementBell-and-hopper arrangementBlast furnace detailsMaterial distributionTest material

The invention relates to a method for measuring a deformation condition of a bulk material interfacial effect of a material distribution model of a blast furnace and belongs to the technical field of model test measurement of metallurgical industry. According to the technical scheme, the method comprises the following steps of: before material distribution, spraying two kinds of dyeing tracer agents with different colors onto the surfaces of sintering ores and cokes respectively to dye different colors on the surfaces of the sintering ores and cokes so as to facilitate the subsequent observation, cutting furnace charges by using a special cutter, separating and weighing to finish the material distribution interfacial effect deformation test of the material distribution model of the blast furnace. The method has the advantages that the method is convenient and intuitive, and wide in application field and easy to operate; the deformation condition can be measured accurately; test materials and furnace charges are saved, the test working amount is reduced, the distribution rule of the section shapes of the bulk materials can be resolved specifically; and the method is a very practical method for researching the material distribution rule in the model a laboratory.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

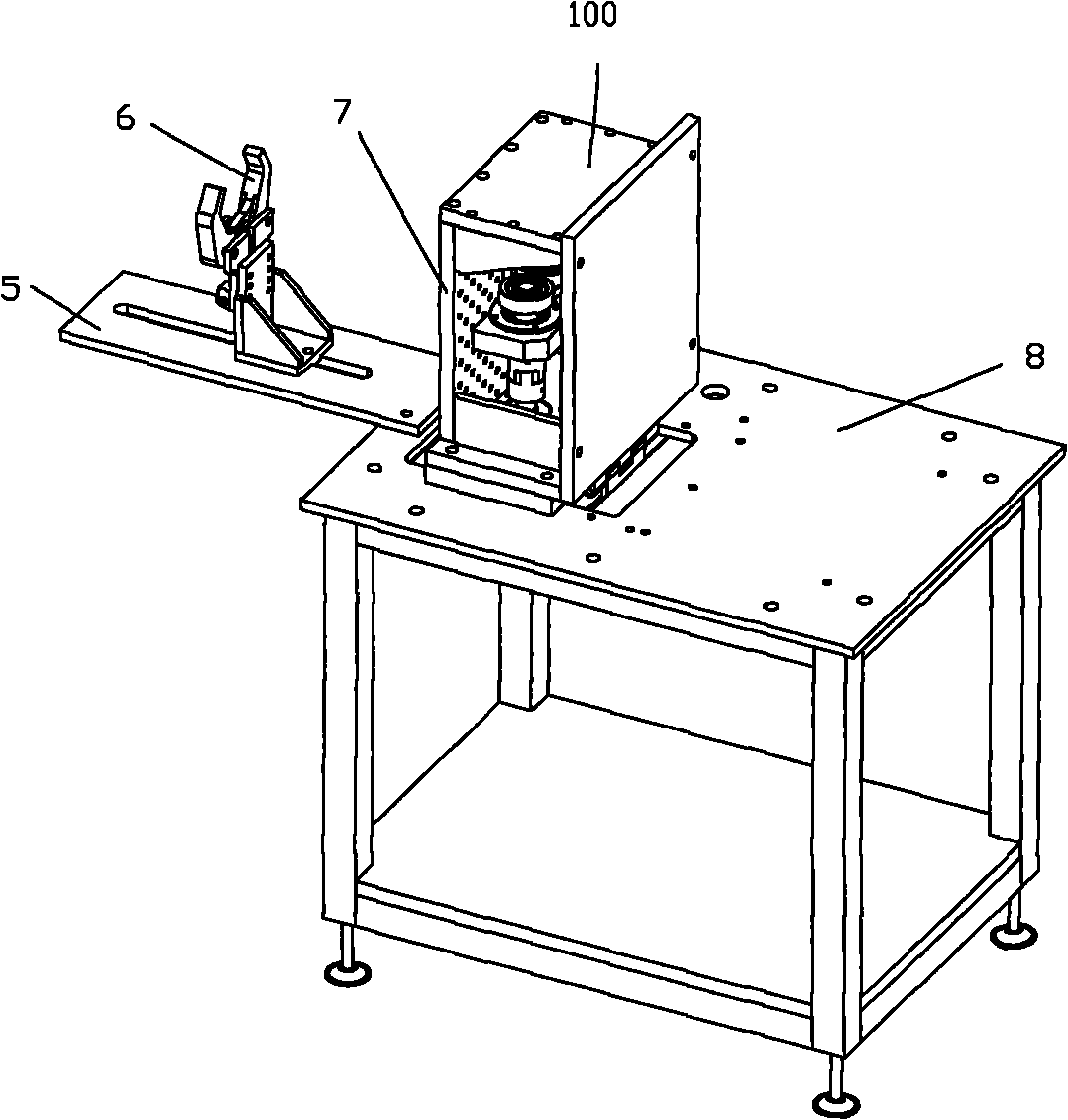

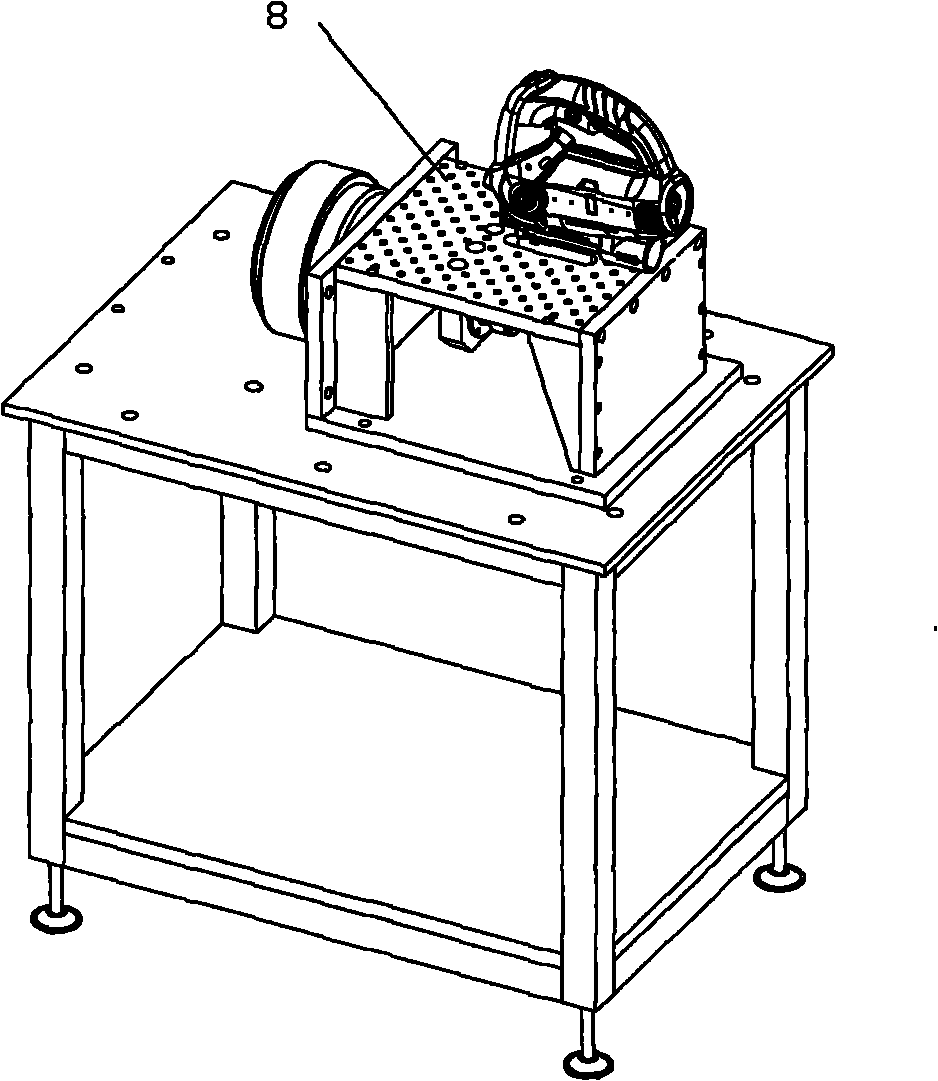

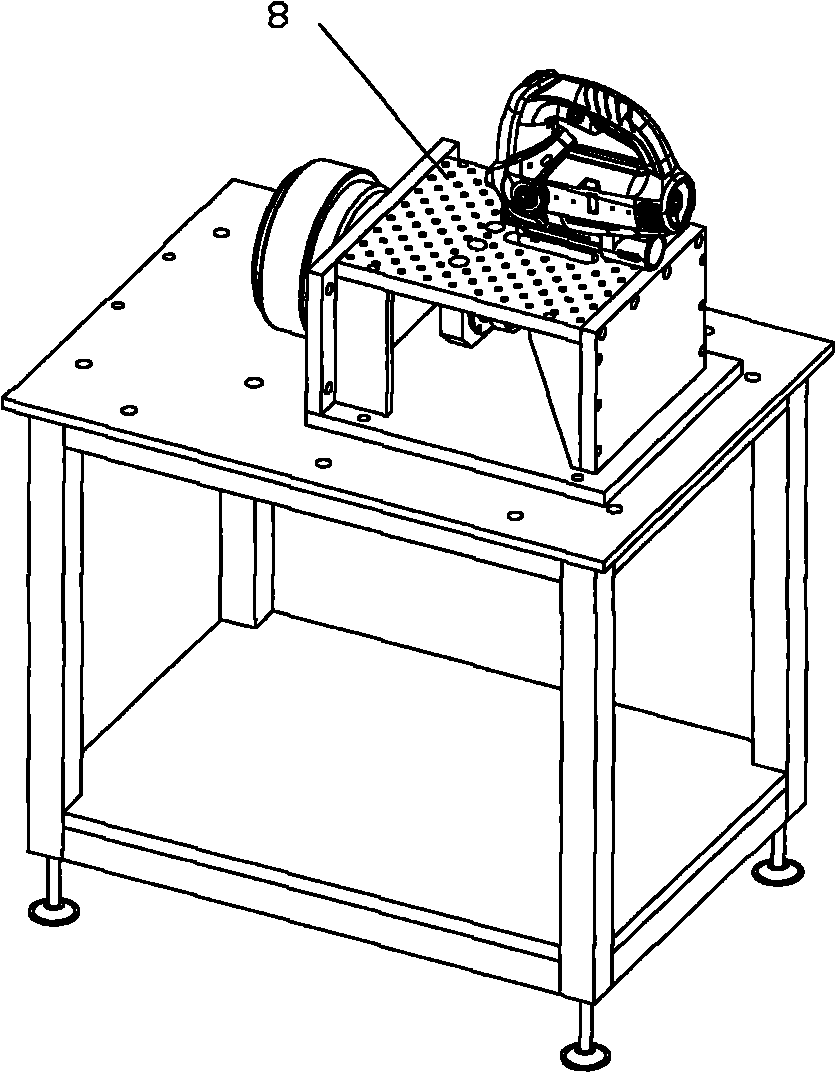

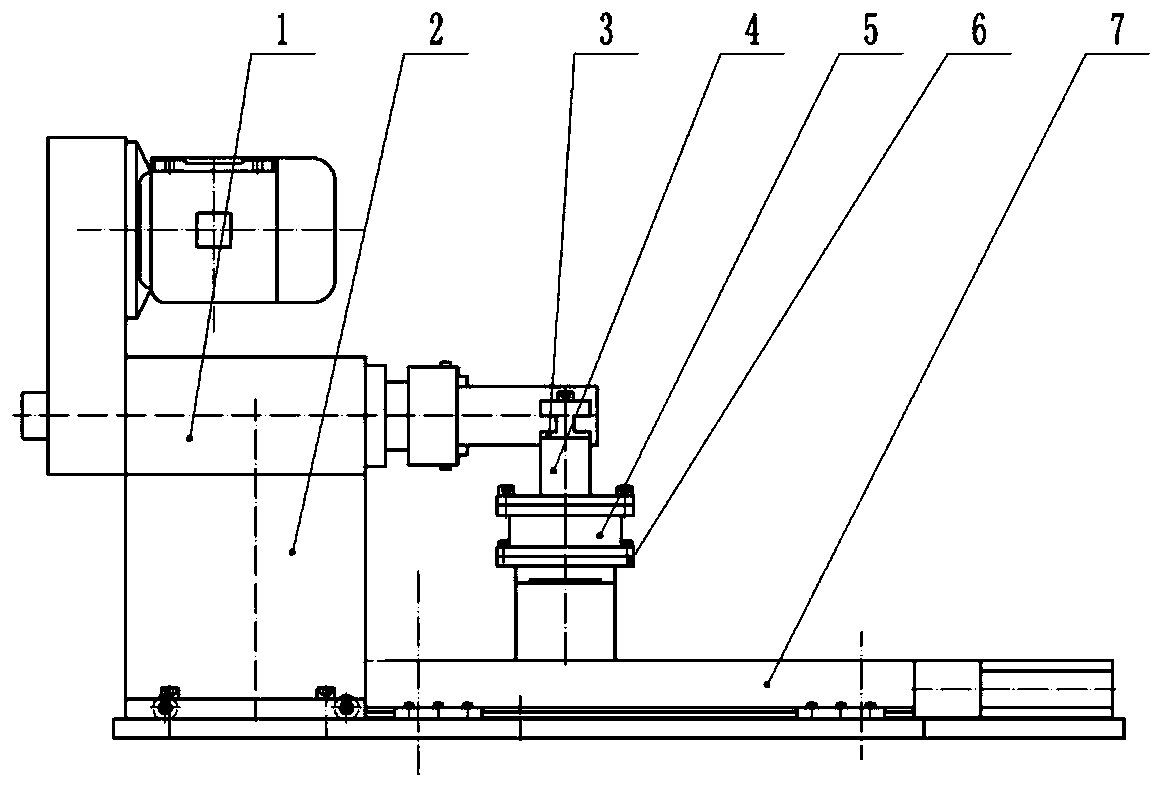

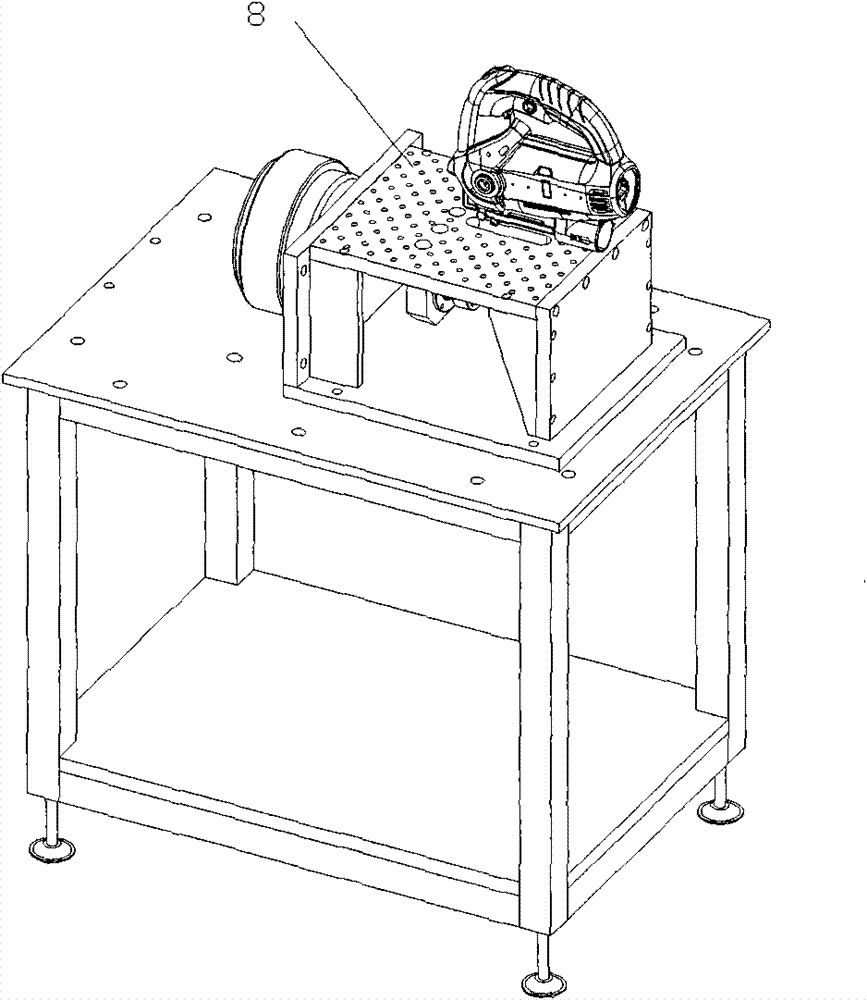

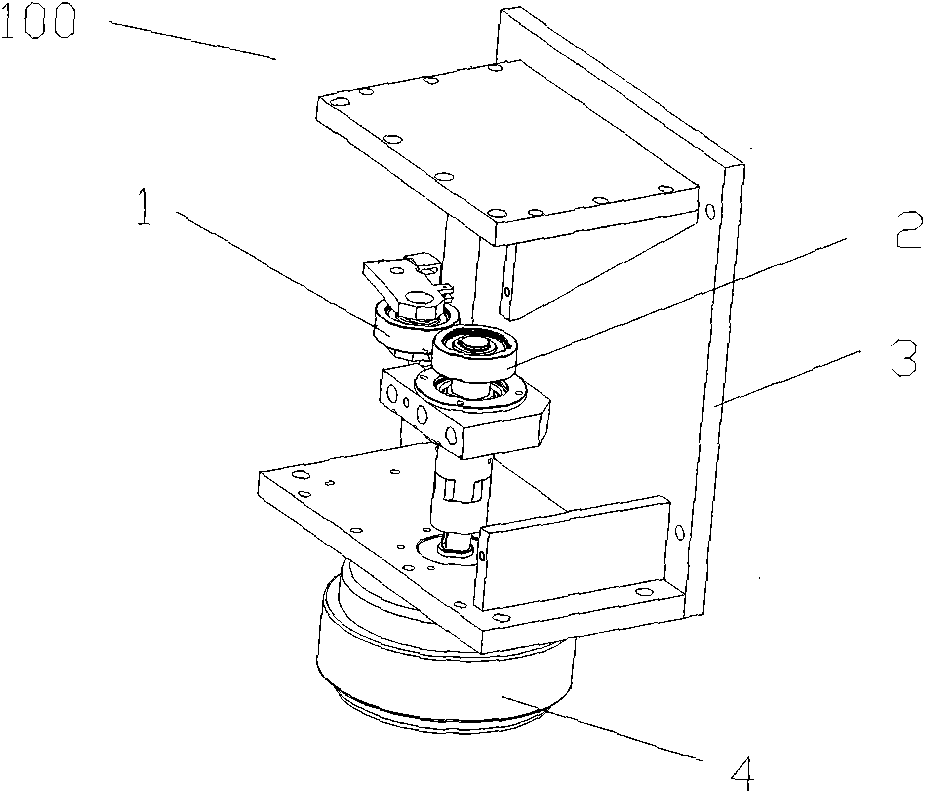

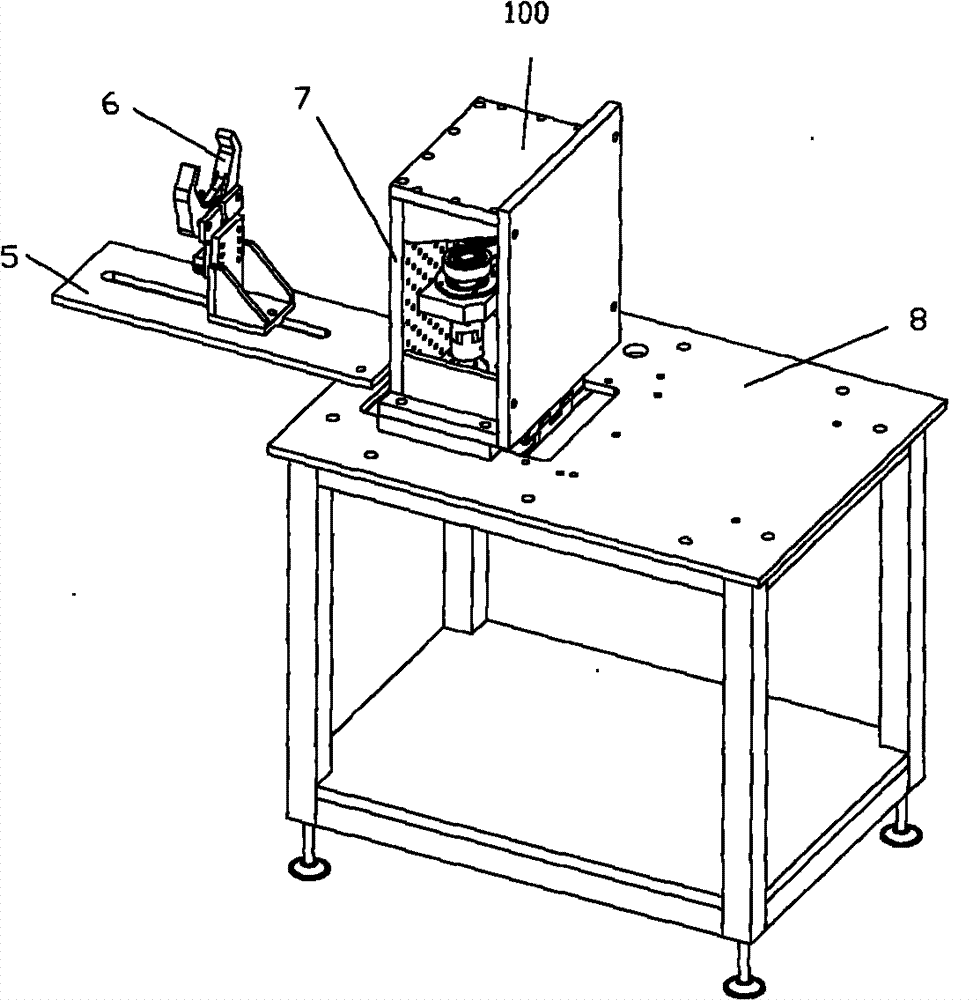

Testing device for load of jig saw

ActiveCN101769839AImprove test efficiencySave test materialMaterial strength using repeated/pulsating forcesTest efficiencyTest fixture

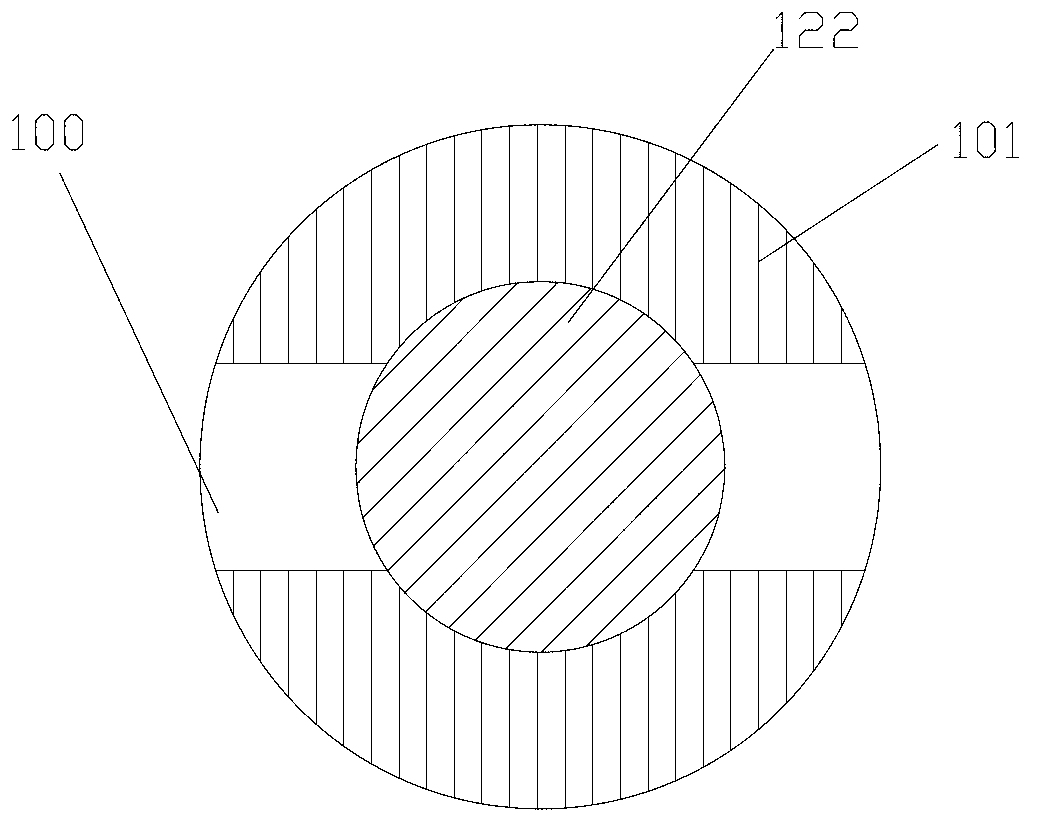

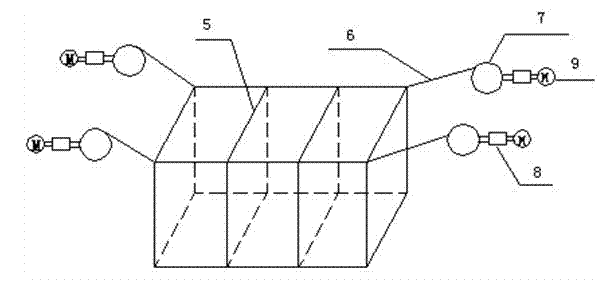

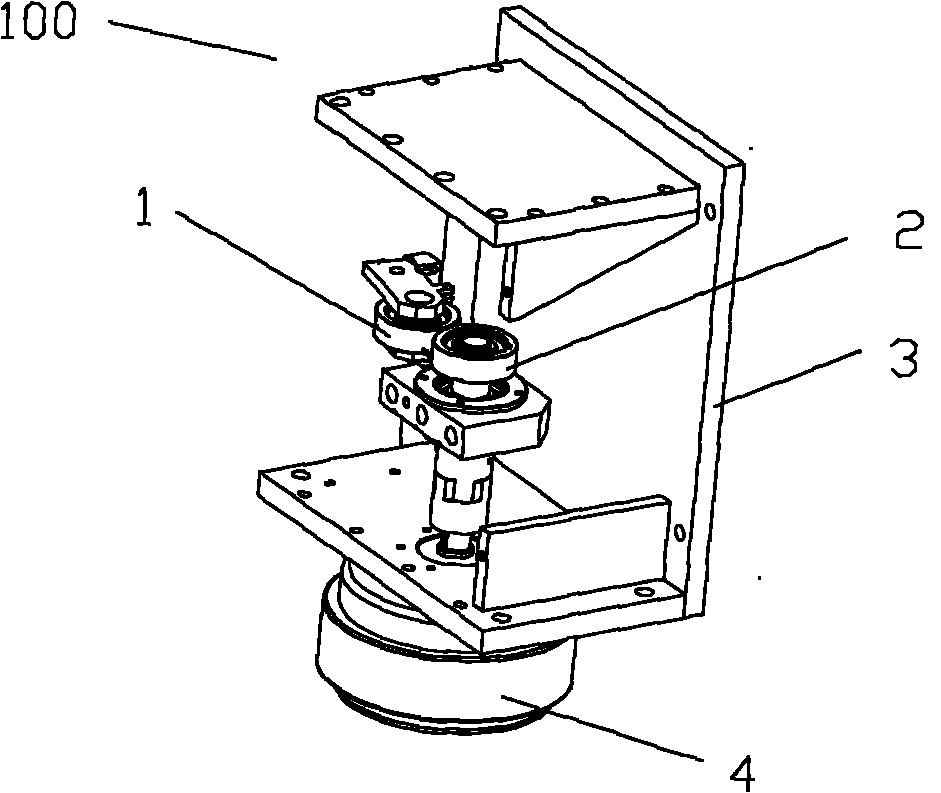

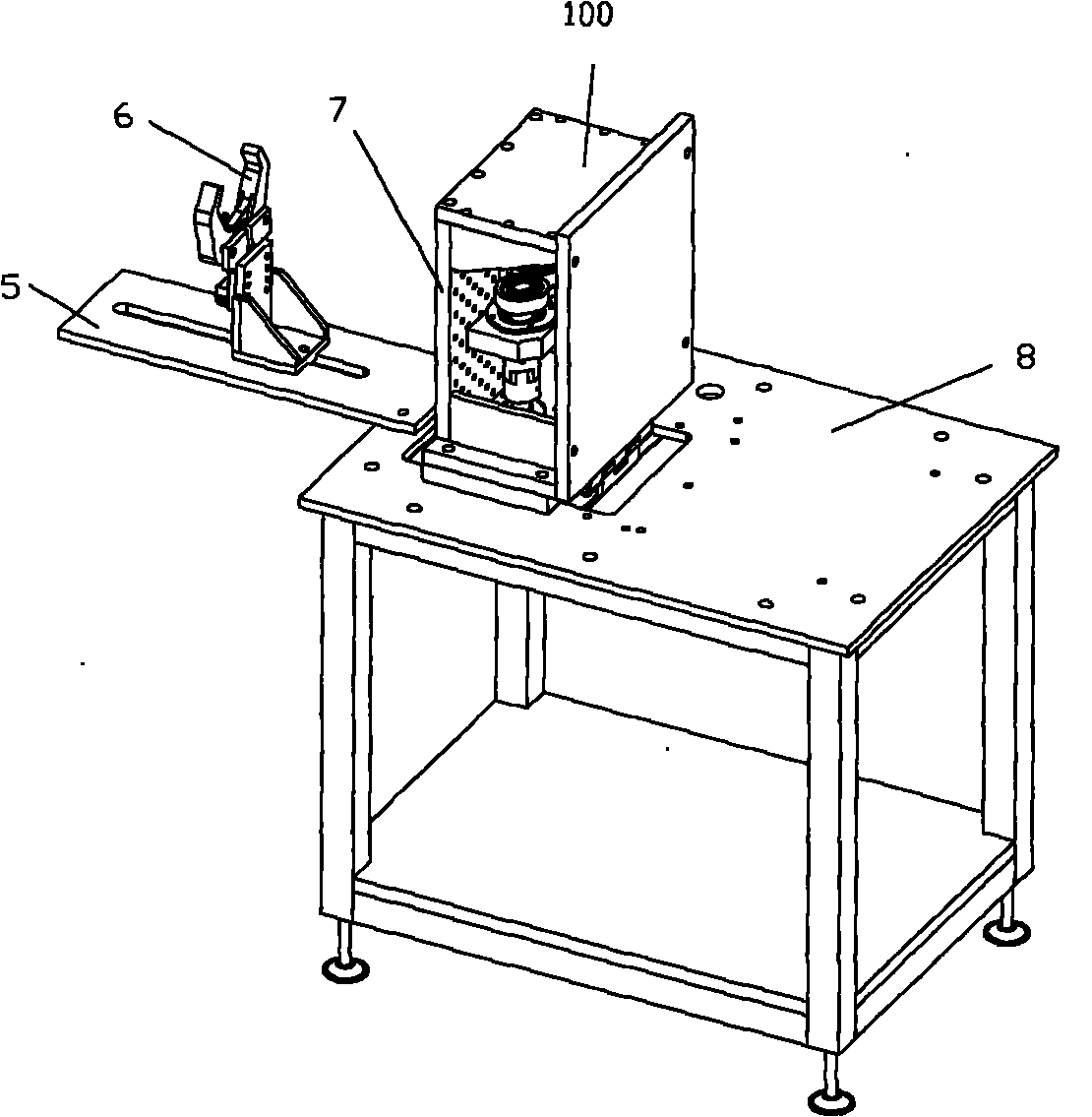

The invention relates to a testing device for load of a jig saw, which is characterized in that the testing device comprises a load simulator (100), a jig saw fixing device and a frame (8), wherein the load simulator (100) comprises a mounting bracket (3), a magnetic powder clutch (4) and two rollers (1 and 2); the magnetic powder clutch (4) is arranged below the mounting bracket (3), and the output end of the magnetic powder clutch (4) is connected with the roller (2) through a one-way bearing; a cantilever of the jig saw fixing device is arranged at the outer side of the frame (8) and consists of a cantilever (5) and a fixing part (6); and a jig saw blade to be tested is arranged in a clearance between the two rollers and clamped by the two rollers. During the testing process of the jigsaw, the load under actual conditions is simulated through the magnetic powder clutch and the one-way bearing completely, and the actual cutting material is not needed during the testing process, therefore the testing device has the characteristics that the testing efficiency is improved, the testing material is saved, the testing cost is reduced, and the operation is simple and convenient.

Owner:SUZHOU INDAL PARK TAIGE ELECTRONICS SCI &TECH

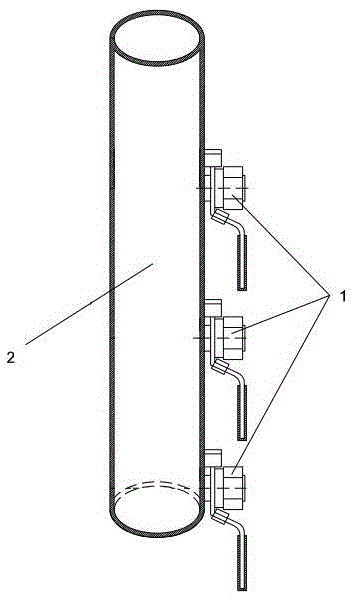

Modified asphalt storage stability standard viscosity detection method

The invention relates to a modified asphalt storage stability standard viscosity detection method. The method comprises the following steps that 1, the bottom end, one-third height position and two-third height position of a stainless steel pipe with two open ends are provided sample outlets respectively, and the sample outlets are provided with ball valves; 2, the ball valve at the bottom end of the stainless steel pipe is turned off, and the ball valves at the one-third height position and two-third height position of the stainless steel pipe are turned on; a filtered modified asphalt sample is heated and poured into the stainless steel pipe; 3, the stainless steel pipe is placed into a drying oven to be heated for 48+ / -1 h, and then naturally cooled to indoor temperature; 4, the modified asphalt sample cooled to indoor temperature is heated and molten again; by adjusting the ball valves to be turned on or off, the upper one-third part of the modified asphalt is injected into a standard viscosity test instrument for standard viscosity testing, and the lower one-third part of the modified asphalt is injected into a standard viscosity test instrument for standard viscosity testing; the two results are compared, and therefore the stability can be analyzed. The modified asphalt storage stability standard viscosity detection method is accurate in result and high in efficiency.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Testing experiment method for reducing heat treatment deformation and optimizing heat treatment technology

PendingCN110205480ASolve the problem that the precise test experiment cannot be performedQuality improvementHeat treatment process controlMechanical solid deformation measurementsGasolineWire cutting

The inventio discloses a testing experiment method for reducing heat treatment deformation and optimizing heat treatment technology. The testing experiment method for reducing the heat treatment deformation and optimizing the heat treatment technology can be used for a deformed testing sample of conventional heat treatment, and includes steps: using slow wire cutting for processing the deformed testing sample, using a metallographic abrasive paper for sanding the deformed testing sample, measuring the original size of the deformed testing sample, using gasoline for washing the deformed testingsample, painting the deformed testing sample with anti-carburizing paint and anti-oxidation paint, setting the deformed testing sample according to the profile of a heat treatment furnace and the structure size of a workpiece, performing a testing experiment for reducing the heat treatment deformation in the heat treatment furnace, measuring the size of the deformed testing sample after being treated, calculating and analyzing deformation rate, performing the testing experiment once more after optimizing the heat treatment technology, and enabling deformation resistance to reach the optimization by optimizing the heat treatment technology. The testing experiment method for reducing the heat treatment deformation and optimizing the heat treatment technology can save a large amount of experiment material and processing cost, substantially reduces the heat treatment deformation of the workpiece, substantially improves heat treatment quality of the workpiece, substantially improves quality uniformity of the workpiece, substantially improves fatigue resistance of the workpiece, and thereby substantially prolongs use life of the workpiece.

Owner:沈阳中金模具集团有限公司

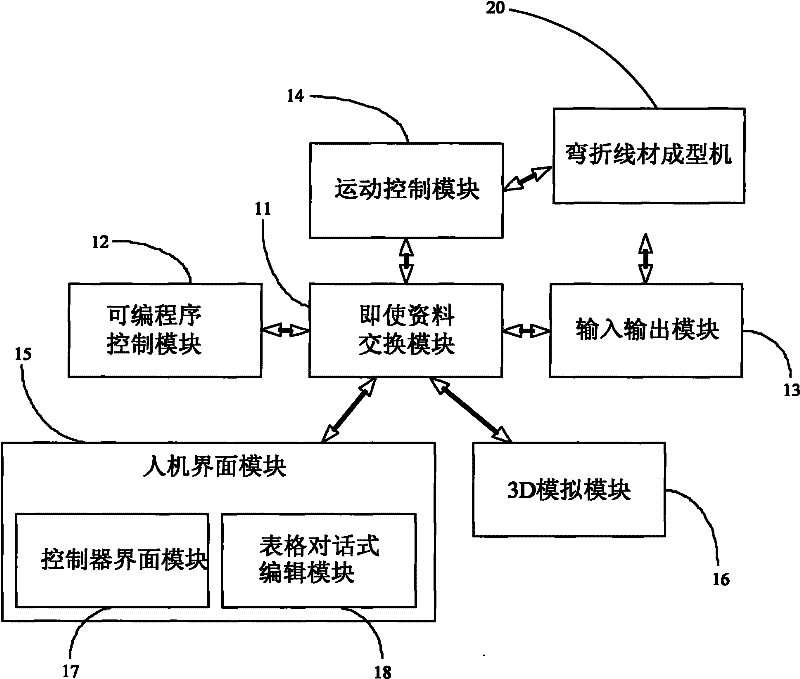

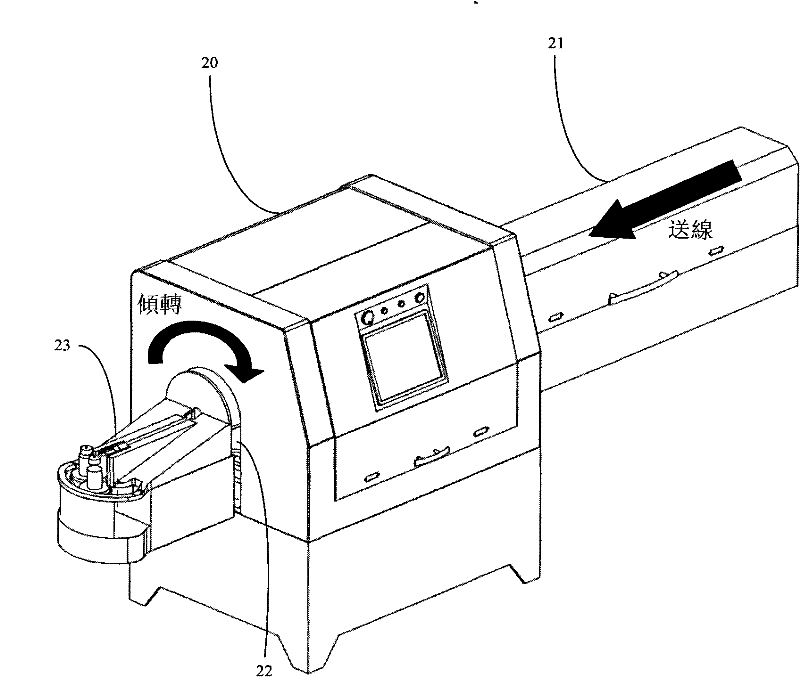

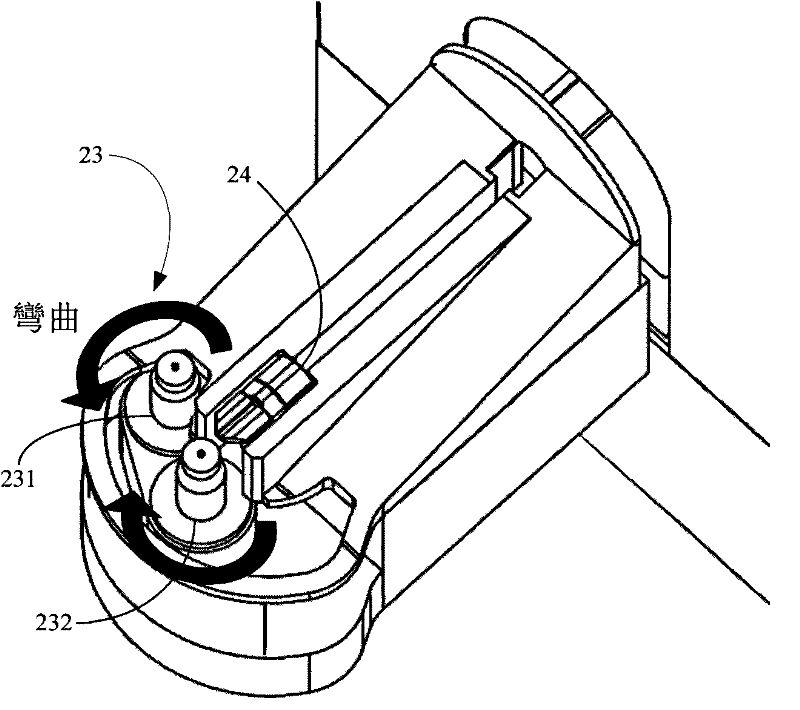

Controller for bending and forming wire rod

InactiveCN102193523AShorten the timeSave test materialNumerical controlWire rodThree dimensional simulation

The invention discloses a controller for bending and forming a wire rod, which integrates a programmable logic controller module, an input / output module, a motion control module, a human-computer interface module, an instant data exchange module and a three-dimensional analog module; and a universal flexible workpiece is processed by matching with a wire rod-bending forming machine. In the controller, wire rod-bending steps of feeding a wire, tilting and bending an angle of the workpiece are set on a conversational editing interface of the human-computer interface module; after the editing is completed, an actual control command is obtained through conversion and three-dimensional simulation and previewing are carried out according to a die geometrical relation; and after a formed resulted is confirmed to be correct and the process is ensured not to be interfered, the control command is actually output to a machine for processing. Software and hardware required by the controller are integrated into a single controller so as to improve the functionality of the controller, reduce wiring of a machine, lower maintenance costs and simplify an upgrading program of a control system.

Owner:HURCO AUTOMATION

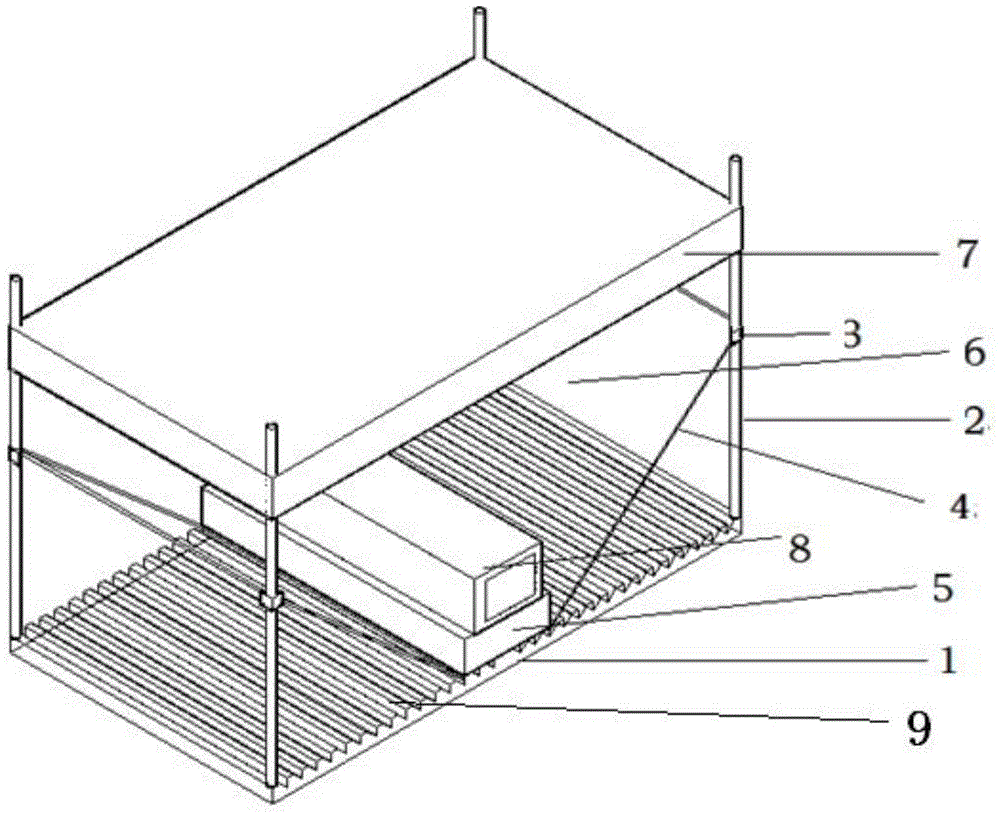

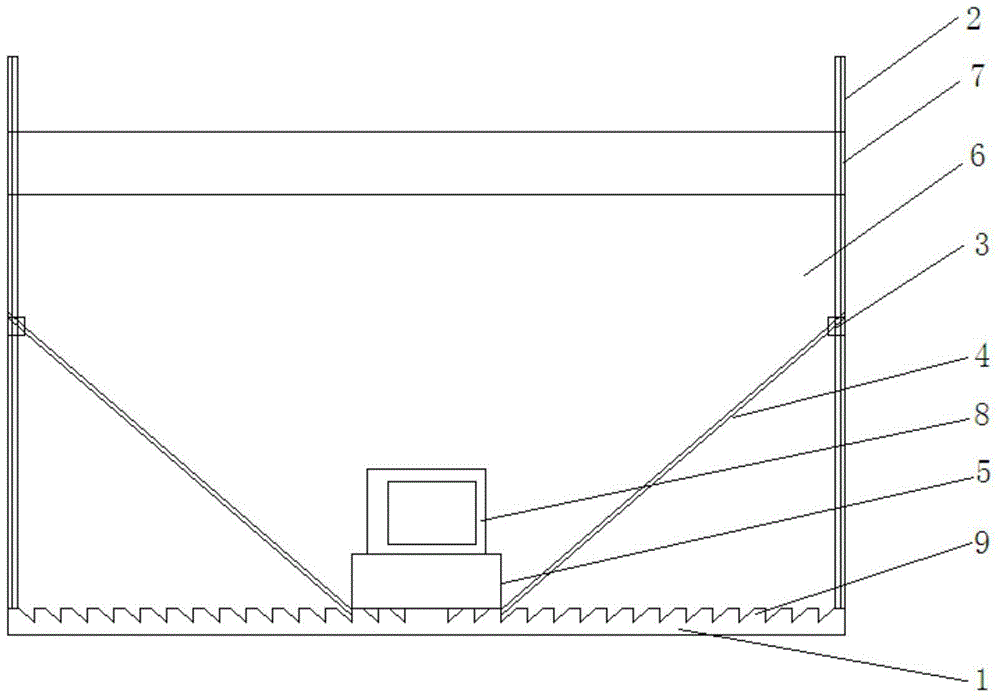

Testing device for measuring lateral soil resistance of pipeline

InactiveCN104677540AFree riseFree fallApparatus for force/torque/work measurementEngineeringSoil resistance

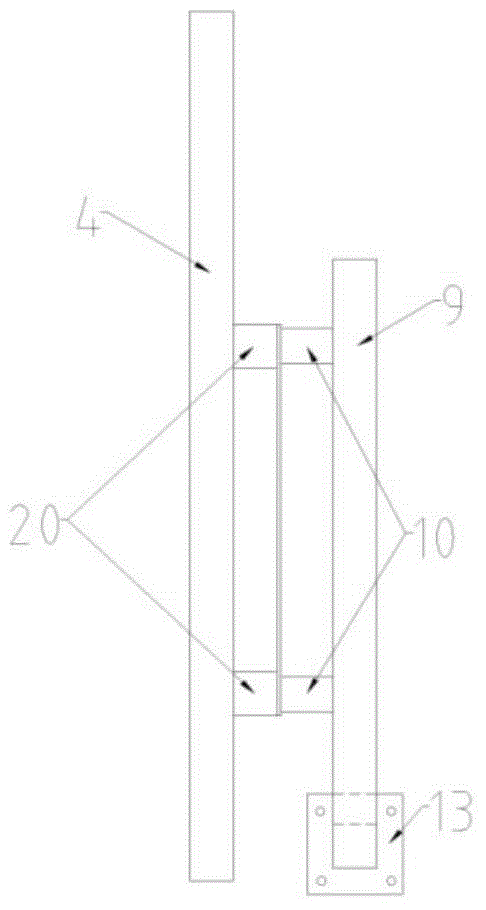

The invention relates to a testing device for measuring lateral soil resistance of a pipeline. The testing device comprises a soil groove (1), two horizontal linear guide rails (2), a horizontal trolley (3), vertical linear guide rails (4), two vertical rods (9), a force measuring system, a displacement measuring system, a pipeline weight regulating system and a power system, wherein the horizontal linear guide rails (2) are arranged along the length direction of the soil groove (1); sliding blocks (14) which are used for fixing the horizontal trolley (3) are arranged on the horizontal linear guide rails (2); the horizontal trolley (3) is fixedly provided with the two vertical linear guide rails (4) which are respectively provided with two sliding blocks, each sliding block (20) is provided with a tension and pressure sensor (10), and the tension and pressure sensors (10) are fixedly connected with the vertical rods (9); the bottom ends of the two vertical rods (9) are respectively and fixedly connected with the two ends of a test pipeline (11). According to the testing device disclosed by the invention, the measured soil resistance is enabled to more approach the stress of a seabed pipeline under a real state.

Owner:TIANJIN UNIV

Metal plate-shaped specimen dynamic hydrogen charging tensile stress corrosion test device

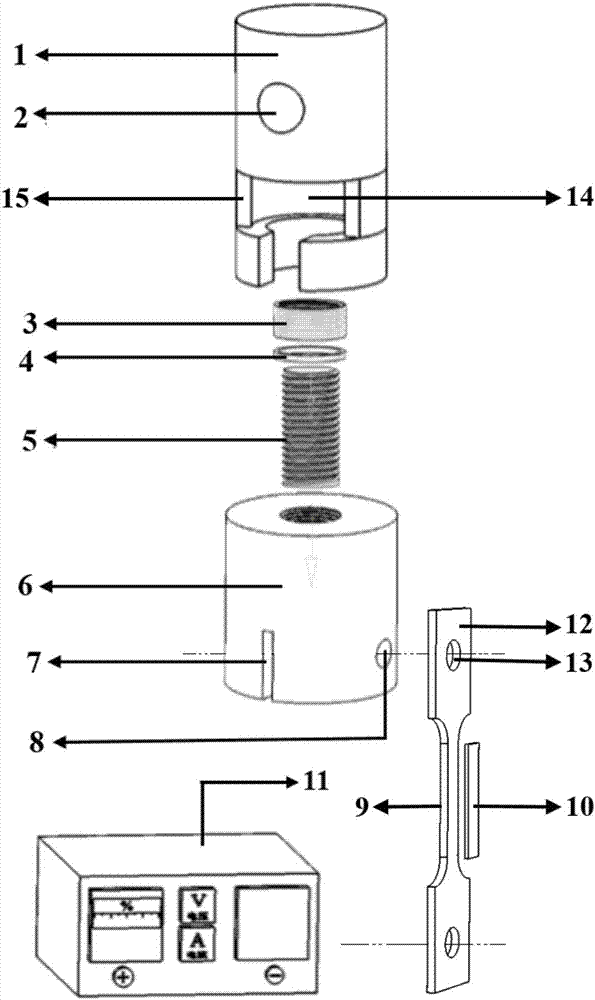

PendingCN107966362AAccurate control of load sizePrevent overflowMaterial strength using tensile/compressive forcesHydrogen concentrationPlatinum

Relating to the field of metal hydrogen charging test methods and stress corrosion measurement, the invention in particular relates to a metal plate-shaped specimen dynamic hydrogen charging tensile stress corrosion test device, which is suitable for systems that have high requirements for hydrogen concentration conditions and perform hydrogen charging at the same time of sample loading. The device includes a sample insulation loading apparatus and an electrochemical hydrogen charging apparatus, and is mainly equipped with a set of insulation jigs, a set of plate-shaped specimen jigs, a tensile specimen, a pair of insulation gaskets, a pair of loading nuts, a pair of connecting screw rods, a segment of platinum sheet and a DC power supply. The device is simple in operation, ca realize hydrogen charging at the same time of specimen loading, also can accurately control the hydrogen charging concentration, and is easy for real-time observation of the specimen stress corrosion state. The device provided by the invention has a small overall size, is suitable for promotion and use in laboratories, and also can be widely applied in steel, non-ferrous and other large-scale industrial production, detection analysis and other fields.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

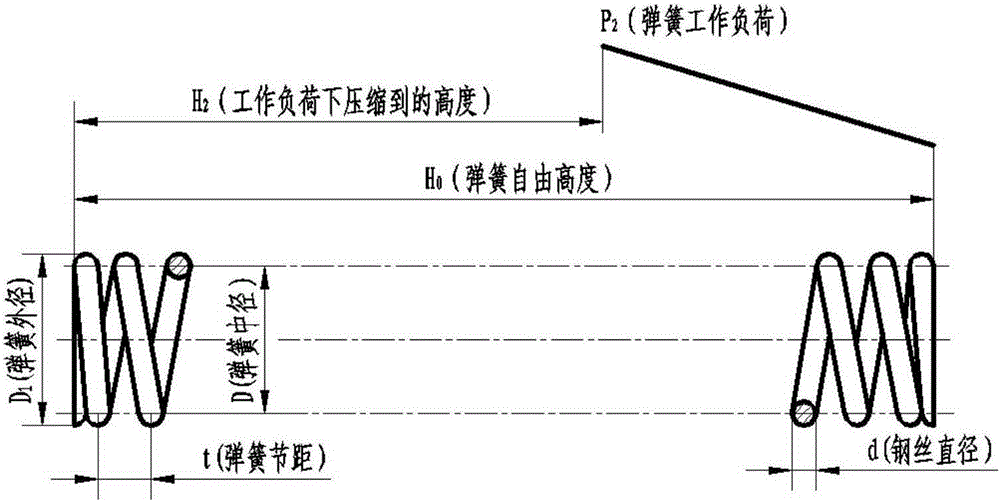

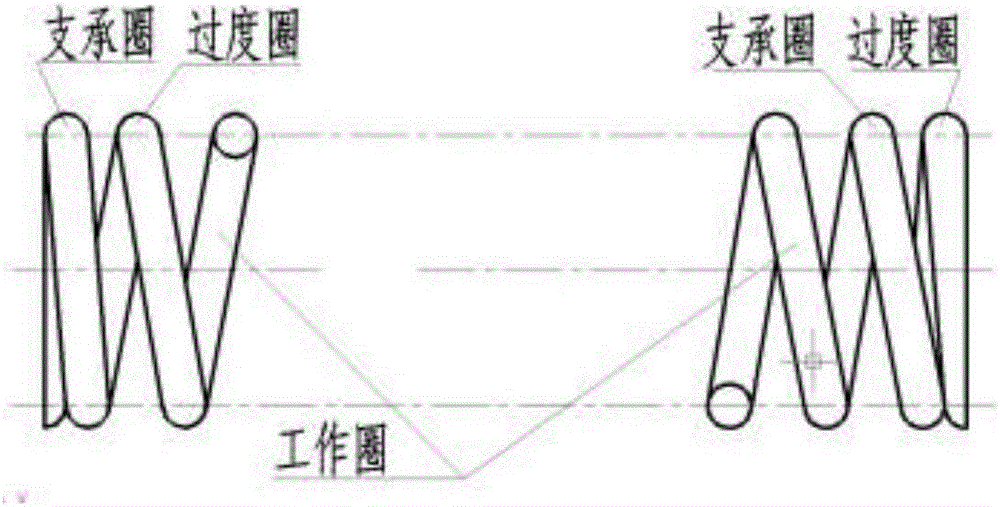

Compression spring coiling method based on automatic spring coiling machine

ActiveCN105195650AReduce blindnessAvoid multiple manipulation trialsWire springsTest materialMachining

The invention relates to a compression spring coiling method based on an automatic spring coiling machine and belongs to the technical field of machining. The compression spring coiling method based on the automatic spring coiling machine comprises the following steps: firstly recording parameter data related to processing of a target spring and process adjustment, and primarily determining machining dimensions according to material properties and dimensional requirements of the target spring; then calculating a set connection angle according to the primarily determined machining dimensions and parameters of the target spring; and finally adjusting the automatic spring coiling machine and trying to coil a sample piece according to the calculated result and the parameters of the target spring, and carrying out mass production when the sample piece is detected to meet the requirements of the target spring. Compared with the traditional method, the compression spring coiling method based on the automatic spring coiling machine has the advantages that a sample piece test material is saved and the sample piece trial production efficiency is high; the automatic spring coiling machine can be widely applied to multi-variety and small-batch spring manufacturing.

Owner:SHANXI NORTH MACHINE BUILDING

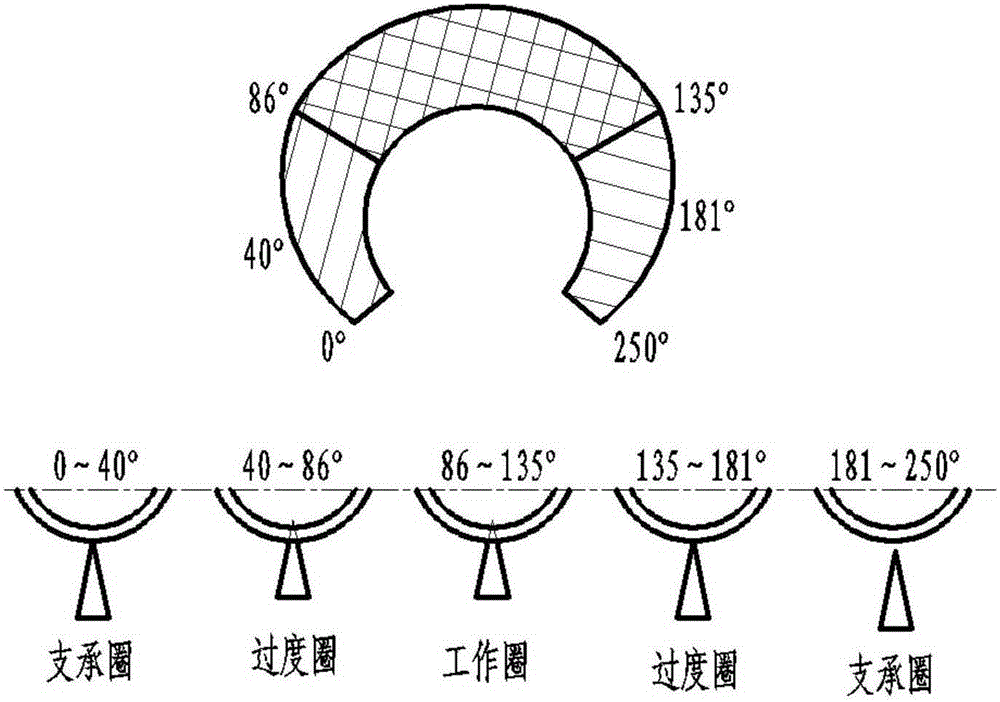

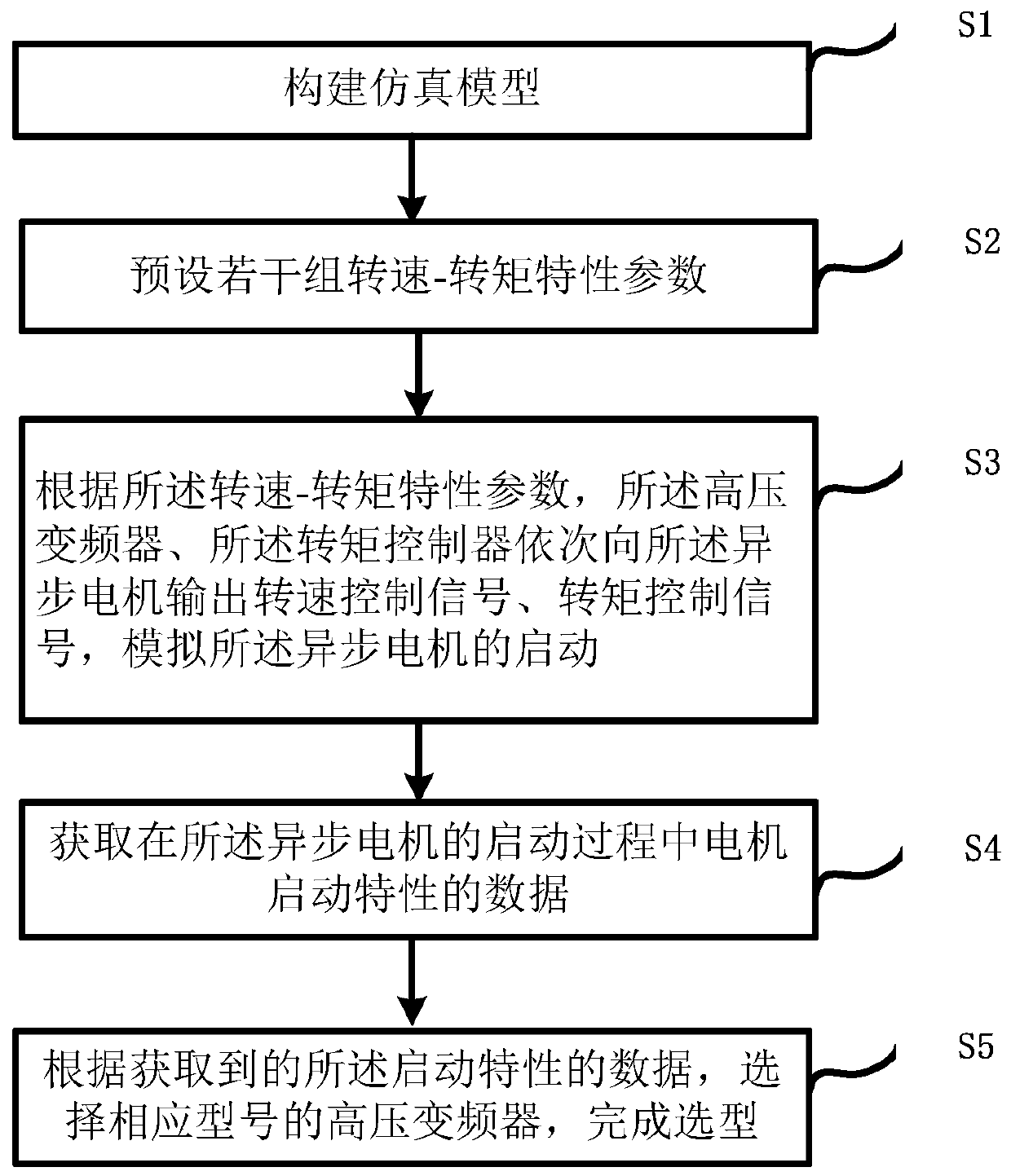

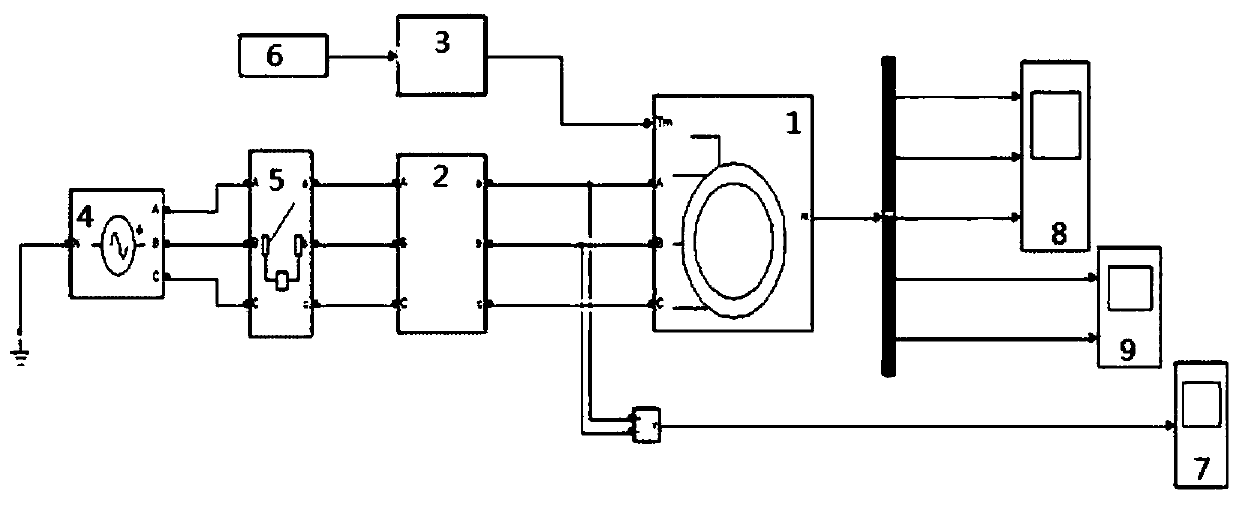

High-voltage frequency converter model selection method based on simulation

ActiveCN110162835ASolve the problem of difficulty in selecting a suitable high-voltage inverterSimple design methodStarter detailsSpecial data processing applicationsModel selectionControl signal

The invention discloses a high-voltage frequency converter model selection method based on simulation, a high-voltage frequency converter is used for starting a high-power motor load, and the method comprises the steps: constructing a simulation model which comprises an asynchronous motor, a high-voltage frequency converter coupled with the asynchronous motor, and a torque controller coupled withthe asynchronous motor; presetting a plurality of groups of rotating speed-torque characteristic parameters; according to the rotating speed-torque characteristic parameters, sequentially outputting arotating speed control signal and a torque control signal to the asynchronous motor by the high-voltage frequency converter and the torque controller to simulate starting of the asynchronous motor; acquiring data of motor starting characteristics in the starting process of the asynchronous motor, wherein the data of the starting characteristics at least comprises the following parameters: voltageand current of the asynchronous motor; and according to the obtained data of the starting characteristics, selecting a high-voltage frequency converter of a corresponding model to finish model selection.

Owner:DAYU ELECTRIC

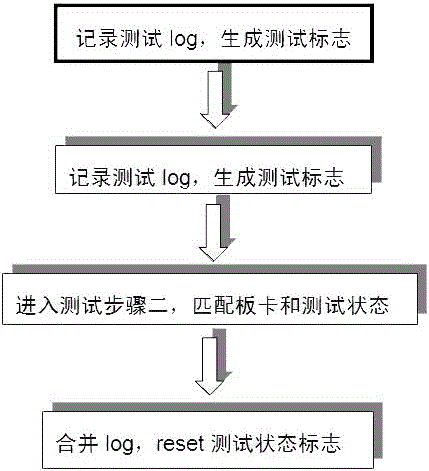

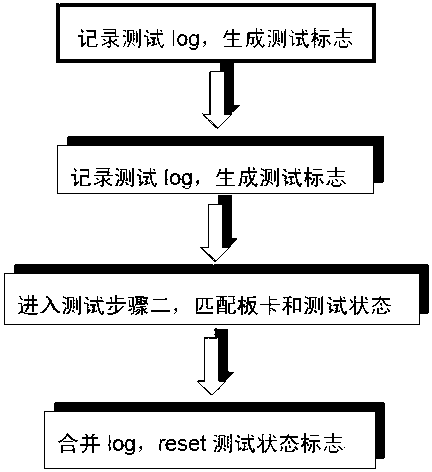

Dual-mode interconnection double board function test method based on Linux

ActiveCN106291314AShorten test timeImprove test efficiencyPrinted circuit testingComputer hardwareFunctional testing

The invention provides a dual-mode interconnection double board function test method based on Linux, and belongs to the field of computer dual-mode interconnection board card factory large-scale testing. In dual-mode interconnection board card testing, single-mode cross testing is performed on two dual-mode interconnection board cards, and equipment information matching and log information matching are performed so that test coverage can be effectively increased and consistency of the dual-mode test board cards can be guaranteed, and the efficiency is high and cost is low without increasing labor intensity of workers.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

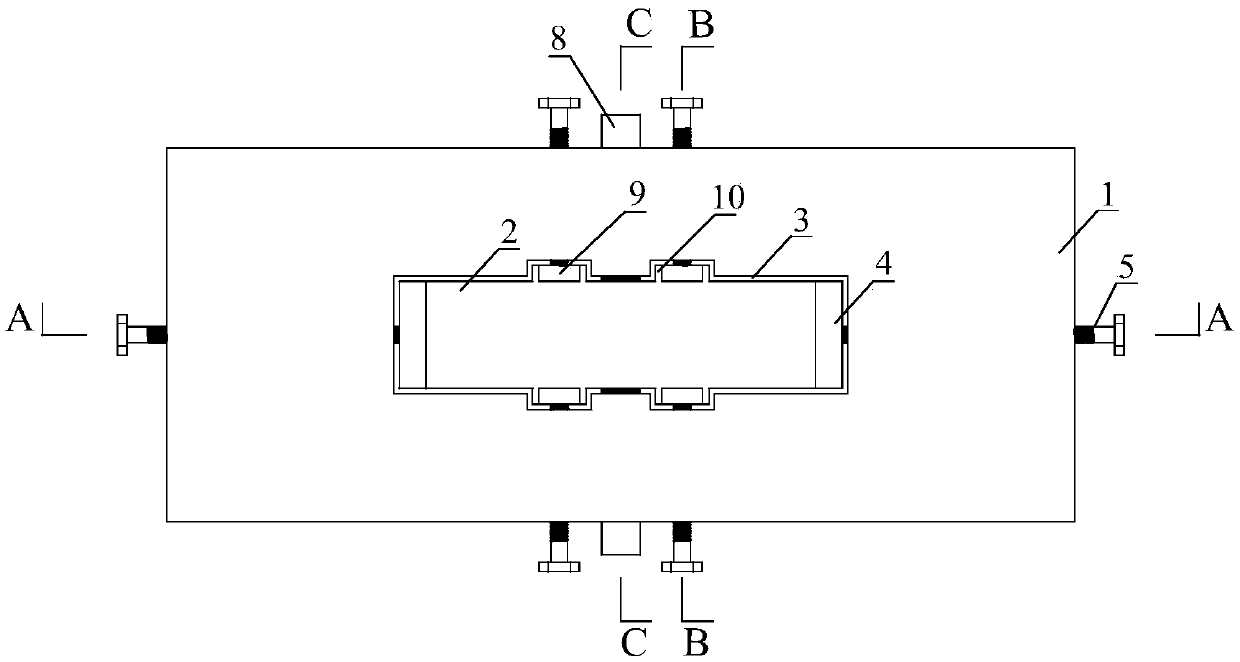

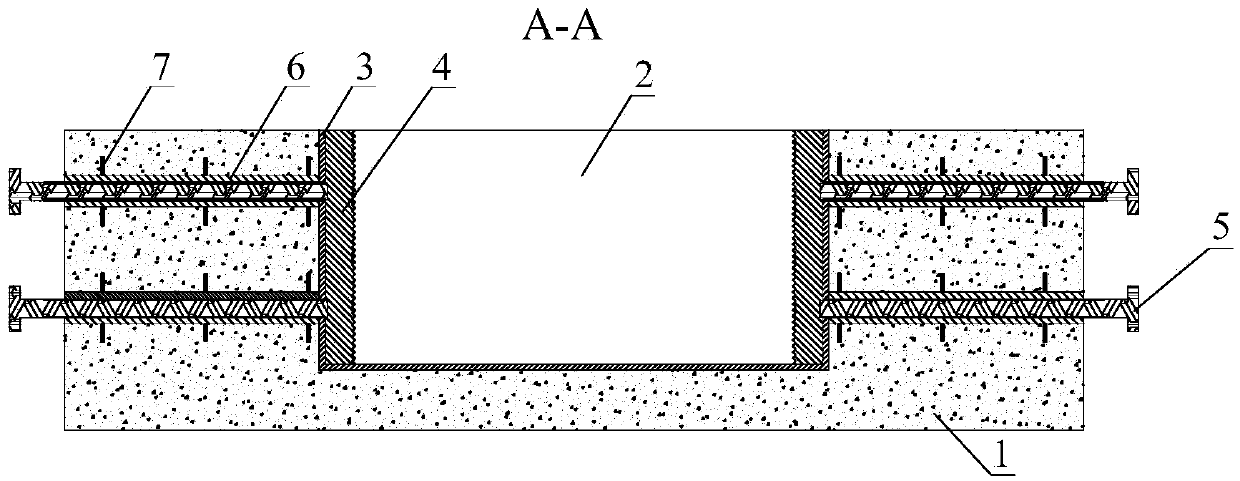

Reusable wall low-cycle repeated loading test foundation

The invention discloses a reusable wall low-cycle repeated loading test foundation, which comprises a base. A rectangular groove is formed in the top surface of the base. A plurality of horizontally arranged casing pipes are embedded in the side walls of the base. One end of each casing pipe is communicated externally and the other end of each casing pipe is communicated with the inner cavity of the groove through the side walls of the base. Fastening bolts are screwed into the casing pipes. According to the invention, solid round steel rods pass through the casing pipes and connecting holes reserved in a wall test piece to fix the wall test piece with the base preliminarily; the fastening bolts are screwed and a first anchoring plate and a second anchoring plate are supported tightly on the wall test piece, so that the wall test piece is fixed in the groove firmly. The base can be reused to avoid repeated making of a reinforced concrete base, so that the test materials and the scientific research cost are saved; the test cycle is reduced; and concrete wastes after the test completion are reduced.

Owner:INNER MONGOLIA UNIV OF TECH

Method for preparing isometric crystal high temperature alloy casting alloy/ceramic interface reaction test sample

ActiveCN102416464AImprove test efficiencySave test materialPreparing sample for investigationSuperalloyReaction timing

The invention relates to a method for preparing an isometric crystal high temperature alloy casting alloy / ceramic interface reaction test sample, which comprises the following steps of: preparing a shell mold in which ceramic cores are arranged by the traditional investment casting process; heating the shell mold in a heater of a directional solidification vacuum induction furnace to different temperatures at which alloy / ceramic interface reaction is expected to be performed, and preserving heat; remelting a high temperature alloy ingot, pouring into a cavity of the shell mold, and pulling the heater out at a certain speed to form directional solidification castings or test samples with the cores; and cutting the directional solidification castings or test samples at different heights to acquire data of alloy and ceramic which react at the same temperature for different time. The method has the advantages that: the interface reaction time can be steplessly changed according to sampling positions, so that test efficiency is improved; the interface reaction results of the ceramic cores with different components can be obtained in one module at the same time; and the interface reaction condition can be visually observed by a microscope, so that reaction products and a reaction mechanism are determined, and the actual production of the isometric crystal castings is instructed.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Acid rain corrosion testing device

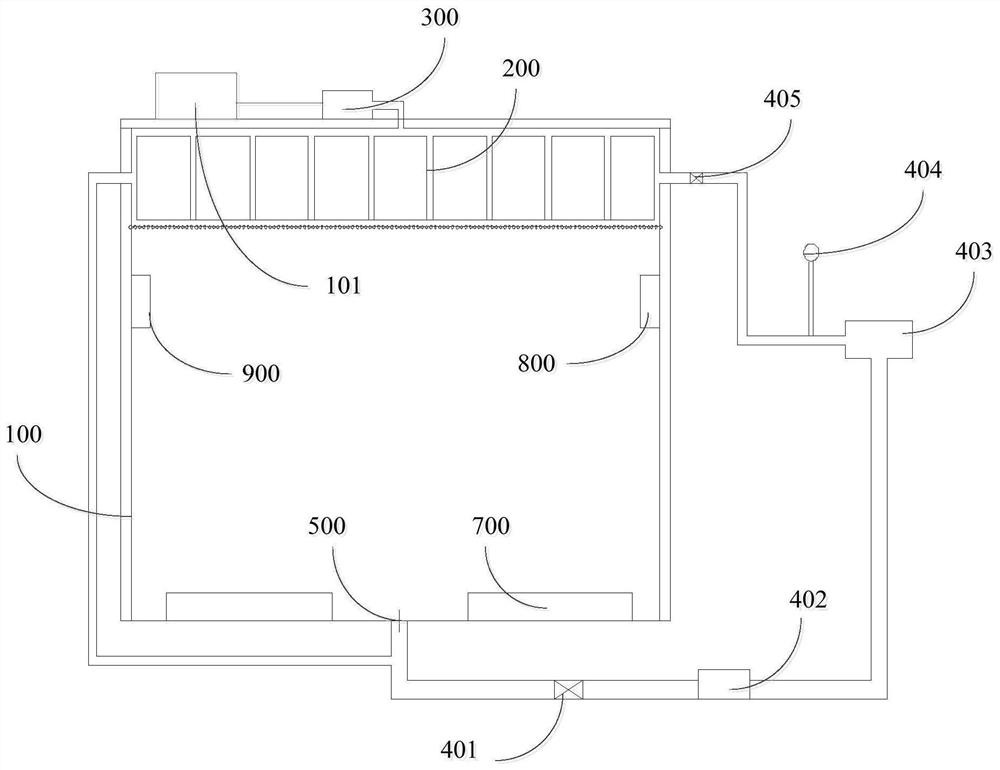

PendingCN113092350AAvoid wastingImprove accuracyWeather/light/corrosion resistanceRainfall simulationSoil science

The invention discloses an acid rain corrosion test device which comprises a rainfall system and a circulation system, the rainfall system comprises a rainfall assembly and a rainfall simulation box, and the rainfall assembly is arranged at the top of the rainfall simulation box; the water inlet end of the circulating system is communicated with the drain hole of the rainfall simulation box, and the water outlet end of the circulating system is communicated with the water inlet of the rainfall assembly. According to the acid rain corrosion test device provided by the invention, the rainfall system and the circulating system are matched to simulate a scene that acid rain corrodes rocks in a natural environment, so that the technical problem that the test result of an acid rain corrosion test in the prior art is inaccurate is solved.

Owner:CHINA RAILWAY 20 BUREAU GRP

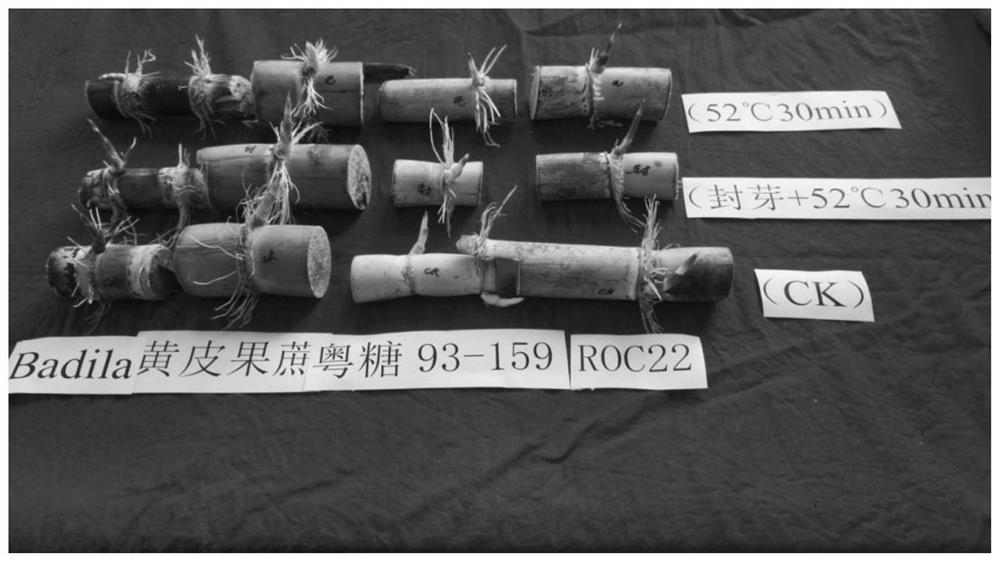

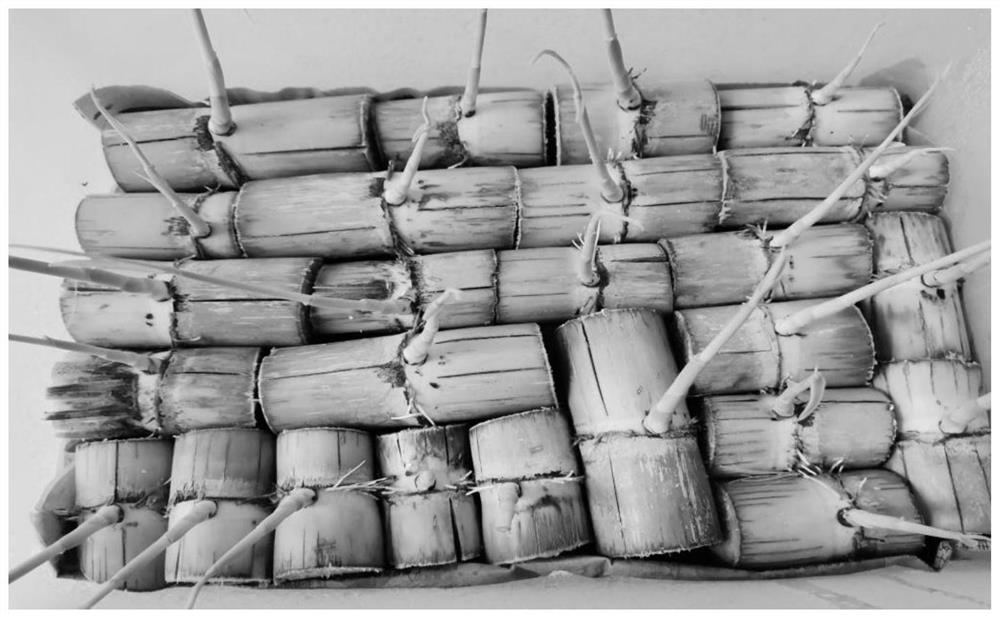

Method for producing sugarcane virus-free seedlings

ActiveCN113170730AAvoid harmGerminate fastPlant tissue cultureHorticulture methodsBiotechnologyPathogenic microorganism

The invention discloses a method for producing sugarcane virus-free seedlings. According to the method disclosed by the invention, when the sugarcane seeds are treated by hot water, a leakage-proof adhesive tape used on a building is used for sticking and sealing sugarcane buds, so that the sugarcane buds can be well protected from being damaged by the hot water, the sugarcane buds rapidly germinate and vigorously grow, effective killing of pathogenic microorganisms in sugarcane stems by the hot water is not influenced, microorganisms at two ends of the sugarcane stems and in a germination accelerating environment are inhibited or the breeding speed is greatly slowed down; normal and pollution-free growing point explants can be easily obtained by separation, micro-propagation starting is fast, cluster buds can be rapidly formed, the propagation coefficient is high, operation is easy, practicability is high, cost is low, and test materials are saved. The method plays an important role in promoting the application of healthy seedlings in production and promoting the sustainable development of the cane sugar industry.

Owner:广东省科学院南繁种业研究所

Integrated working condition simulation device and test method for centrifugal model test of highway culvert

The invention discloses an integrated working condition simulation device of a highway culvert centrifugal model test and a test method. The device comprises a bottom plate, a height fixing frame, a pair of telescopic plates, a foundation model, a test soil sample, a counterweight device and a culvert model; the bottom plate is flatly spread on the bottom surface of a centrifugal model box; the height fixing frame is installed on the bottom plate; the foundation model is placed on the bottom plate; the culvert model is placed on the foundation model; the telescopic plate are symmetrically installed on the bottom plate at both sides of the foundation model; the telescopic plates are arranged obliquely; a hollow cavity enclosed by the centrifugal model box, the bottom plate, the pair of telescopic plates, the foundation model and the culvert model is filled with the test soil sample; the counterweight device is spread on the test soil sample. The test device is simple in structure, convenient to operate, free of frequency disassembly and assembly, and capable of efficiently and accurately satisfying the requirements of designing the highway culvert centrifugal model test and improving the test efficiency and precision.

Owner:CHANGAN UNIV

Linux-based dual-mode interconnection dual-board function test method

ActiveCN106291314BShorten test timeImprove test efficiencyPrinted circuit testingComputer hardwareFunctional testing

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

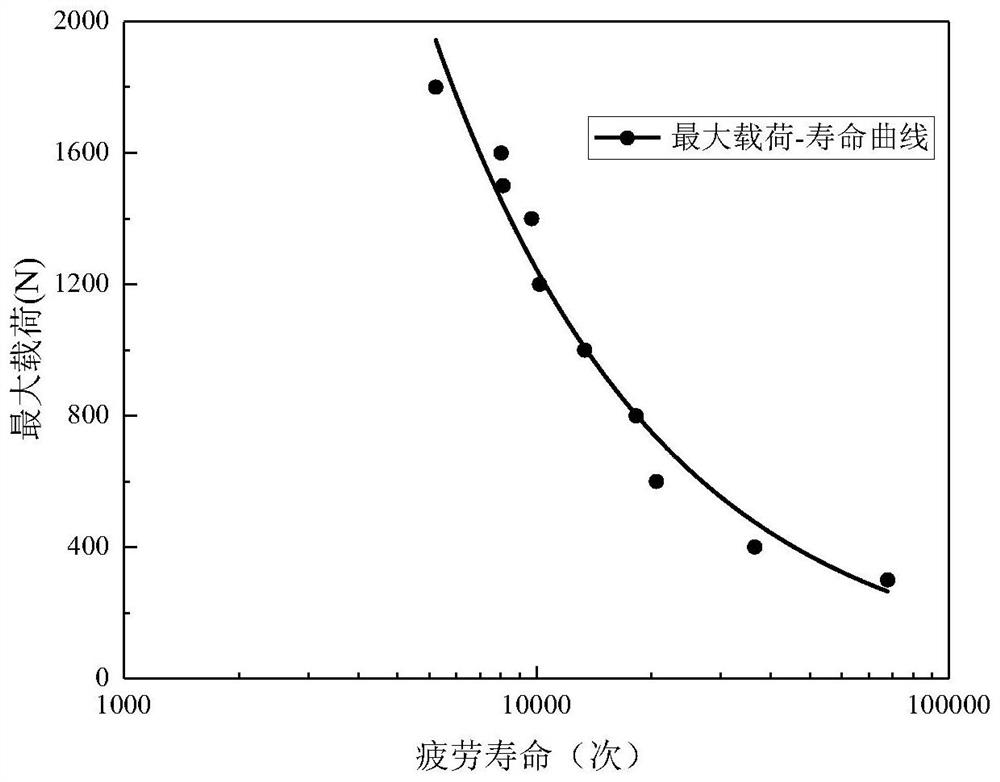

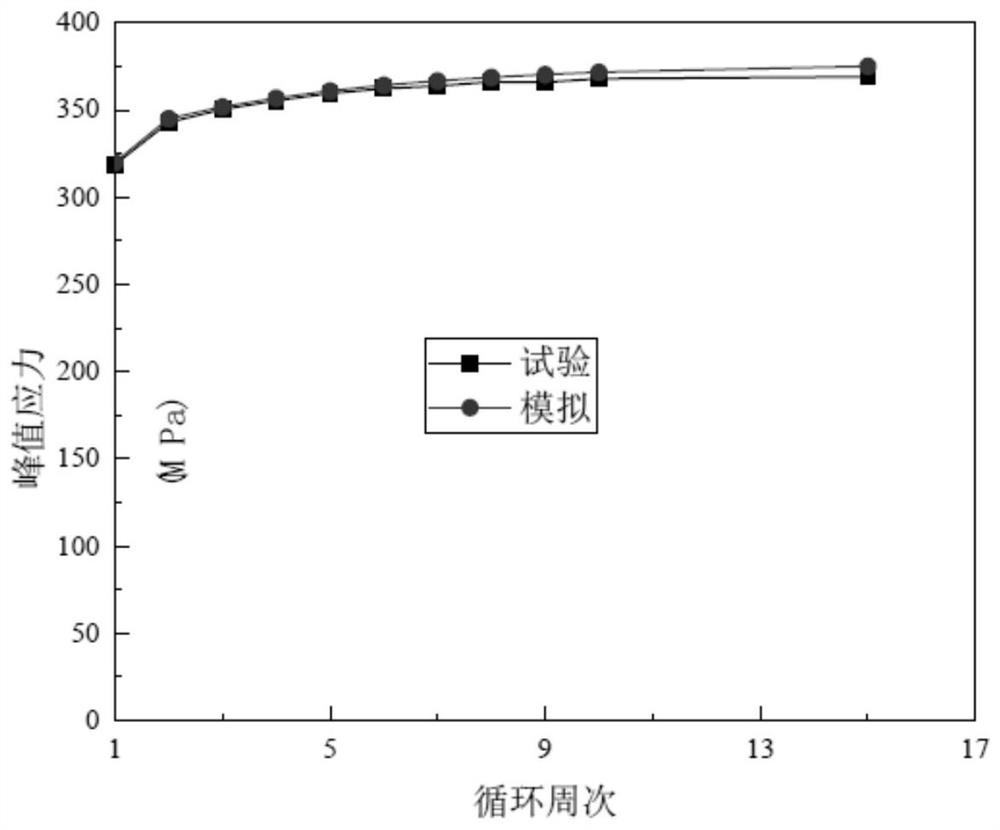

A Method of Obtaining Material Strain-Life Curve by Small Punch Fatigue Test

ActiveCN113312817BTroubleshooting Uniaxial Fatigue Test ResultsSave test materialDesign optimisation/simulationSpecial data processing applicationsElement modelElement analysis

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

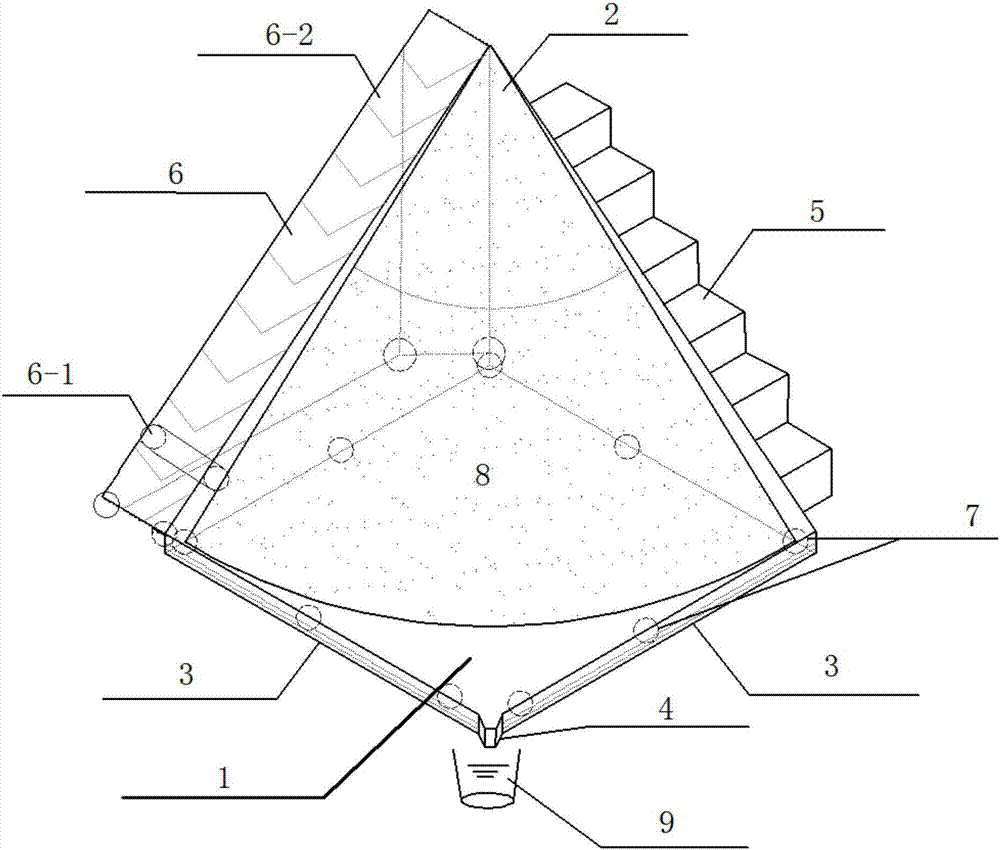

Movable water-and-soil-loss testing apparatus capable of simulating engineering accumulation body

ActiveCN107228930AReduce usageEliminate destructionEarth material testingEcological environmentAgricultural engineering

The invention discloses a movable water-and-soil-loss testing apparatus capable of simulating an engineering accumulation body, belonging to the technical field of water-and-soil-loss testing. The movable water-and-soil-loss testing apparatus comprises a fan-shaped accumulation platform; the bottom of the accumulation platform is provided with universal wheels; two sides of the accumulation platform are provided with two baffle plates; each of the two baffle plates comprises a right angle; one right-angle side of one of the two baffle plates is connected with one right-angle side of the other baffle plate, and the other two right-angle sides of the two baffle plates are connected with the accumulation platform; the part, located between the two baffle plates, of the accumulation platform is an accumulation zone; the edges of the accumulation zone are provided with flow collecting grooves; each of the flow collecting grooves is provided with a water outlet, and a collection container is arranged below the water outlet; and the side surfaces, defining the accumulation zone, of the baffle plates are defined as inner sides, and the outer side of one of the baffle plates is provided with a passage allowing a tester to observe tests. The movable water-and-soil-loss testing apparatus provided by the invention is simple in structure, low in cost and convenient to move and provides basic data for control of and scientific research on water and soil loss so as to eliminate destroy of engineering accumulation bodies to ecological environment.

Owner:NORTHWEST A & F UNIV

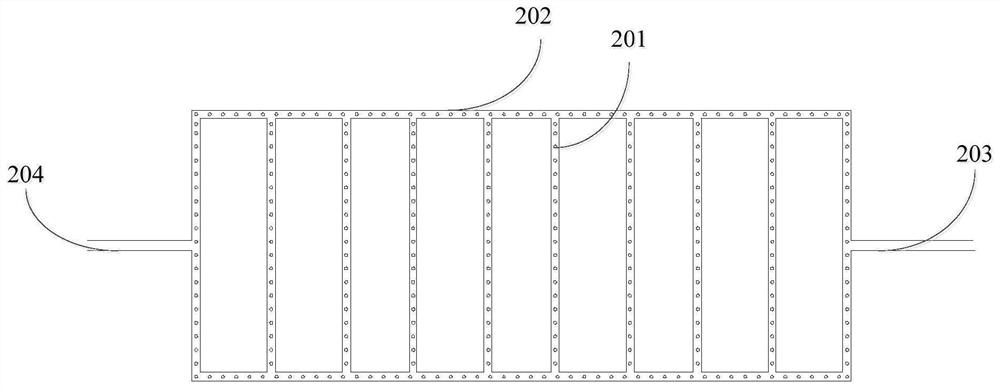

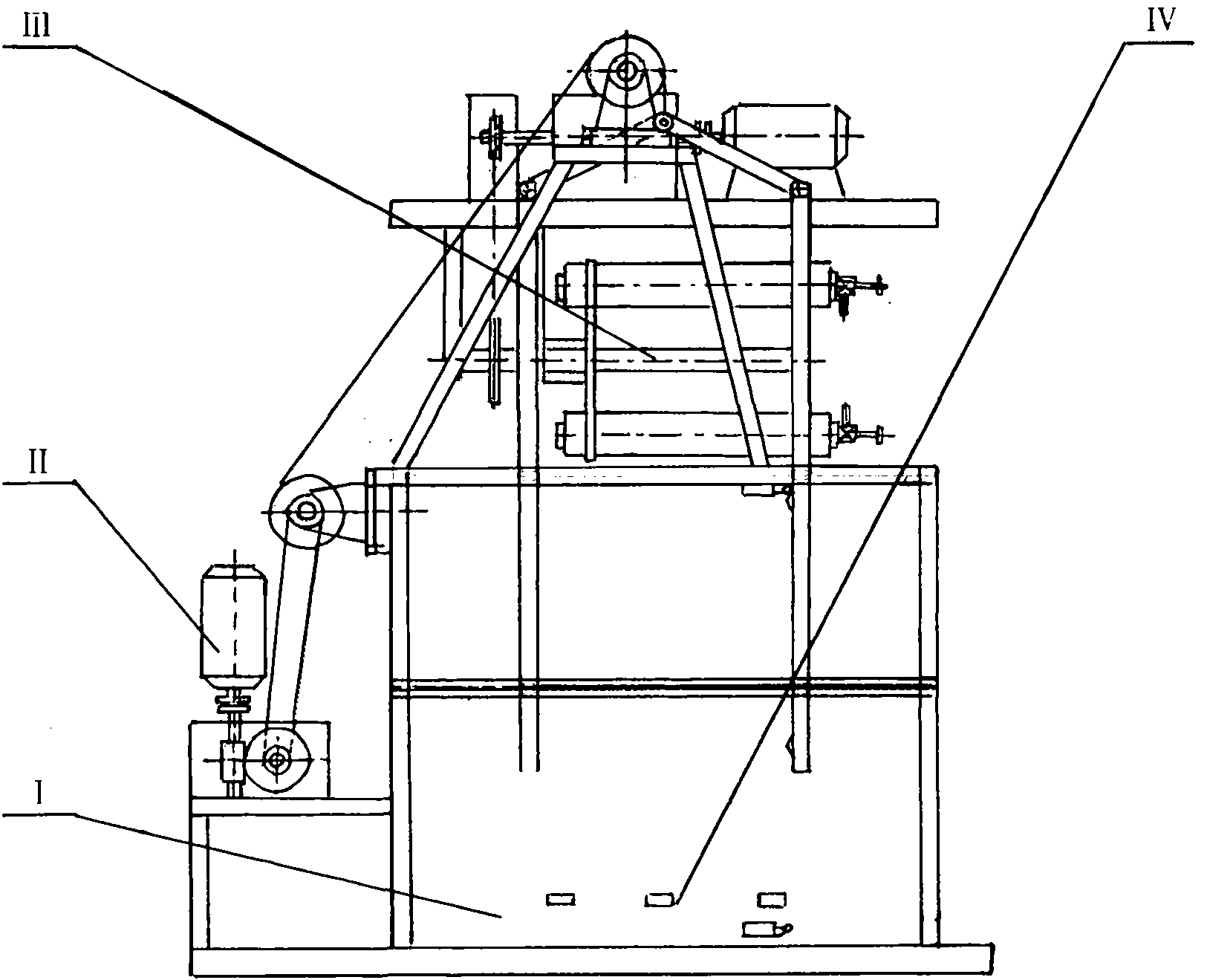

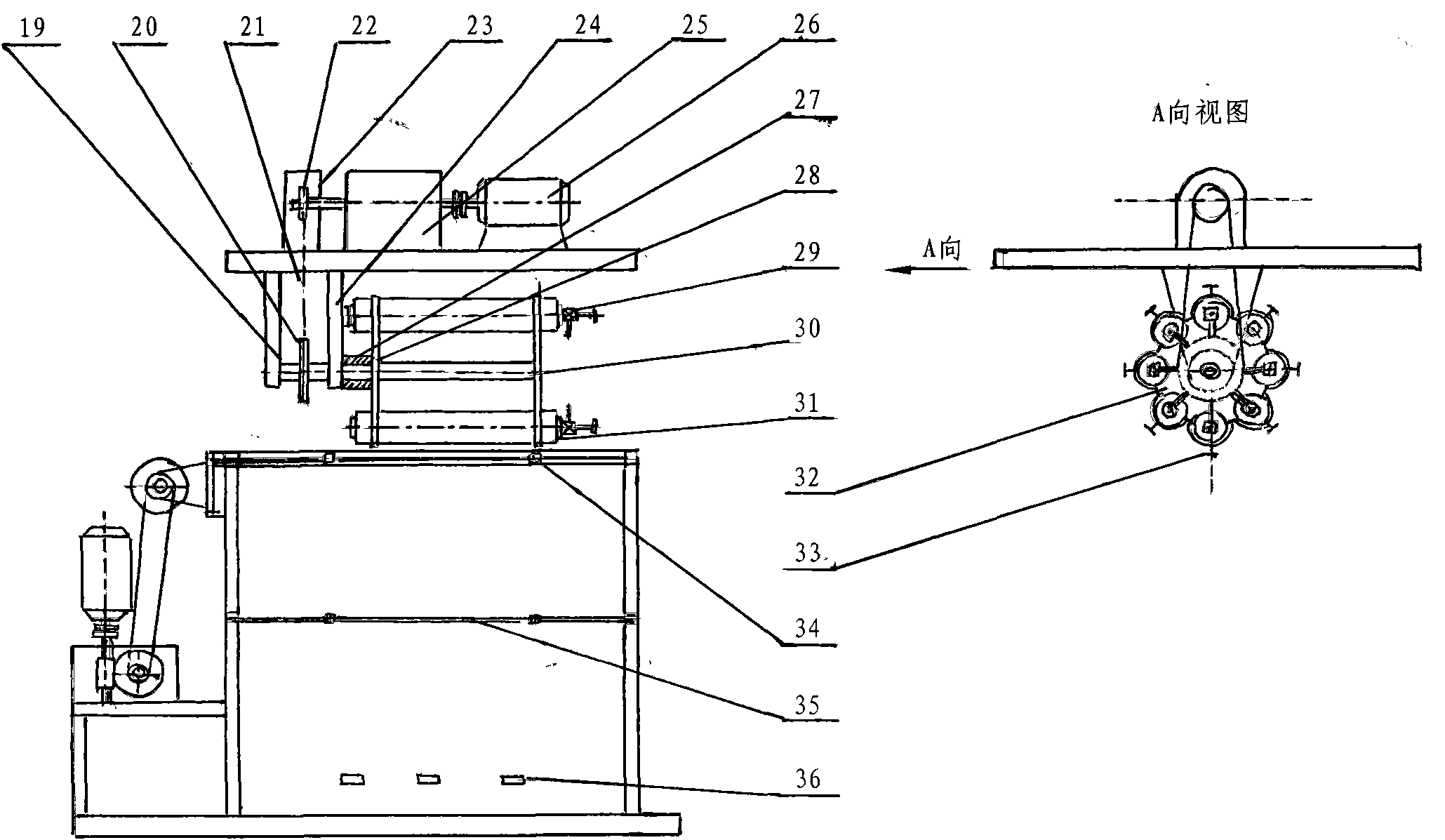

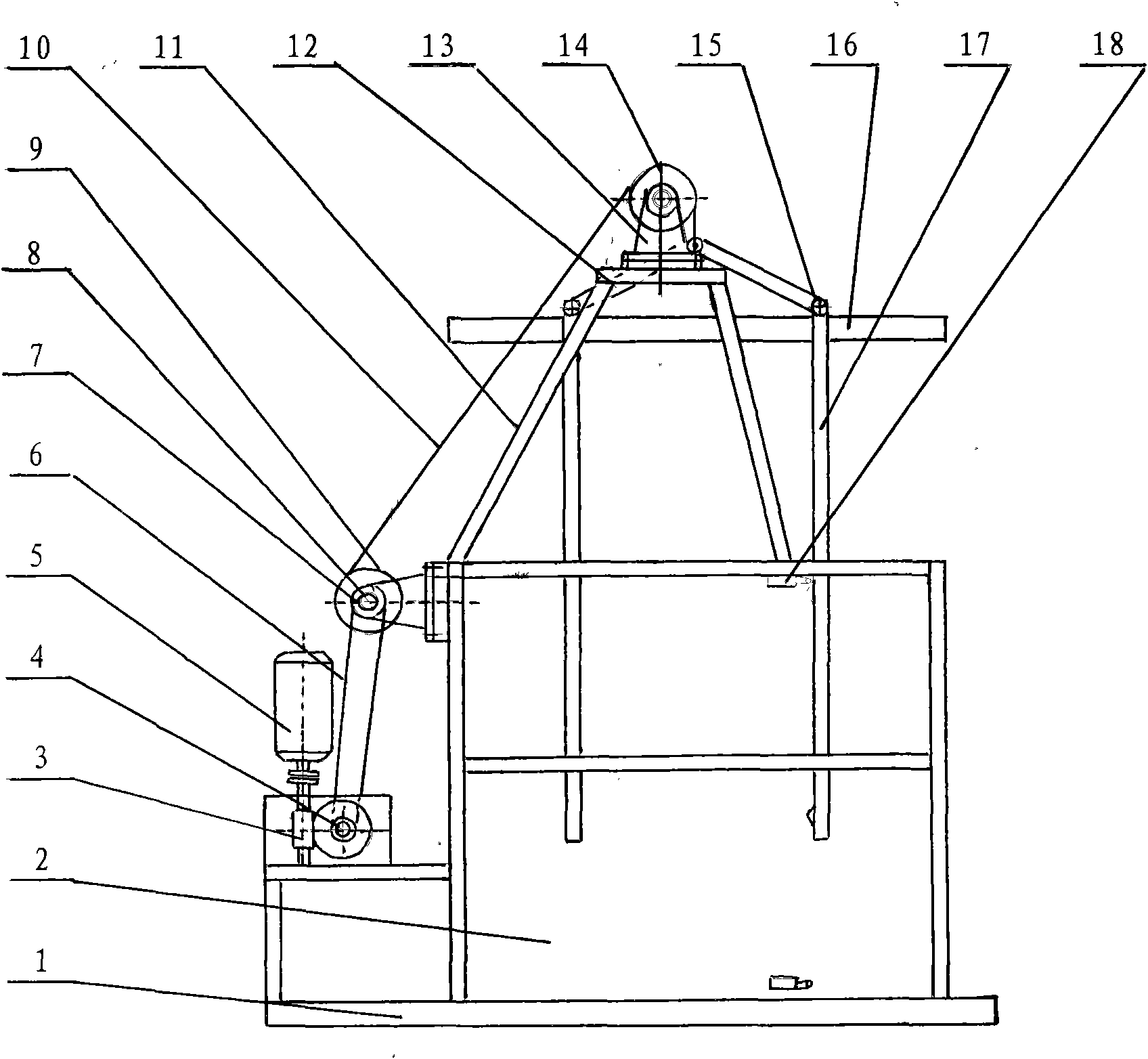

Cooking testing machine for multi-pot papermaking

InactiveCN102072917BReduce media capacitySave test materialMaterial thermal analysisTemperature controlTest efficiency

The invention relates to a group-pot papermaking and cooking test machine. The main structure of this group-pot papermaking and cooking test machine includes four parts: a box body and a frame I. The frame is used to accommodate the box body and support two sets of motion systems, and the box lid motion system Ⅱ, complete the smooth opening and sealing closing of the box lid; the cooking group pot movement system Ⅲ, complete the fixation of the group pots and drive the group pots to rotate around the rotating axis of the faceplate bracket in the box thermal oil; the heating measurement control system Ⅳ, complete the alignment Heating of thermal oil, temperature measurement, display and control. It can complete small-capacity multi-pot cooking at one time, achieving the purpose of saving test materials and improving test efficiency. It also has the characteristics of uniform heating and stirring, precise temperature control, reliable sealing, simple operation, and easy control of the test process.

Owner:KUNMING UNIV OF SCI & TECH

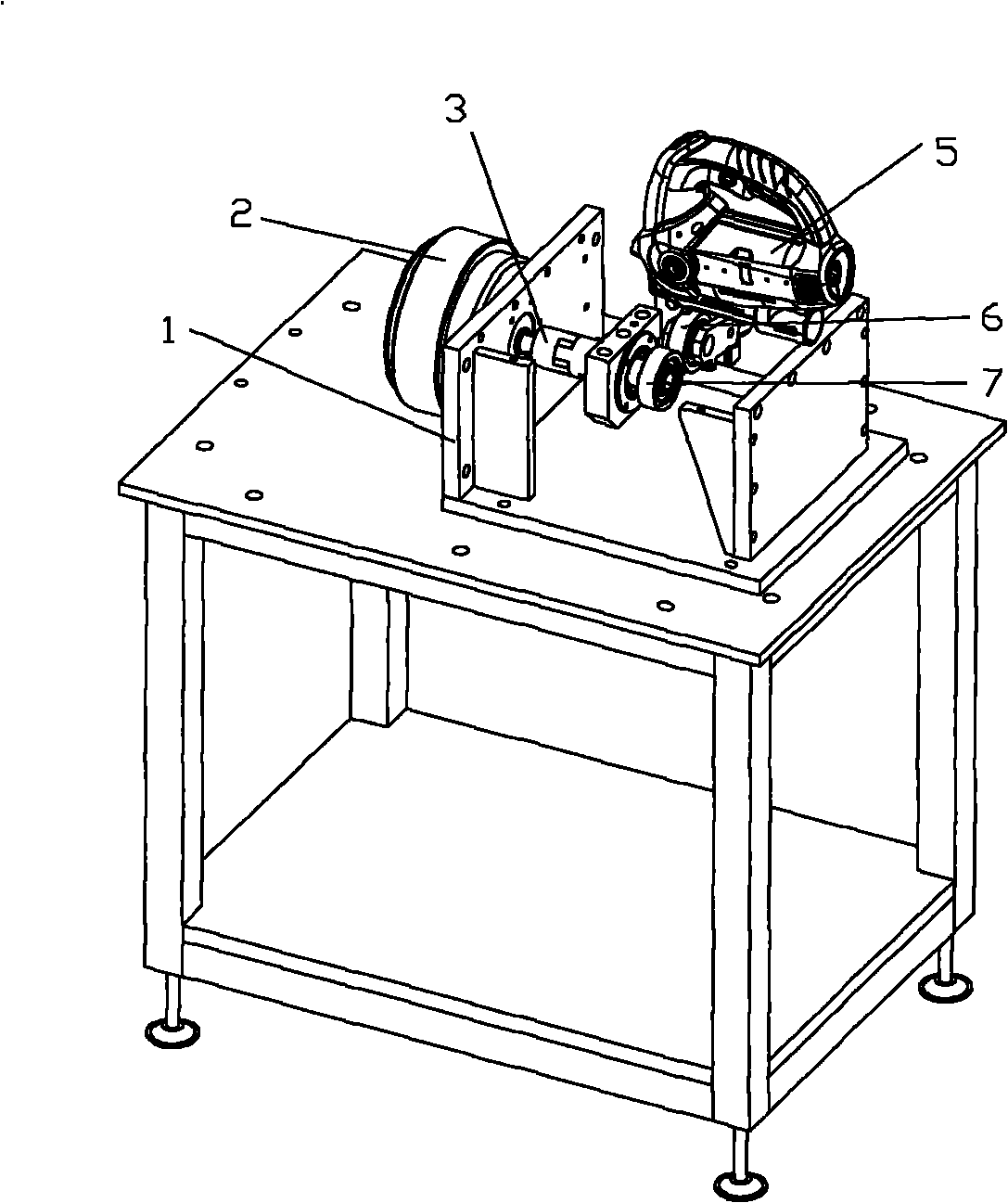

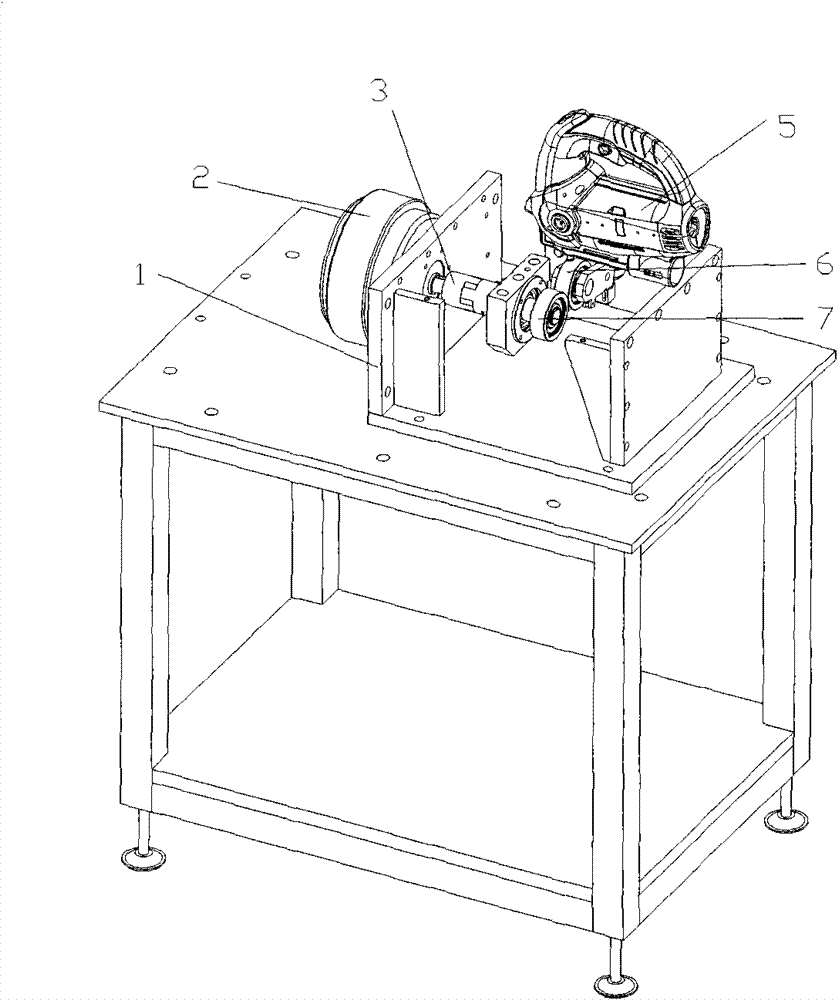

Coping saw load testing device

InactiveCN101788434AImprove test efficiencySave test materialMaterial strength using repeated/pulsating forcesTest efficiencyEngineering

The invention relates to a coping saw load testing device which is characterized in that the testing device comprises a mounting rack (1), a magnetic powder clutch (2) and two rollers (6, 7). The magnetic powder clutch (2) is installed at the outer side of the mounting rack (1), with the output end (3) connected with the roller (6) through a unilateral bearing; and the saw blade of the coping sawto be tested is arranged in the clearance between the two rollers and is clamped by the two rollers. In the process of testing the coping saw, the testing device entirely employs the magnetic powder clutch and the unidirectional bearing to simulate the load under the practical working condition and no real cutting material is used in the testing process. Therefore, the testing device can improve the testing efficiency, save testing material and reduce the testing cost and is simple and convenient to operate.

Owner:南通市乐悦实业有限公司

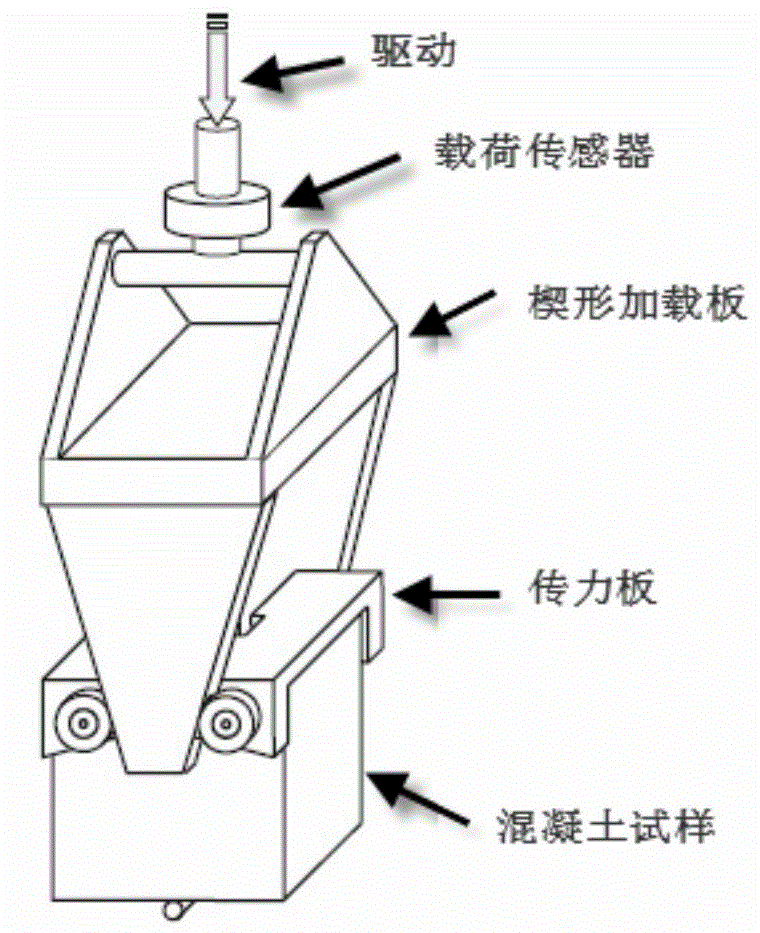

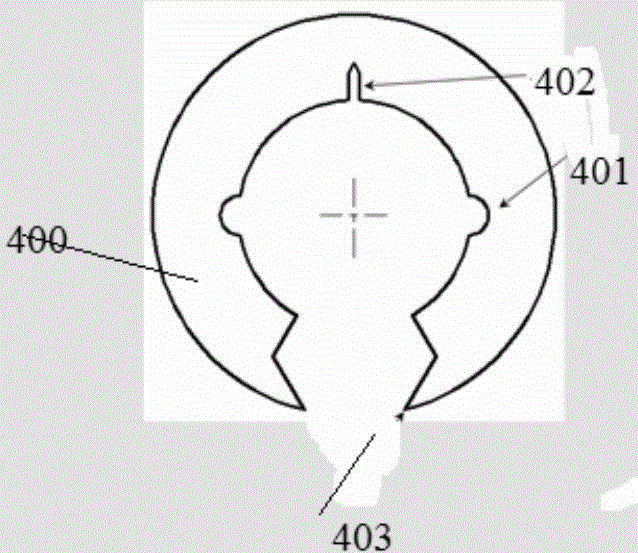

Method and device for wedging test of fracture performance of metallic materials

InactiveCN103558083BGood effectClear principleMaterial strength using tensile/compressive forcesEngineeringVertical load

The invention discloses a metal material fracture property wedge testing method and a metal material fracture property wedge testing device. A force-transmission cotter pin (200) acts on a wedge-shaped loading head (100), a vertical load is applied, is converted into a horizontal load and then is transmitted to a C-shaped ring sample (400); a loading device consists of the wedge-shaped loading head (100), the force-transmission cotter pin (200) and a supporting base (300). The loading mode is changed to realize the fracture property test of metal constructions with small sizes, the test effect is ideal, the structure is simple, the production is convenient, and the method can be used for the fracture property test of metal constructions with big sizes and can realize the effects of saving test materials and reducing experiment cost.

Owner:SOUTHWEST JIAOTONG UNIV

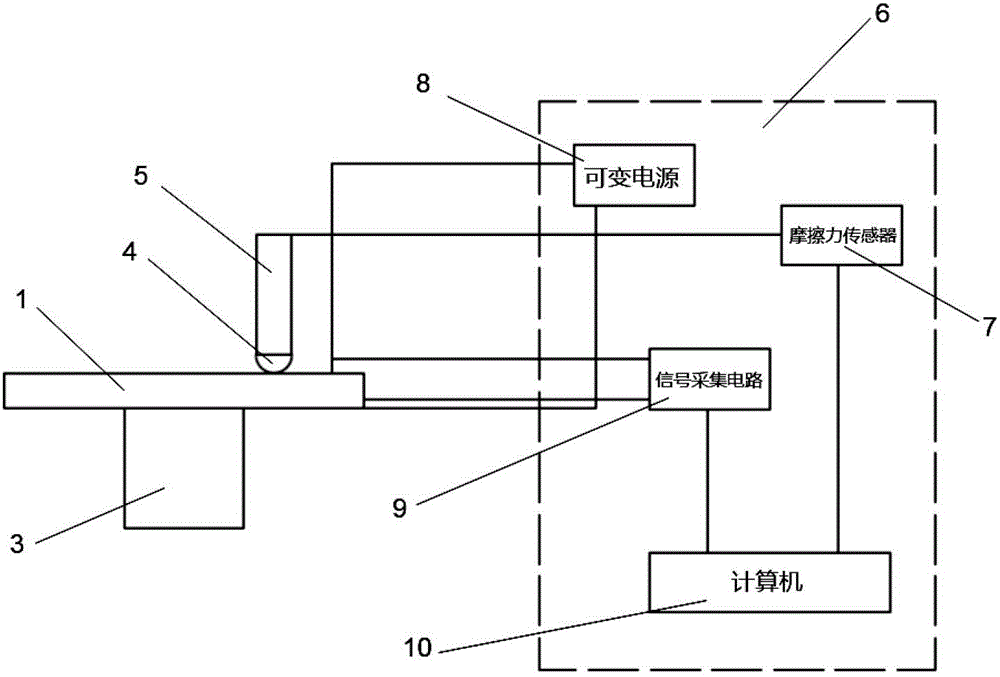

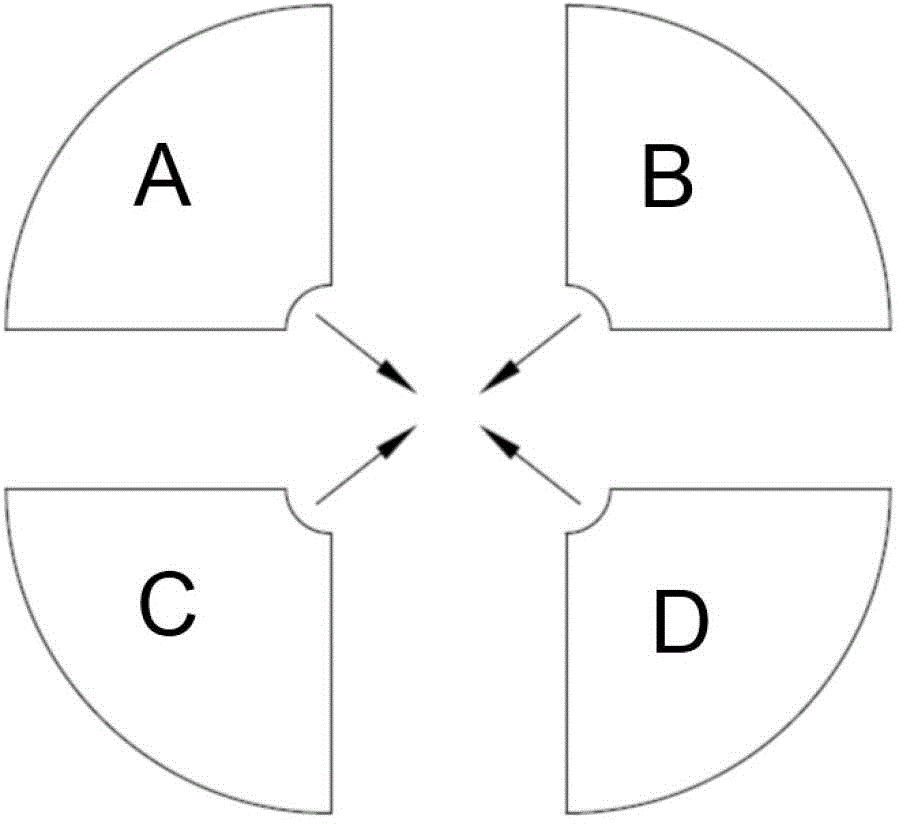

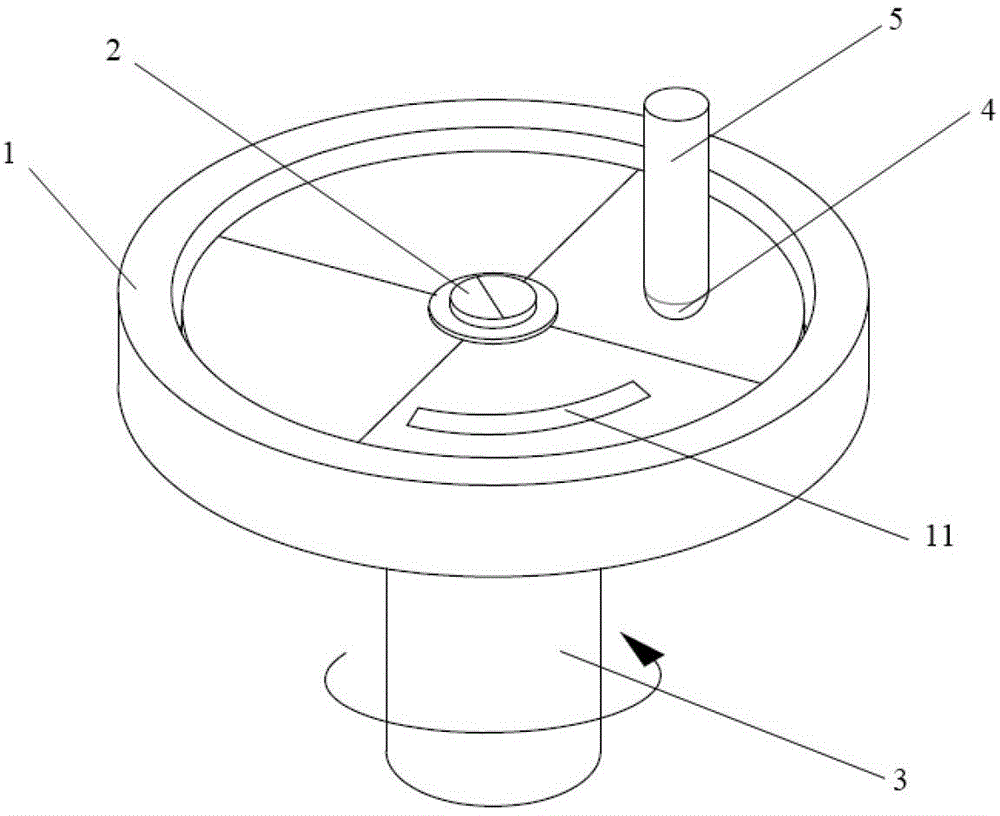

Turntable type multi-sample synchronous friction abrasion testing device and testing method

ActiveCN103308409BEasy to installPracticalInvestigating abrasion/wear resistanceElectrical resistance and conductanceMeasurement device

Owner:SHANGHAI JIAOTONG UNIV

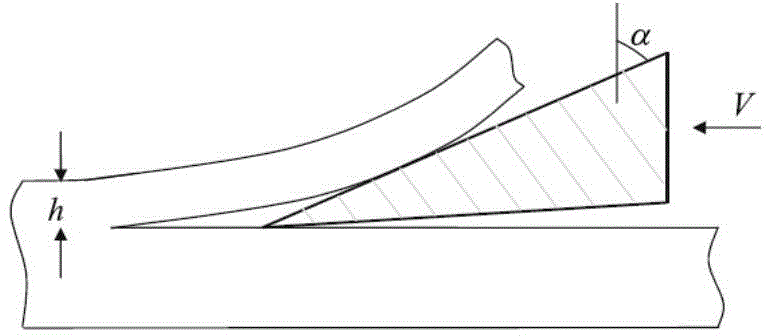

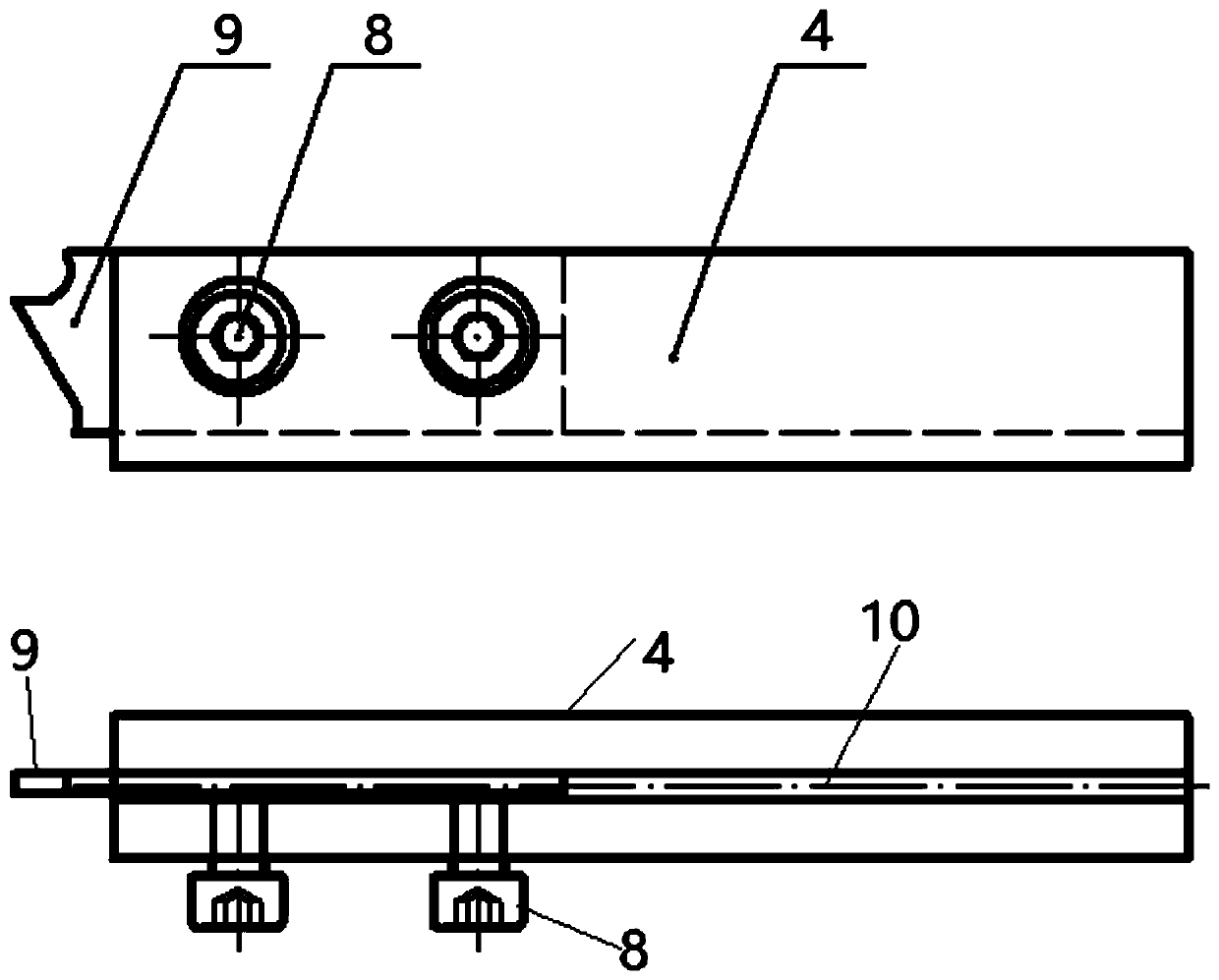

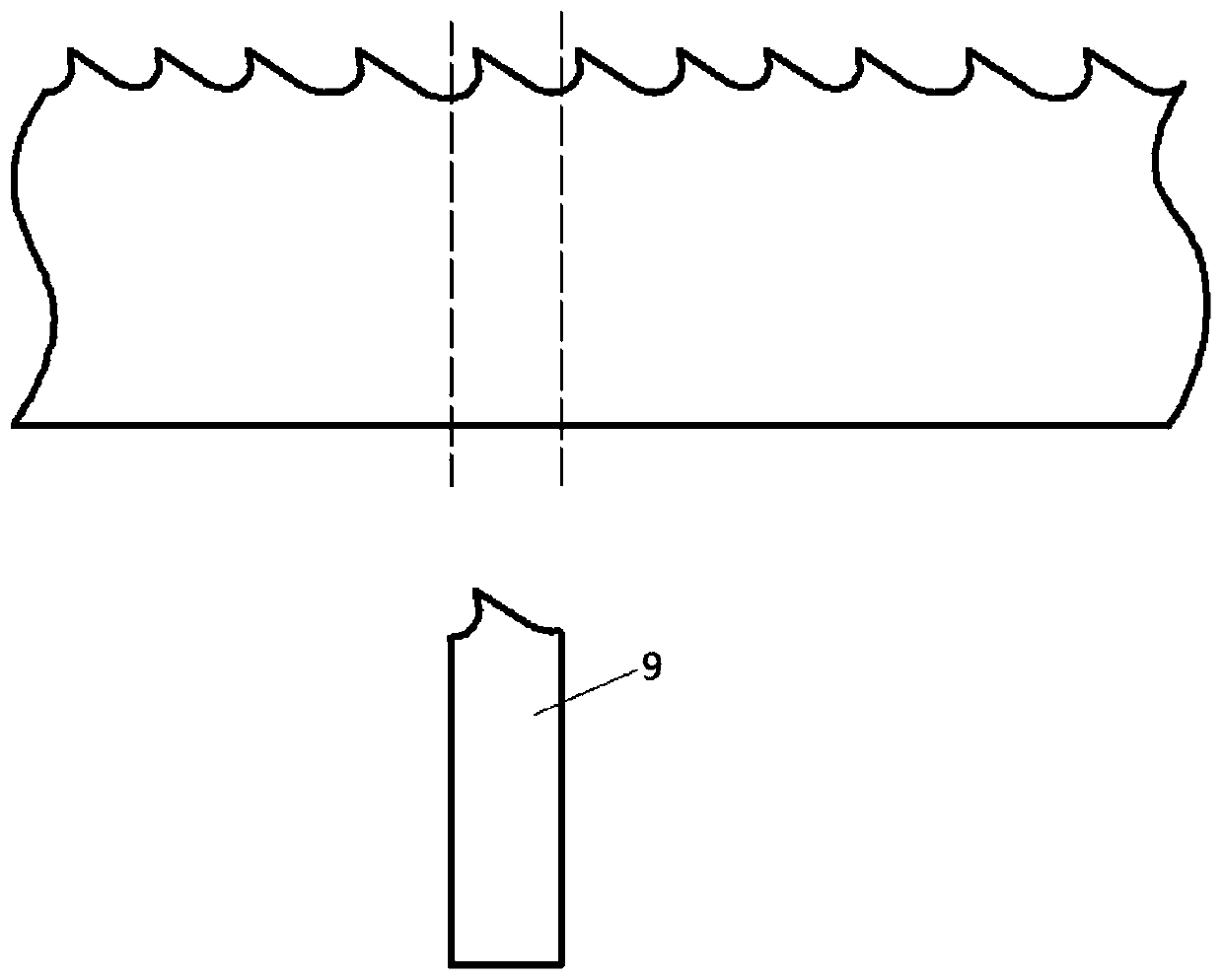

A sawing simulation test device and test method

ActiveCN108020479BSave test materialReduce testing costsInvestigating machinabilityFeeding forceClassical mechanics

The invention relates to a saw cutting simulation testing method. The method comprises the steps that a toothed blade is installed on a blade holder; the relative position of the toothed blade and a workpiece is adjusted through a transmission mechanism, a connecting line of the tooth top of the toothed blade and a workpiece rotation center is parallel to the length direction of the toothed blade,the plane where the toothed blade is located is perpendicular to the axial direction of the workpiece, blade setting is conducted, and cutting simulation testing is ready to be conducted; after bladesetting is completed, constant feed rate simulation cutting testing or constant feed force simulation cutting testing is conducted as needed. Accordingly, a large number of testing materials can be saved, and the testing cost is reduced; a saw cutting simulation testing device is wide in application, people only need to make adaptive change on the blade holder, and then the device can be applicable to simulating testing of band saw blades of various specifications; the influence caused by the factors such as equal altitude and tooth amount error of the band saw blade manufacturing process onthe testing process is eliminated, abrasion resistance and tooth-shaped cutting force of single sawtooth are detected directly, and meanwhile data is stable.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

Coping saw load testing device

InactiveCN101788434BImprove test efficiencySave test materialMaterial strength using repeated/pulsating forcesTest efficiencyEngineering

The invention relates to a coping saw load testing device which is characterized in that the testing device comprises a mounting rack (1), a magnetic powder clutch (2) and two rollers (6, 7). The magnetic powder clutch (2) is installed at the outer side of the mounting rack (1), with the output end (3) connected with the roller (6) through a unilateral bearing; and the saw blade of the coping sawto be tested is arranged in the clearance between the two rollers and is clamped by the two rollers. In the process of testing the coping saw, the testing device entirely employs the magnetic powder clutch and the unidirectional bearing to simulate the load under the practical working condition and no real cutting material is used in the testing process. Therefore, the testing device can improve the testing efficiency, save testing material and reduce the testing cost and is simple and convenient to operate.

Owner:南通市乐悦实业有限公司

Testing device for load of jig saw

ActiveCN101769839BImprove test efficiencySave test materialMaterial strength using repeated/pulsating forcesTest efficiencyClassical mechanics

The invention relates to a testing device for load of a jig saw, which is characterized in that the testing device comprises a load simulator (100), a jig saw fixing device and a frame (8), wherein the load simulator (100) comprises a mounting bracket (3), a magnetic powder clutch (4) and two rollers (1 and 2); the magnetic powder clutch (4) is arranged below the mounting bracket (3), and the output end of the magnetic powder clutch (4) is connected with the roller (2) through a one-way bearing; a cantilever of the jig saw fixing device is arranged at the outer side of the frame (8) and consists of a cantilever (5) and a fixing part (6); and a jig saw blade to be tested is arranged in a clearance between the two rollers and clamped by the two rollers. During the testing process of the jigsaw, the load under actual conditions is simulated through the magnetic powder clutch and the one-way bearing completely, and the actual cutting material is not needed during the testing process, therefore the testing device has the characteristics that the testing efficiency is improved, the testing material is saved, the testing cost is reduced, and the operation is simple and convenient.

Owner:SUZHOU INDAL PARK TAIGE ELECTRONICS SCI &TECH

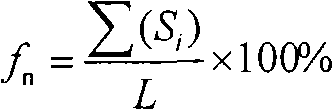

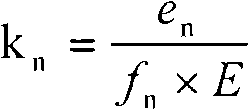

Impact energy test of metallic weld seam and calculation method

ActiveCN101975702BReduce repetitive testingSave test materialStrength propertiesWeld seamTest material

The invention relates to an impact energy test of a metallic weld seam and a calculation method. The calculation method comprises the following steps: 1. calculating the fine grain proportion of an impact specimen of the metallic weld seam; 2. carrying out the impact test on parent metal and the metallic weld seam; 3. calculating the impact energy and the proportional constant k of the parent metal and the metallic weld seam; and 4. calculating the impact energy of the target metallic weld seam according to the formula (4) e=f*k*E to obtain the impact energy e of the target metallic weld seam. The invention can reduce trivial repeatability tests, save a large quantity of test materials and lower the test cost.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Method for preparing isometric crystal high temperature alloy casting alloy/ceramic interface reaction test sample

ActiveCN102416464BImprove test efficiencySave test materialPreparing sample for investigationSuperalloyReaction mechanism

The invention relates to a method for preparing an isometric crystal high temperature alloy casting alloy / ceramic interface reaction test sample, which comprises the following steps of: preparing a shell mold in which ceramic cores are arranged by the traditional investment casting process; heating the shell mold in a heater of a directional solidification vacuum induction furnace to different temperatures at which alloy / ceramic interface reaction is expected to be performed, and preserving heat; remelting a high temperature alloy ingot, pouring into a cavity of the shell mold, and pulling the heater out at a certain speed to form directional solidification castings or test samples with the cores; and cutting the directional solidification castings or test samples at different heights to acquire data of alloy and ceramic which react at the same temperature for different time. The method has the advantages that: the interface reaction time can be steplessly changed according to sampling positions, so that test efficiency is improved; the interface reaction results of the ceramic cores with different components can be obtained in one module at the same time; and the interface reaction condition can be visually observed by a microscope, so that reaction products and a reaction mechanism are determined, and the actual production of the isometric crystal castings is instructed.

Owner:GUIYANG AVIC POWER PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com