Controller for bending and forming wire rod

A technology of bending forming and controller, applied in the direction of digital control, electrical program control, etc., can solve the problems of time-consuming, equipment damage, and the difficulty of increasing use by users, and achieve the effect of saving test materials and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

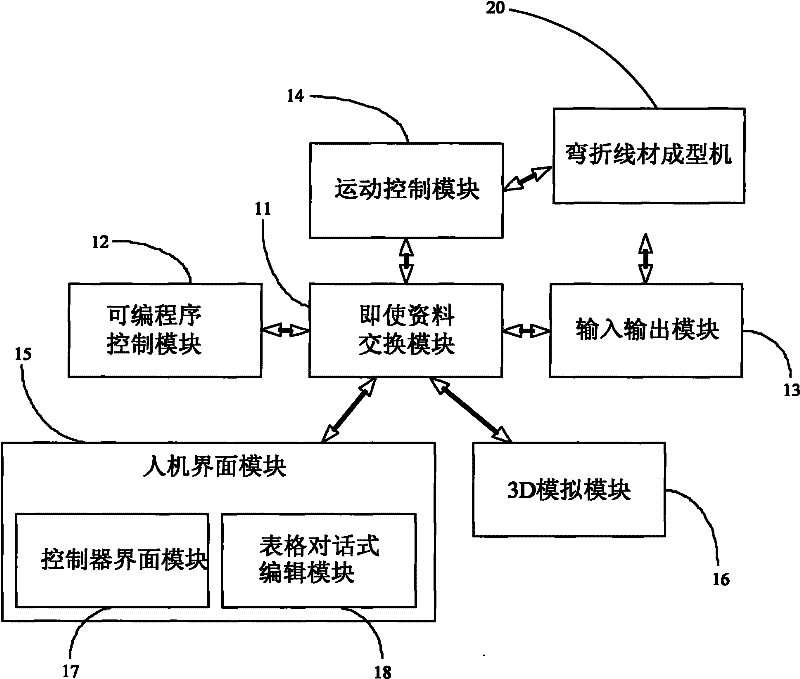

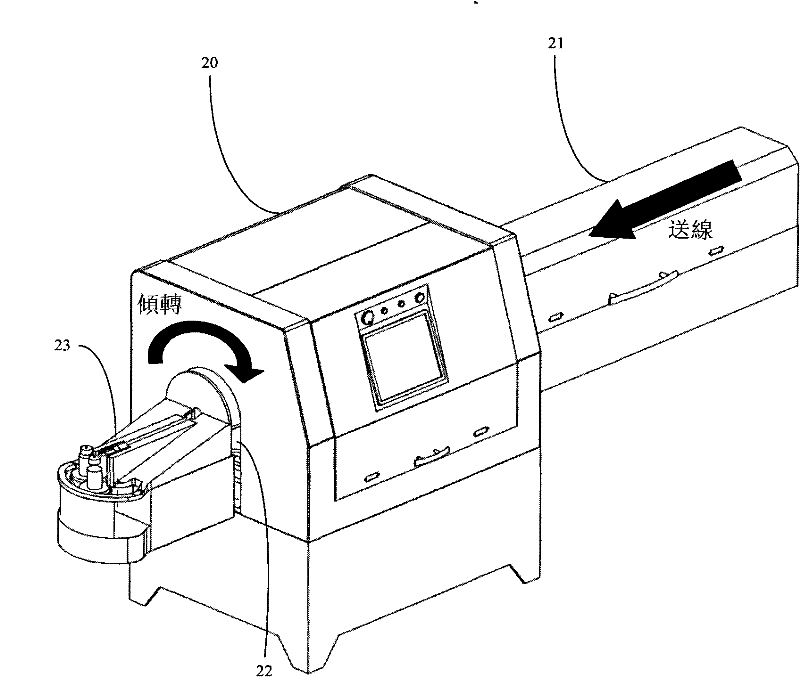

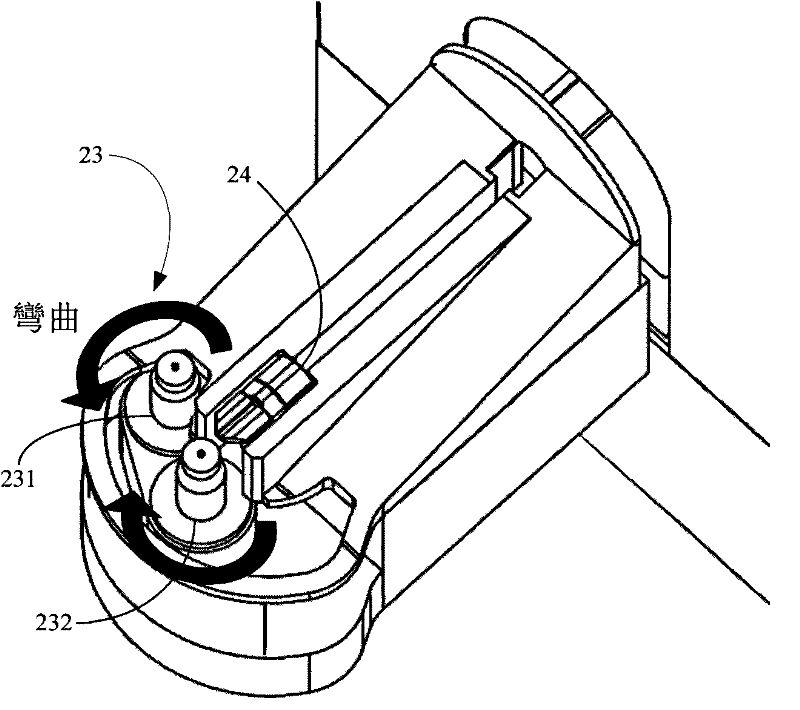

[0033] Please refer to FIG. 1 , the wire bending and forming controller of the present invention is a general-purpose processing auxiliary system cooperating with a bending wire forming machine 20 for processing and forming flexible wires. It is mainly composed of a general-purpose industrial computer host, which includes: real-time data exchange module 11, programmable logic controller module 12, input / output (I / O) module 13, motion control module 14, man-machine interface module 15 and 3D simulation module 16.

[0034] The real-time data exchange module 11 is responsible for handling the data access and exchange between modules. There is no direct data exchange between modules. The data of all modules is only accessed by the data exchange modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com