Method for measuring deformation condition of bulk material interfacial effect of material distribution model of blast furnace

A technology of interface effect and measurement method, applied in blast furnaces, furnace types, measuring devices, etc., can solve the problems of increasing difficulty in the shape of the material surface, segregation and rolling, and change of the shape of the ore coke material surface, so as to save test materials and test charges. , Reduce the test workload, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below by embodiment, the present invention will be further described.

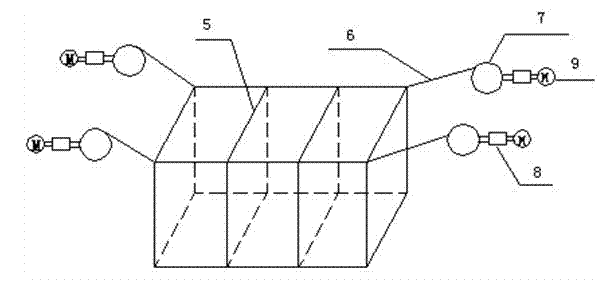

[0023] An example is the deformation aspect of interface effects within a blast furnace cloth model.

[0024] In the process of distributing materials, due to the impact and pushing of the upper layer of charge on the lower layer of charge, the surface of the charge is irregularly deformed. The main manifestations are: segregation, rolling and even collapse of bulk materials. Through the research, it is found that the deformation of the interface effect is mainly caused by the rolling of the charge along the horizontal direction, and the deformation mainly occurs where the shape of the charge surface has a slope.

[0025] The cross-sectional shape of the material surface is essentially the change curve along the radial section of the blast furnace after a batch of material is placed into the furnace. Most of the cloth is multi-ring cloth, and the shape of the furnace throat material surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com