High-voltage frequency converter model selection method based on simulation

A high-voltage inverter, simulation model technology, applied in the direction of instruments, starter parts, special data processing applications, etc., can solve the problems of affecting project progress, increasing cost investment, current changes, etc., to save test costs, and simplify the design method. , the effect of increasing the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The embodiment of the present invention provides a method for selecting a high-voltage inverter based on simulation. The high-voltage inverter is used to start a high-power motor load, which solves the problem that it is difficult to select a suitable high-voltage inverter for large or even super-large high-voltage motors.

[0039] In order to achieve the above-mentioned technical effects, the general idea of the application is as follows:

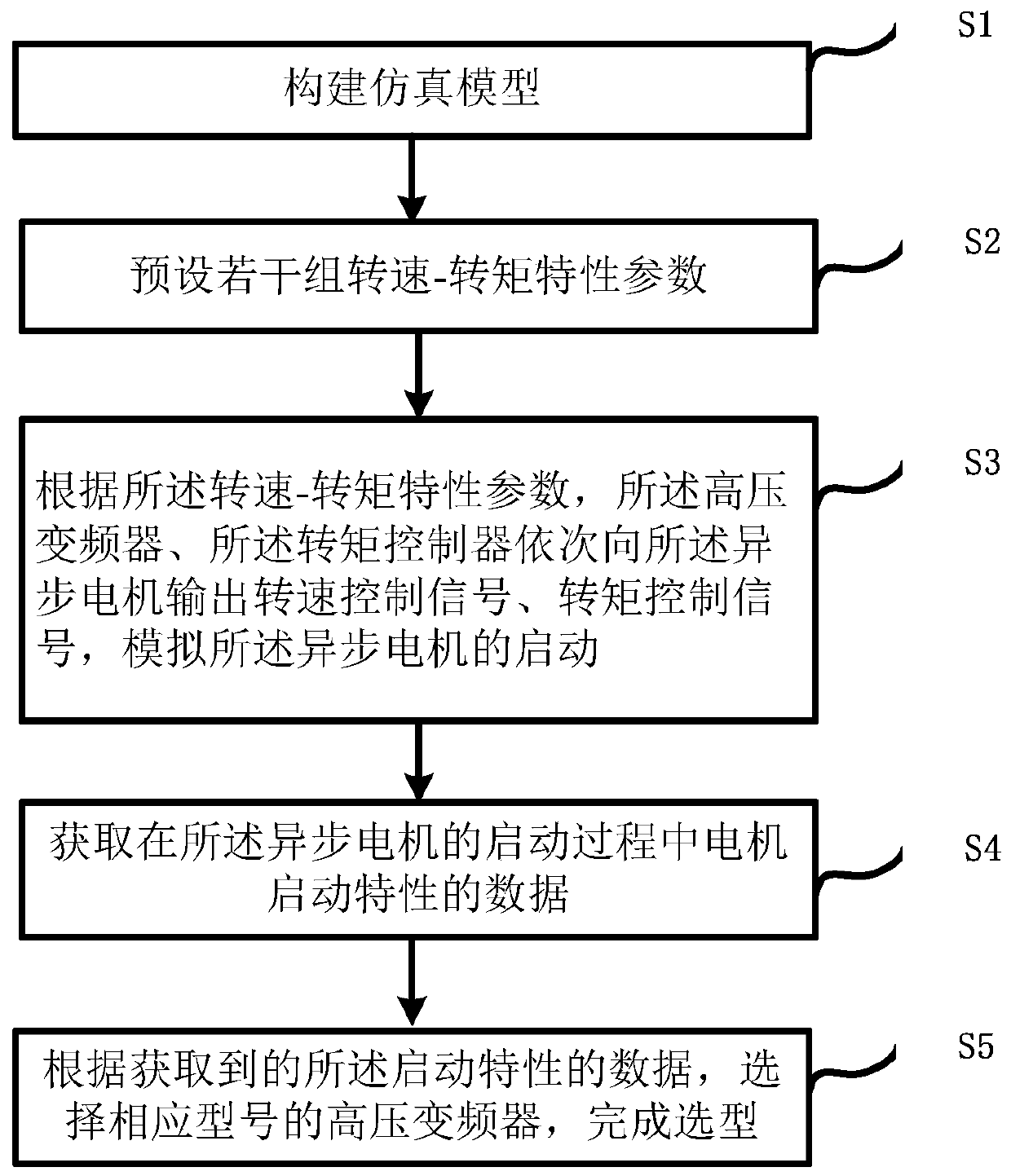

[0040] see figure 1 As shown, the embodiment of the present invention provides a method for selecting a high-voltage inverter based on simulation, and the high-voltage inverter is used for starting a high-power motor load. The steps of the method include:

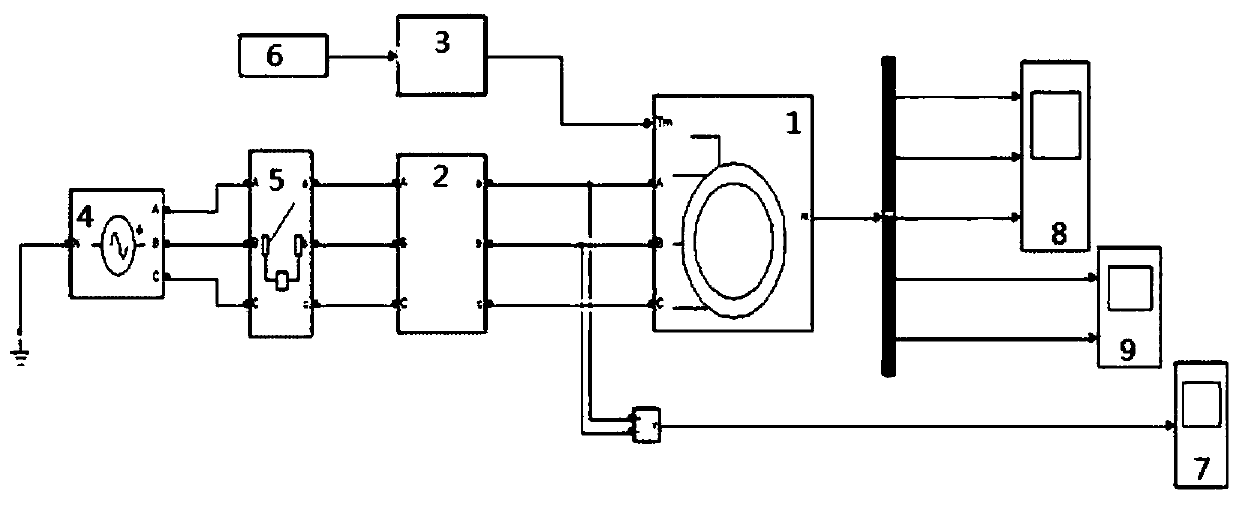

[0041] Step S1: Build a simulation model, such as figure 2 As shown, the simulation model includes an asynchronous motor 1, a high-voltage frequency converter 2 coupled with the asynchronous motor 1, and a torque controller 3 coupled with the asynchronous motor 1; wherein, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com