Pre-stress lining design method for shield tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

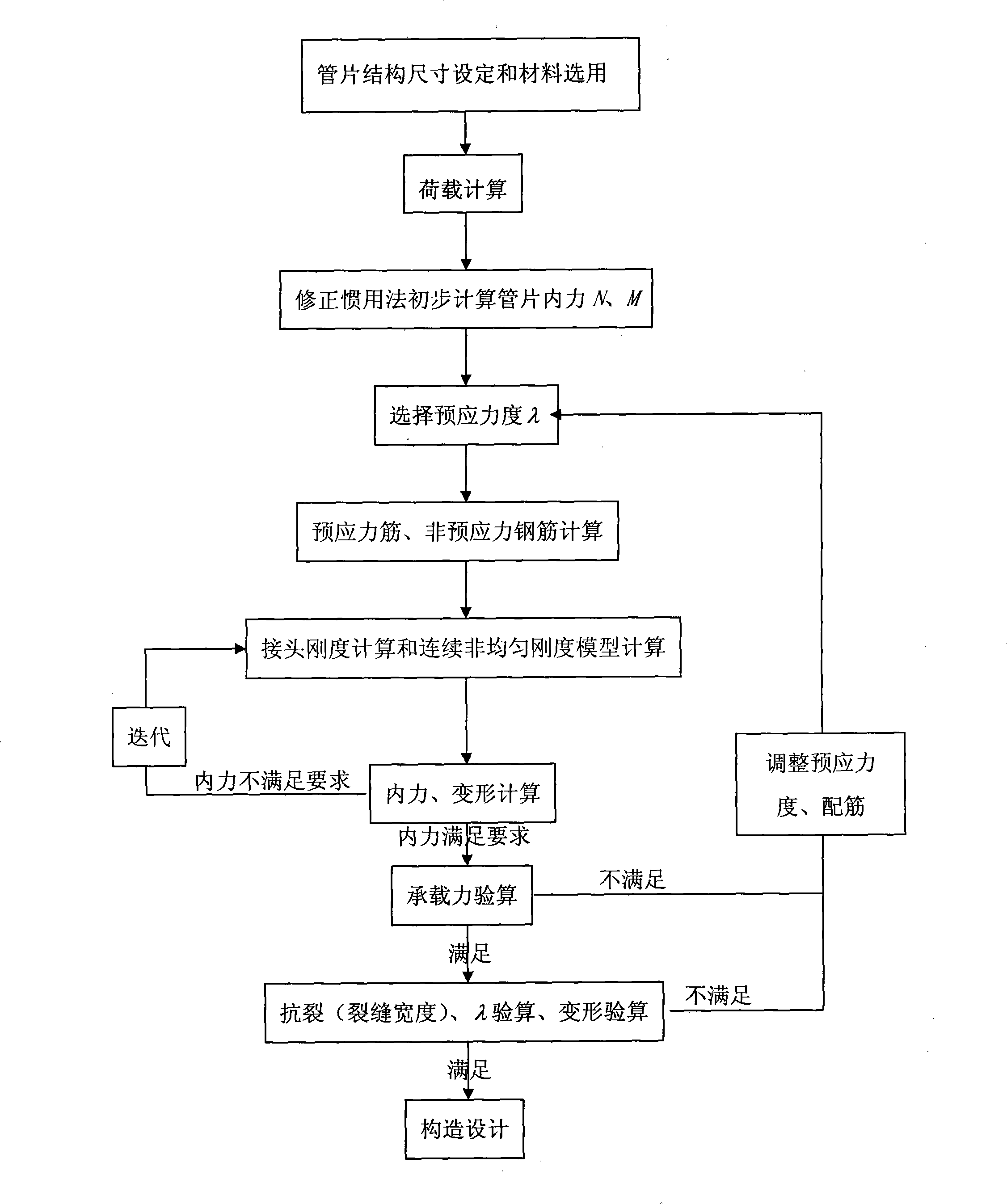

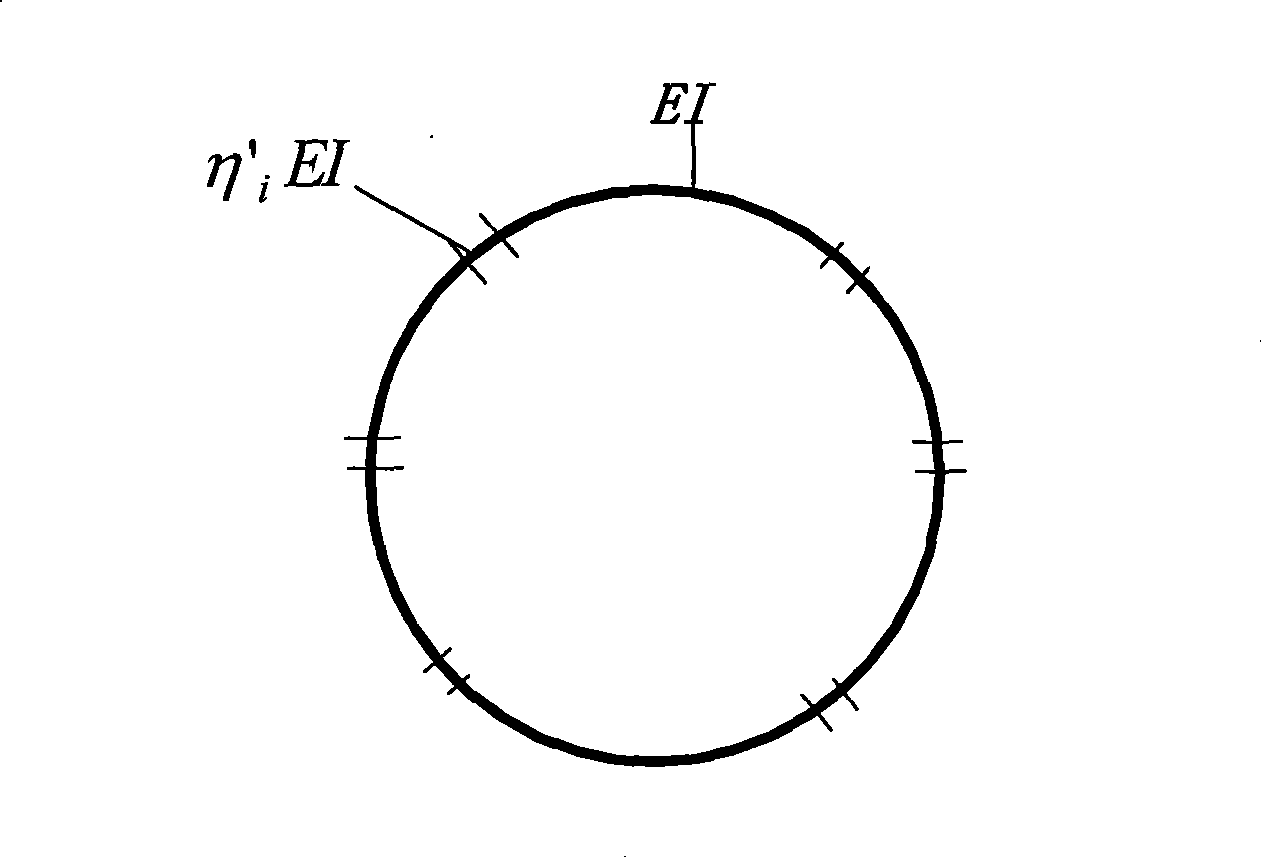

Method used

Image

Examples

Embodiment Construction

[0029] Before designing, several key issues in the design of prestressed lining of shield tunnels should be solved first:

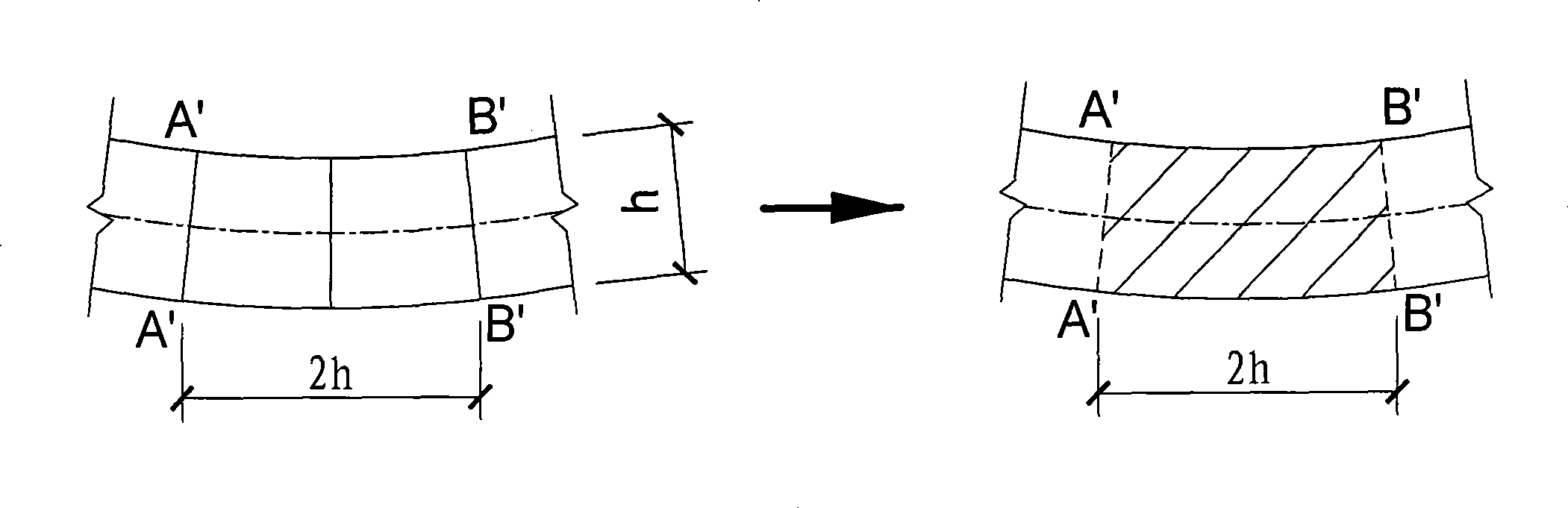

[0030] 1. Calculation of opening angle of prestressed lining joints

[0031] The opening angle calculation of prestressed lining joints can be carried out according to the following formula:

[0032] 1 4 E c ′ bxθ - T p - E p A p Δ l ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com