Impact energy test of metallic weld seam and calculation method

A technology of impact energy and impact sample, which is applied in the field of metal weld impact energy test and calculation, can solve the problems of high test cost, cumbersome process, irregular sample notch processing, etc., to reduce test cost and save test materials , reduce the effect of repeated experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below according to specific embodiments,

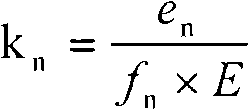

[0036] 1. Take P92 steel weld impact samples numbered 1-8, conduct macroscopic metallographic observation on both sides, and calculate the fine grain ratio f according to formula (1) n , as shown in Table 2 after calculation.

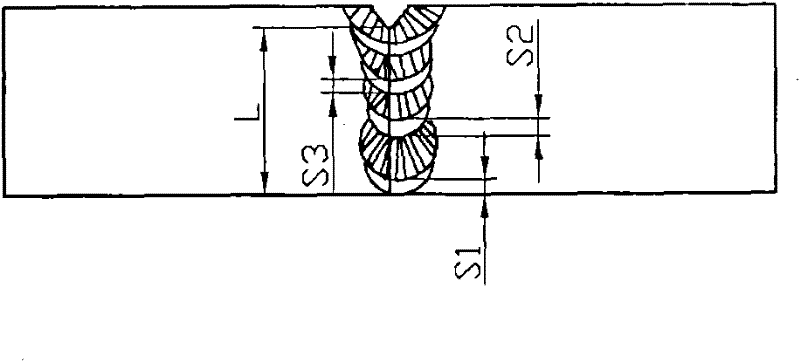

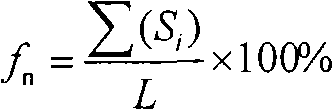

[0037] f n = Σ ( S i ) L × 100 % Formula 1)

[0038] Among them, S i is the length of the i-th fine grain at the side of the P92 steel weld, in mm; L is the length of the side of the P92 weld, in mm;

[0039] 2. Conduct an impact test on the P92 steel parent materials numbered A, B and C. The test steps are:

[0040] Take three 55mmx10mmx10mm P92 steel base materials numbered A, B and C and eight 55mmx10mmx10mm P92 st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weld impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com