Testing device for load of jig saw

A technology of load testing and curve sawing, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of increased cost, material waste, high work intensity, etc., and achieve easy operation and save testing materials, the effect of reducing the cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Attached below Figure 1-2 The technical solution of the present invention is described in detail.

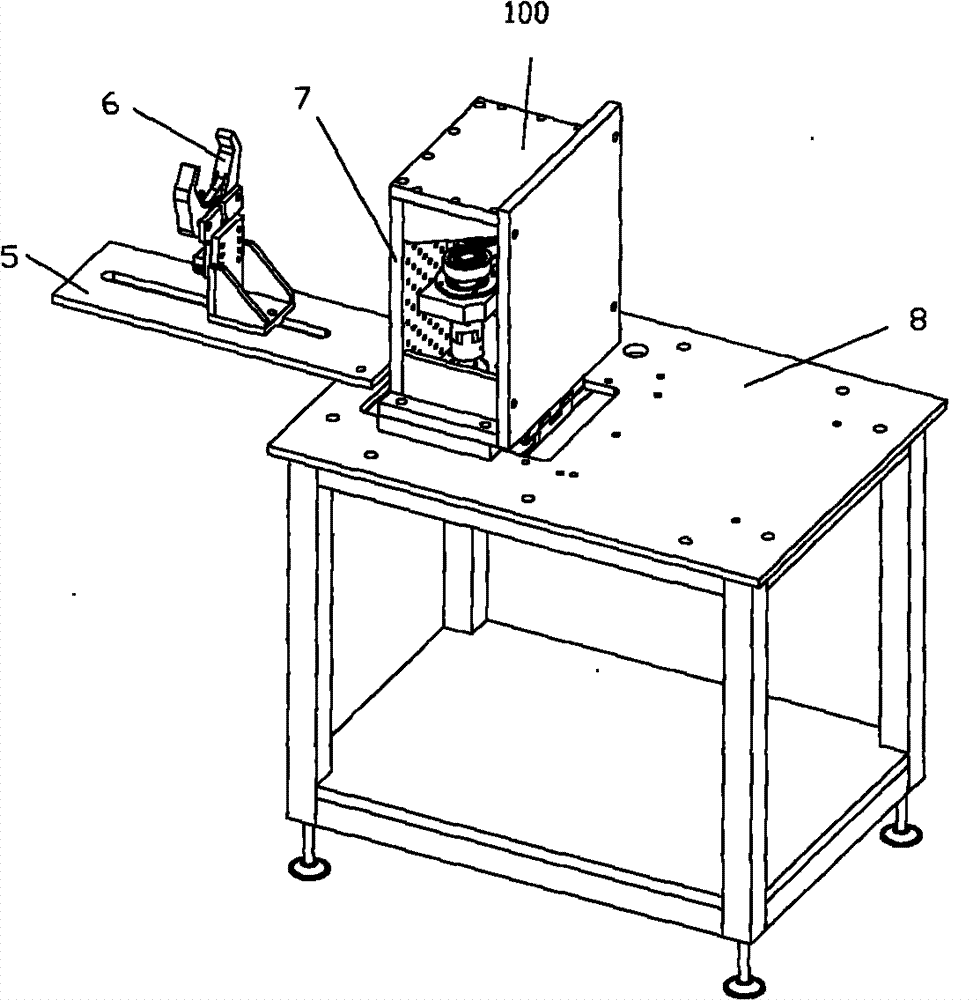

[0013] The jigsaw load testing device includes a load simulation device 100 , a jigsaw fixing device and a frame 8 .

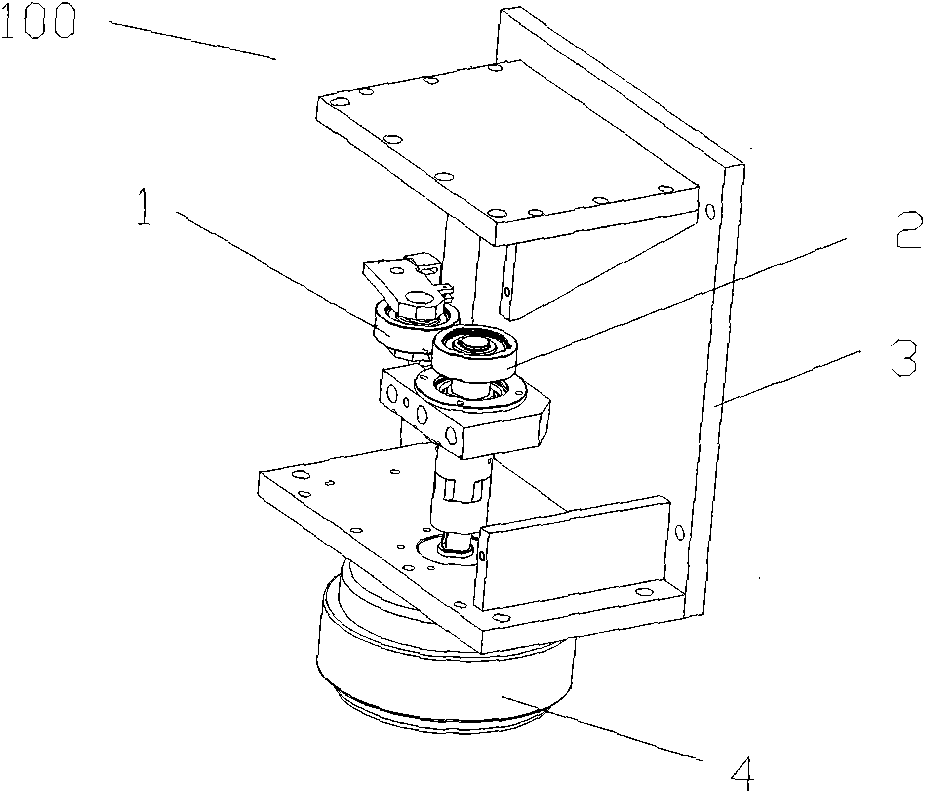

[0014] The load simulation device 100 includes a mounting frame 3, a magnetic powder clutch 4, and rollers 1, 2; the magnetic powder clutch 4 is installed at the lower end of the mounting frame 3, and its output end is connected with the roller 2 through a one-way bearing , the one-way bearing can only rotate freely in one direction, but cannot rotate in the other direction. There is a gap between the rollers 1 and 2. During the test, the saw blade of the jigsaw to be tested is located in the gap and clamped by the rollers 1 and 2. The load simulation device 100 is installed on the frame 8 through an opening in the frame 8 .

[0015] On the outside of the frame 8, the cantilever is provided with the jigsaw fixing device; the fixing device is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com