Coping saw load testing device

A technology of load testing and curve sawing, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc. It can solve the problems of reduced strength of the saw blade, high working intensity, fatigue of the saw blade, etc., so as to reduce the test cost, save test materials, The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

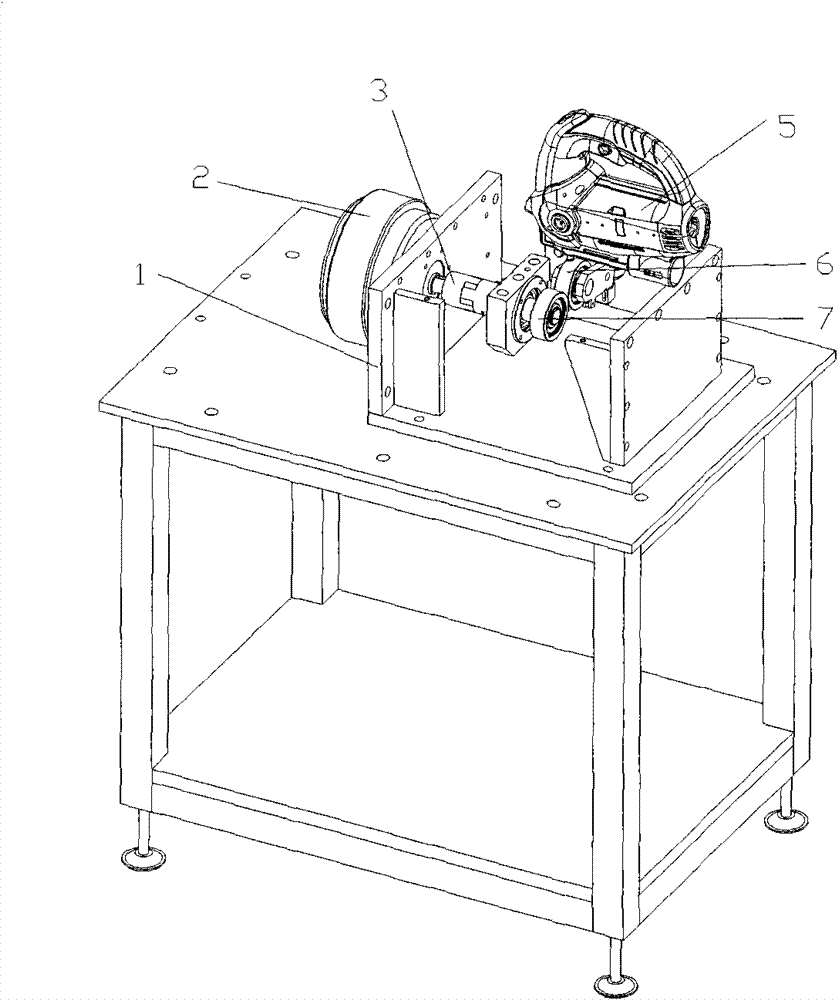

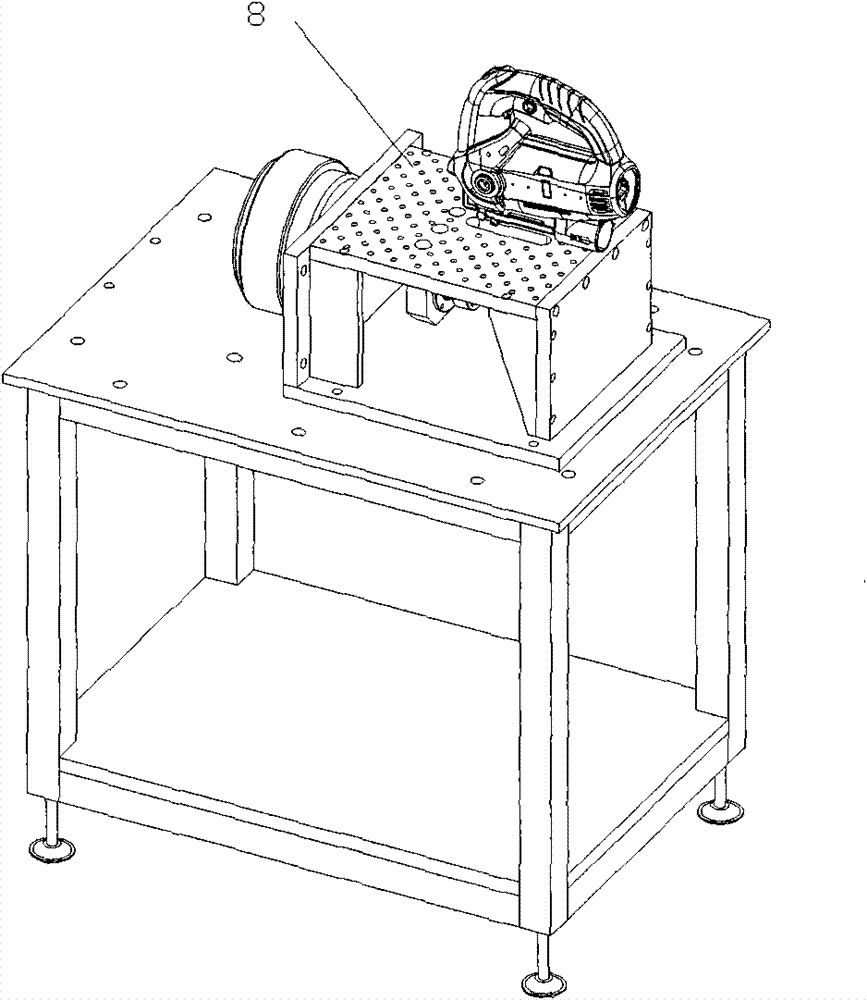

[0010] Attached below Figure 1-2 The technical solution of the present invention is described in detail.

[0011] The jigsaw load testing device includes a mounting frame 1, a magnetic powder clutch 2, and rollers 6, 7; the magnetic powder clutch 2 is installed on the outside of the mounting frame 1, and its output end 3 is connected to the roller through a one-way bearing. 6, the one-way bearing can only rotate freely in one direction, but cannot rotate in the other direction. There is a gap between the rollers 6 and 7. During the test, the saw blade of the jigsaw 5 to be tested is located in the gap and clamped by the rollers 6 and 7.

[0012] Due to the characteristics of the sawtooth structure of the jigsaw, when the jigsaw is working, the saw blade reciprocates along the cutting direction. The saw blade is free.

[0013] Therefore, the present invention utilizes the resistance produced by the magnetic powder clutch 2 to simulate the load received by the jigsaw in actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com