Cooking testing machine for multi-pot papermaking

A technology of testing machines and group pots, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large waste of raw materials, large capacity, and long test process time, and achieve the effect of reducing medium capacity and saving test materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

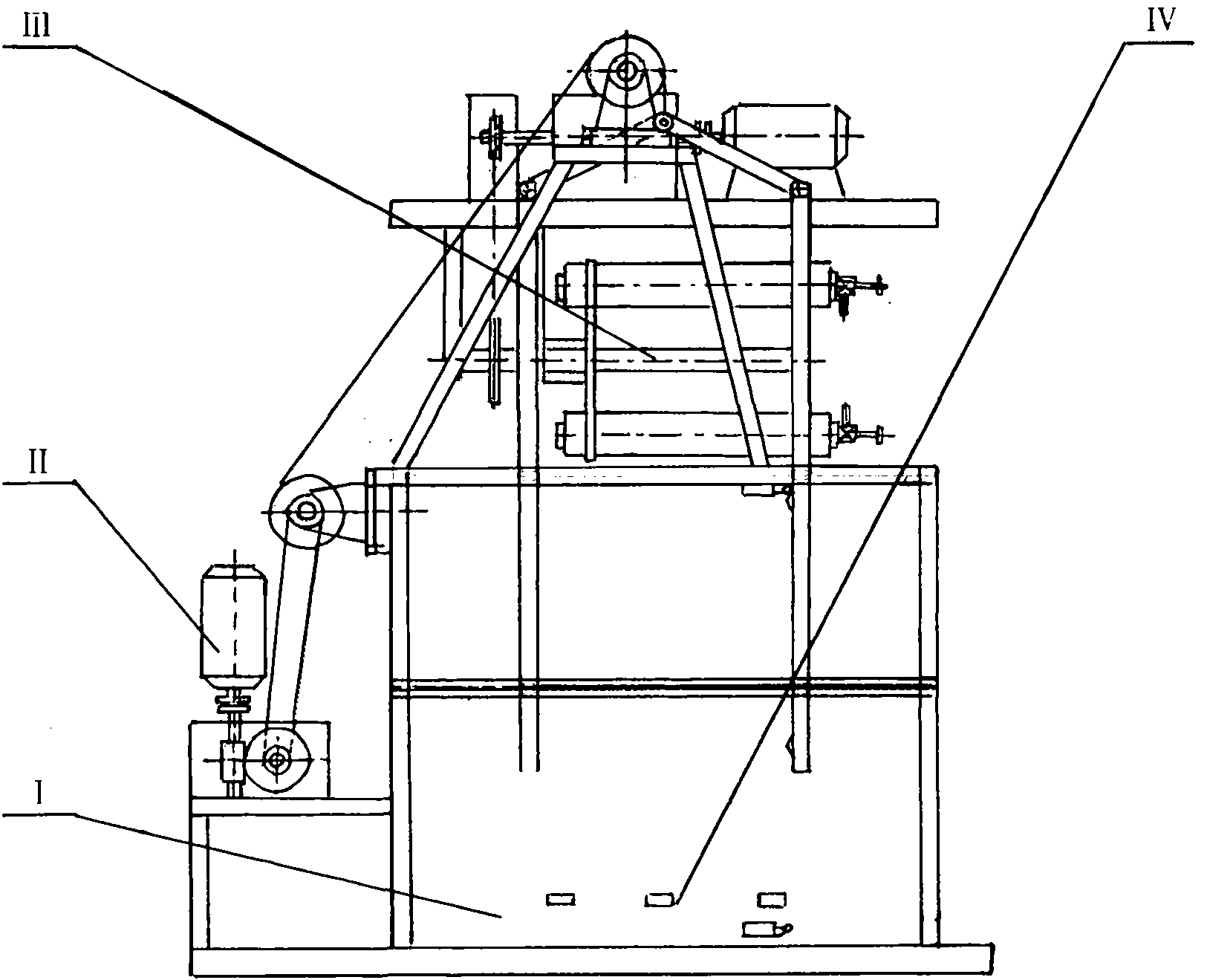

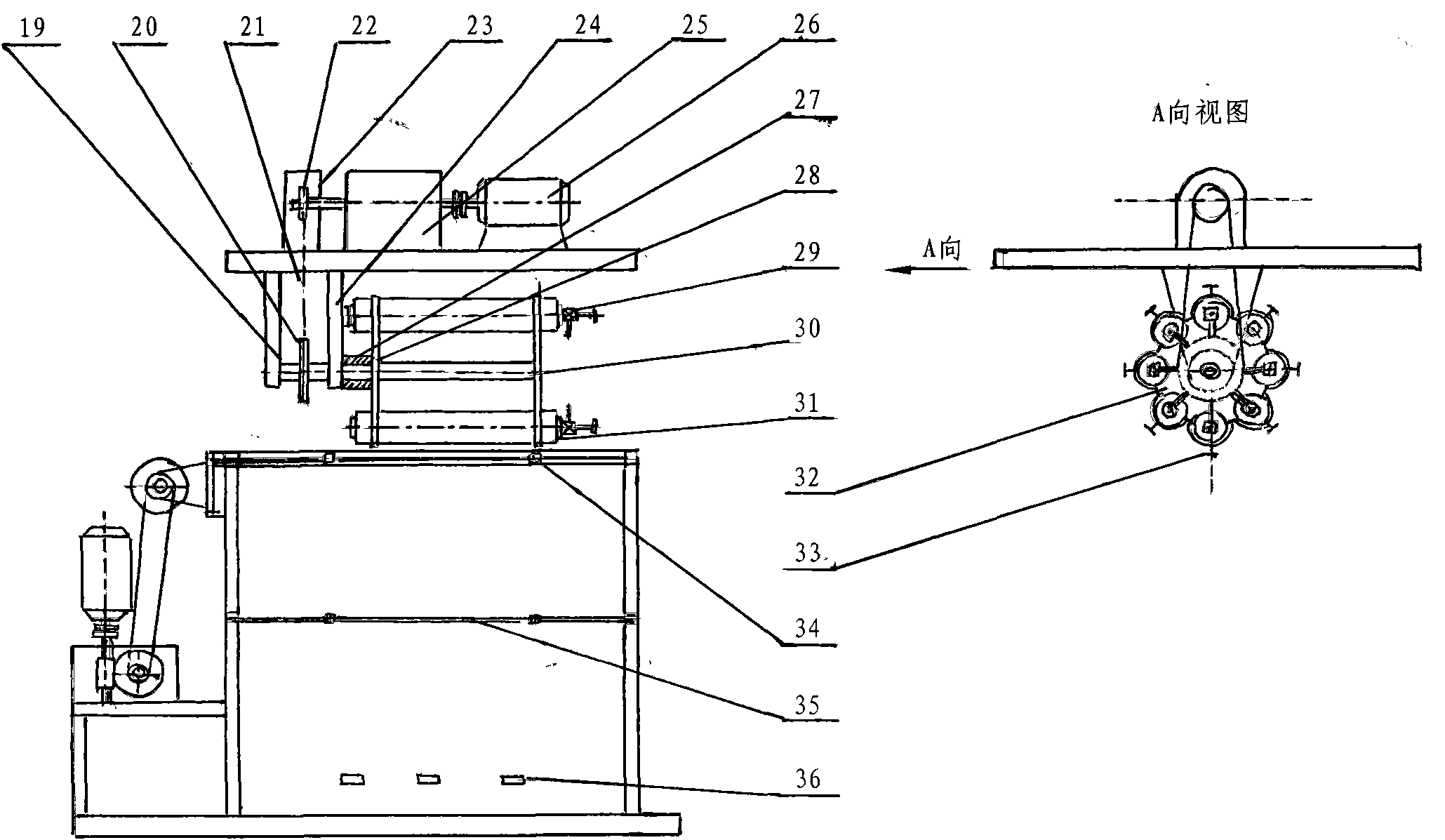

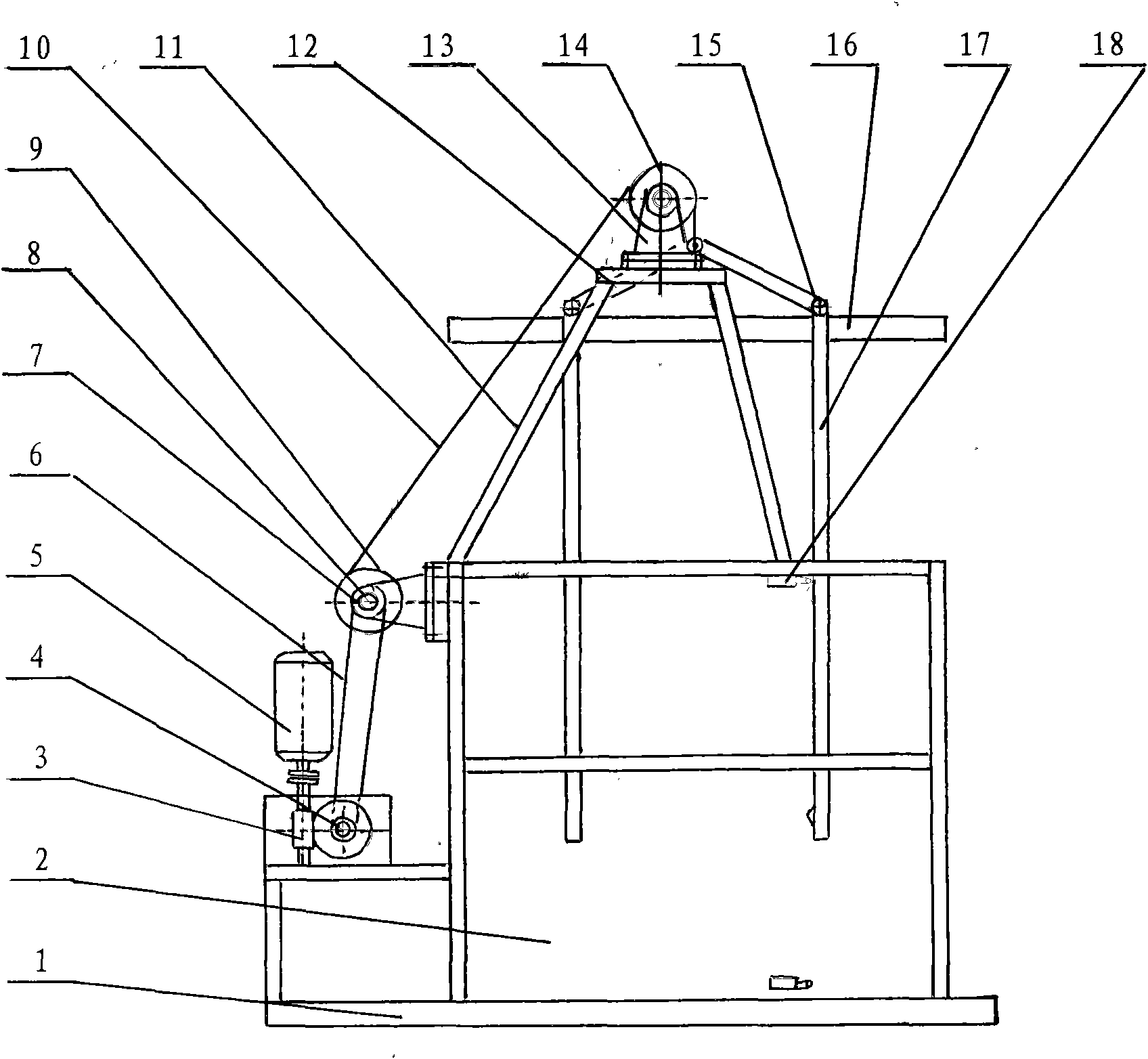

[0023] Below in conjunction with accompanying drawing, the present invention will be described in further detail, the overall structure of this group pot papermaking cooking test device is as follows figure 1 As shown, the main structure includes four parts: Ⅰ is the box body and the frame, and the frame is used to contain the box body and support two sets of motion systems; Ⅱ is the box cover motion system, which consists of a motor, a reducer, and three sprocket mechanisms. , 4 guide rails, 8 pairs of guide wheels and travel switches to complete the stable opening and sealing of the lid; Ⅲ is the cooking group kinematic system, which consists of a frequency modulation motor, a reducer, a sprocket mechanism, two faceplate brackets and Composed of rotating shafts, it completes the fixing of the group pots and drives the group pots to rotate around the disc-type bracket and the rotating shaft in the heat-conducting oil of the box; IV is the heating measurement control system, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com