Injection valve

A jet valve and gap technology, applied in the field of jet valves, can solve problems such as short service life of metering needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

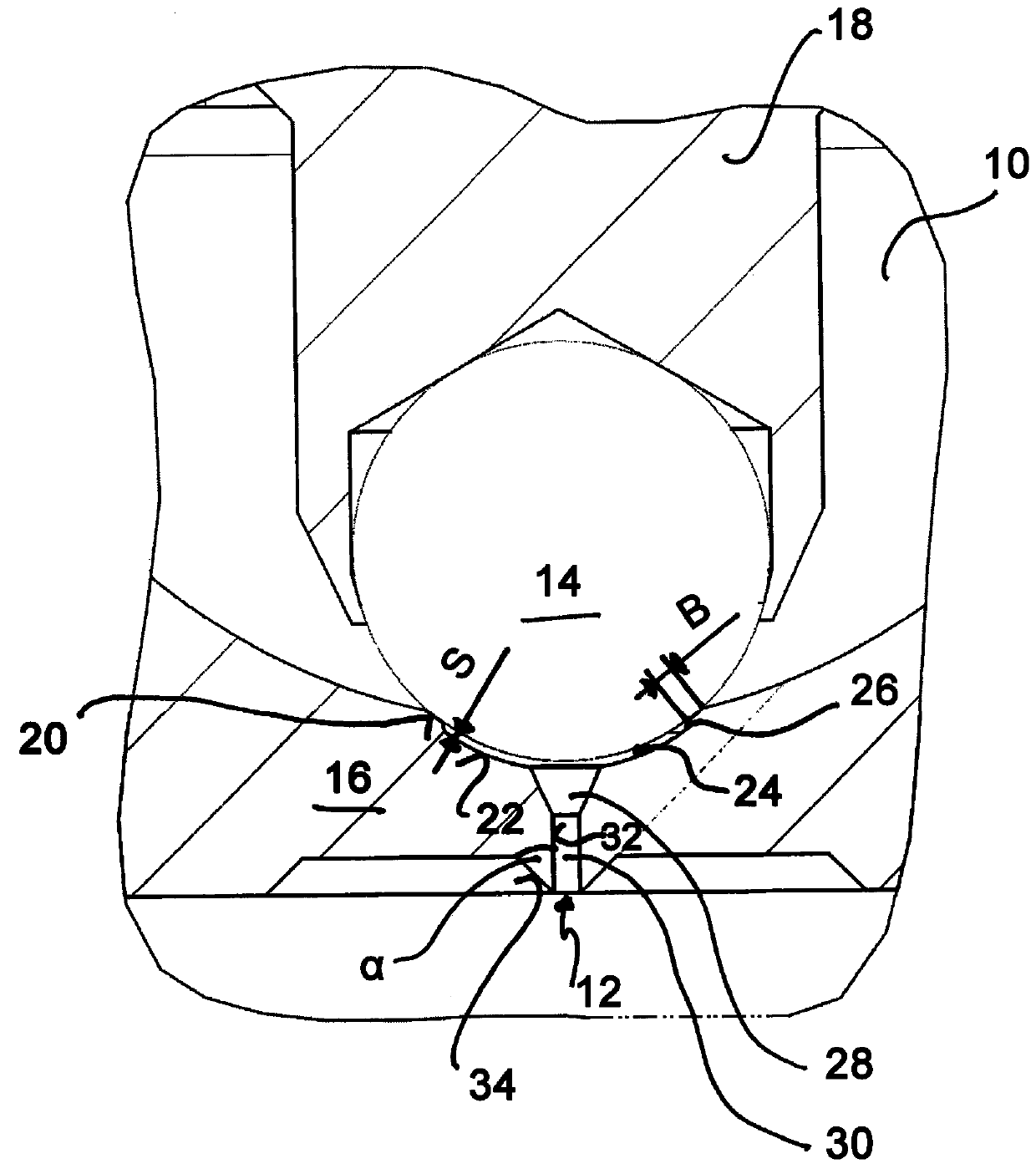

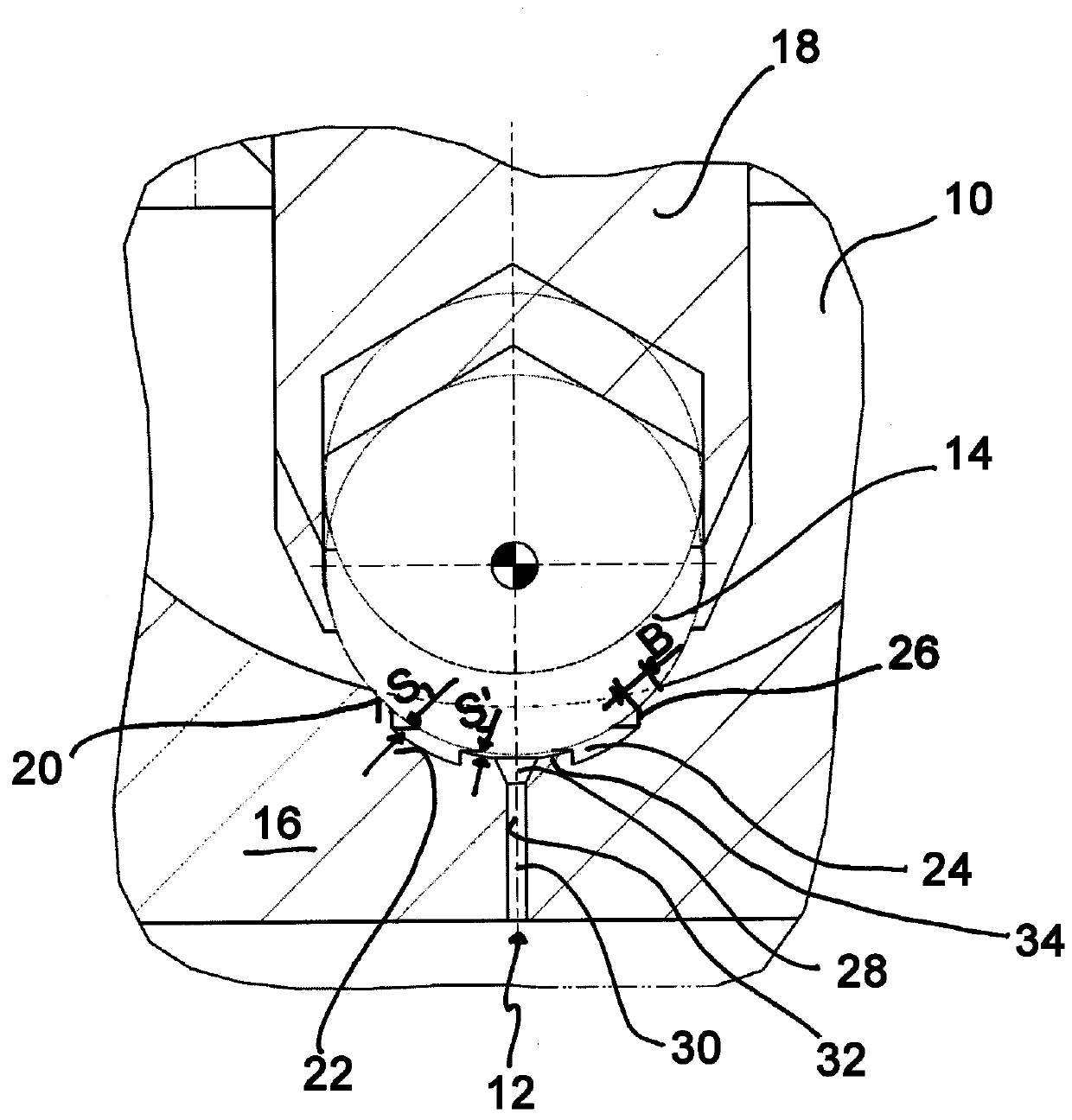

[0025] figure 1 The injection valve shown only partially in FIG. 2 has a medium channel 10 which leads to an outlet opening 12 and which can be closed by a sealing element 14 which can be arranged against a sealing seat 16 . The sealing element 14 in the illustrated embodiment has a spherical shape, which is fixed to one end of the valve needle 18 . Here, the valve needle is arranged in a known manner on the sealing seat by a valve drive having a sufficiently high number of cycles against the force of the spring.

[0026] A sealing surface 20 formed on the valve seat 16 serves for sealing between the sealing element 14 and the valve seat 16 . Said sealing face 20 is formed in the form of a sealing chamfer and has the shape of an annular strip of width B as part of the spherical surface of the illustrated embodiment.

[0027] The sealing seat 16 also has a surface contour 22 behind the sealing surface 20 in the direction of the outlet opening 12 , which is spaced apart from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com