Modified asphalt storage stability standard viscosity detection method

A technology of storage stability and standard viscosity, applied in flow characteristics, measuring devices, instruments, etc., can solve problems such as large differences, waste of resources, and accelerated aging of modified asphalt, so as to improve test efficiency, save test materials, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Modified asphalt storage stability standard viscosity detection method, including the following steps:

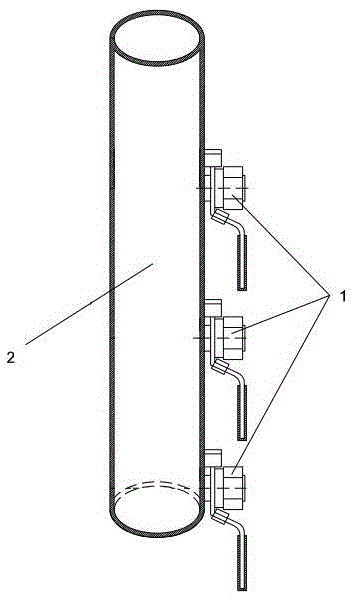

[0023] (1) There are sample outlets at the bottom, 1 / 3 height, and 2 / 3 height of the stainless steel tube 2 with openings at both ends, and ball valves 1 are provided at the sample outlets (see figure 1 ).

[0024] Wherein: the inner diameter of the stainless steel pipe 2 is 40mm, and the length is 250mm.

[0025] (2) Close the ball valve 1 at the bottom of the stainless steel pipe 2 obtained in the step (1), open the ball valve 1 at the 21 / 3 height and 2 / 3 height of the stainless steel pipe; then heat the 200 ± 5g modified asphalt sample filtered through a 0.3mm sieve And pour into the stainless steel pipe 2.

[0026] (3) Put the stainless steel tube 2 obtained in step (2) into an oven, heat at 163°C±5°C for 48±1h, and then cool naturally to room temperature.

[0027] (4) Heat and melt the modified asphalt sample cooled to room temperature at 163°C±5°C; then, clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com