Integrated working condition simulation device and test method for centrifugal model test of highway culvert

A technology of centrifugal model test and working condition simulation, applied in soil material testing, material inspection products, etc., can solve problems such as insufficient accumulation of experimental design experience, unstable test results, and inability to carry out tests, and achieve easy popularization and use, structure Simple, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

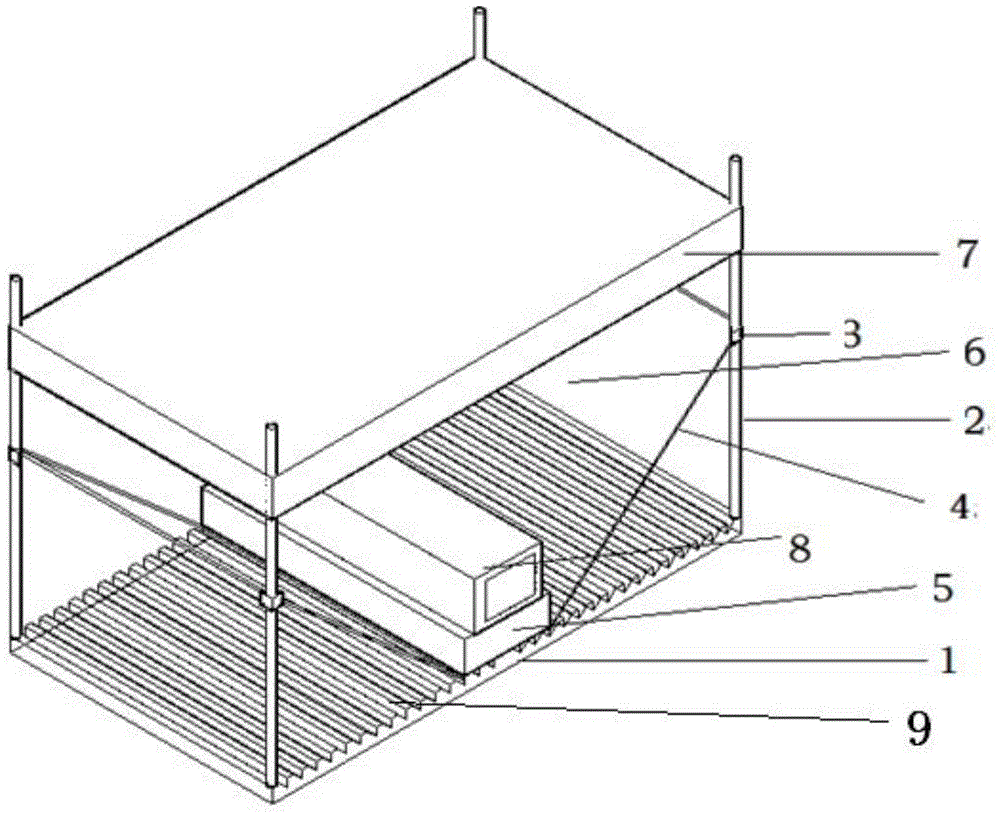

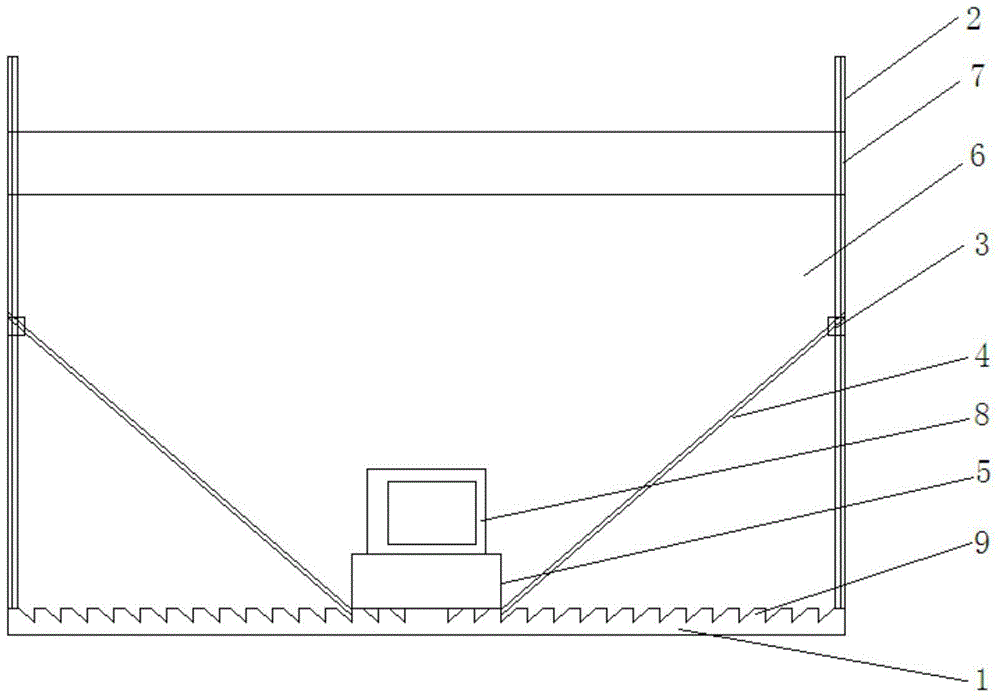

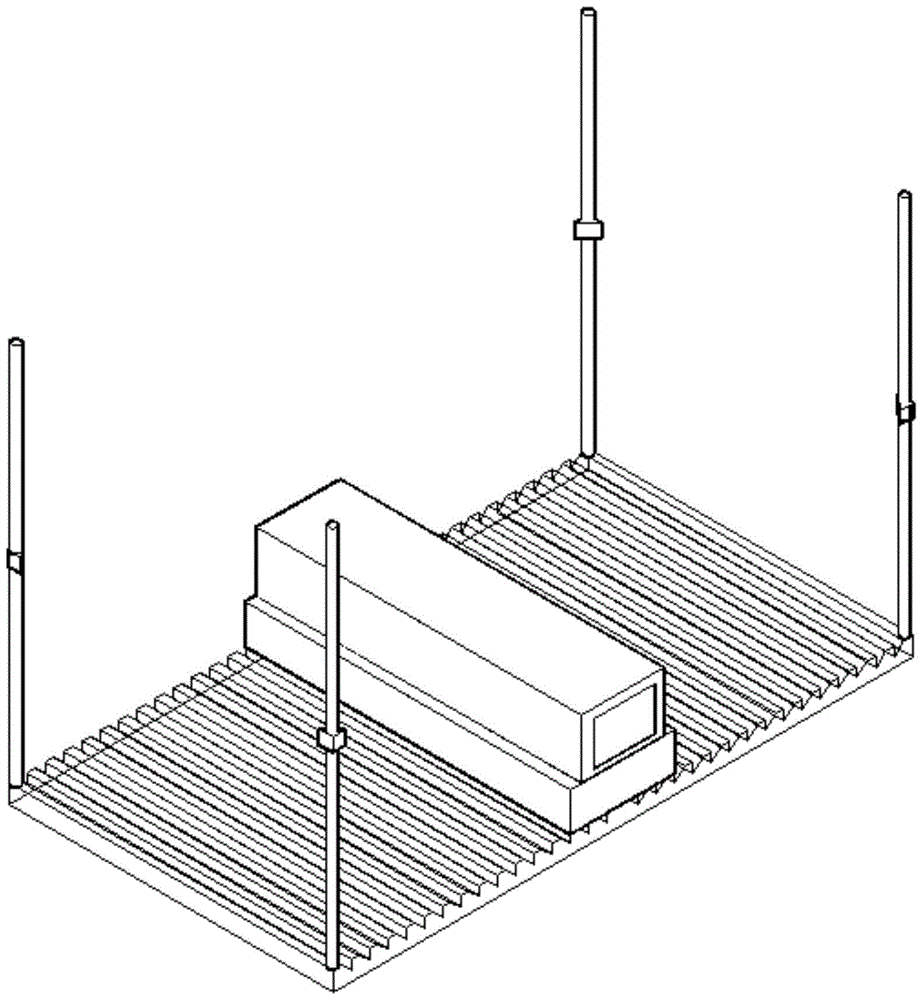

[0055] see Figure 5 , the culvert model 8 is a circular pipe culvert; the test soil sample 6 is sandy soil; the counterweight plate of the counterweight device 7 is a steel plate, and the length and width of the steel plate are slightly smaller than the length and width of the centrifuge model box for easy installation; the sandy soil and the steel plate The density ratio is 1:4, the centrifuge test is carried out at the acceleration level of 50g, the similarity ratio of the model test is 1:50, and the test condition of the simulated filling height is 20m.

[0056] Since the filling height to be simulated is as high as 20m, the filling height still needs to reach 40cm under the similarity ratio of 1:50; due to the limited height of the centrifuge model box, it is impossible to fill 40cm of sand in the test. At this time, Just need counterweight device 7 to carry out counterweight to it. In the test, in order to realize the filling height of 40cm, first fill with sand to a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com