Micro pressure shear experimental device and testing method of mechanical property of fusion welding microcell

A technology of fusion welding and experimental device, which is applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problems of inconvenient test operation, waste of samples, strict samples, etc. Simple, simple-shaped effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

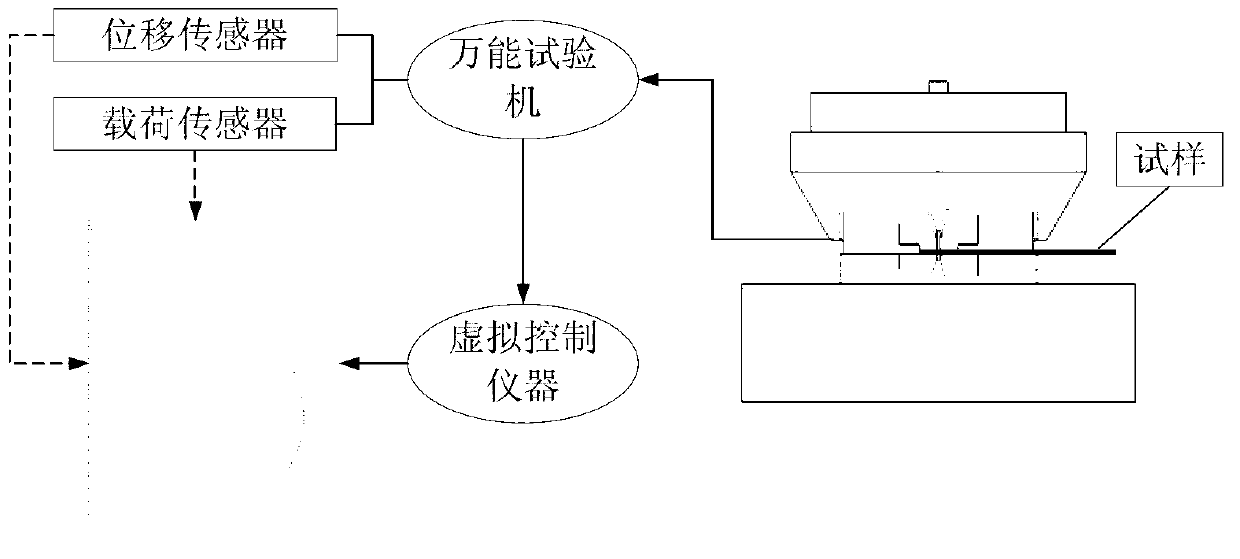

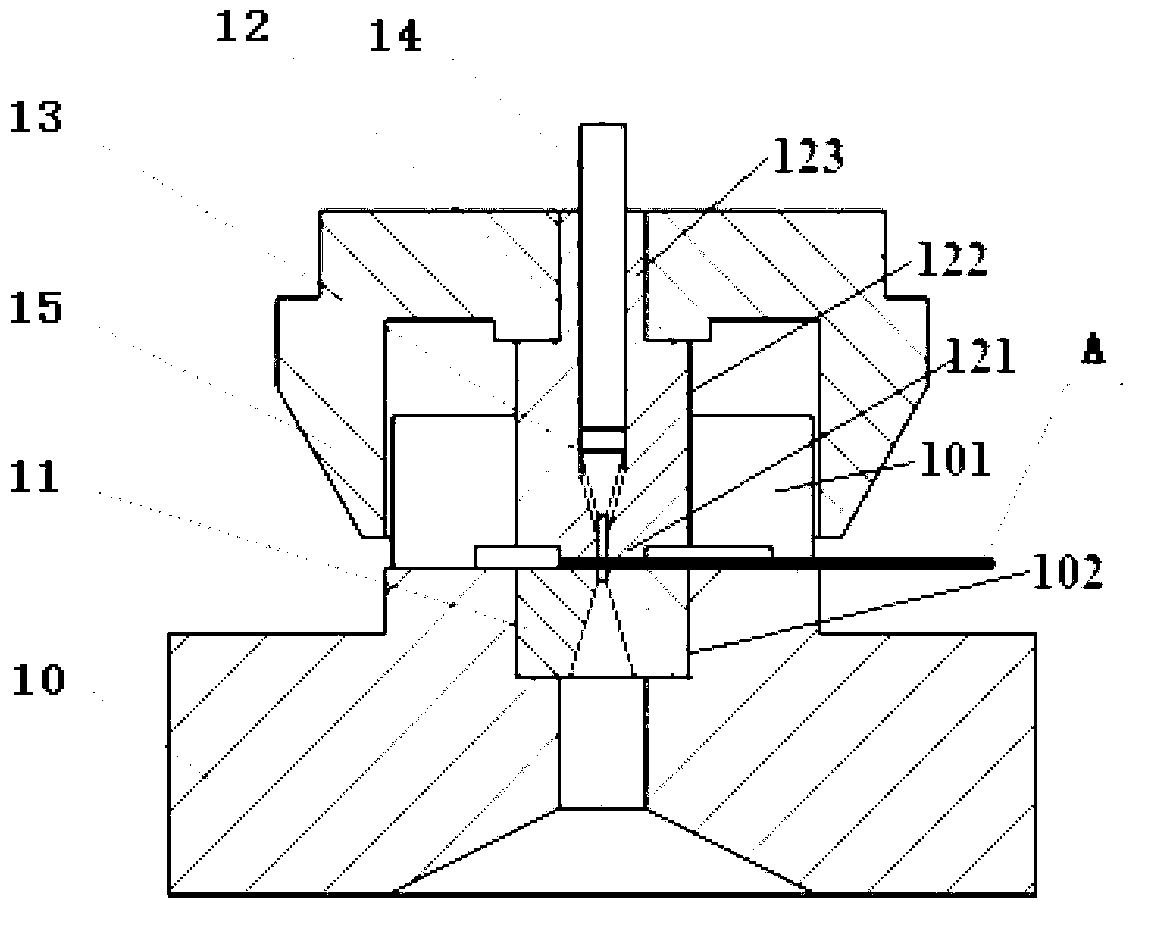

[0042] Before the test, the samples were first ground. Then there is the installation of the test equipment and the adjustment of the test machine. After everything is ready, the micro-compressive shear test can be carried out. During the test, the test system starts to work, and the load-displacement curve is continuously output, and the data is also stored in the computer. After the test is completed, the data can be taken out from the computer and processed to obtain the required mechanical property data and curves. The test example of the nuclear power rotor material 20Cr2NiMo submerged arc welding joint is illustrated:

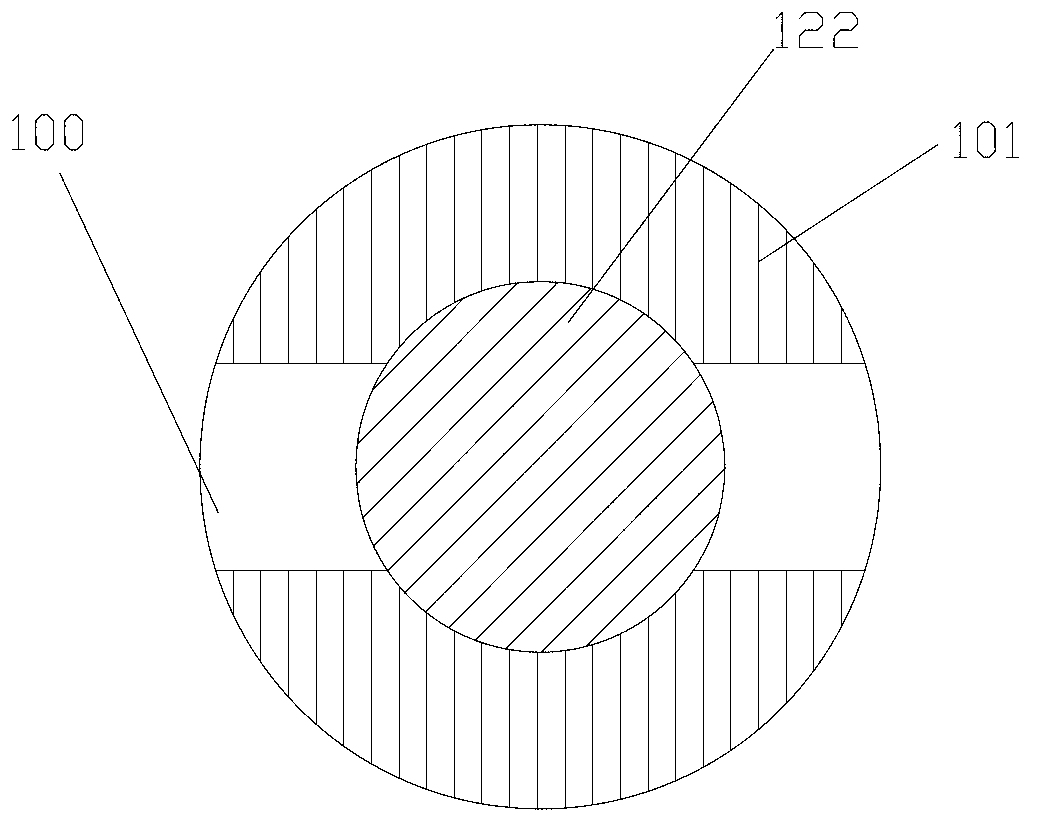

[0043] 1) Grinding samples such as Figure 4 As shown, a sample with a size of 60×10×0.8mm was cut from the weld (the sample includes the heat-affected zone of the weld and the base metal on both sides of the weld). Then the surface of the sample is polished from rough grinding to fine grinding, using water sandpaper according to 90 # , 400 # , 800 #...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com