High-frequency vibration auxiliary foil plate micro-blanking forming method

A high-frequency vibration and micro-blanking technology, which is applied in the direction of using vibrating fluids and pushing out equipment, can solve the problems of increased punching power due to size effects, small gap between punch and die, and low service life, so as to inhibit crack growth and punching. The effect of small force and reduced ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

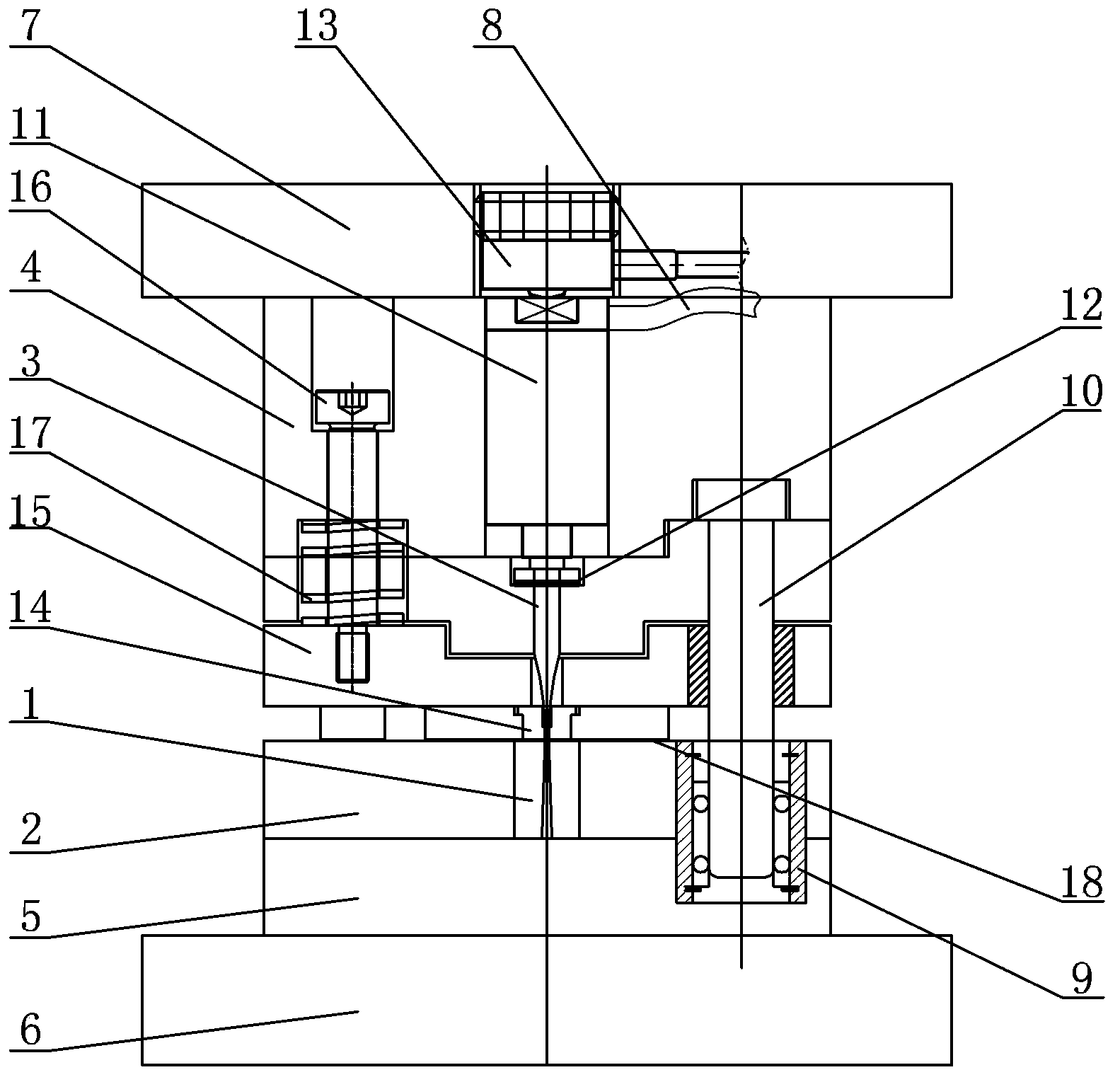

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment, the high-frequency vibration assisted foil plate micro-punching forming device in this embodiment includes a die 1, a die fixing plate 2, a punch 3, a punch fixing plate 4, a lower backing plate 5, and a lower template 6 , upper template 7, high-frequency power supply 8, guide sleeve 9, guide post 10 and vibration assembly, die fixing plate 2, lower backing plate 5, and lower template 6 are connected sequentially from top to bottom, upper template 7, punch fixing plate 4. Arranged sequentially above the die fixing plate 2 from top to bottom, the die 1 is embedded in the middle of the upper surface of the die fixing plate 2, and the vibrating assembly and punch 3 are sequentially inserted on the punch fixing plate from top to bottom 4, and the center line of the punch 3 coincides with the center line of the die 1, the vibration assembly is connected with the high-frequency power supply 8, the gu...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 Describe this embodiment, the vibration assembly of the high-frequency vibration auxiliary foil plate micro-punching forming device in this embodiment includes a piezoelectric ceramic 11 and a disc spring 12, and the upper end of the punch 3 passes through the disc spring 12 and the piezoelectric ceramic 11. the lower end connection.

[0014] In this embodiment, the punch 3 is constantly vibrating at high frequency under the action of the piezoelectric ceramic 11 . Due to the high-frequency vibration of the punch 3 , the deformation resistance of the foil plate 18 is reduced, so the deformation is relatively easy.

[0015] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 To describe this embodiment, the high-frequency vibration assisted foil plate micro-punching forming device in this embodiment further includes a pressure sensor 13 , and the upper end of the piezoelectric ceramic 11 is connected to the pressure sensor 13 . In this embodiment, the pressure sensor 13 is connected with the data acquisition device, and the data acquisition device can collect data, which is convenient for data analysis on the punching and forming process. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com