Composite powder composition for ceramic coating and ceramic coating, and preparation method thereof

A ceramic coating and composite powder technology, applied in the field of wear-resistant coatings, can solve the problems of insufficient wear resistance of pure-phase ceramic coatings, unsatisfactory friction performance, and increased friction coefficient, so as to inhibit the initiation of cracks And expand, improve brittleness and wear resistance, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A. Preparation of composite powder composition by mechanical ball milling

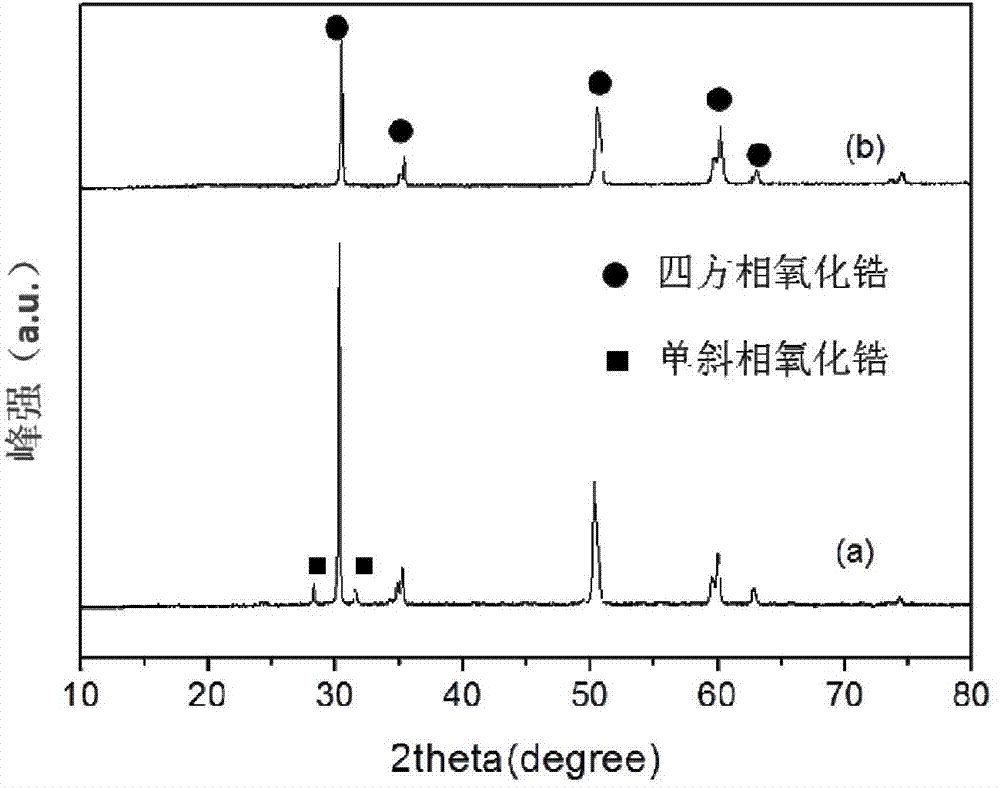

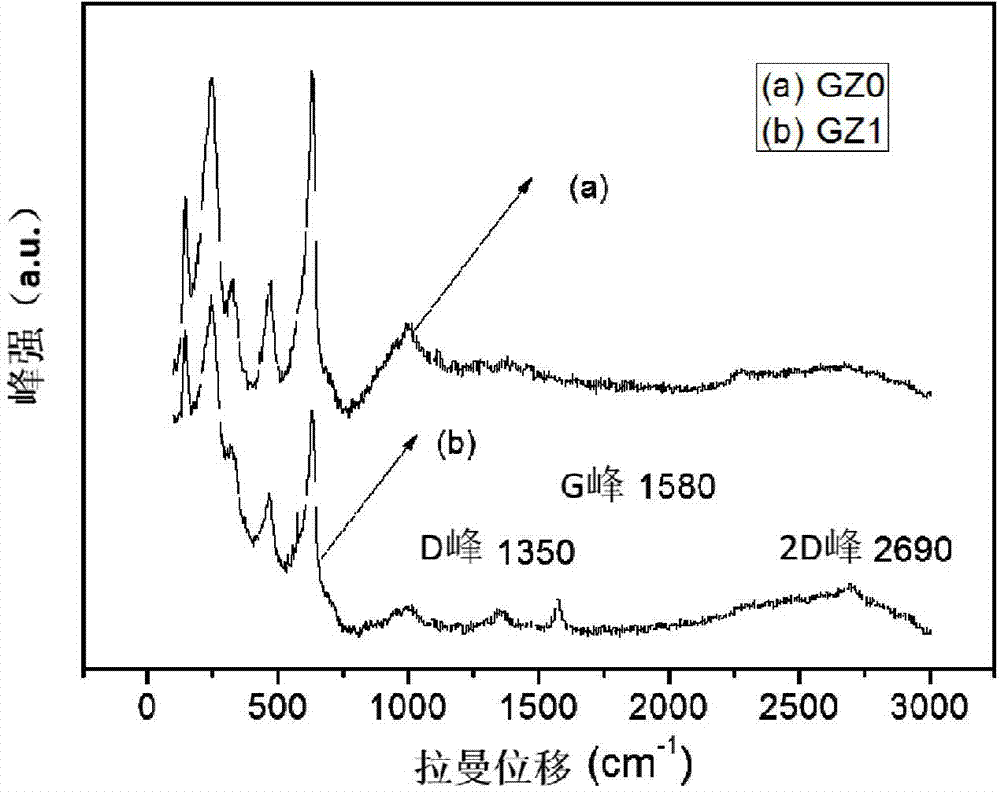

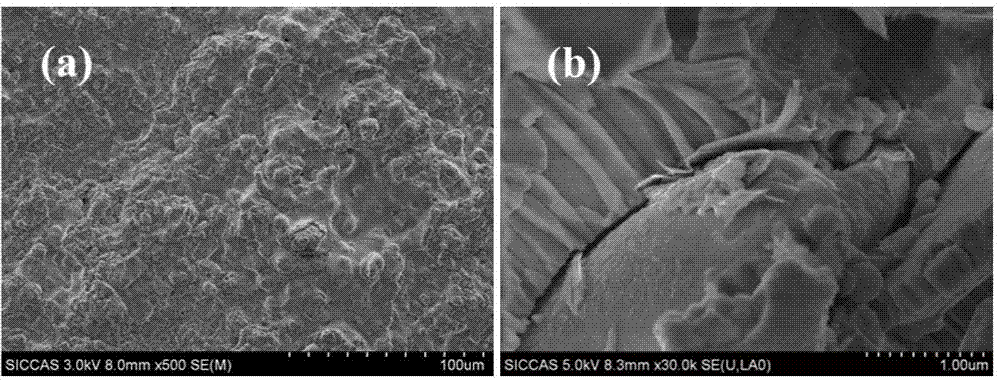

[0025] Graphene nanosheets (GNs), yttria-stabilized zirconia powder (ZrO 2 :Y 2 o 3 The molar ratio is 1:3.2%), zirconia grinding balls (ZrO 2 :Y 2 o 3 The molar ratio is 1:3%) mixed according to the mass ratio of 1:99:200, put into a polytetrafluoroethylene grinding tank, and perform ball milling in a planetary ball mill, the ball milling speed is 400r / min, and the ball milling time is 300min. After passing through a 40-mesh sieve and drying at 110°C to obtain a composite powder composition, the XRD pattern is as follows: figure 1 Shown in a.

[0026] B. Preparation of ceramic coating by plasma spraying process

[0027] The surface of the titanium alloy (Ti-6Al-4V) was sandblasted (pressure 0.3 MPa), then ultrasonically cleaned twice in anhydrous ethanol solution for 4 minutes each time, and then dried at 110°C for 1.5 hours for later use.

[0028] Using the plasma spraying process, th...

Embodiment 2

[0046] A. Preparation of composite powder composition by mechanical ball milling

[0047] Graphene nanosheets (GNs), yttria-stabilized zirconia powder (ZrO 2 :Y 2 o 3 The molar ratio is 1:3.2%), zirconia grinding balls (ZrO 2 :Y 2 o 3 The molar ratio is 1:3%) mixed according to the mass ratio of 0.5:99.5:100, put into a polytetrafluoroethylene grinding tank, and perform ball milling in a planetary ball mill, the ball milling speed is 500r / min, and the ball milling time is 60min. After that, pass through a 40-mesh sieve, and dry at 100° C. for 1 hour to obtain a composite powder composition.

[0048] B. Preparation of ceramic coating by plasma spraying process

[0049] The surface of stainless steel (316L) was sandblasted (pressure 0.5MPa), then ultrasonically cleaned twice in anhydrous ethanol solution for 4 minutes each time, and then dried at 110°C for 1.5 hours before use.

[0050] Using the plasma spraying process, the composite powder composition is sprayed onto th...

Embodiment 3

[0064] A. Preparation of composite powder composition by mechanical ball milling

[0065] Graphene nanosheets (GNs), yttria-stabilized zirconia powder (ZrO 2 :Y 2 o 3 The molar ratio is 1:3.2%), zirconia grinding balls (ZrO 2 :Y 2 o 3 The molar ratio is 1:3%) mixed according to the mass ratio of 1.5:98.5:300, put into a polytetrafluoroethylene grinding tank, and perform ball milling in a planetary ball mill, the ball milling speed is 500r / min, and the ball milling time is 120min. Then pass through a 40-mesh sieve and dry at 120° C. to obtain a composite powder composition.

[0066] B. Preparation of ceramic coating by plasma spraying process

[0067] The surface of the titanium alloy (Ti-6Al-4V) was sandblasted (pressure 0.3MPa), then ultrasonically cleaned twice in anhydrous ethanol solution for 4min each time, and then dried at 100°C for 1 hour for later use.

[0068] Using the plasma spraying process, the composite powder composition is sprayed onto the treated titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com