Method and device for wedging test of fracture performance of metallic materials

A technology of fracture performance and metal materials, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effects of saving test materials, convenient production, and clear principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, method and structure of the present invention are described in further detail

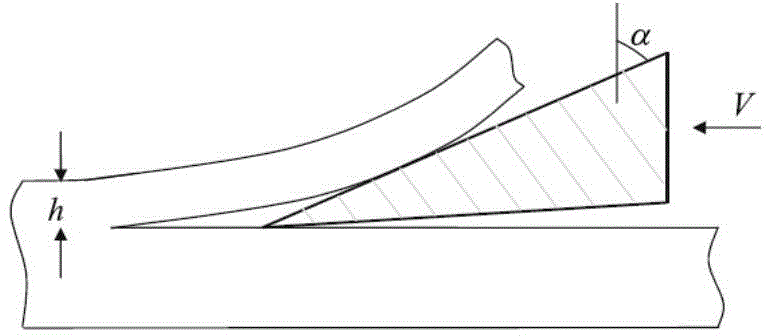

[0029] The technical scheme adopted by the present invention includes three parts, namely a sample with a special configuration design, a loading device and a theoretical system based on wedge loading.

[0030] (1) Specimen configuration suitable for wedge loading

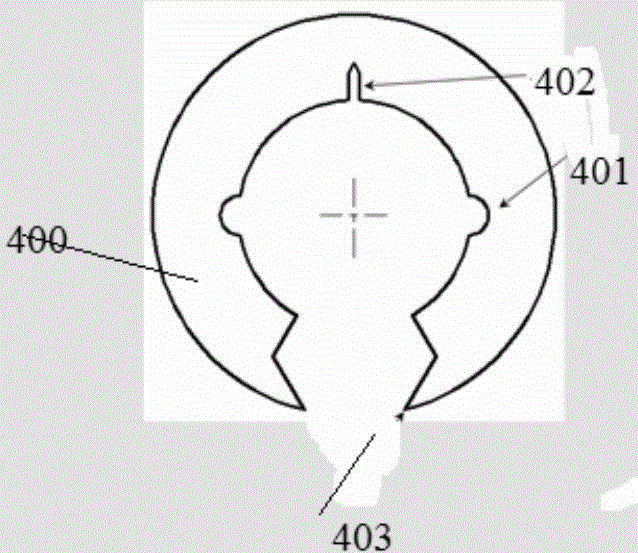

[0031] The sample used for the technical solution of the present invention is a C-shaped ring sample ( image 3 ), with a symmetrical loading hole 401, an initial crack notch 402, and a knife edge 403 for measuring the opening displacement of the sample.

[0032] The distance between the knife edges 403 can be designed according to the gauge length of the displacement meter.

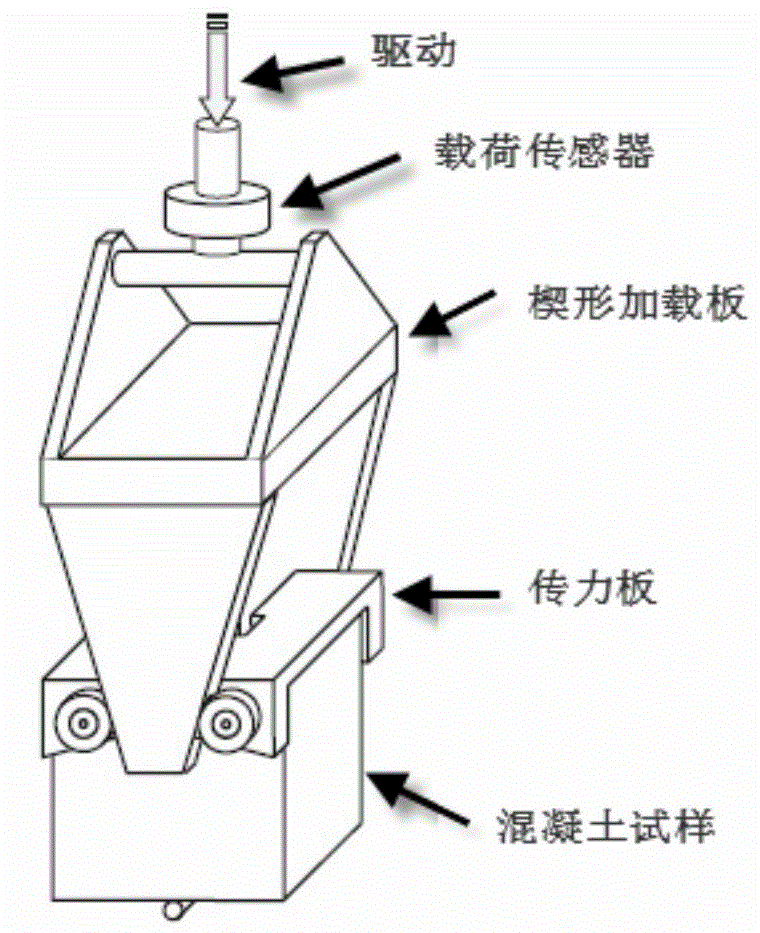

[0033] (2) Loading device

[0034] The loading device consists of a wedge-shaped loading head ( Figure 5 ), force transmission cotter pin ( Image 6 with Figure 7 ) and support base ( Figure 8 ) cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com