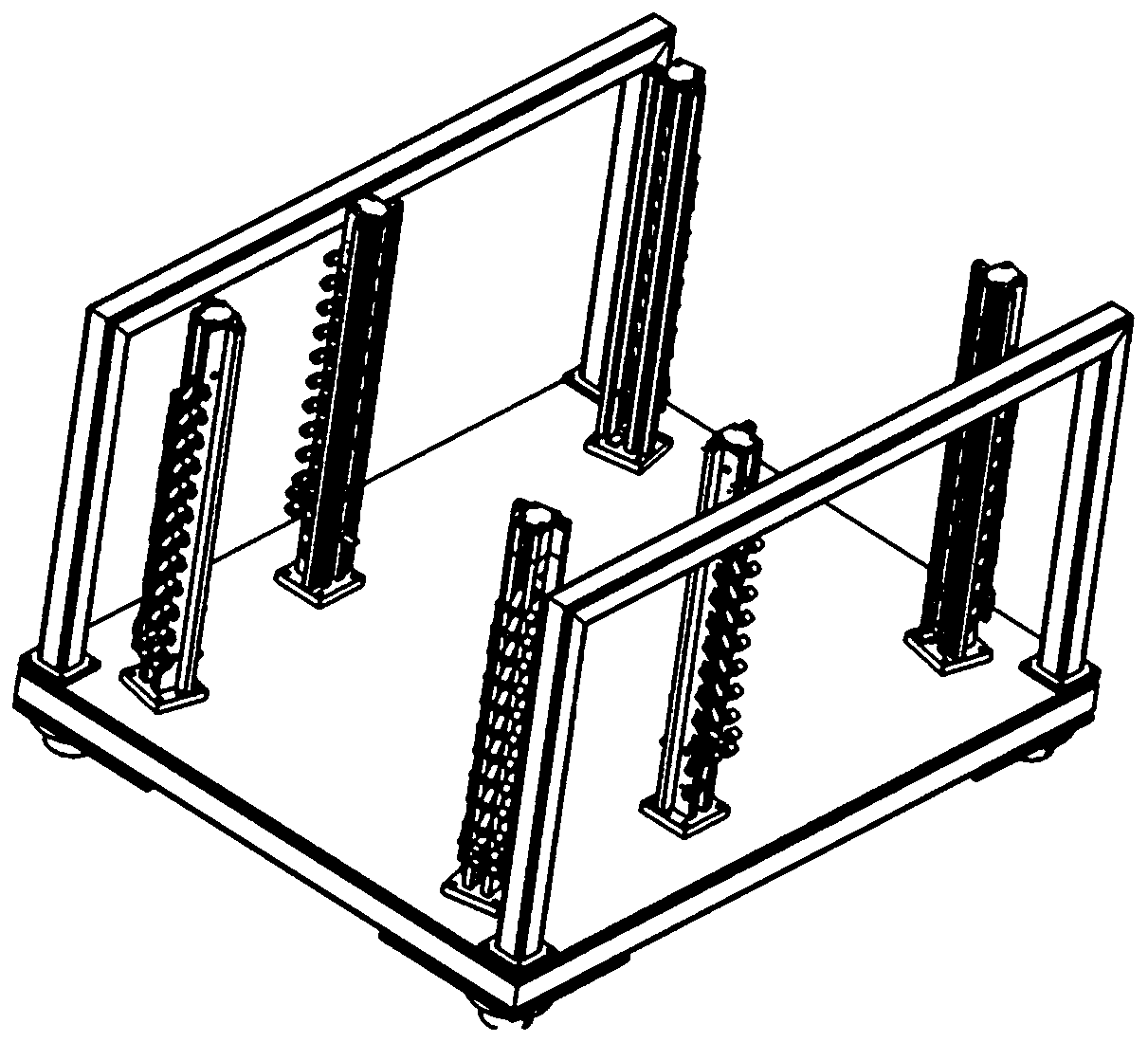

car roof rack

A car roof and material rack technology, which is applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of high requirements on the shape of power-assisted machinery and the inconvenience of picking up parts from the car roof material rack, and achieve the effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

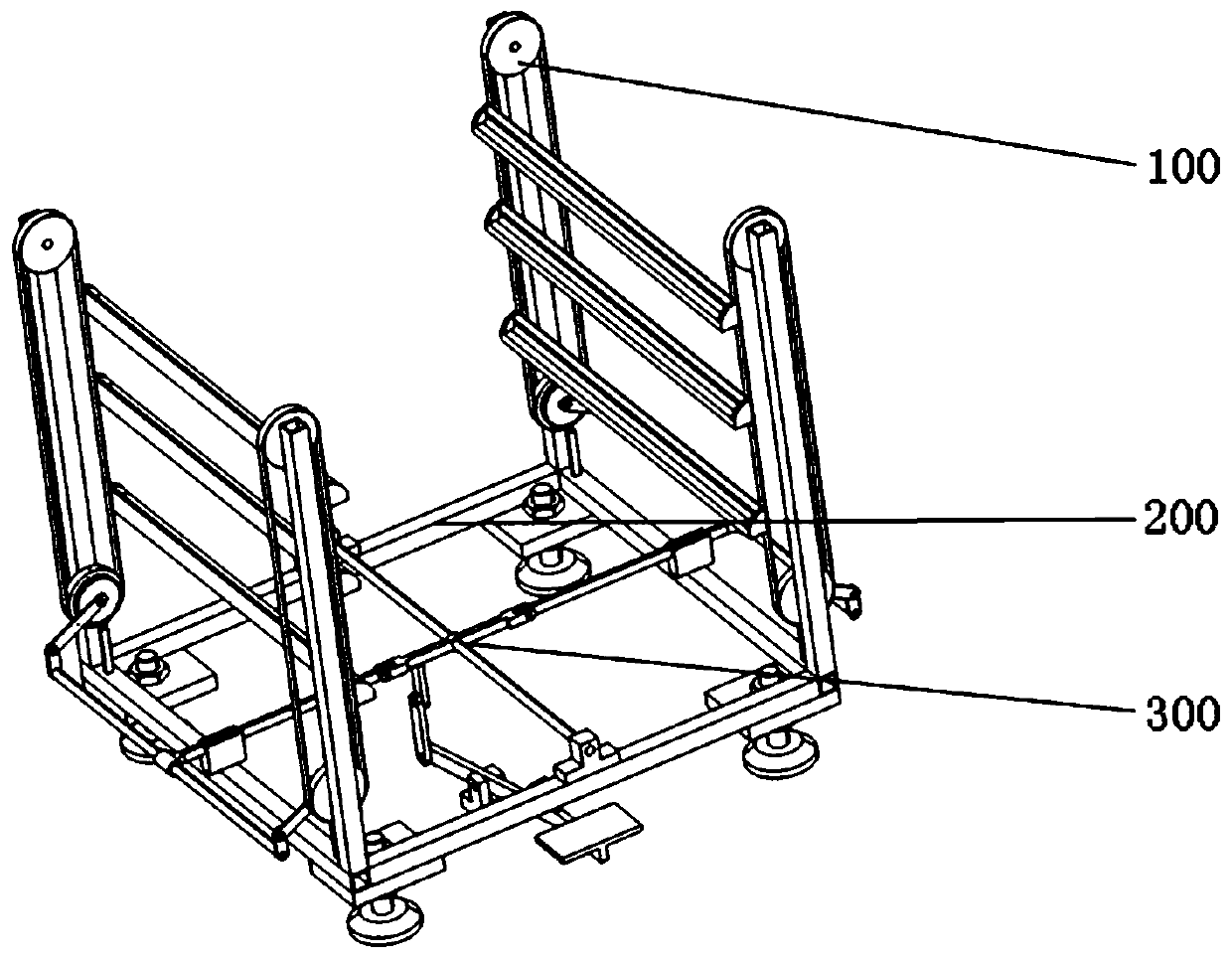

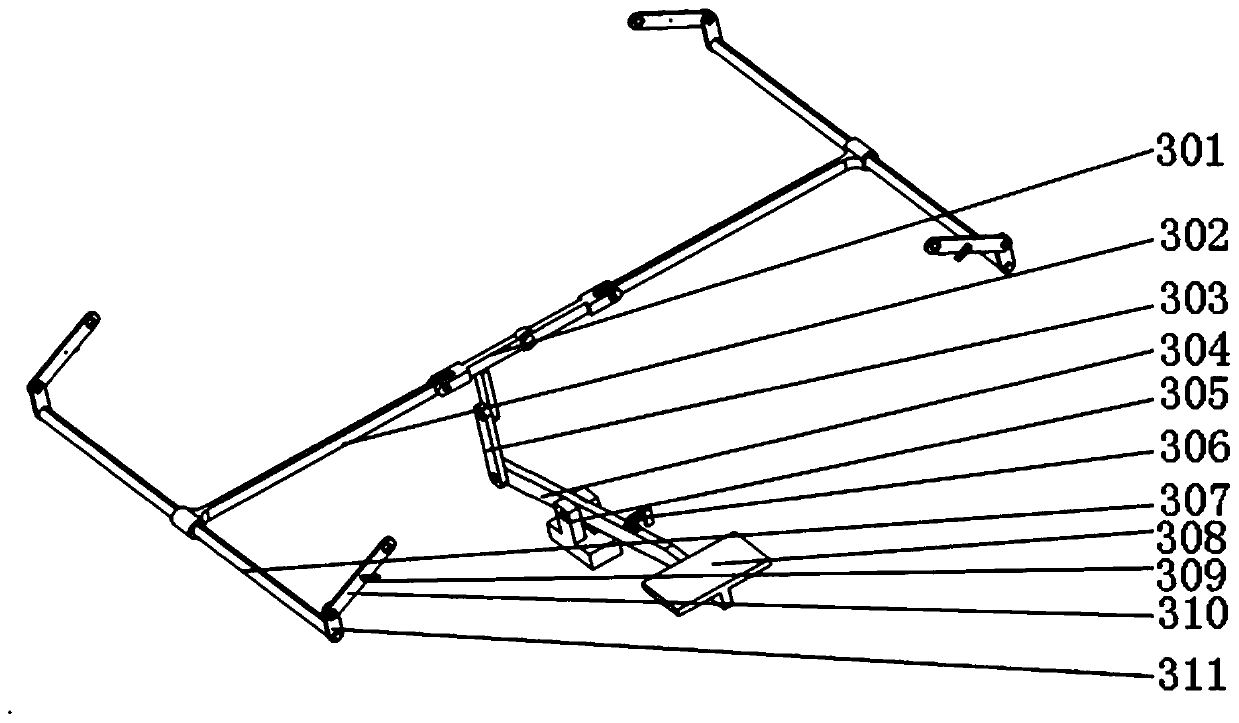

[0036] Such as figure 2 As shown, this application is composed of three horizontal blocks, and the external force drives the driven system 100 to rotate through the transmission system 300, so that the top cover placed in this application is gradually raised, and the purpose of always taking parts at the top of the material rack is achieved.

[0037] Such as Figure 5 As shown, the driven system 100 shares two sets, which are left-right symmetrical mechanisms, and each set itself is also a self-symmetrical structure. The driven system includes a left driven system, a right driven system and a roof support 103;

[0038] The left driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com