Patents

Literature

64results about How to "Realize circular motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

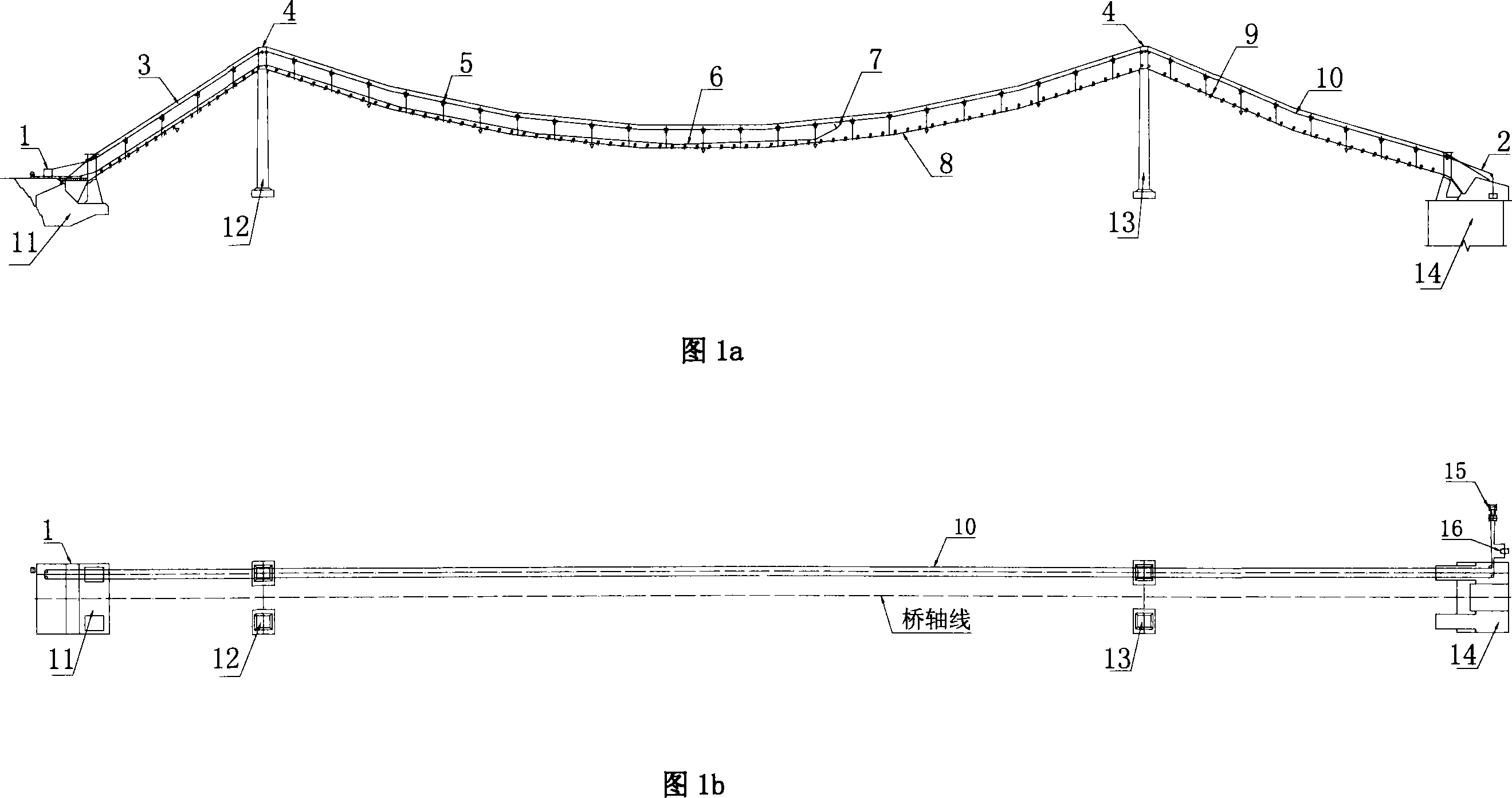

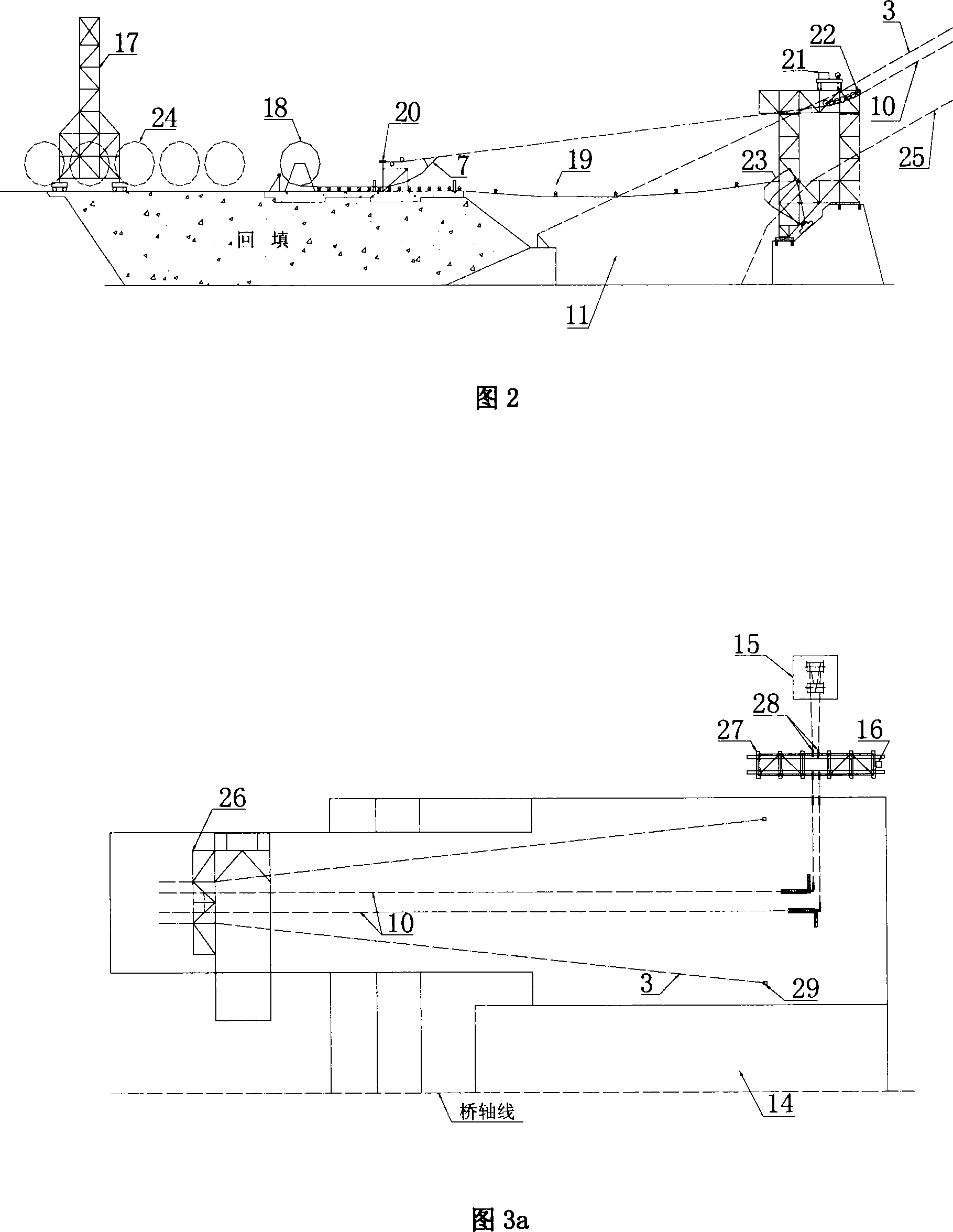

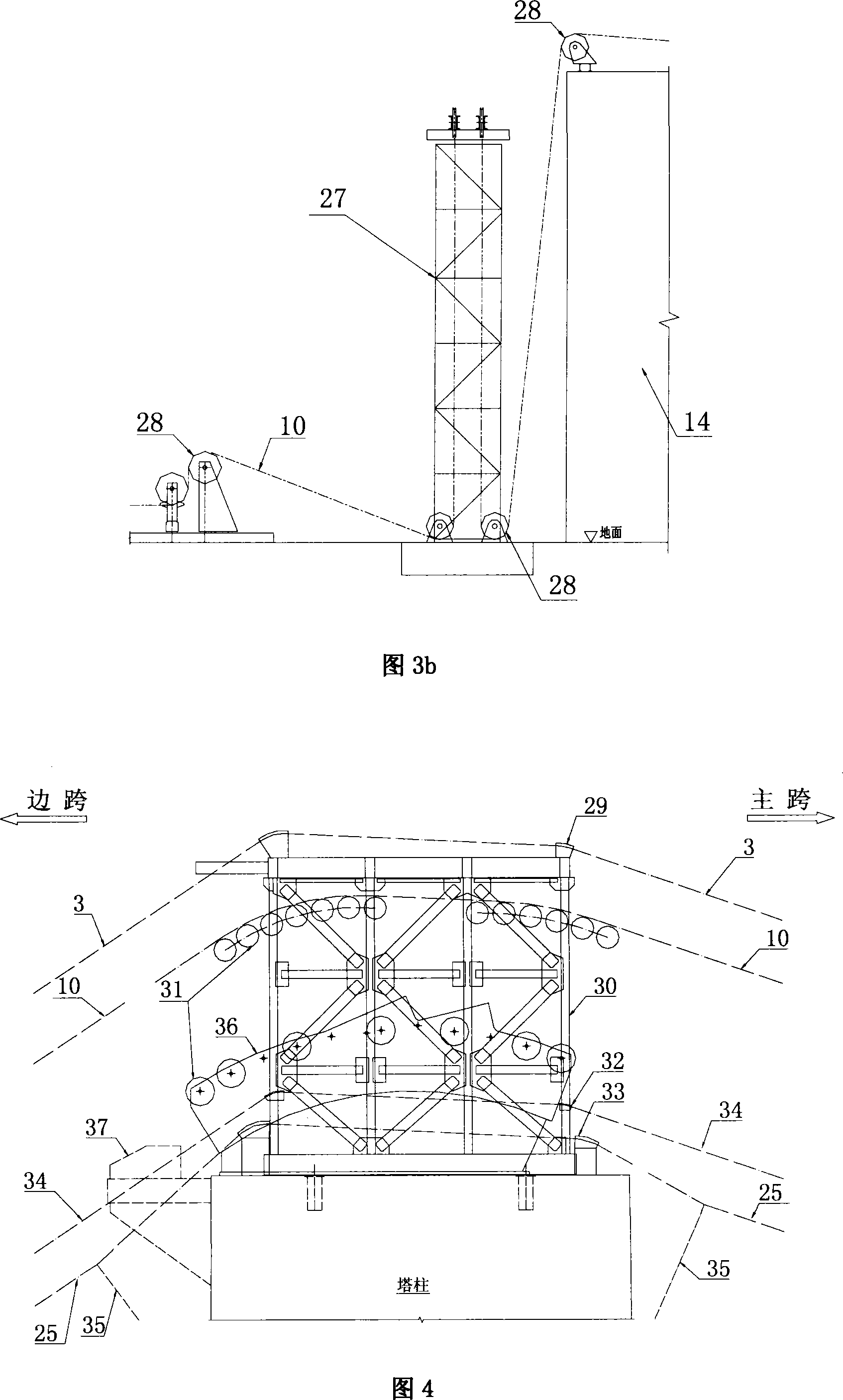

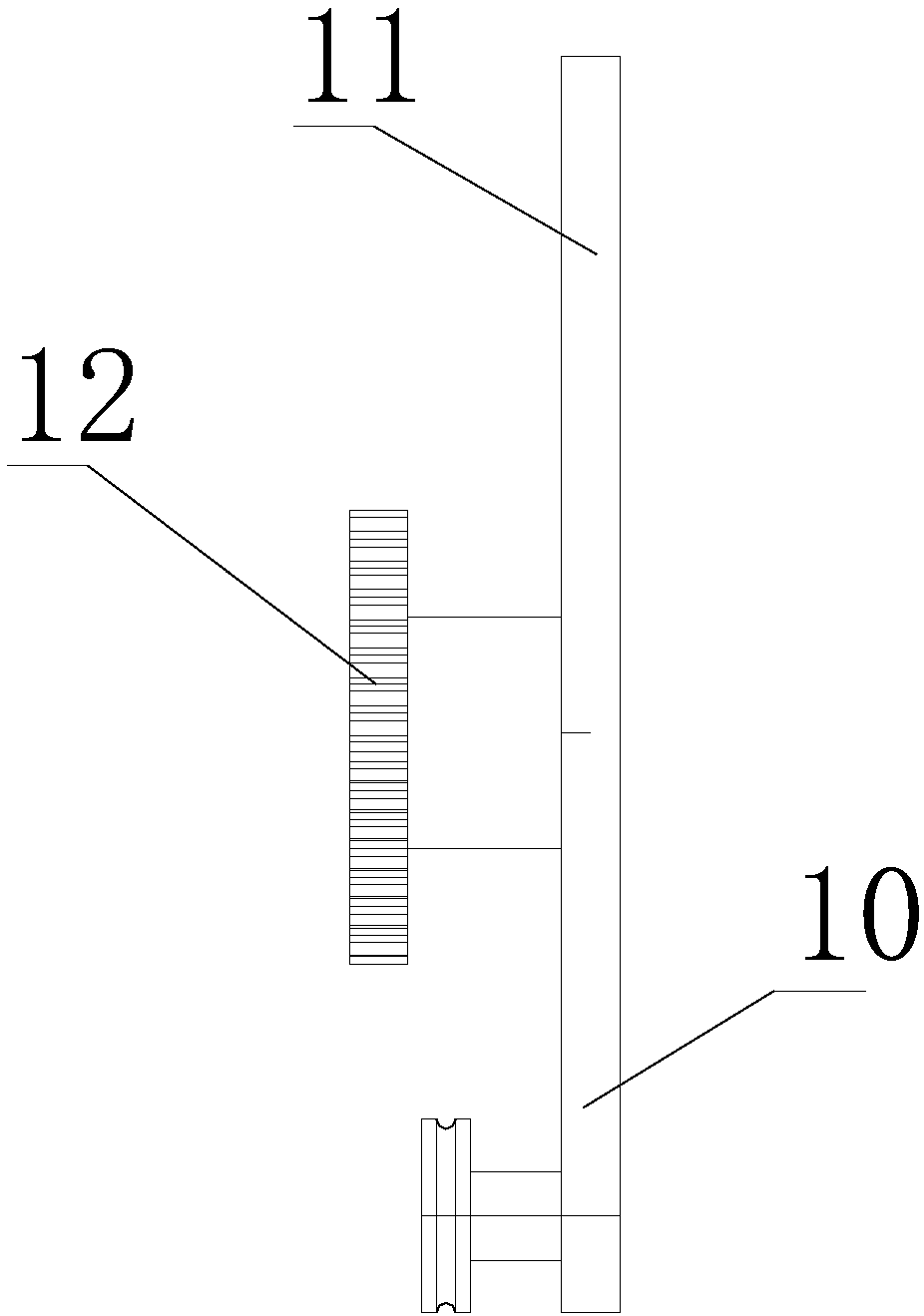

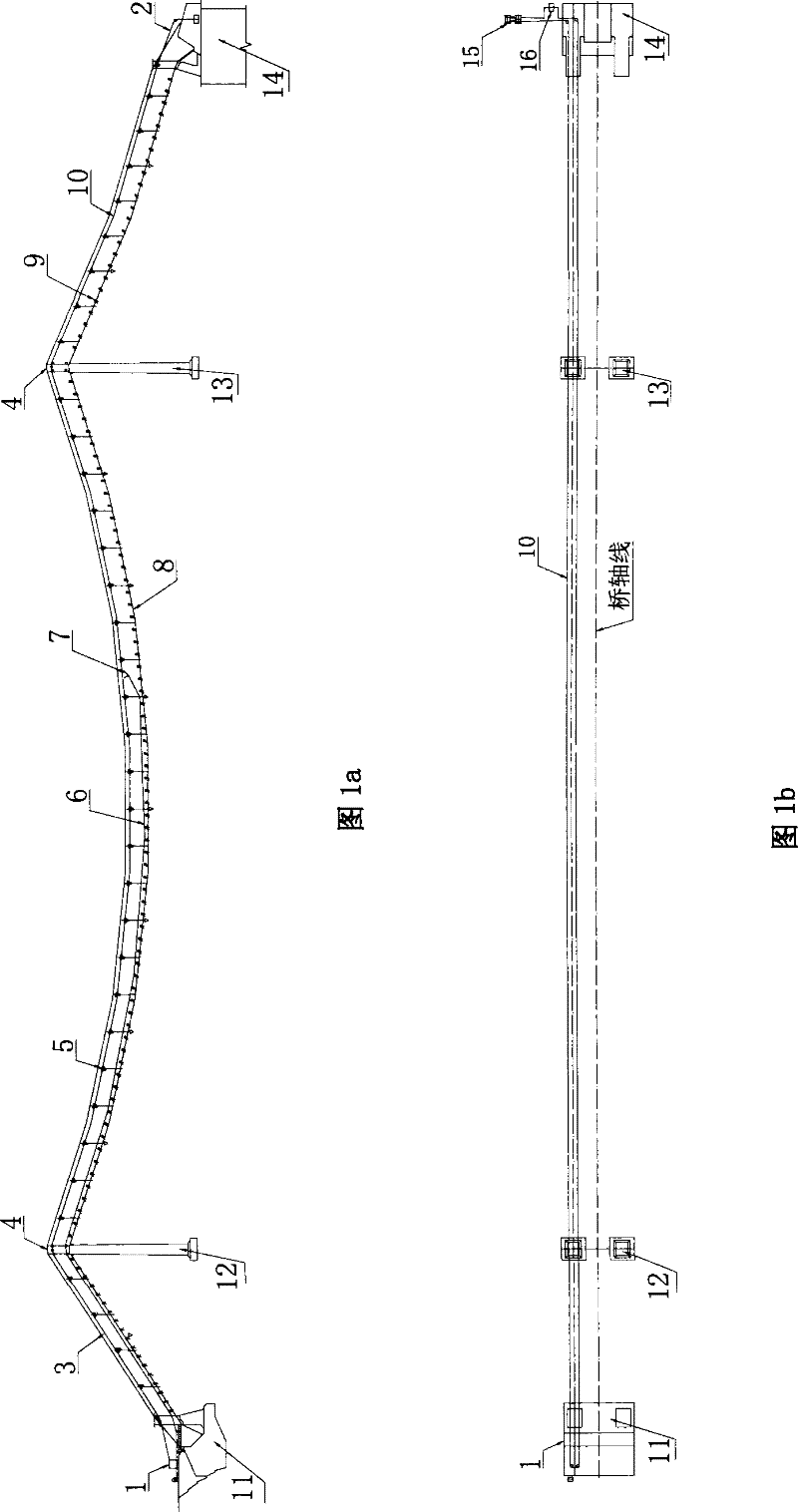

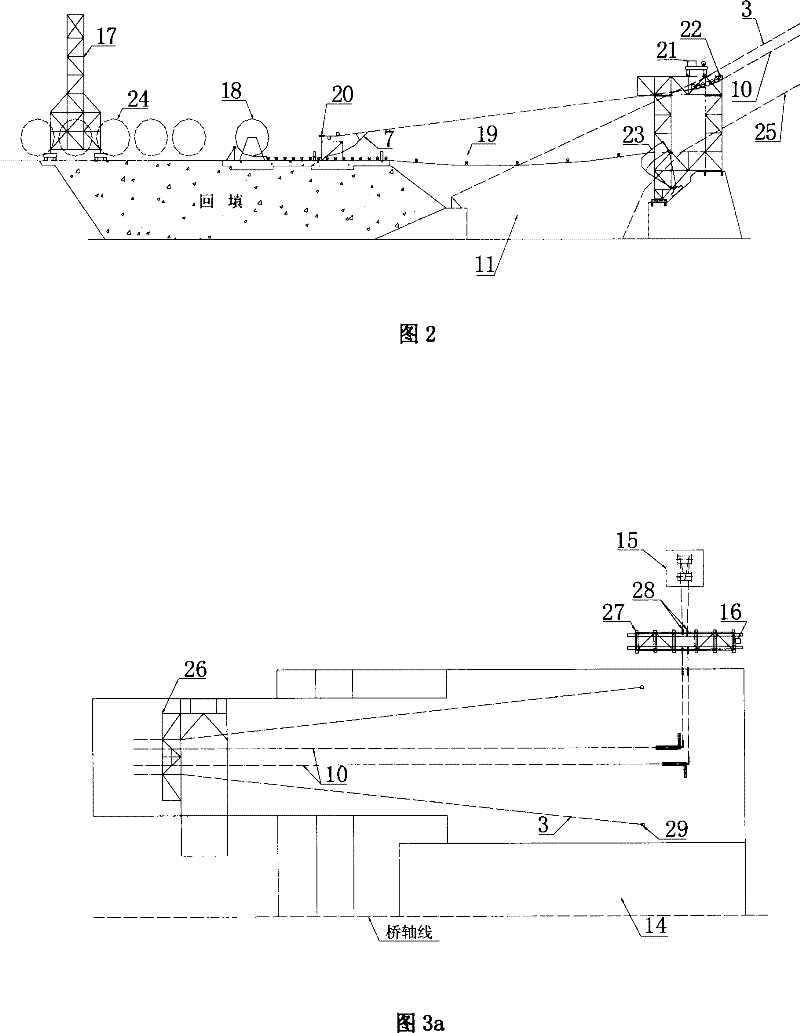

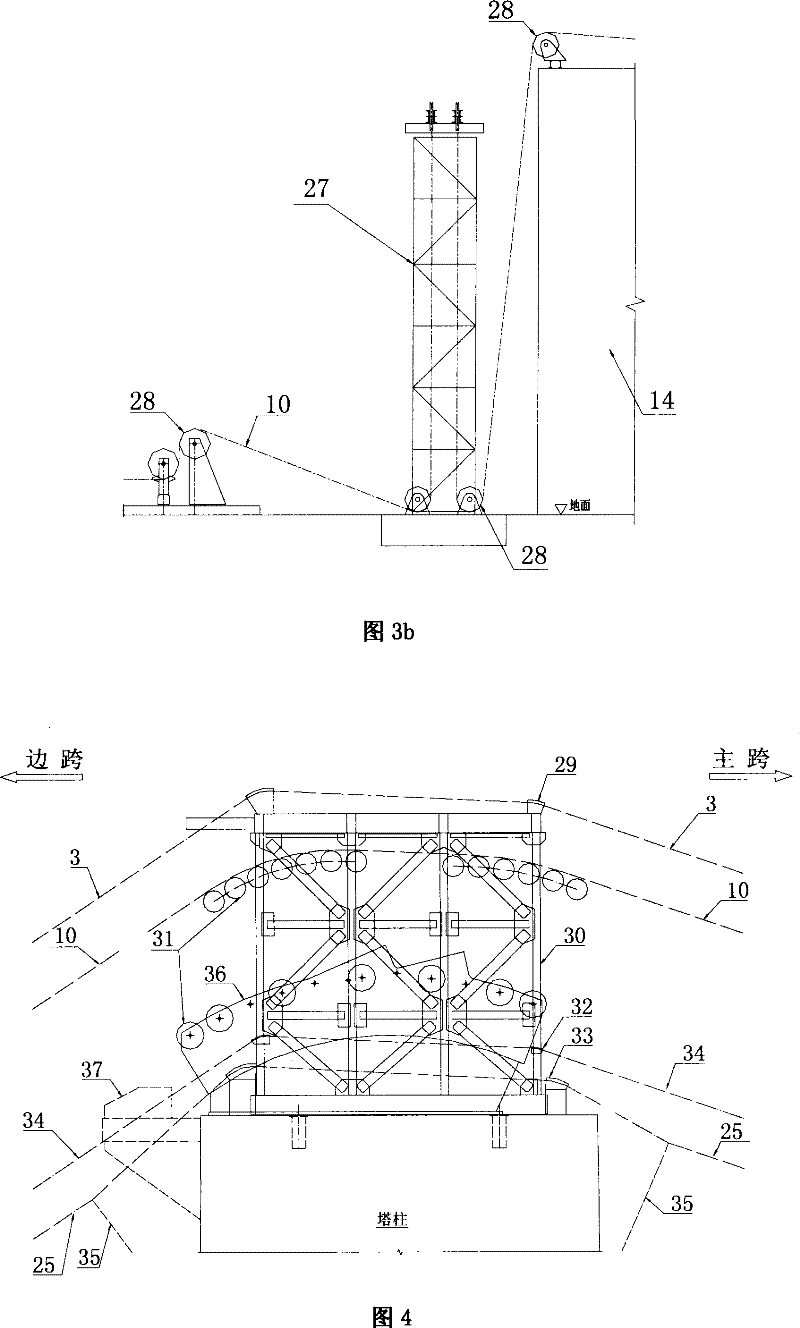

Erection of gantry type small-cycle traction system on large-span suspension bridge main cable

ActiveCN101177931AStable tractionImprove erection qualityBridge erection/assemblyTraction systemTraveling block

The utility model relates to a gantry type small circulation traction system for a main cable erection of a large-span suspension bridge, which belongs to the technical field of bridge superstructure construction. Set up a cable storage area behind the A anchorage, and install a 60-ton gantry crane and a cable-laying bracket; set up a traction cable revolving wheel behind this anchorage; set up a 25-ton main traction hoist and a balance weight bracket on the side of the B anchorage. The traction cable is connected by a puller at Anchor Anchor, bypasses the hoist drum at B Anchor Anchor, and is inserted through the balance weight bracket and each steering block to form a ring-shaped endless cable. Make a horizontal circular motion to form an independent small circular traction system. The small circulation system has the advantages of high power, large traction force, high construction efficiency and low cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

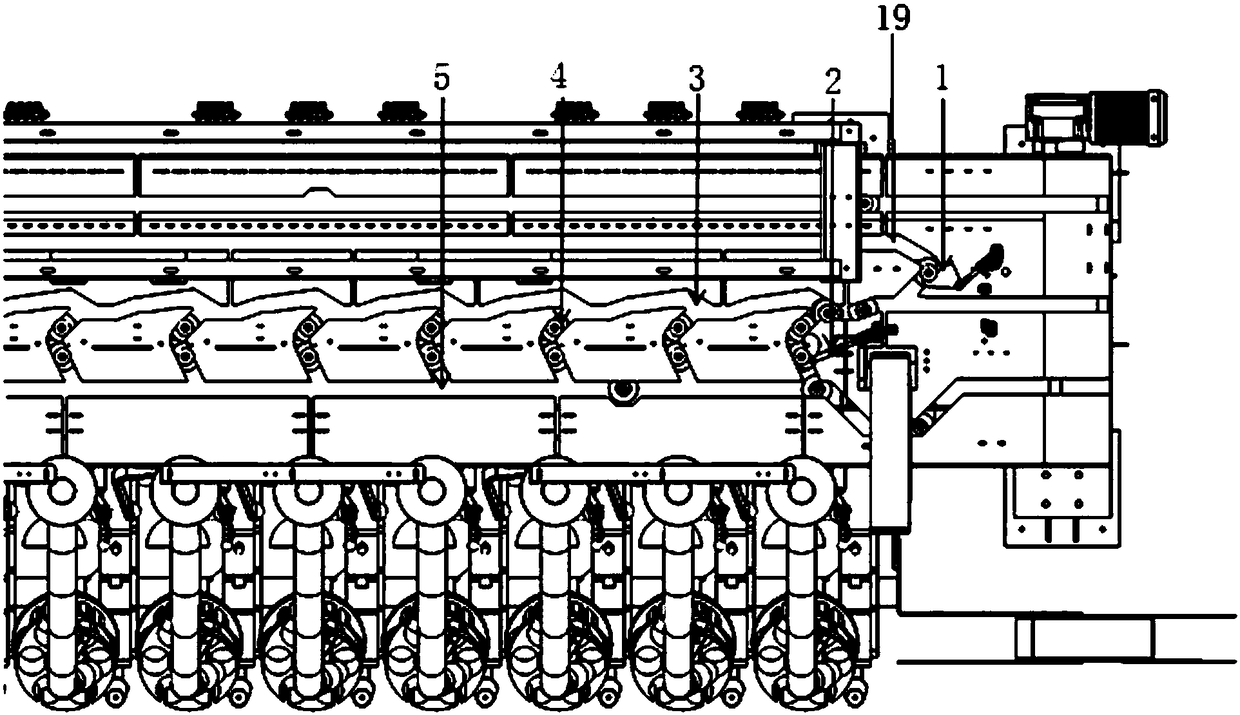

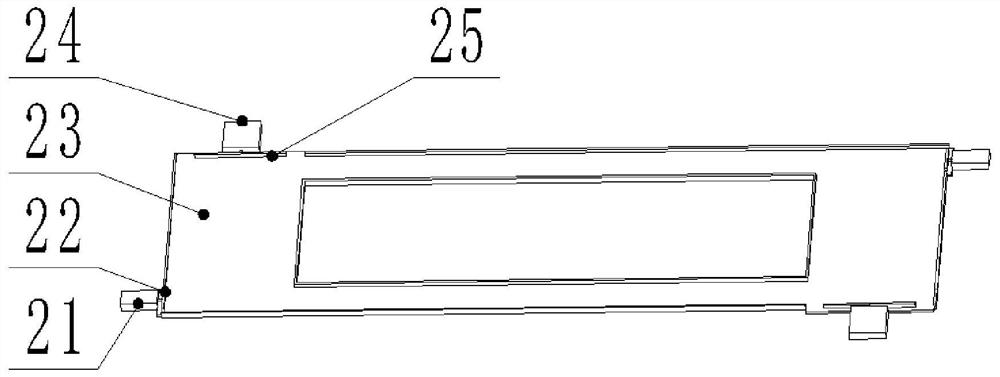

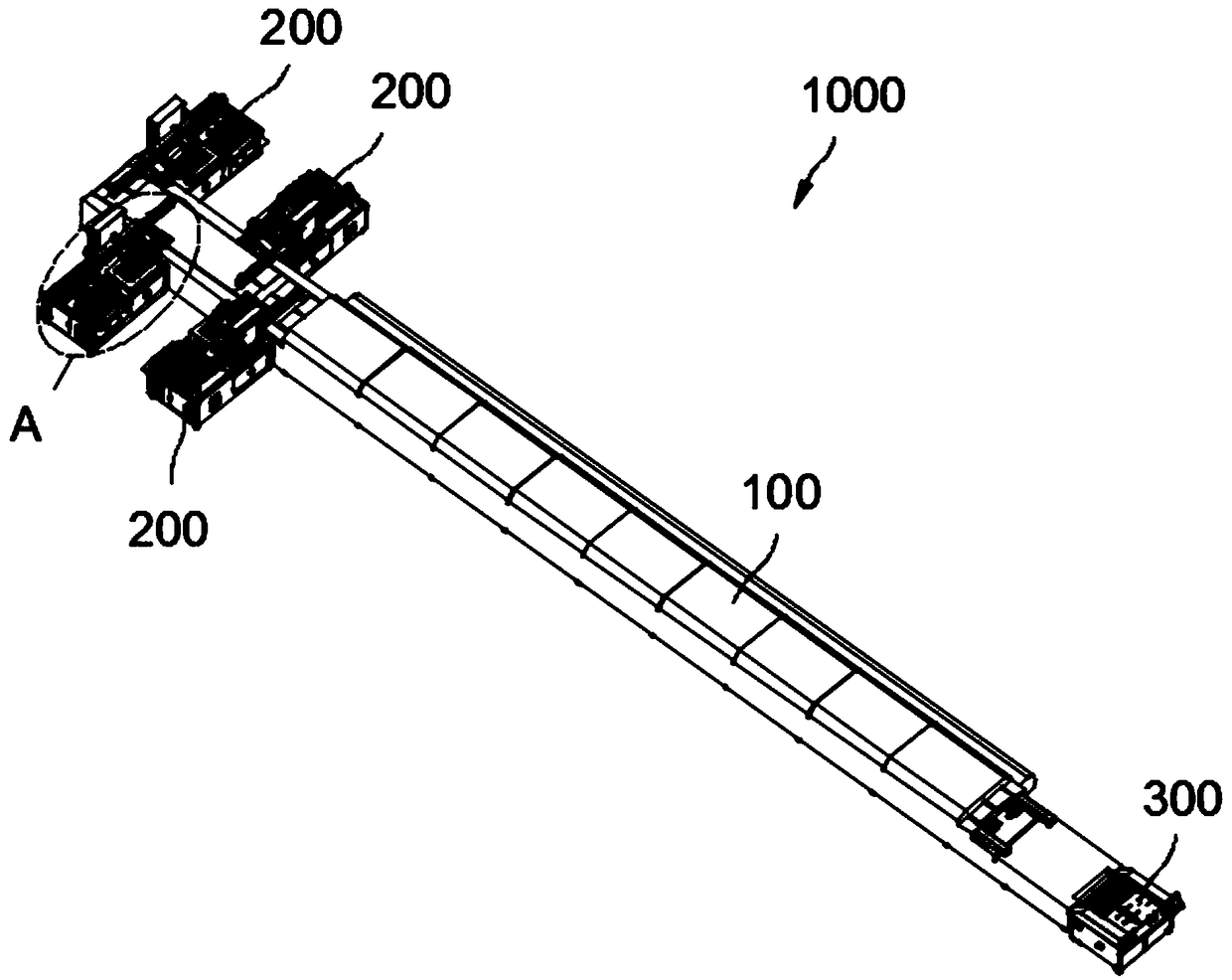

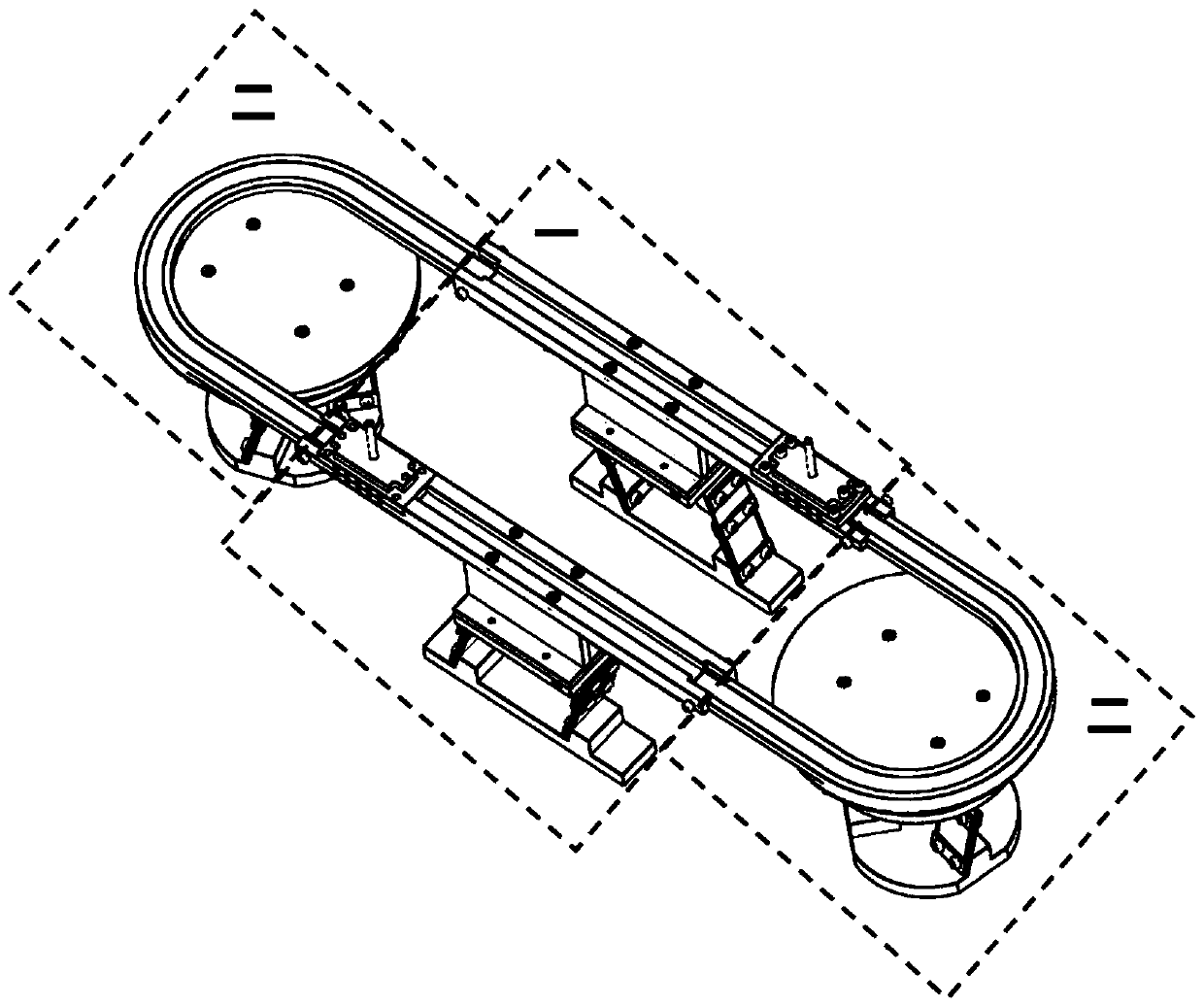

Conveying system of automatic yarn feeding equipment

PendingCN108529337AWith automatic sortingFunctionalFilament handlingTextile disintegration and recoveryYarnBobbin

The invention provides a conveying system of automatic yarn feeding equipment. According to the conveying system of the automatic yarn feeding equipment, the bobbin yarn distribution way of an original magazine-type automatic winder is improved; a frame platform structure is mainly adopted by the conveying system, and a whole bobbin yarn conveying platform is erected above original equipment; anda belt is adopted by a conveying platform for transmission, and channel movement formed by a guiding-type cover plate is used for achieving bobbin yarn distribution. In this way, the conveying systemhas the functions of automatically sorting and feeding bobbin yarn; and the production efficiency is improved, and the labor cost is reduced.

Owner:江阴市凯业纺织机械制造有限公司

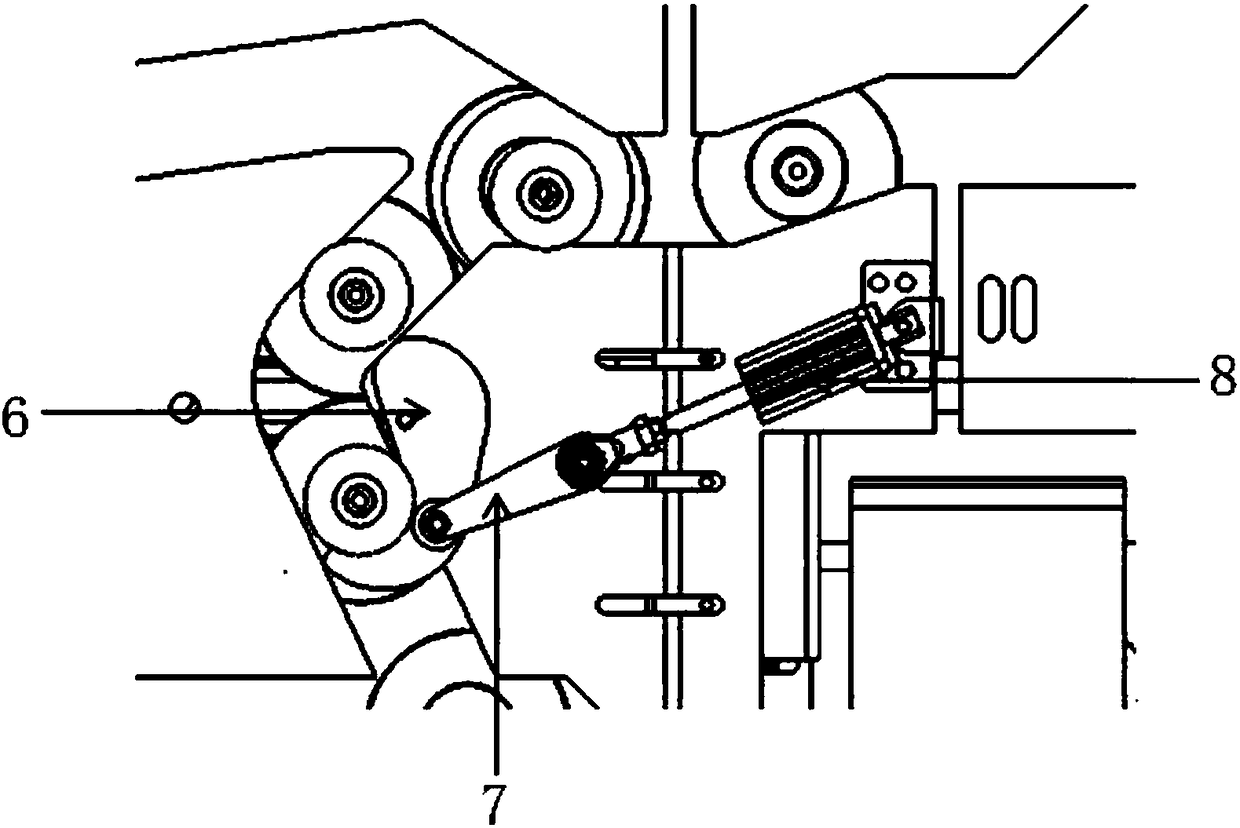

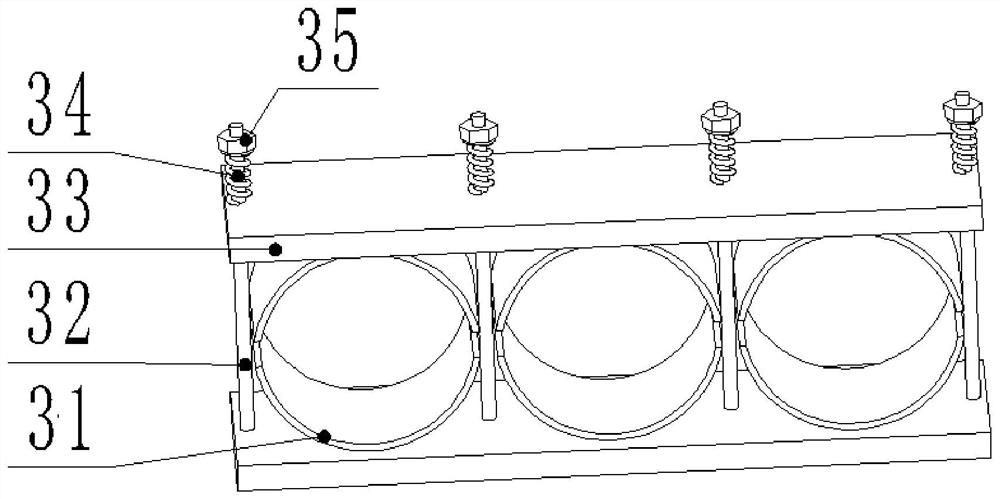

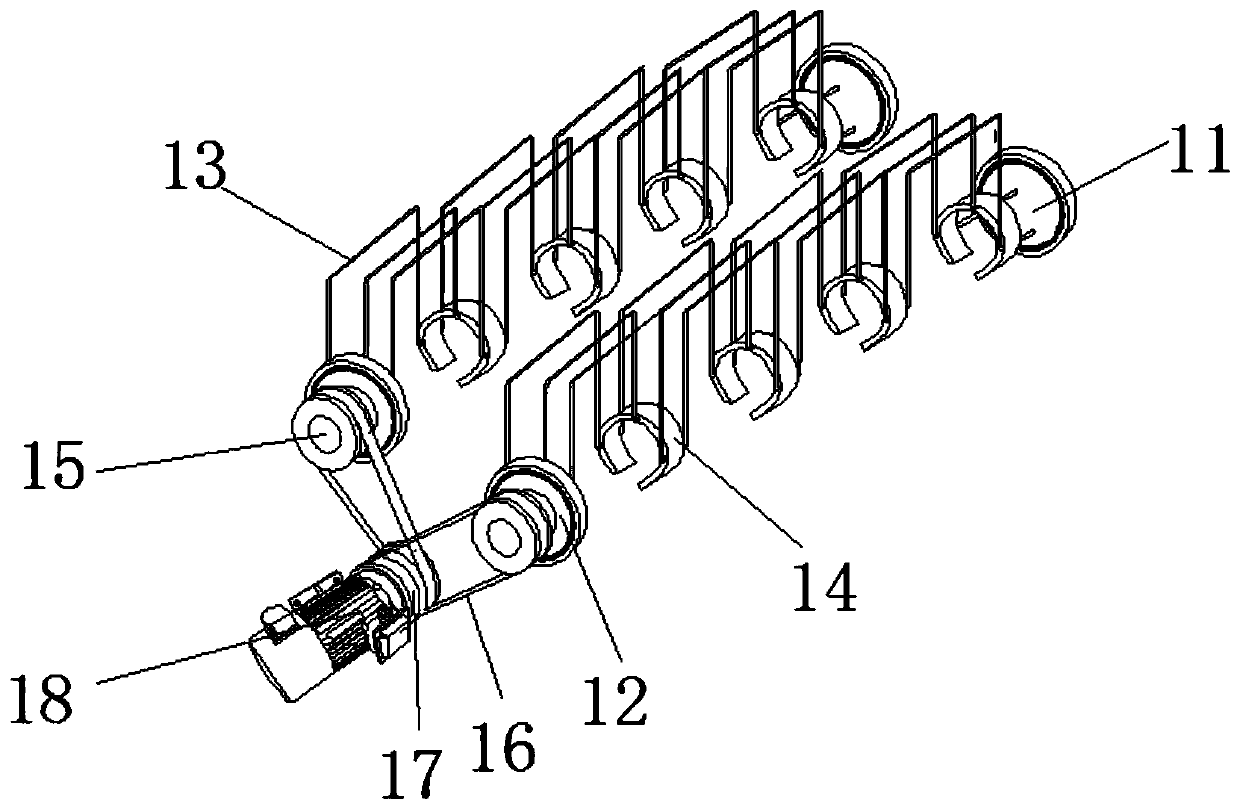

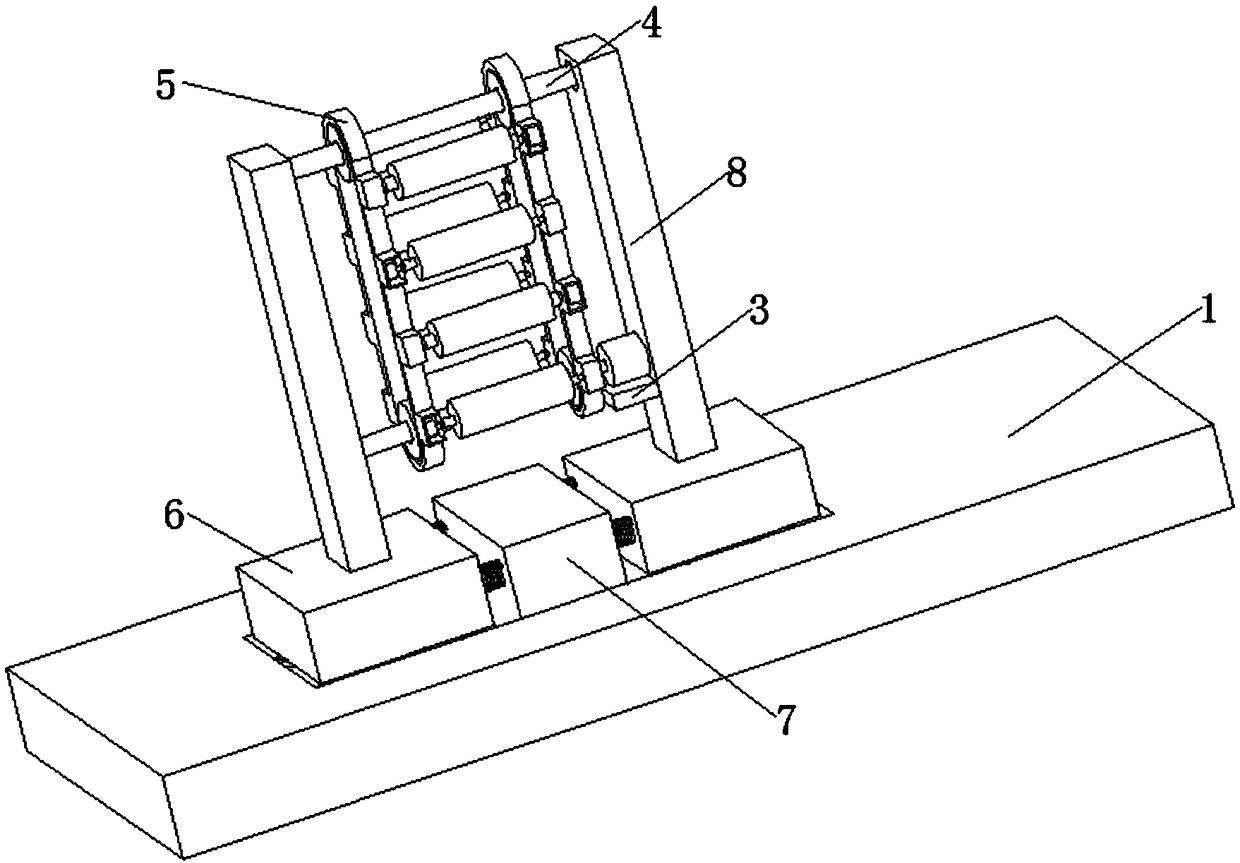

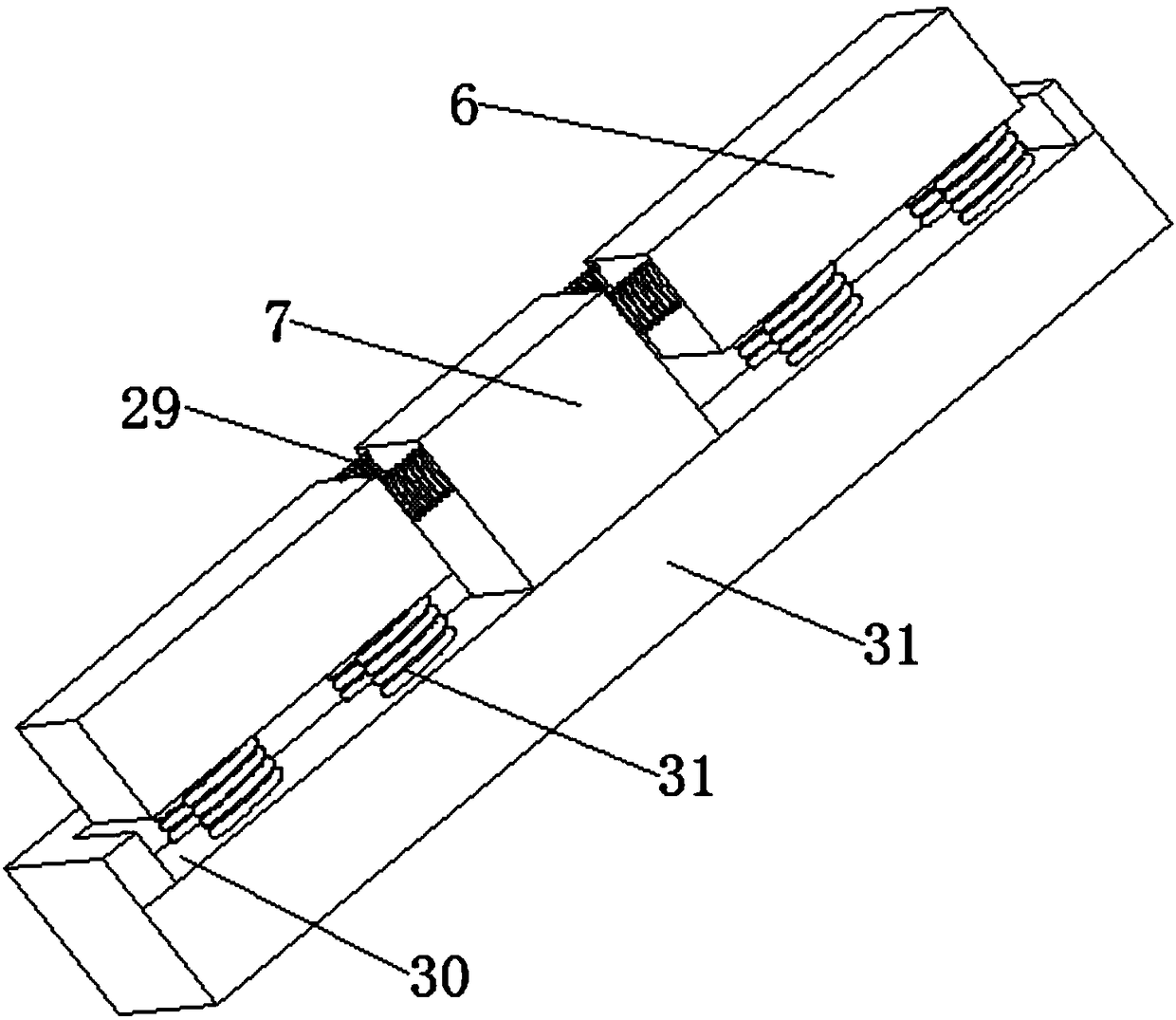

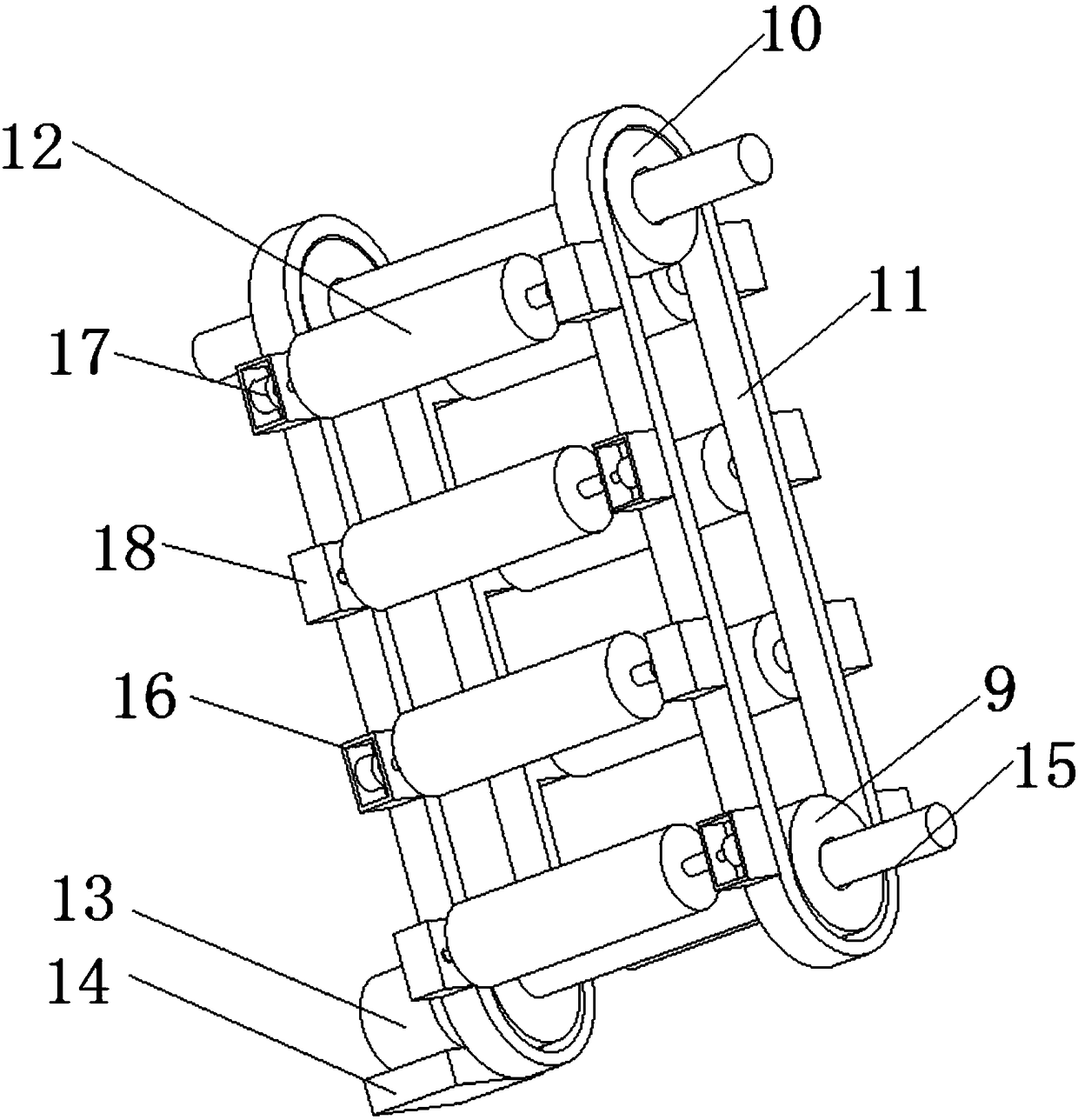

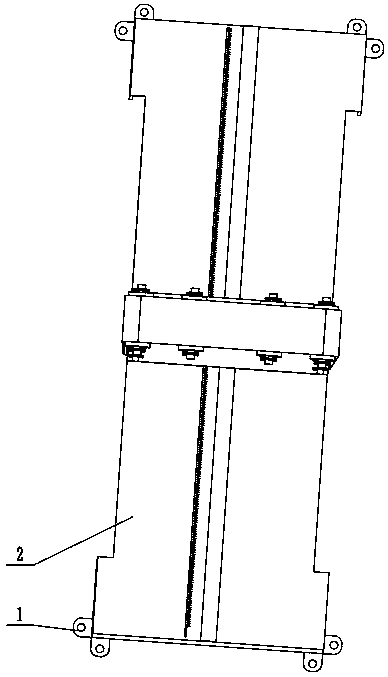

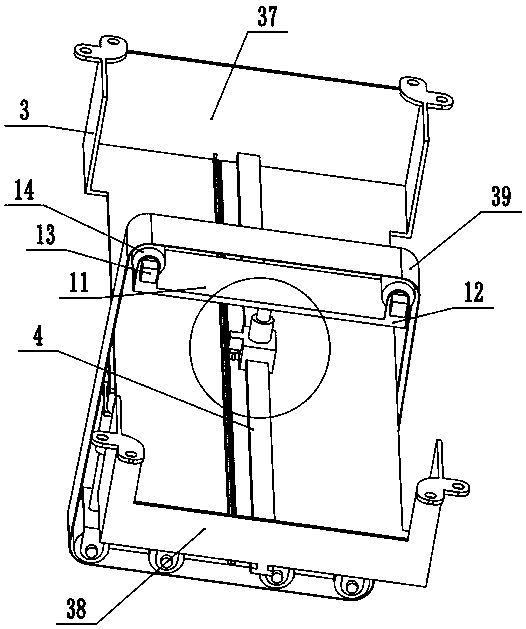

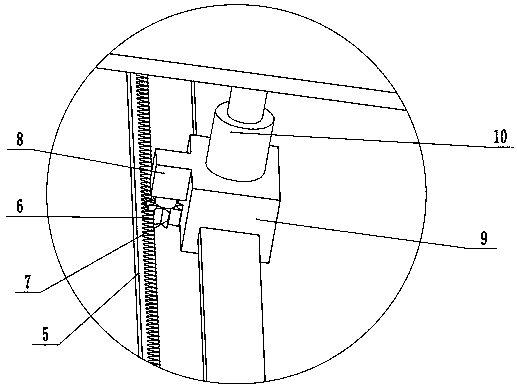

Coarse yarn circulating device in spinning frame

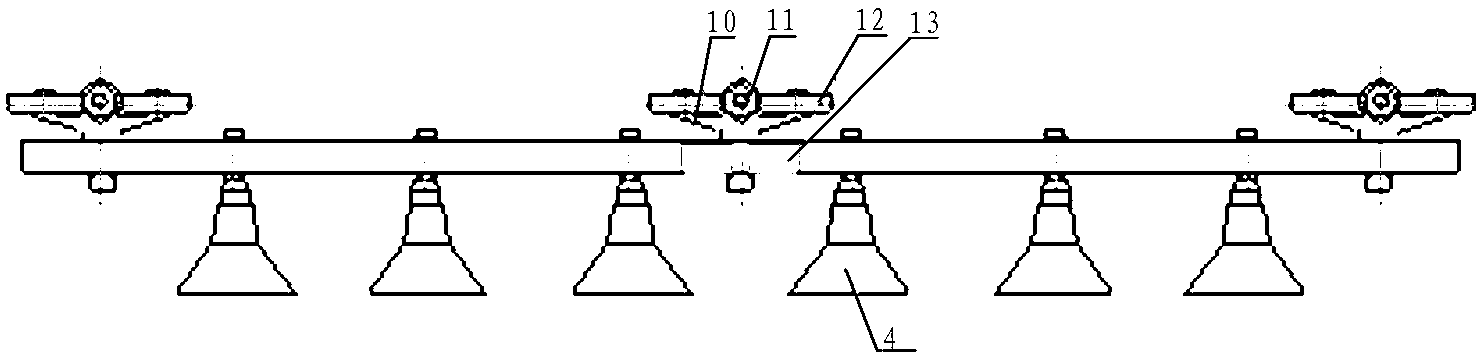

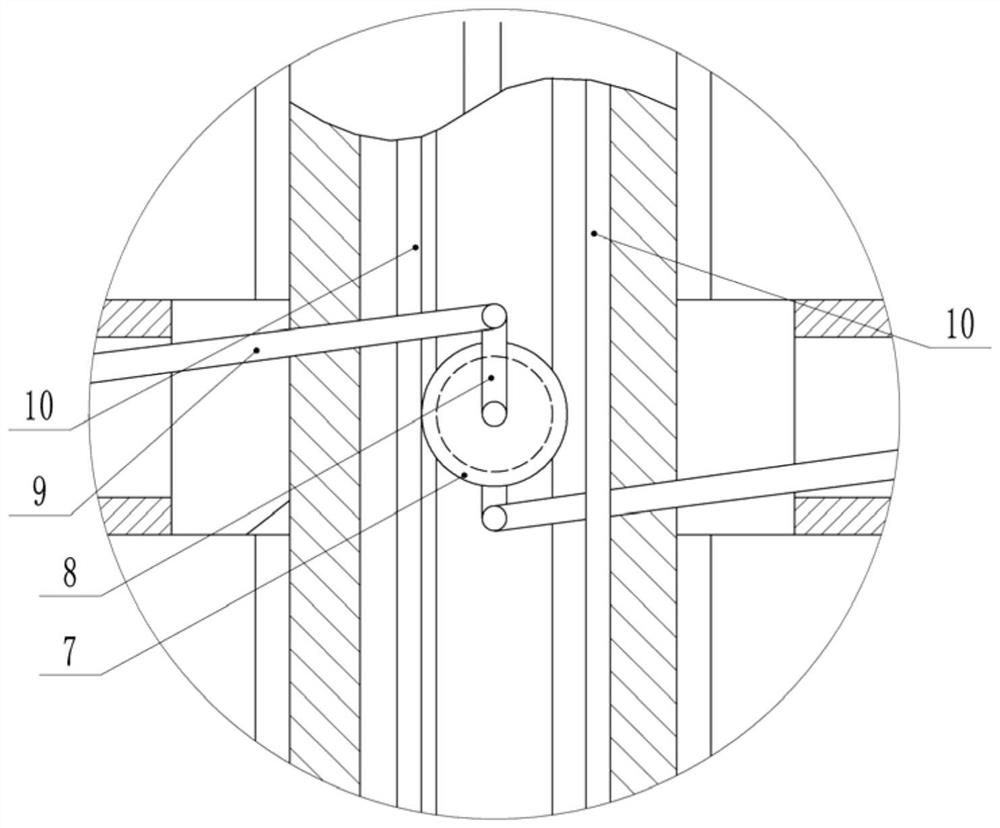

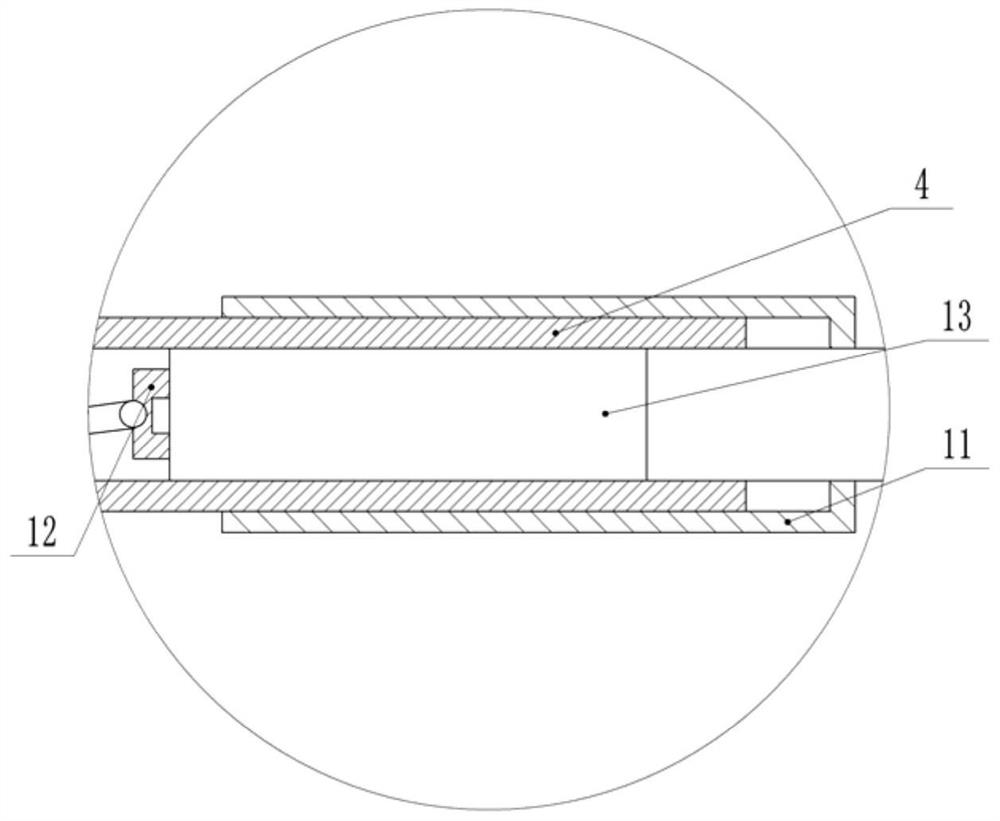

The invention relates to a coarse yarn circulating device in a spinning frame. A motor (5) is arranged below a track (1), gears (6) are arranged on an output shaft of the motor (5), first friction wheels (8) and second friction wheels (9) are arranged on the track (1), the first friction wheels (8) are connected with the gears (6) through synchronous belts (7), a conveying rod (2) is arranged in a groove of the track (1) through a conveying guide device (3), suspended spindles (4) are arranged below the conveying rod (2), a hinging piece (13) is arranged at each of two ends of the conveying rod (2), the adjacent hinging pieces (13) are connected through a shaft on the conveying guide device (3), the conveying rod (2) is positioned between the first friction wheels (8) and the second friction wheels (9), and the first friction wheels (8) and the second friction wheels (9) are connected with the conveying rod (2) in a rolling mode. Through the device, automatic circulating motion of coarse yarns is realized, the coarse yarns can be conveniently conveyed by roving workers, the labor intensity of the roving workers is reduced, and the working efficiency is improved.

Owner:山西经纬合力机械制造有限公司四厂

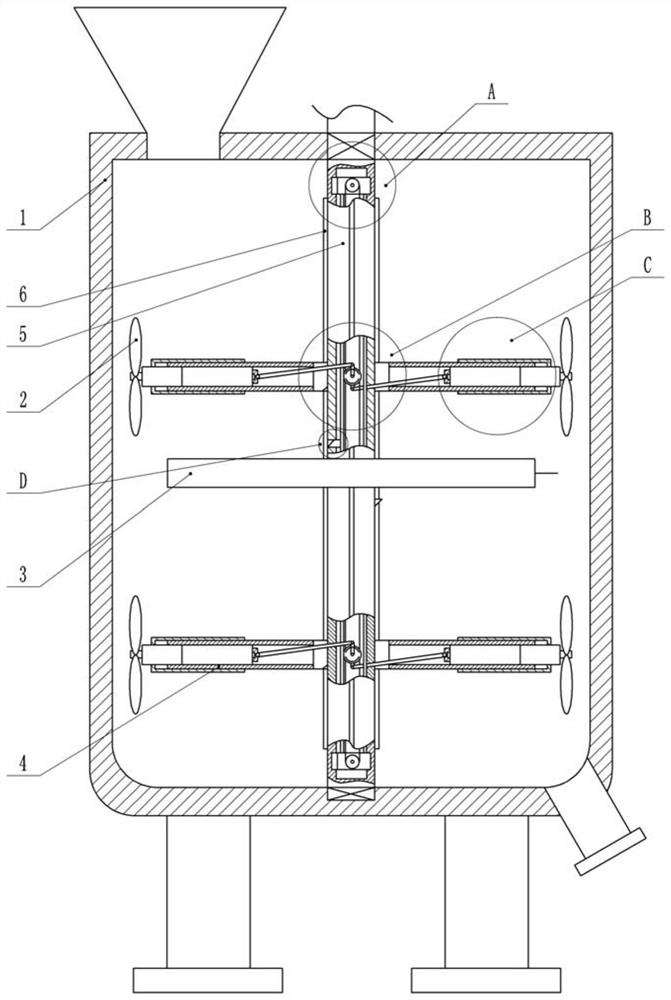

Pneumatic conveying device for conveying laminar materials

InactiveCN102602704APrevent bridgingReduce touch pointsLarge containersBulk conveyorsCement kilnEngineering

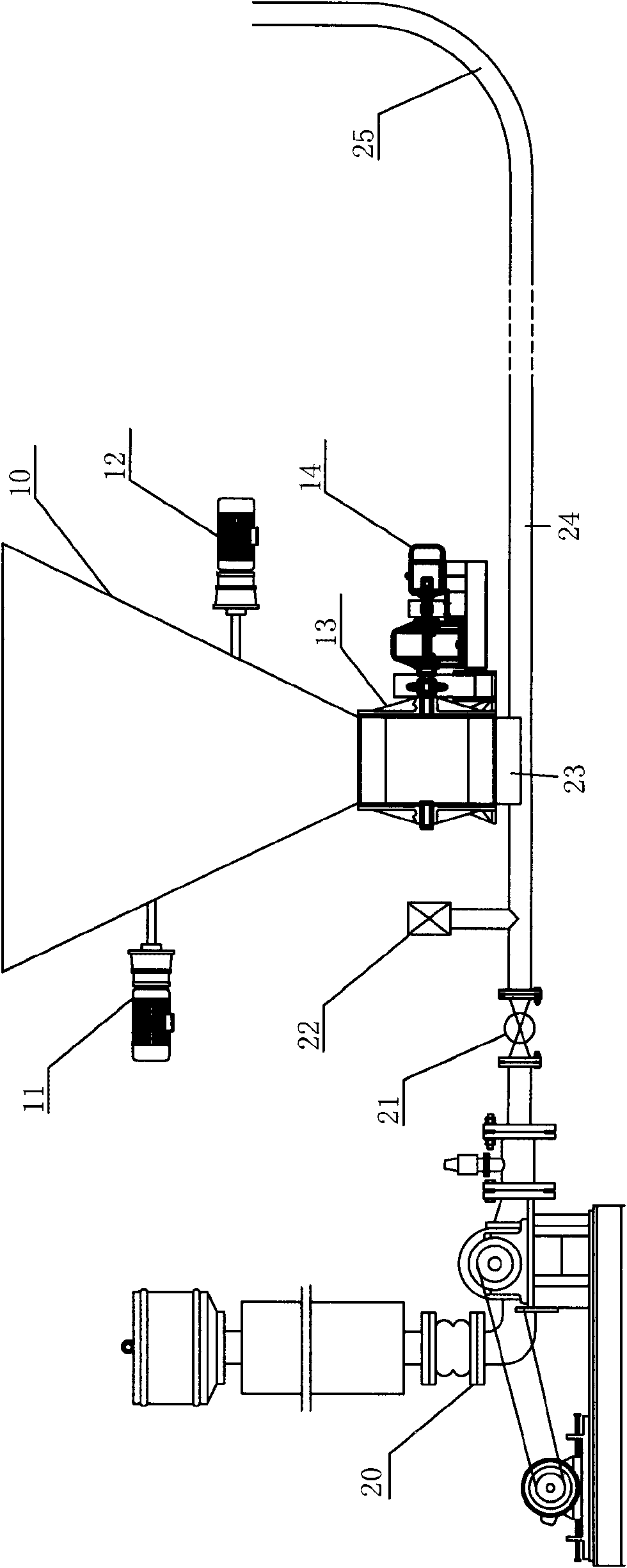

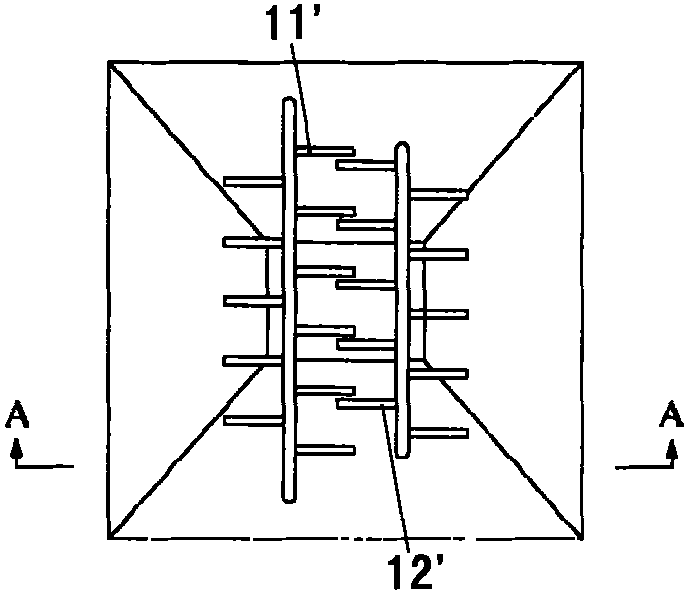

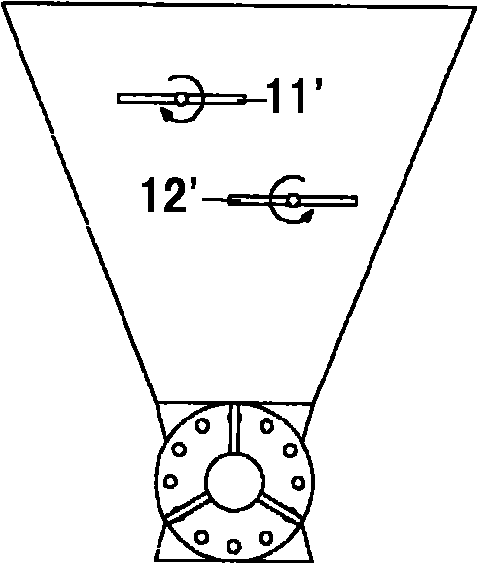

The invention discloses a pneumatic conveying device for conveying laminar materials, which is mainly composed of a metering, air locking and blanking part and a part of conveying air into a kiln; the metering, air locking and blanking part comprises a buffer blanking bin, wherein the lower port of the buffer blanking bin is connected with a rotary blanking device; two kick-out devices arranged up and down are transversely arranged in the buffer blanking bin, and the axle centers of the two kick-out devices are respectively situated at the two sides of a central line in the buffer blanking bin; and comb-shaped material kick-out teeth are arranged on a rotating shaft of the kick-out device, and the comb-shaped material kicking teeth are staggered with each other. The part of conveying air into the kiln comprises a roots blower connected with an air conveying pipeline; the rotary blanking device of the metering, air locking and blanking part is connected with the air conveying pipeline through a blanking chute; and the other end of the air conveying pipeline is connected with a multi-passage combustor of a cement kiln precombustion furnace or a cement kiln front. The pneumatic conveying device for conveying laminar materials, disclosed by the invention, can effectively convey glass fiber reinforced plastic composite materials serving as cement to replace fuel.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH

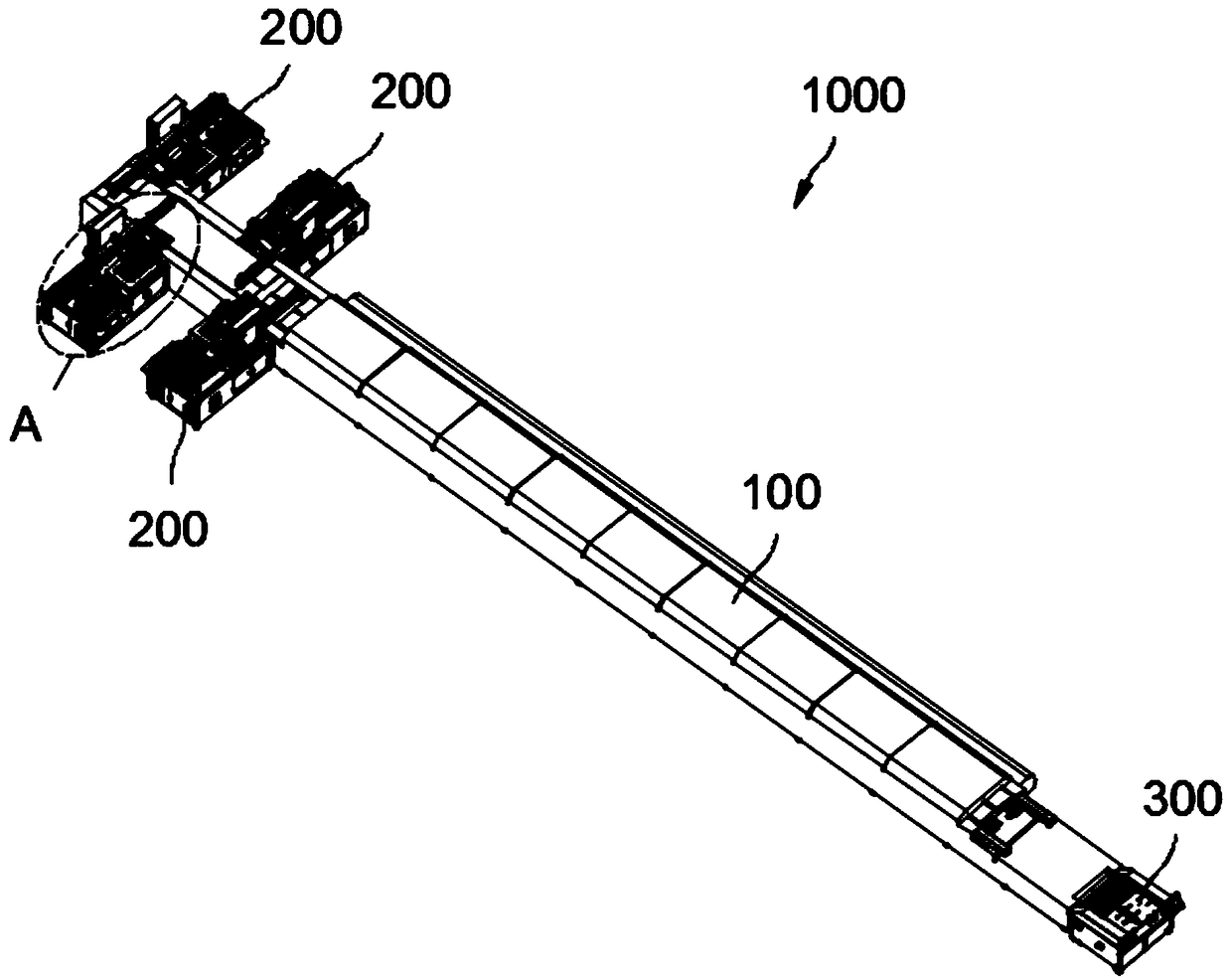

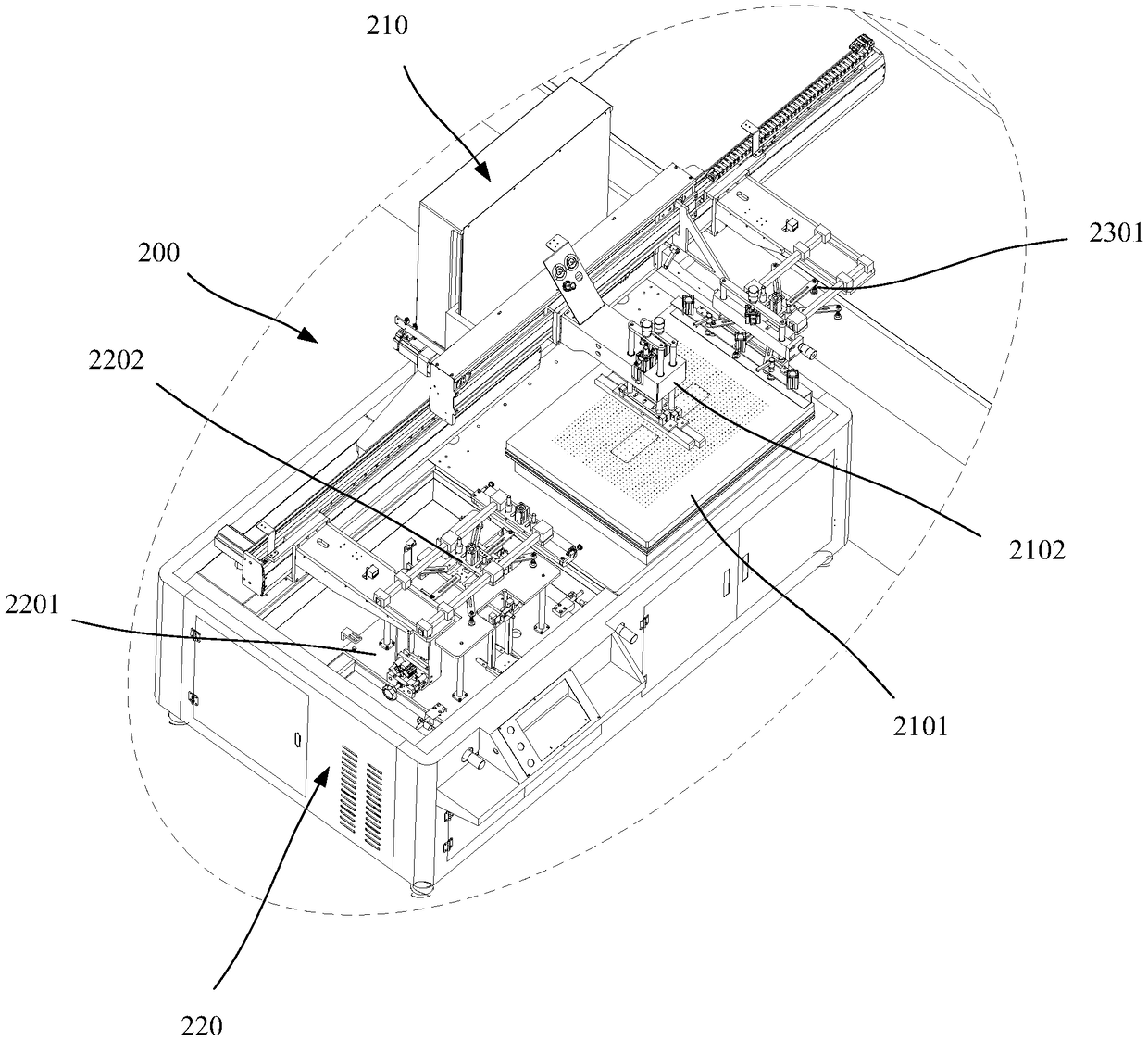

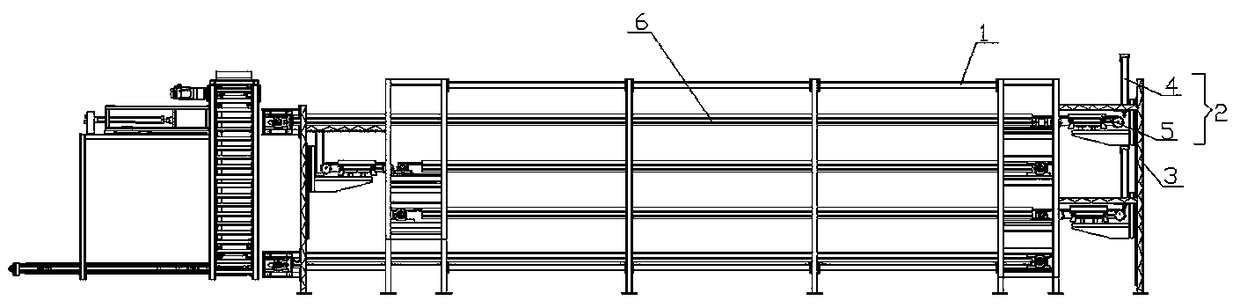

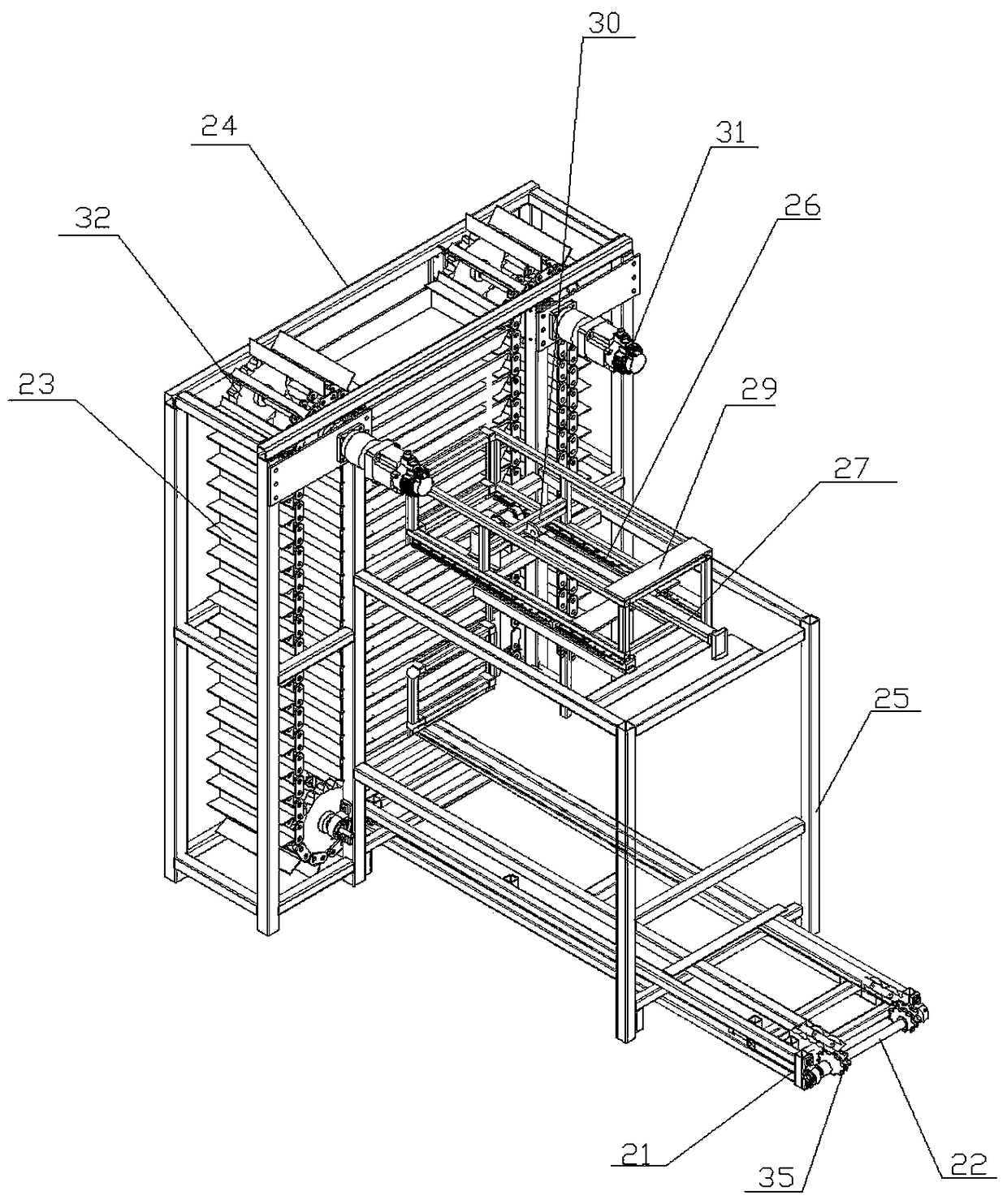

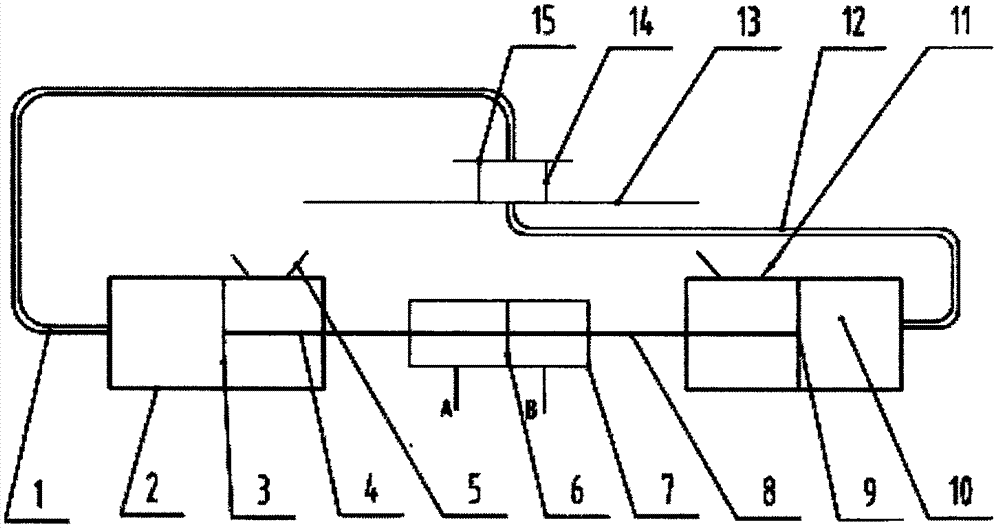

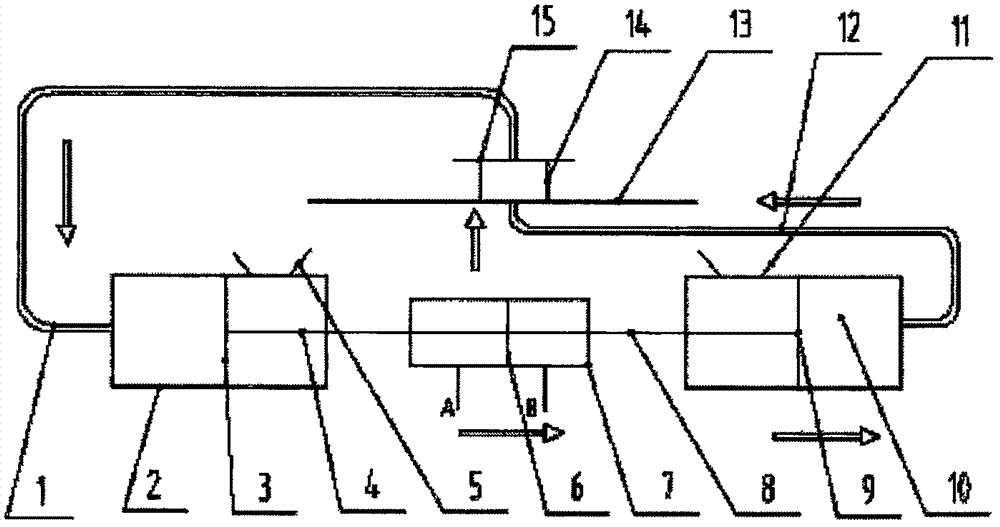

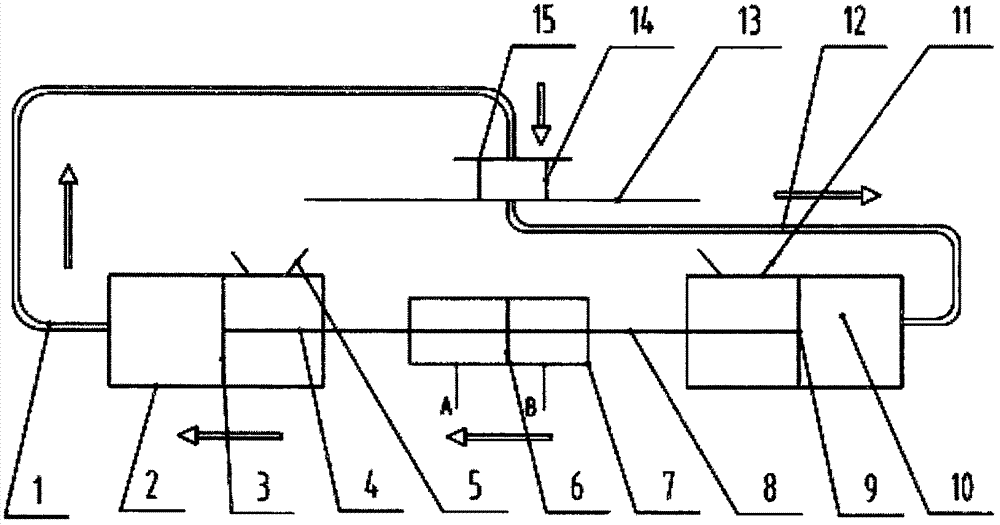

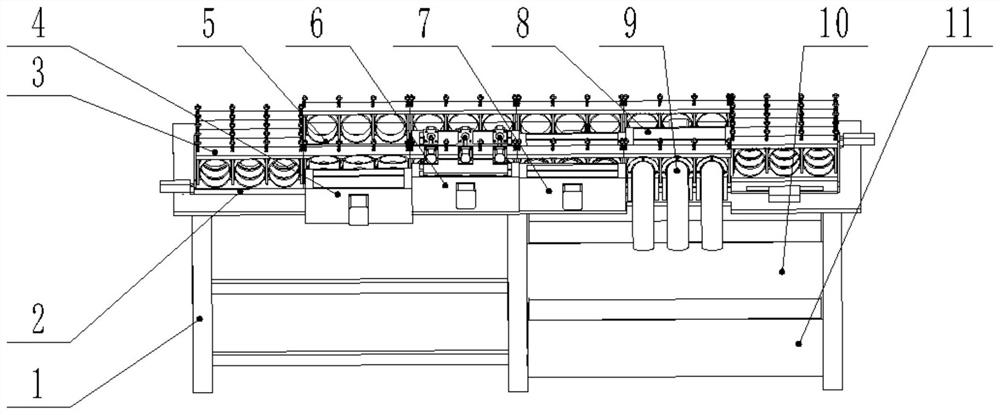

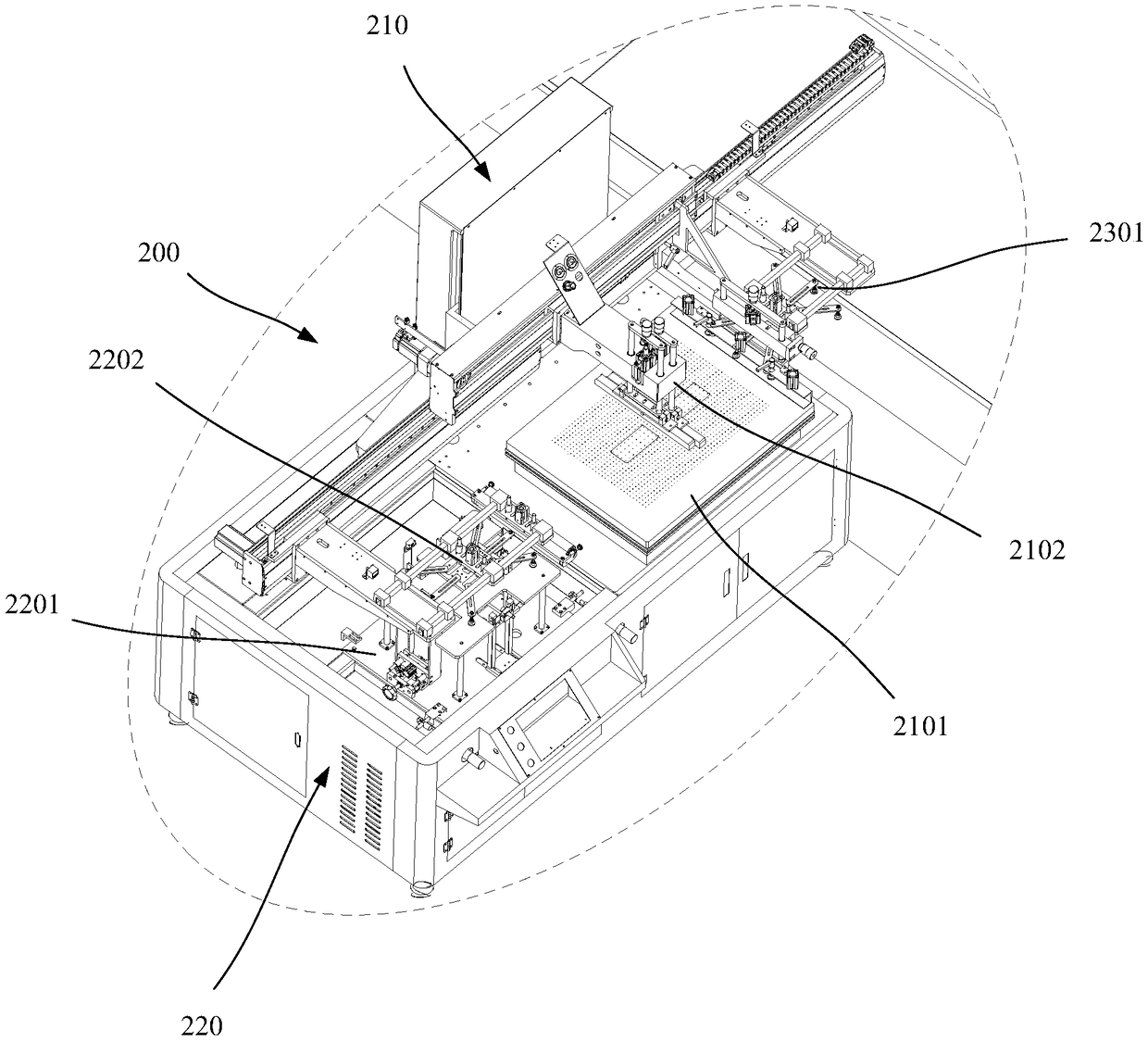

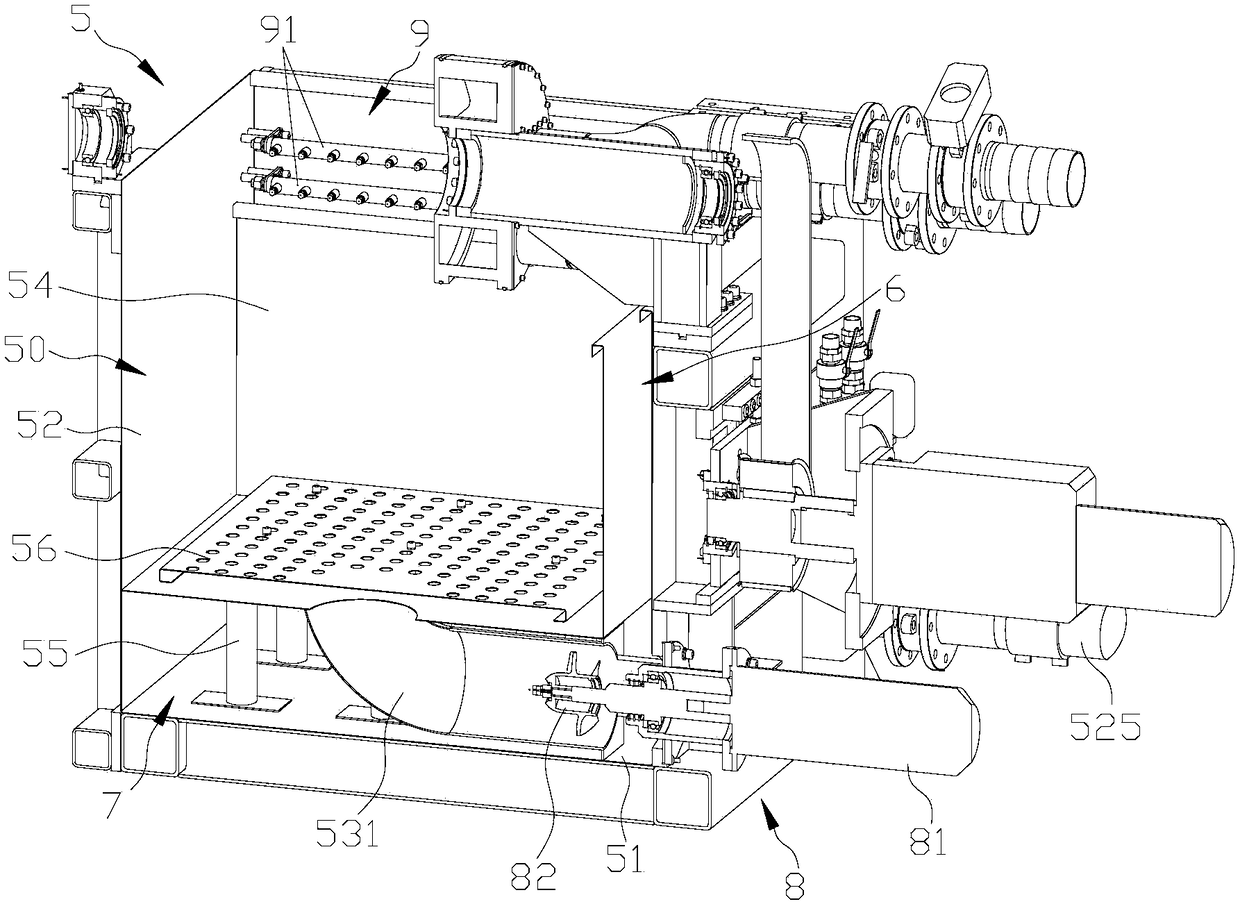

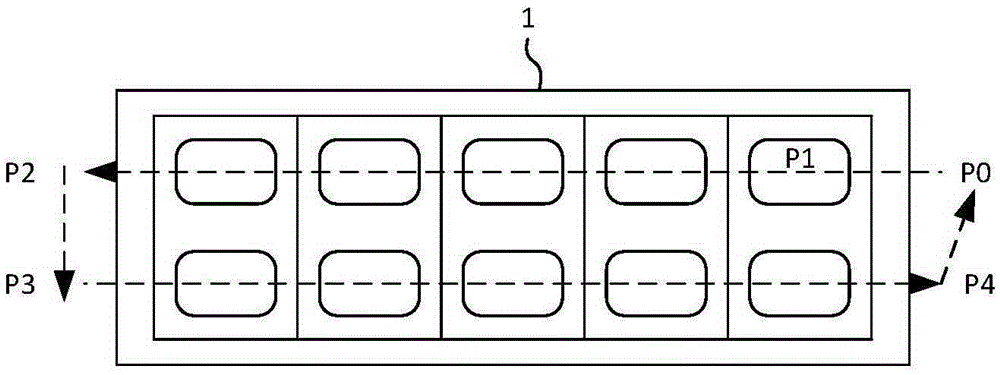

Printing production system

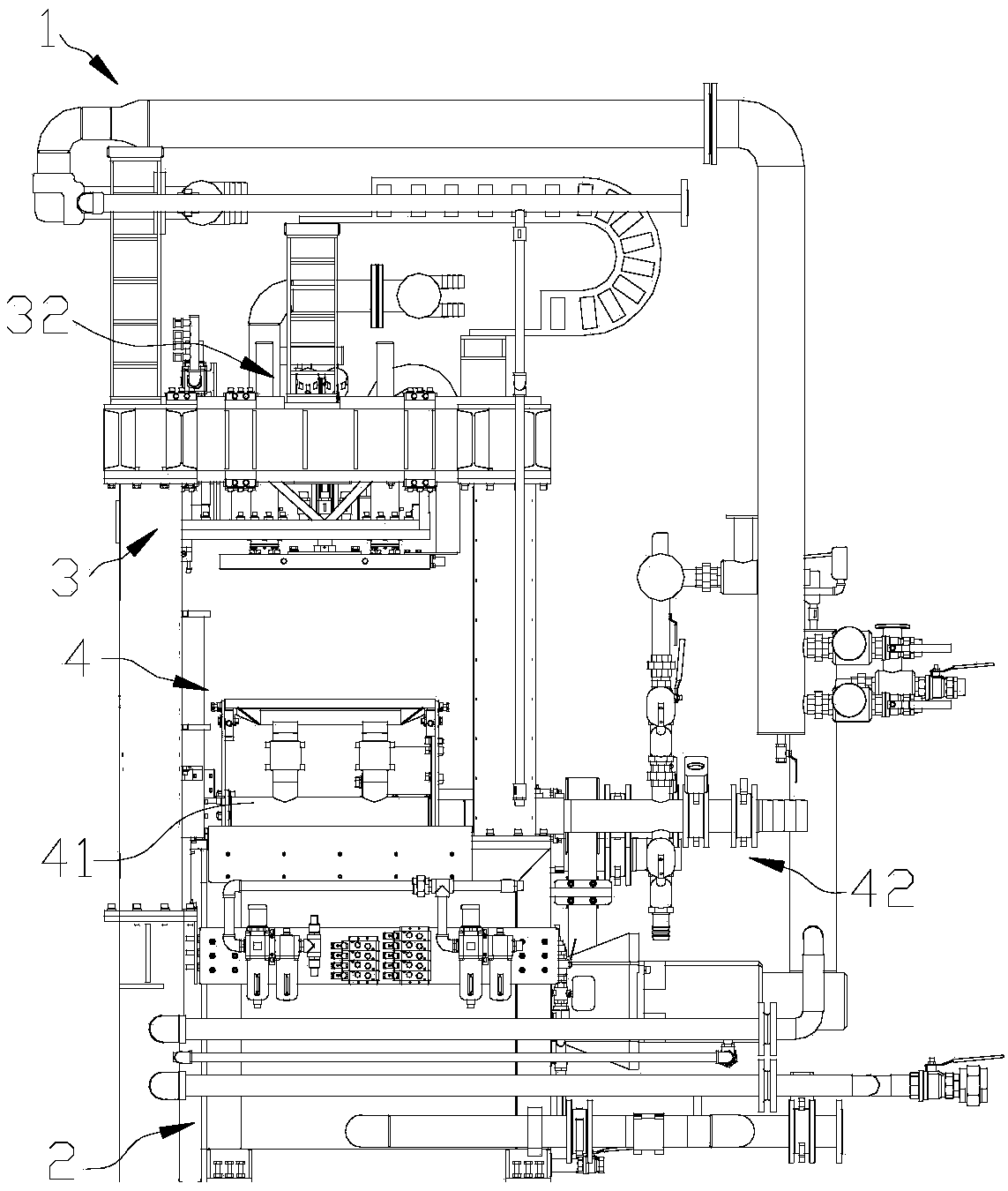

PendingCN109228645ARealize circular motionExtended drying timePrinting press partsEngineeringPrinting press

The invention discloses a printing production system. The printing production system comprises a multi-layer circular tunnel furnace and printing machines arranged at the feeding end of the multi-layer circular tunnel furnace, wherein printing materials printed by the printing machines are delivered to the multi-layer circular tunnel furnace, the multi-layer circular tunnel furnace comprises shells, multiple layers of in-furnace conveying belts and transferring mechanical arms, drying channels are arranged in the shells, multiple layers of the in-furnace conveying belts are distributed in thedrying channels at intervals in the vertical direction, and the transferring mechanical arms are used for converting the printing materials between the different layers of in-furnace conveying belts so that the printing materials can be circularly conveyed on the different layers of in-furnace conveying belts. According to the printing production system, the occupied space of the multi-layer circular tunnel furnace and the occupied space of the printing production system can be reduced, the multi-layer circular tunnel furnace and the printing production system can be suitable for small production sites, and the cost can be reduced.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Printer ink supply system with circulating piezoelectric pump

The invention relates to a printer ink supply system with a circulating piezoelectric pump. The printer ink supply system comprises an ink cartridge, a nozzle, a first connecting pipe, a second connecting pipe, a third connecting pipe and the circulating piezoelectric pump, wherein the ink cartridge is connected to the nozzle through the first connecting pipe, the ink cartridge is connected to the ink inlet of the piezoelectric pump through the second connecting pipe, and the ink outlet of the piezoelectric pump is connected to the ink cartridge through the third connecting pipe. A piezoelectric vibrator is energized to form vertical reciprocating deformation, when the piezoelectric vibrator moves downwardly, the volume of an accommodating cavity increases, pressure intensity reduces, and ink in the ink cartridge enters the accommodating cavity; when the piezoelectric vibrator moves upwardly, the volume of the accommodating cavity increases, pressure intensity increases, the ink in the accommodating cavity flows back to the ink cartridge, and ink circulation in the ink cartridge and the piezoelectric pump is achieved. The printer ink supply system has the advantages that ink dye precipitation and sedimentation are prevented, nozzle scaling and blocking are prevented, nozzle service life is prolonged, the ink can be evenly mixed, and ink flowability is enhanced.

Owner:JILIN UNIV

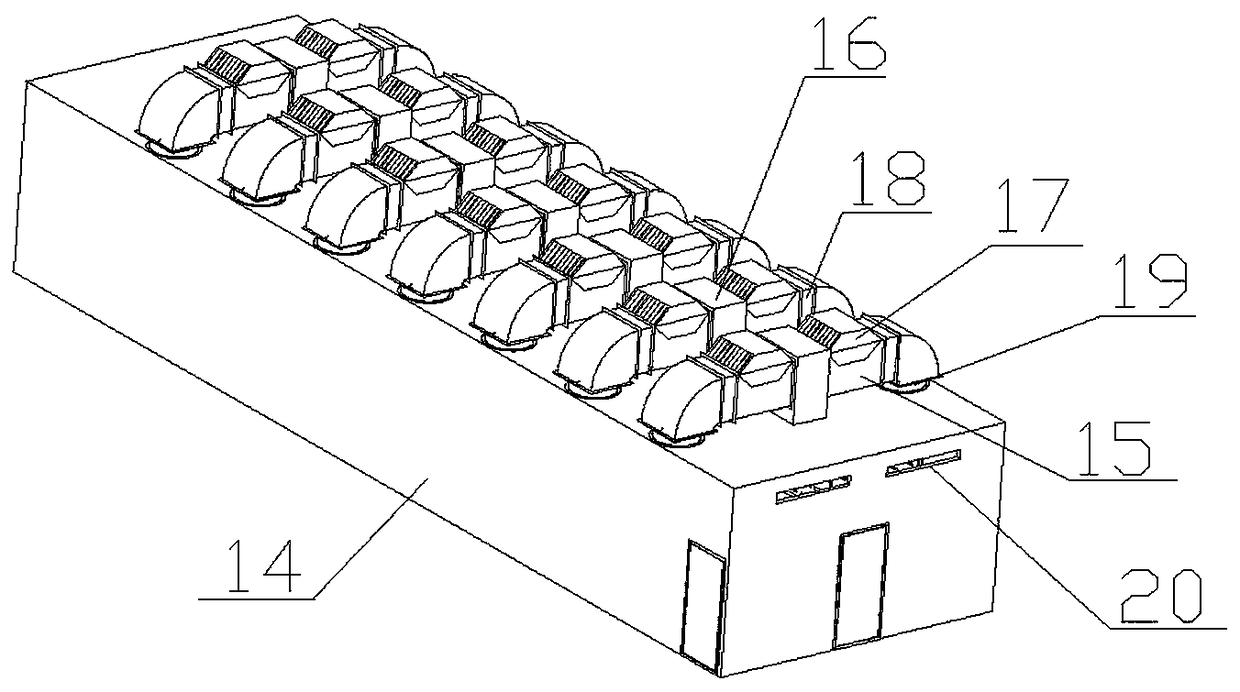

Hawthorn fruit drying device with charging machine

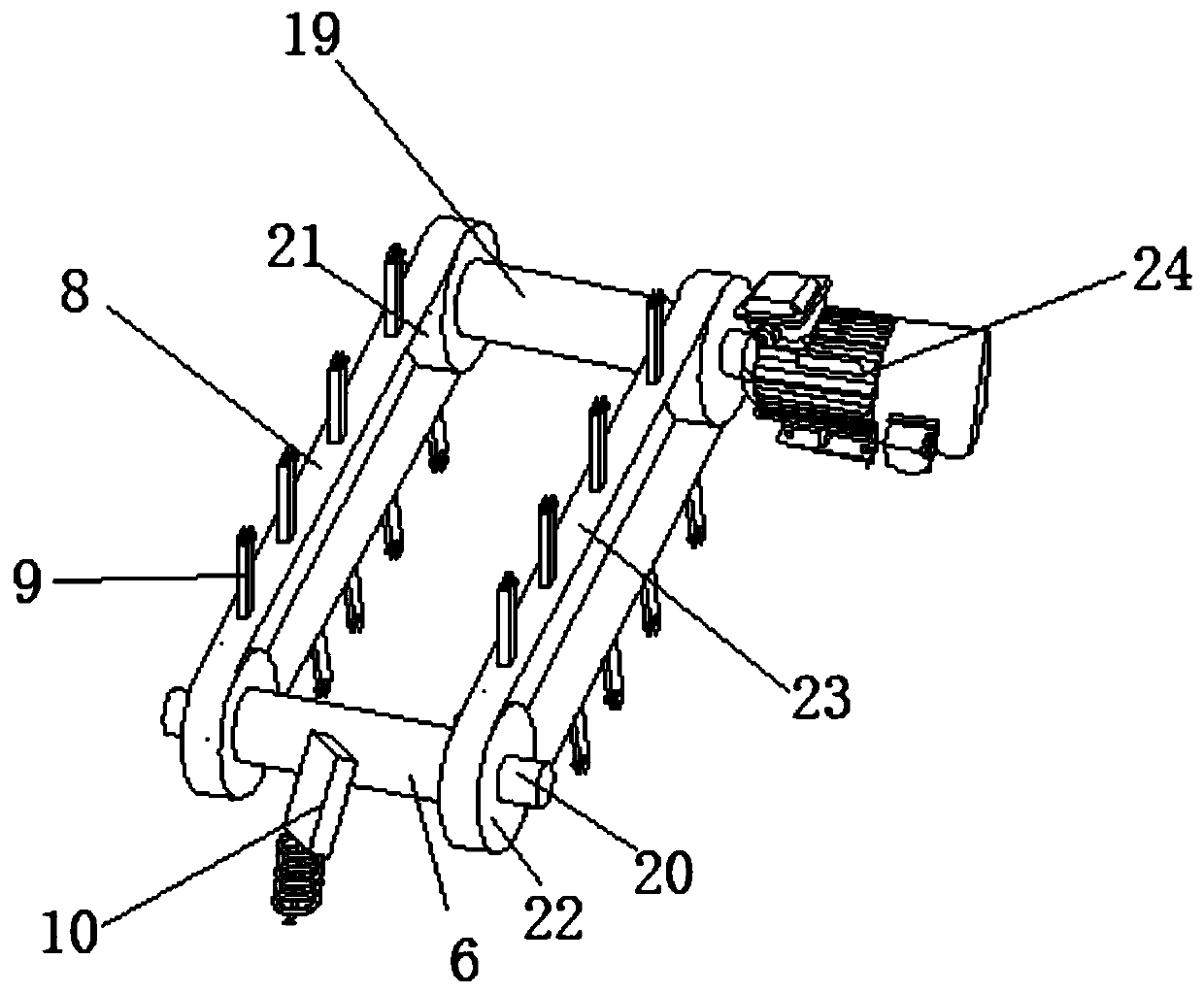

ActiveCN109170974AIncrease frictionImprove stabilityFood treatmentFood processingEngineeringMechanical engineering

The invention discloses a hawthorn fruit drying device with a charging machine. The hawthorn fruit drying device comprises a drying room, the charging machine, a plurality of heat transforming systemsand a conveying device, wherein the charging machine is arranged outside the drying room; the heat transforming systems are arranged in parallel above the drying room; the conveying device is positioned in the drying room; a material inlet is formed at the top of one end of the drying room, and a material outlet is arranged at the bottom of the drying room; the charging machine comprises a conveying part arranged at the bottom of one side of the material inlet of the drying room, a lifting part positioned at the end part of the inner side of the conveying part and a pushing part positioned atthe outer side of the lifting part; and the conveying device comprises a support frame, lifting mechanisms symmetrically arranged at both ends of the support frame, and a plurality of conveying mechanisms arranged in parallel on the support frame. The hawthorn fruit drying device with the charging machine has simple structure, energy conservation, environment friendliness, high drying efficiencyand good quality of hawthorn fruits, uniformity of operation in a transport process and no noise pollution, and can realize continuous transfer among transfer devices of different height.

Owner:河南中联热科工业节能股份有限公司

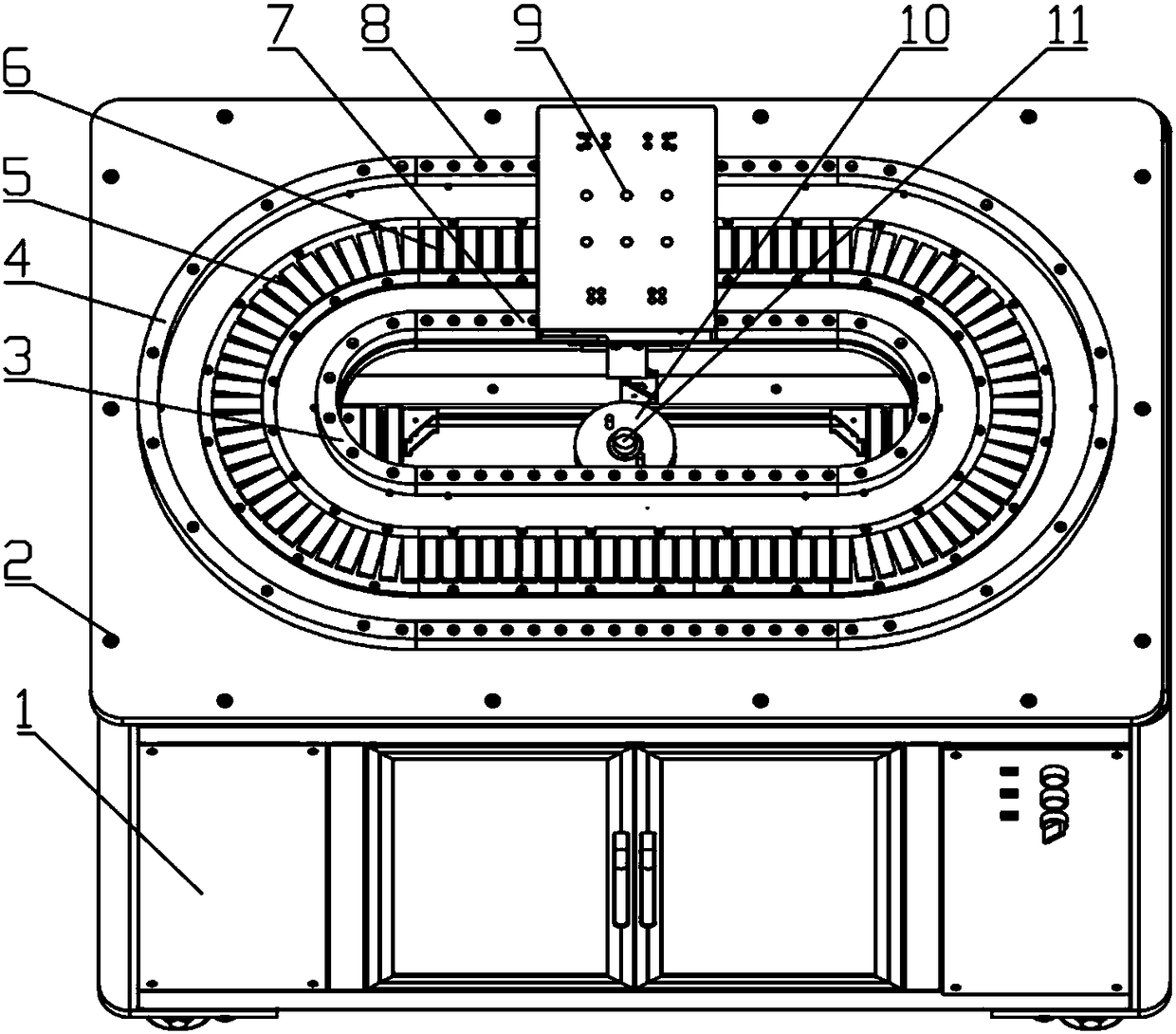

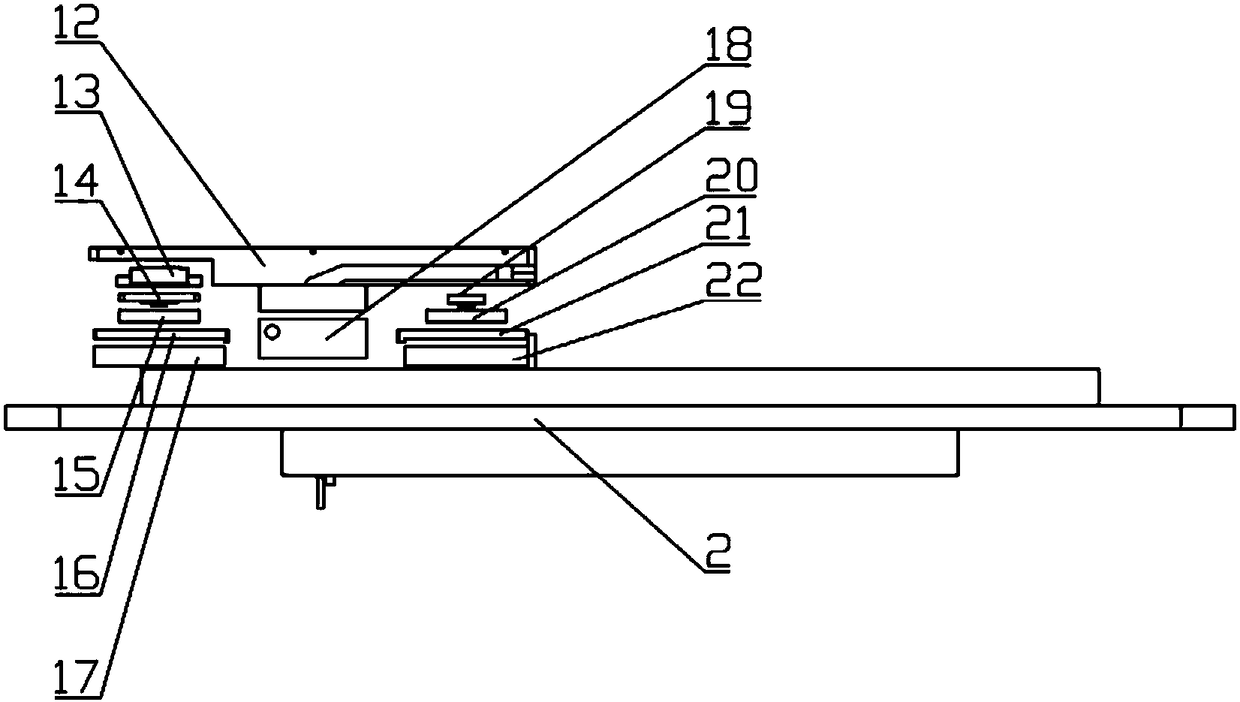

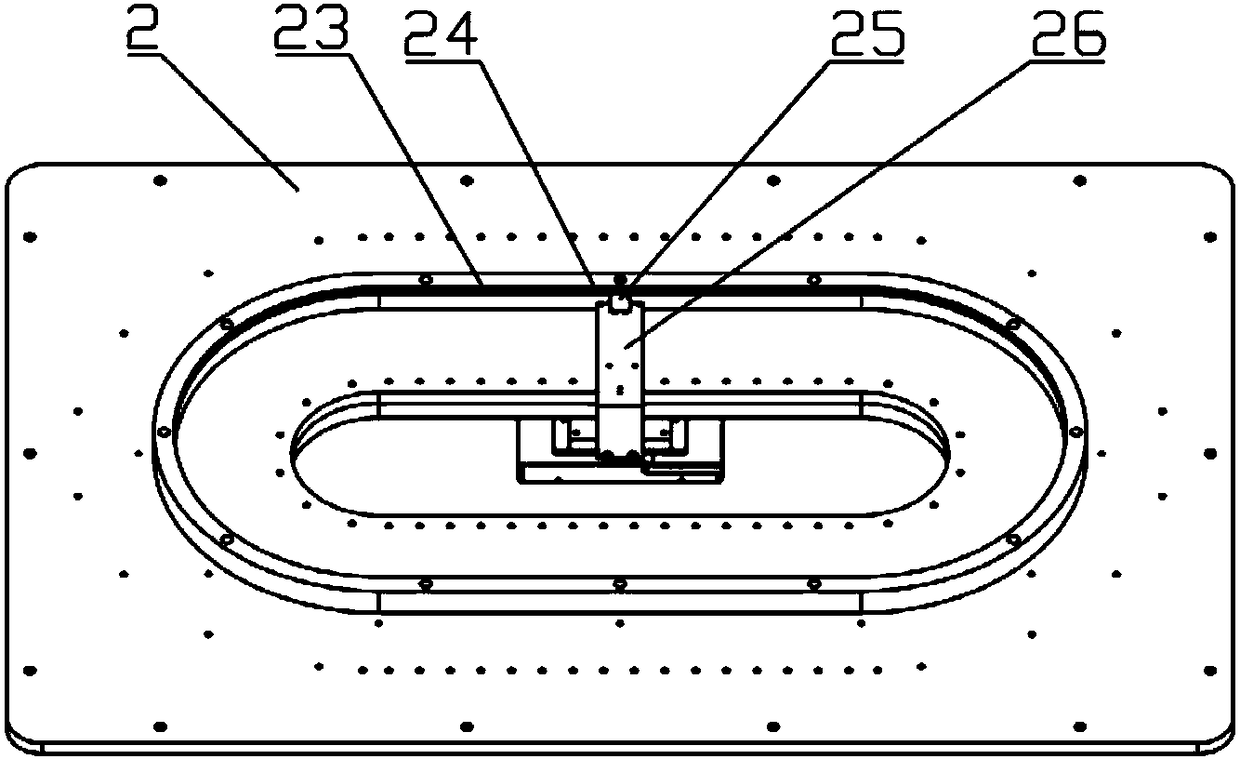

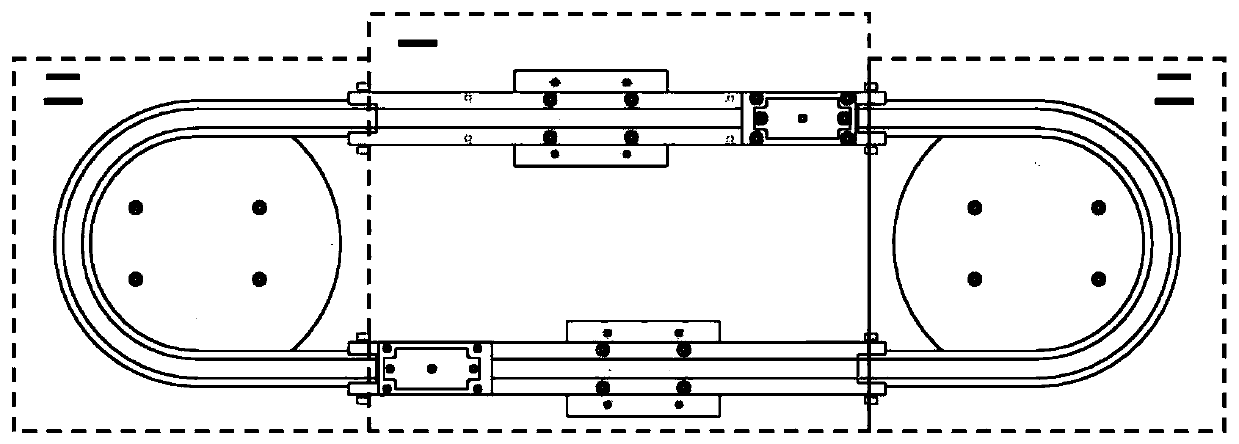

High-precision annular production device for linear motor

PendingCN108365732AReduce cumulative errorImprove response speed and transmission accuracyStructural associationPropulsion systemsStatorEngineering

The invention discloses a high-precision annular production device for a linear motor. The high-precision annular production device for the linear motor comprises a rack, a bottom plate fixedly installed on the rack, an annular stator magnetic steel fixedly installed on the bottom plate, an outer ring guide rail fixedly installed on the bottom plate and located on the outer side of the annular stator magnetic steel, an inner ring guide rail fixedly installed on the bottom plate and located on the inner side of the annular stator magnetic steel, a sliding seat installed on the outer ring guiderail and the inner ring guide rail in a sliding way, a position feedback structure installed below the bottom plate, a sliding ring fixing shaft fixedly installed at the bottom part of the rack, and ahollow electric conduction sliding ring installed on the sliding ring fixing shaft, the sliding ring fixing shaft and the hollow electric conduction sliding ring are located in the inner part of thespace enclosed by the inner ring guide rail, and the hollow electric conduction sliding ring is electrically connected with the sliding seat and the position feedback structure through a connecting wire. The device improves the response speed and the transmission precision, the positioning accuracy of the device is improved, and the annular cyclic motion of a linear motor rotor is achieved.

Owner:SUZHOU UNIV

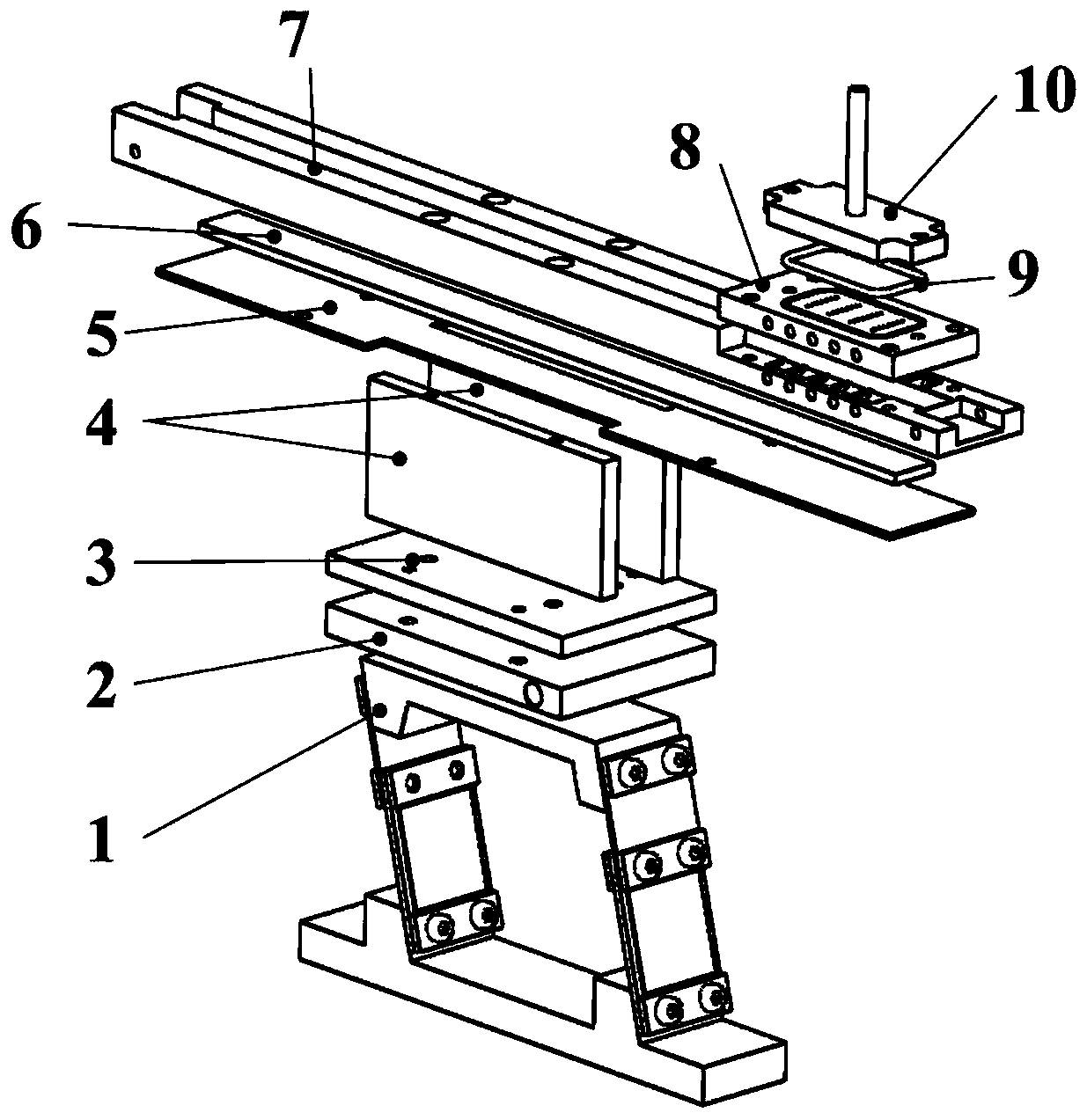

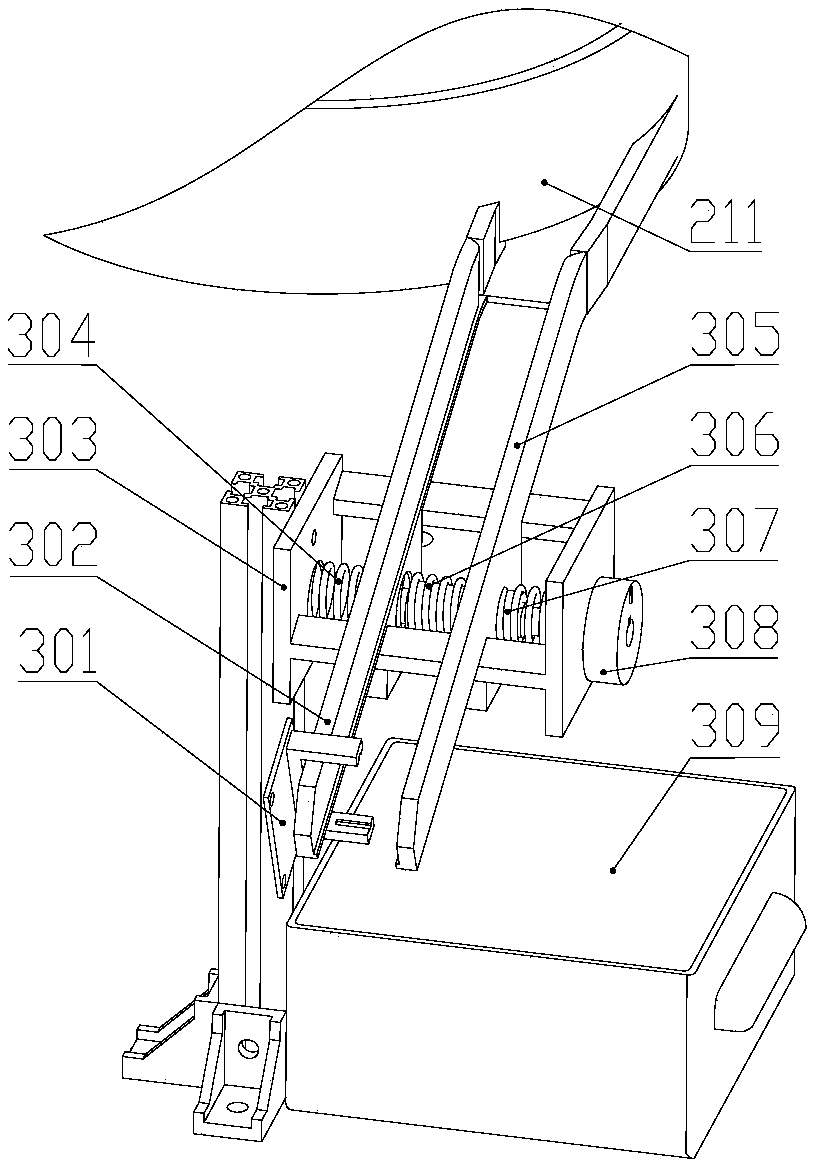

Horizontal reciprocating abrasive grain current polisher mechanical structure

PendingCN107350957ARealize circular motionSolve wasted energy consumptionEdge grinding machinesPolishing machinesHydraulic cylinderEngineering

The invention discloses a horizontal reciprocating abrasive grain current polisher mechanical structure. The mechanical structure comprises an abrasive motion circulating device, a power device, a working platform, a fixture and the like. The abrasive motion circulating device is divided into a left abrasive motion device, a right abrasive motion device and an abrasive circulating pipe; the left abrasive motion device comprises a charging barrel, a hopper and a pressure plate; the right abrasive motion circulating device comprises a charging barrel, a hopper and a pressure plate; the power device is provided by a double-output-rod hydraulic cylinder, and comprises left and right output cylinders, a piston, an oil port and the like; the working platform and the fixture are used for fixing workpieces; the abrasive circulating pipe is respectively connected with the bottom end of the machining platform and the top end of the fixture; the double-output-rod hydraulic cylinder is driven by power; the pressure plate and the charging barrel are coacted to extrude abrasives; and the abrasive circulating pipe is acted on a hole part. The mechanical structure can preferably realize machining of the hole part, uses the double-output-rod hydraulic rod for realizing circular motion of the abrasives, greatly reduces the power consumption, and can guarantee better machining quality.

Owner:苏州方德锐精密机电科技有限公司

Disc cutter type full-automatic orange peeling machine

InactiveCN112586767ARealize circular motionFully automatedVegetable peelingElectric machineryEngineering

The invention discloses a disc cutter type full-automatic orange peeling machine. The disc cutter type full-automatic orange peeling machine comprises a first supporting frame, a guide rail mechanism,a clamp mechanism, a feeding mechanism, a feeding baffle, peeling mechanisms, peel removing mechanisms, a pushing mechanism, a guide pipe mechanism, a peel collecting box and a pulp collecting box. The guide rail mechanism is horizontally installed on the first supporting frame; the clamp mechanism is arranged on the guide rail mechanism; a feeding station, a peeling station, a peel removing station and a pushing station are sequentially arranged on the first supporting frame in the moving direction of the clamp mechanism; the feeding mechanism is installed on the outer side of the feeding station; the peeling mechanisms are installed on the two sides of the peeling station; the peel removing mechanisms are installed on the two sides of the peel removing station; and the pushing mechanismand the guide pipe mechanism are arranged on the two sides of the pushing station correspondingly. According to the disc cutter type full-automatic orange peeling machine, a plurality of motors and air cylinders are adopted as power sources, the function of peeling each orange can be achieved by controlling the air cylinders and the motors, and peels and pulp are collected in a classified mode.

Owner:ZHEJIANG UNIV OF TECH

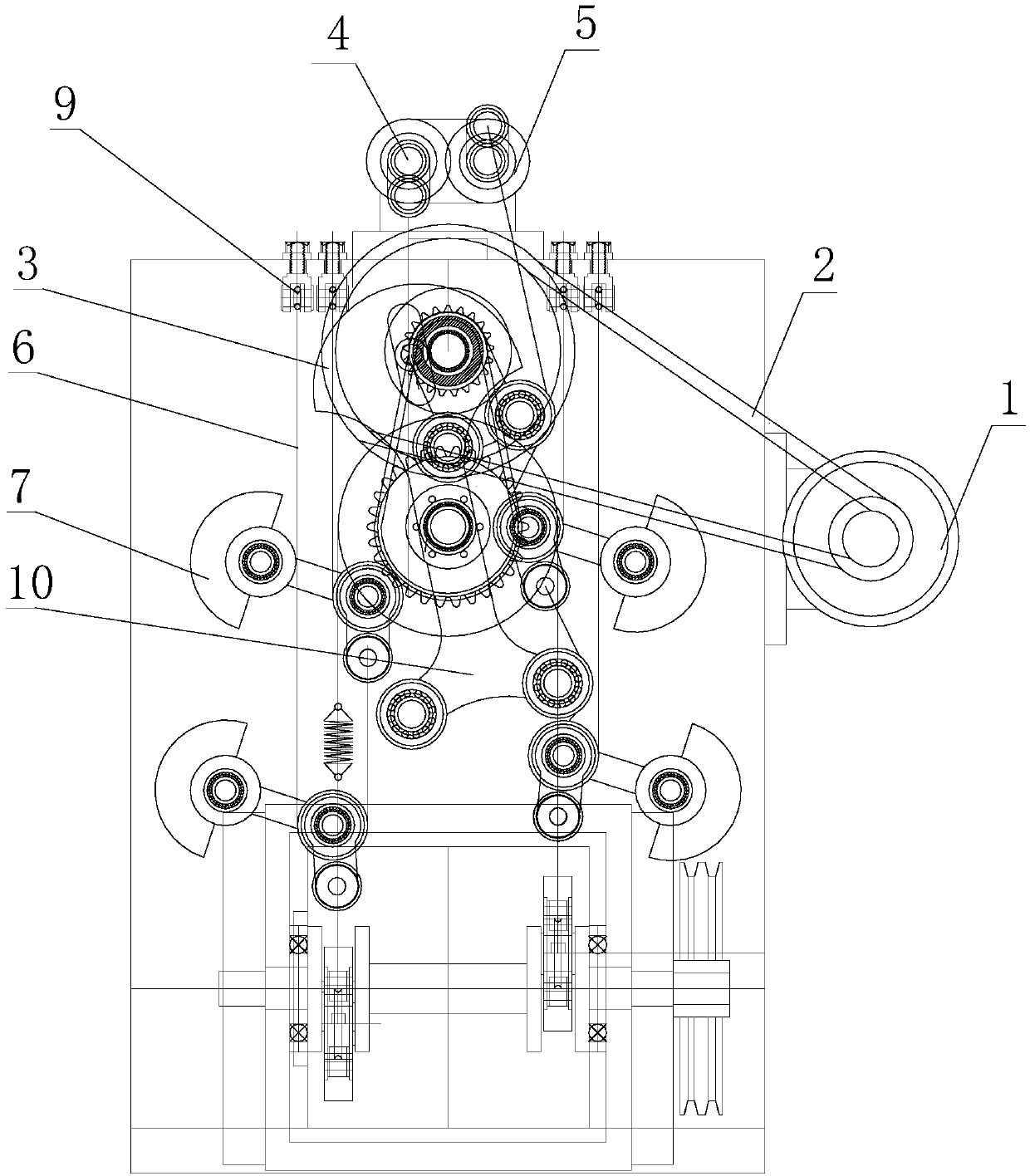

Circulation generator and transmission method capable of saving time and labor

InactiveCN109519511AThe itinerary is not reducedAchieve the effect of super power generatorGearingMachines/enginesBlock and tackleEngineering

The invention provides a circulation generator and a transmission method capable of saving the time and labor. The power of an engine is transmitted by a transmission mechanism to two movable shafts moving in opposite directions, and planetary positioning pulleys arranged at cranks of the movable shafts are connected with one ends of steel wire ropes; the steel wire ropes bypass pulleys in a labor-saving balance lever to be matched with the pulleys, and then bypass the pulleys from bottom to top to the top of a machine body to be connected with fixed seats of the steel wire ropes and adjustingscrews; and a track tension lever is arranged between the steel wire ropes suspended by the two movable shafts, the cranks push an active track tension lever through rolling and pushing bearings configured on the cranks to swing left and right with a support shaft in a center support shaft hole as a fulcrum, and then a lever is pried by periodic bending of the steel wire ropes. According to the circulation generator and the transmission method capable of saving the time and labor, the generator pushes the track tension lever to force the steel wire ropes to move in a curve mode, and the pulleys are lifted upwards, so that the effect that a pulley set can save the half labor without reducing the stroke is achieved.

Owner:湖南泰铭新能源电力科技有限公司

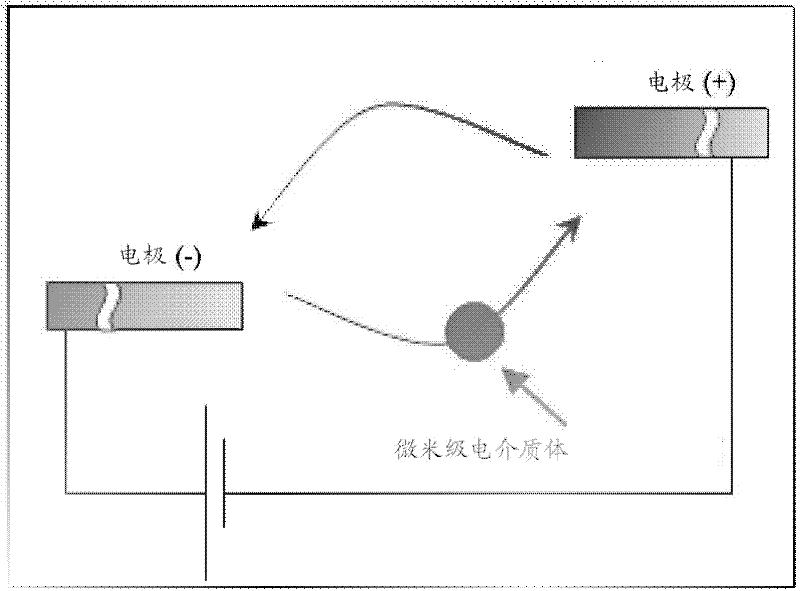

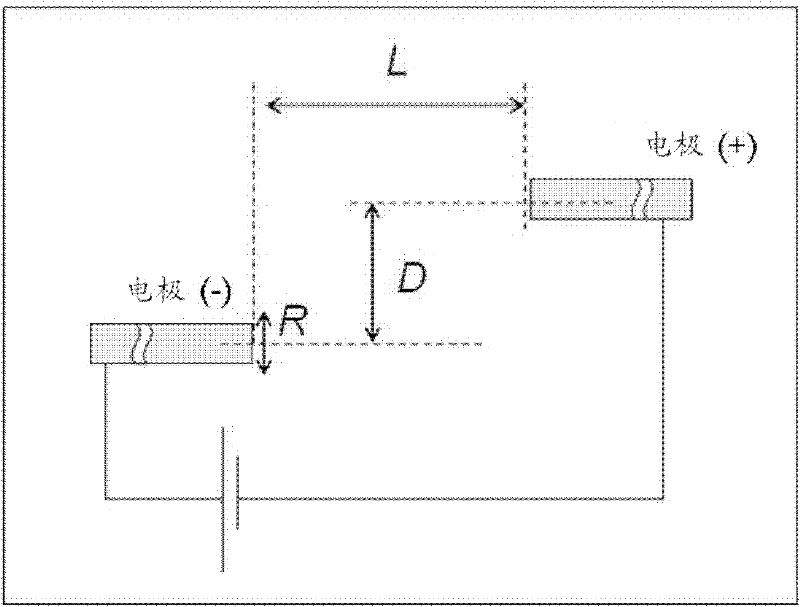

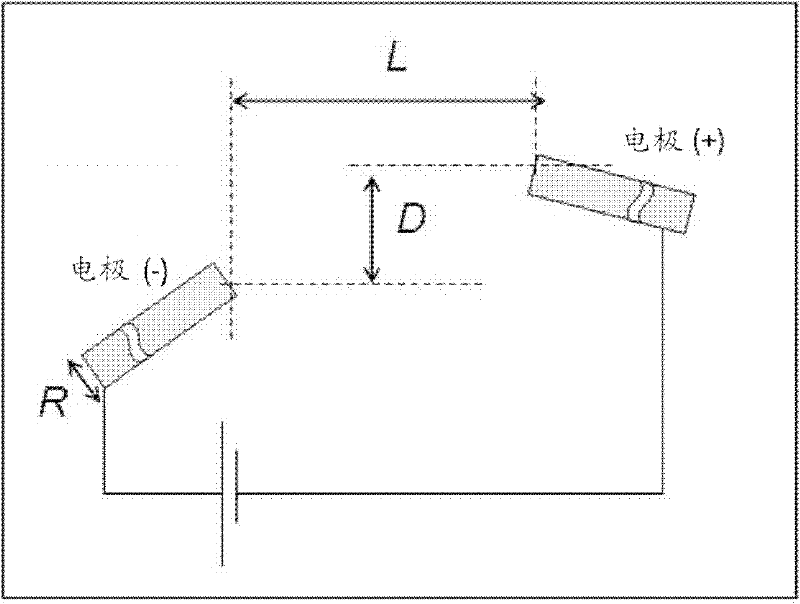

Transportation of object of micro-size and retrieval of mechanical work by means of constant electric field

InactiveCN102395424ASimple periodic motionRealize circular motionMicromanipulatorSamplingElectricityObject motion

Provided is a technique, wherein, in a micro-size, an object can be moved at will without generating a current and transported to retrieve the mechanical work. As a result of earnest consideration, the inventors have found out that a dielectric body can be three-dimensionally transported at will simply by arranging two electrodes for generating an electric field in, for example, a dielectric body of a micro-size or the like in an insulation fluid such as oil, in such a manner that the central axes of the two electrodes are not on the same line, and applying an electric field (for example, constant electric field) thereto, thereby making it possible to retrieve the mechanical work, and have solved the problem.

Owner:JAPAN SCI & TECH CORP

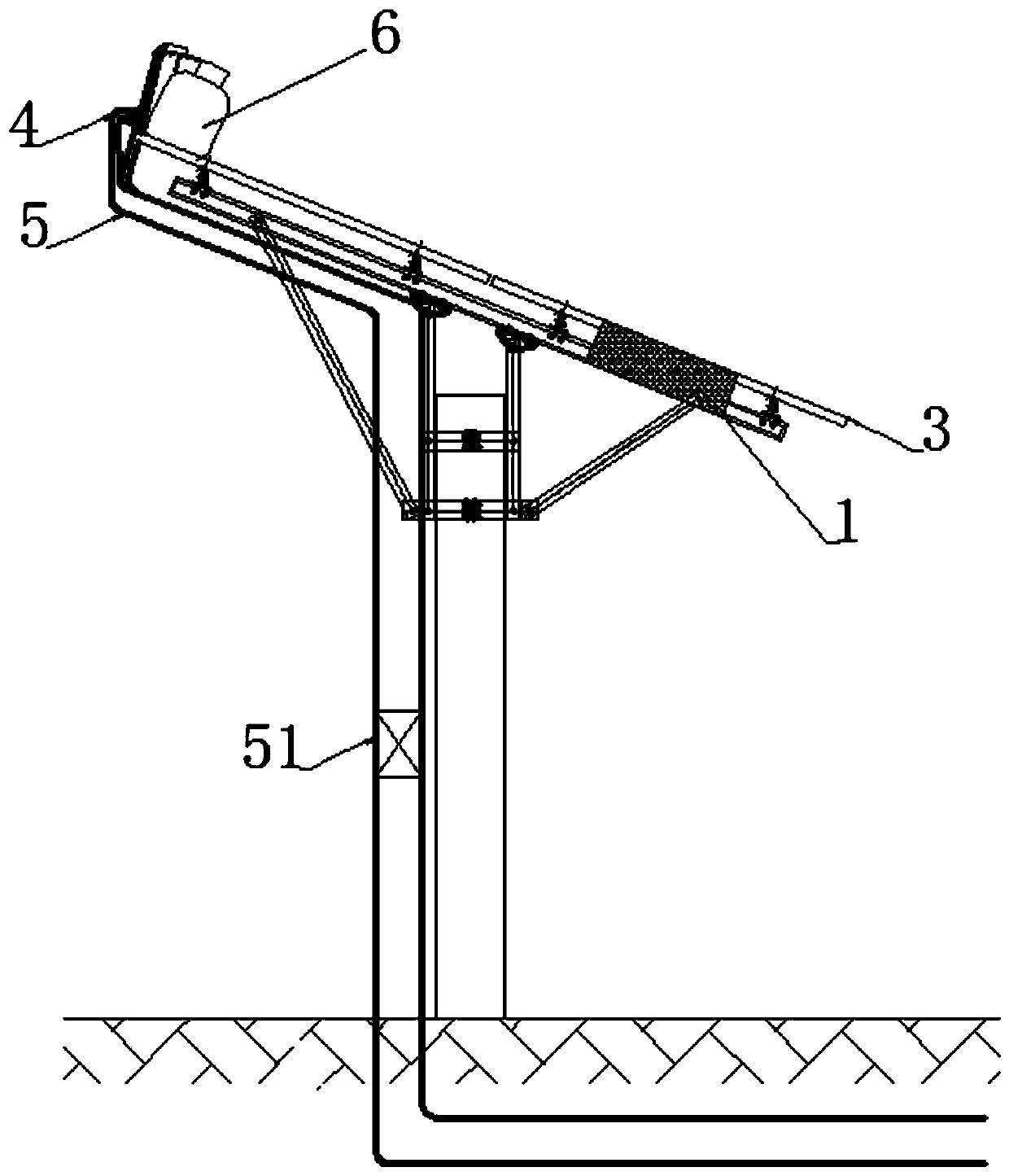

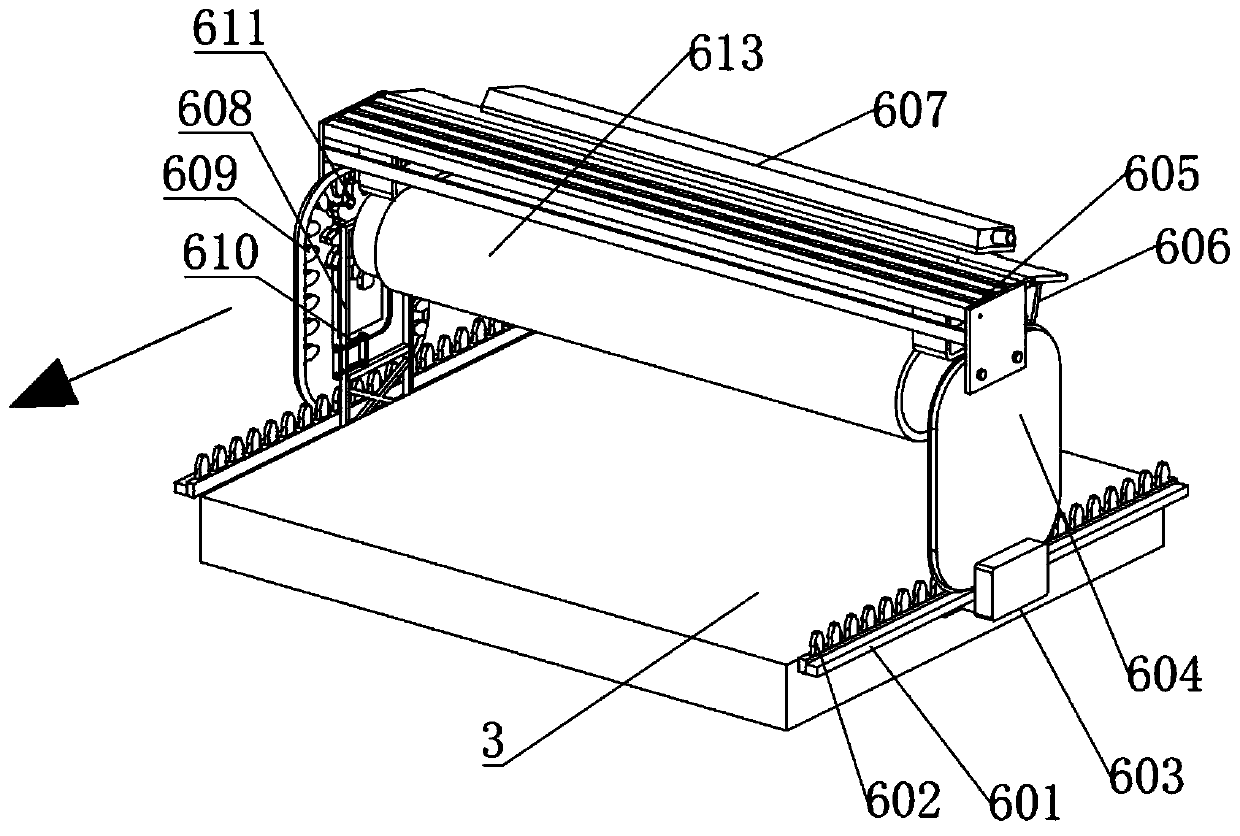

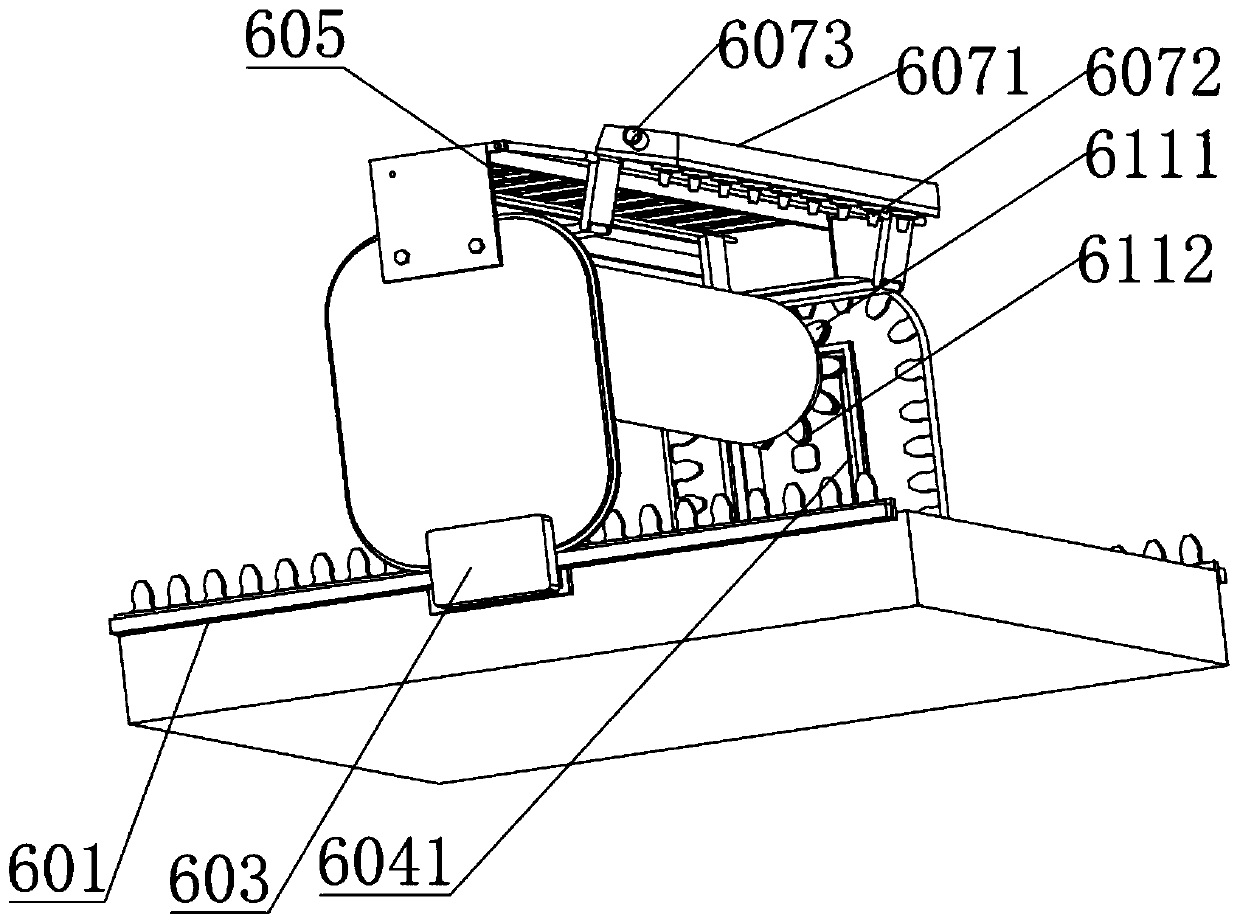

Automatic cleaning device according to surface fouling degree of solar module

ActiveCN111404474AReduce the impact of converting energyGuaranteed cleaning effectPhotovoltaicsCleaning using toolsControl systemDust detection

The invention discloses an automatic cleaning device according to the surface fouling degree of a solar module. The device comprises a dust detection device, a control system, a water supply system and a cleaning mechanism. The dust detection device is used for detecting dust and dirt on the surface of the photovoltaic module and sending a signal to the control system; the control system controlsthe water supply system and the cleaning mechanism to carry out cleaning; the cleaning mechanism comprises a reinforced cleaning mechanism; a cleaning roller circularly moves up and down along a rectangular annular rack; the tops of the moving assemblies are fixedly connected through a top support, a water spraying swing mechanism is installed on the top support, and a water sprayer is installed on the water spraying swing mechanism; and the cleaning roller presses the water spraying swing mechanism to drive the water sprayer to rotate when ascending. Concentrated scrubbing can be carried outon dirt which cannot be washed away, and the shielding effect on the photovoltaic module is reduced on the premise that the dirt is effectively removed.

Owner:安徽海螺新能源有限公司

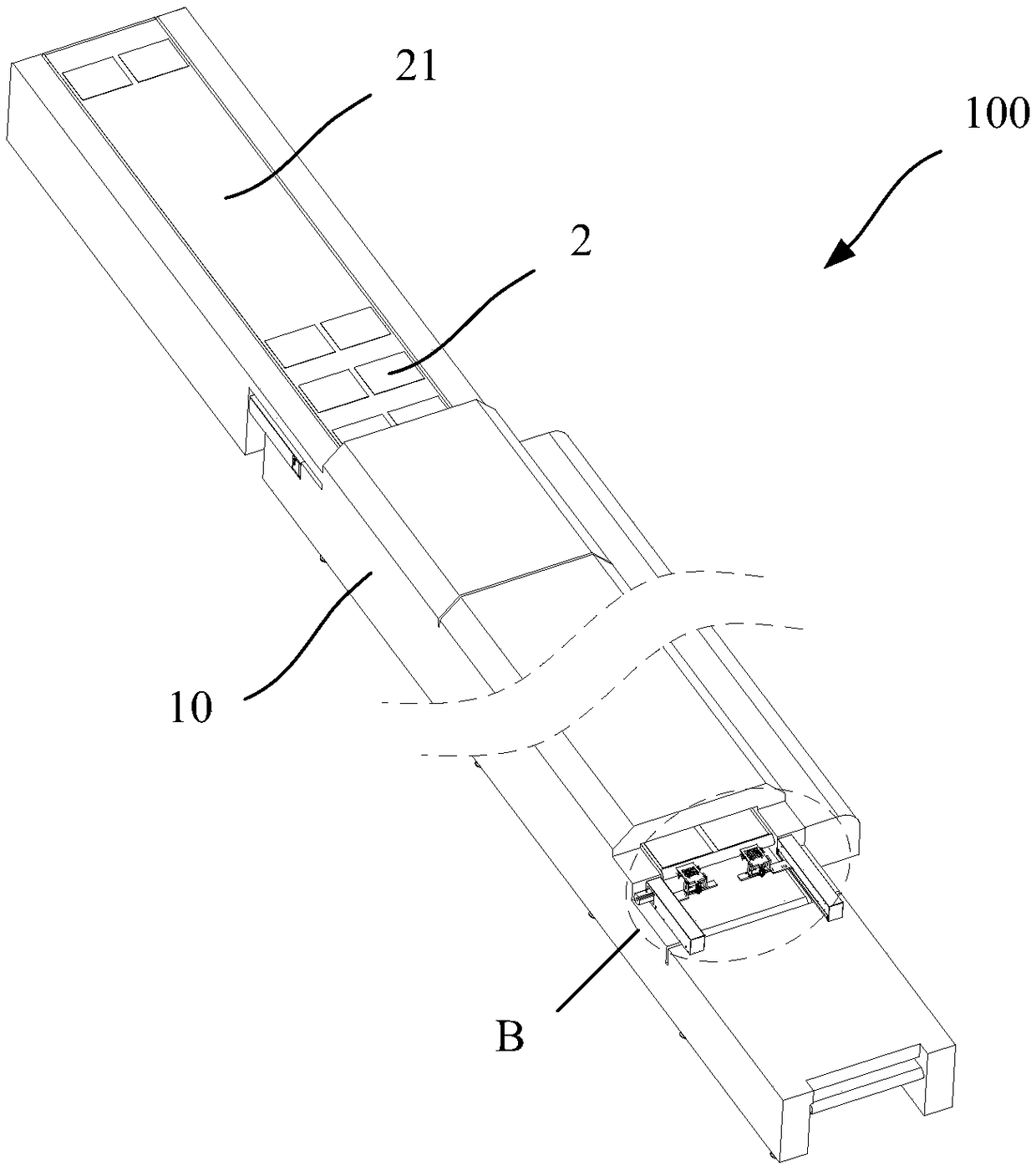

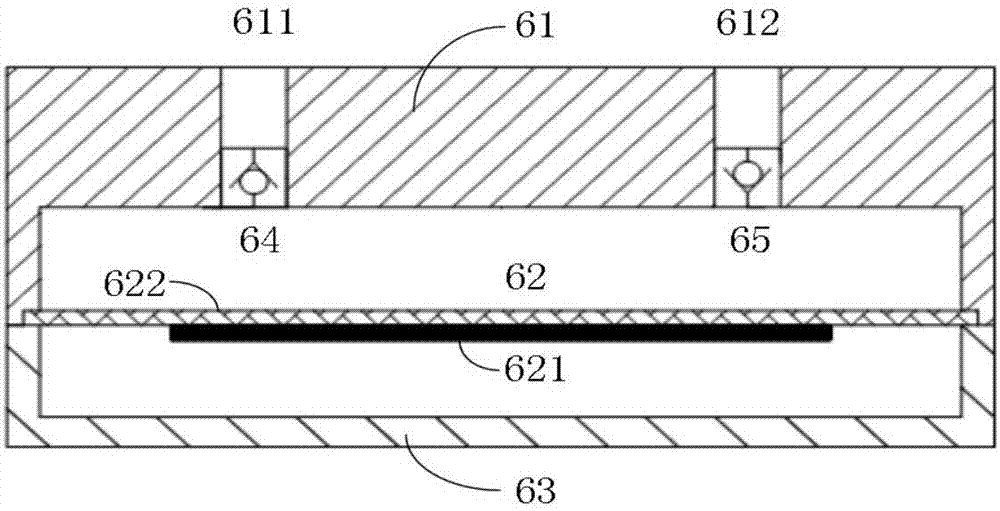

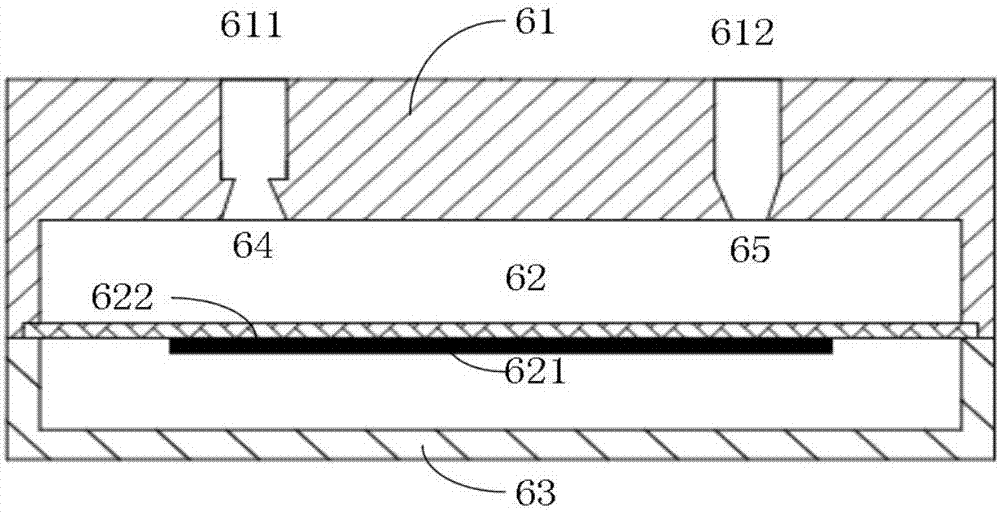

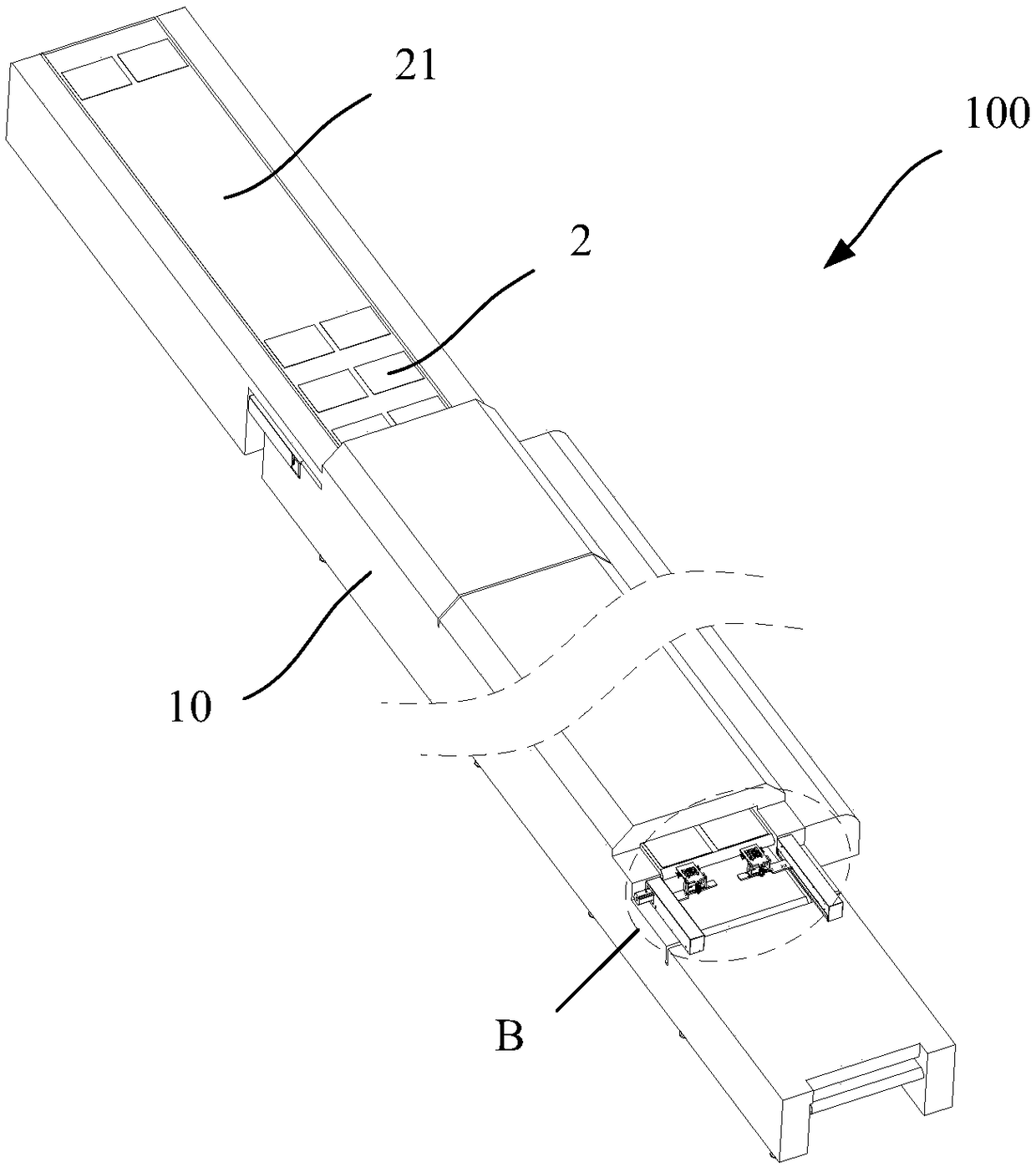

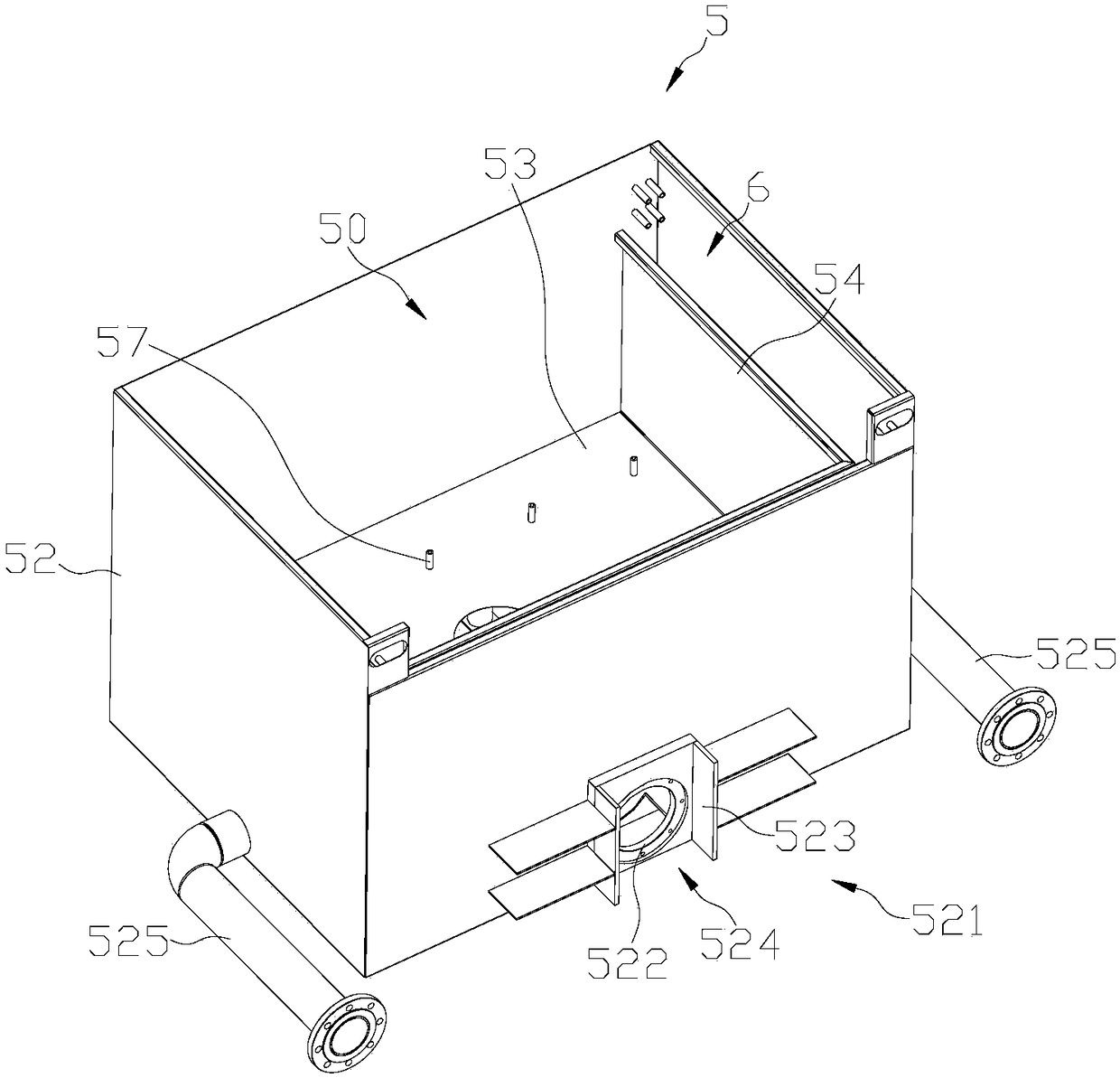

Multilayer circulating tunnel furnace

PendingCN109435457AExtended drying timeSmall footprintPrinting press partsEngineeringMechanical engineering

The invention discloses a multilayer circulating tunnel furnace. The multilayer circulating tunnel furnace comprises a housing, a plurality of layers of in-furnace conveyor belts and a transfer mechanical hand, wherein the housing is provided with a drying channel; the in-furnace conveyor belts are arranged in the drying channel vertically in a spaced mode, and are used for transferring a printingmaterial; and the transfer mechanical hand is mounted on the housing and is used for converting the printing material among different layers of the in-furnace conveyor belts, so that the printing material is transferred in a circulating mode on different layers of the in-furnace conveyor belts. According to the multilayer circulating tunnel furnace disclosed by the invention, the multiple layersof in-furnace conveyor belts are arranged, and the transfer mechanical hand is arranged, so that the printing material moves in a circulating mode among different layers of the in-furnace conveyor belts, drying time, in the multilayer circulating tunnel furnace, of the printing material is prolonged in case of not increasing the length of the multilayer circulating tunnel furnace, and occupied space of the multi-layer circulating tunnel furnace can be reduced, and therefore, the multilayer circulating tunnel furnace can be suitable for a relatively small production site, and the cost can be reduced.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Erection of gantry type small-cycle traction system on large-span suspension bridge main cable

ActiveCN101177931BStable tractionImprove erection qualityBridge erection/assemblyTraction systemGyroscope

The invention relates to a small-circulation traction system of a door frame type for main cable erection of a suspension bridge with large span, pertaining to the construction technical field of the upper structure of a bridge. A cable storing area is arrange at the back of an anchorage A, and a 60-ton gantry crane and a cable stent are positioned in the cable storing area; a traction rope gyroscope wheel is arranged at the back of the anchorage A; a 25-ton main traction winch and a balance stent are arranged at the side of an anchorage B; a traction cable is connected with a pulling device at the place of the anchorage A and bypasses a drum of the winch at the place of the anchorage B, and the traction cable is plugged after passing the balance stent and each corner block, so as to forman annular endless cable; through traction driving and a door frame tackle, the guide-wheel group moves in horizontal and circling, so as to form a separate small circulation traction system; the small circulation has the advantages of large power, large traction force, high construction efficiency and low cost.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

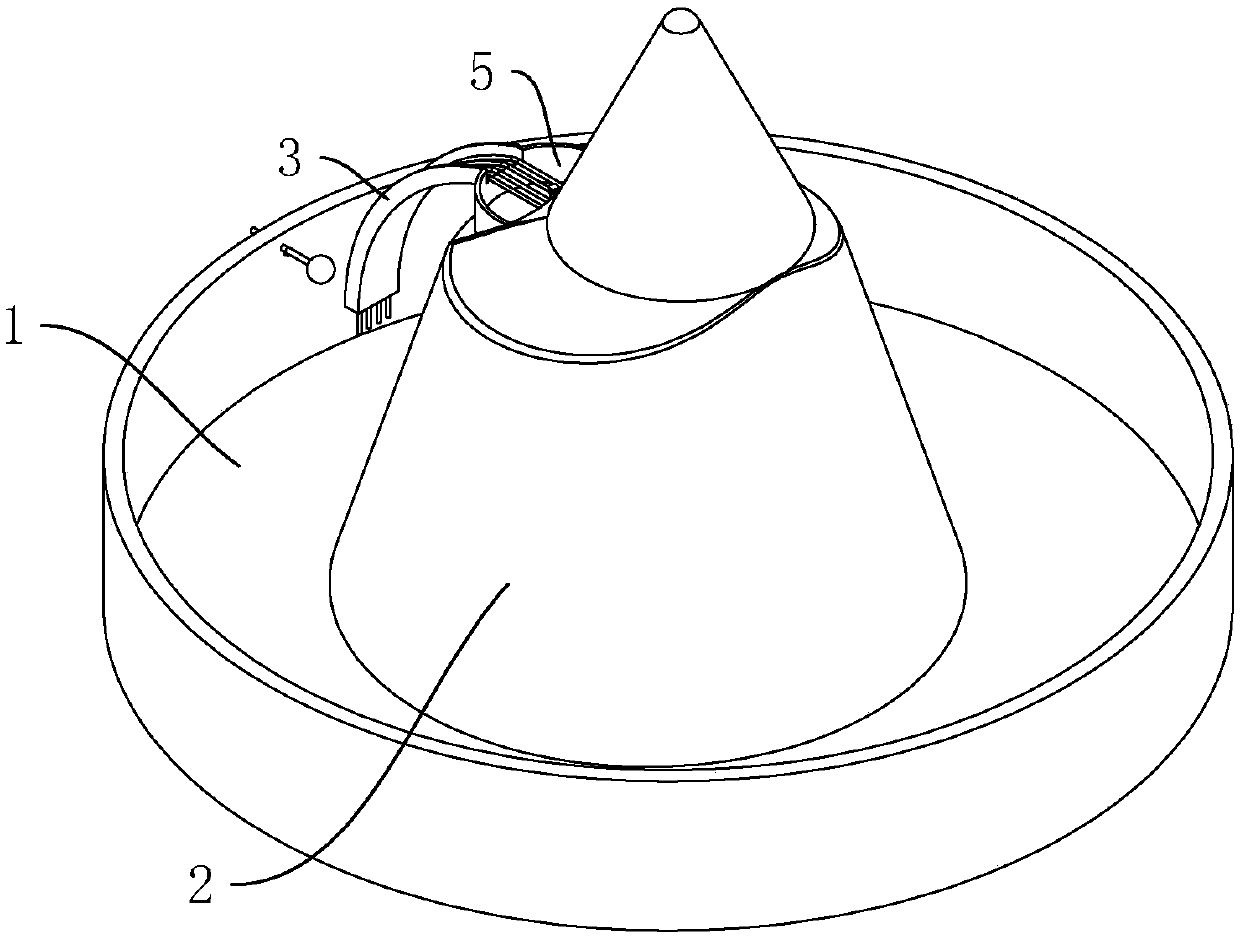

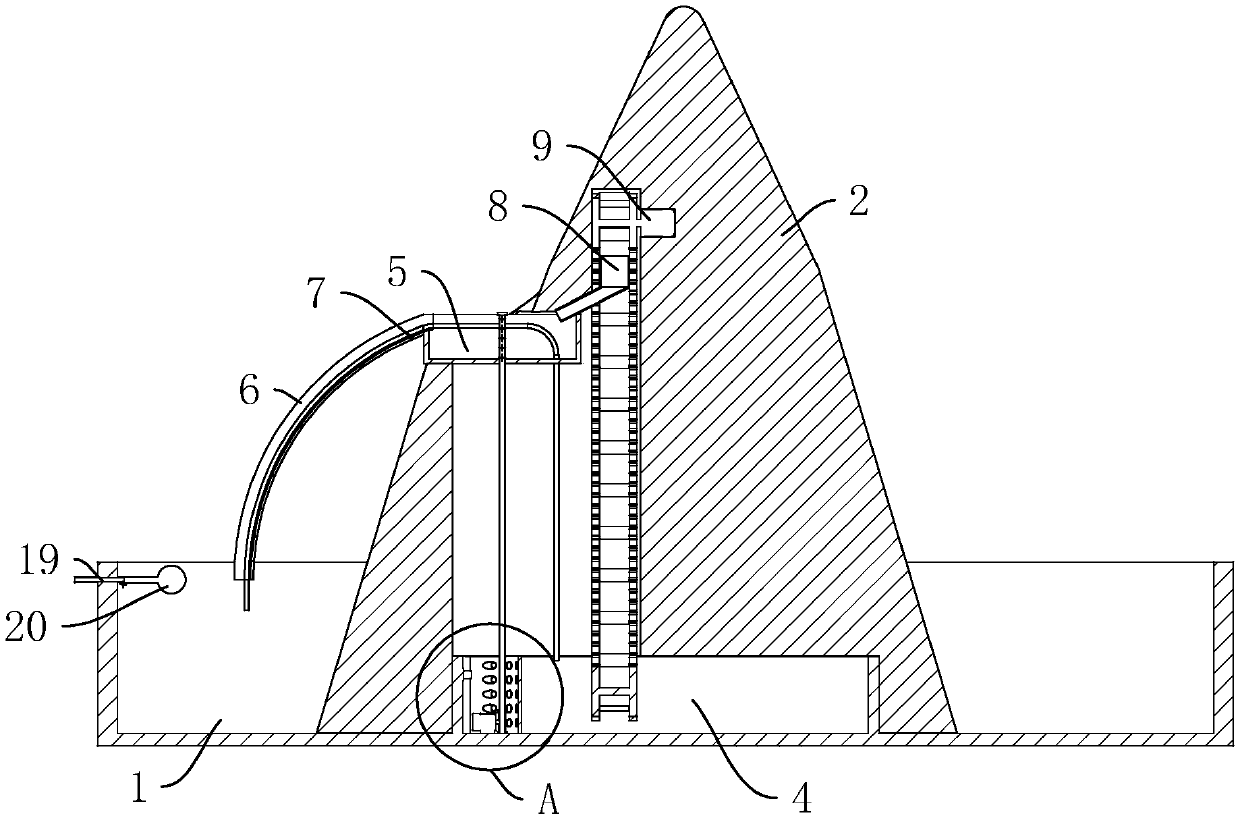

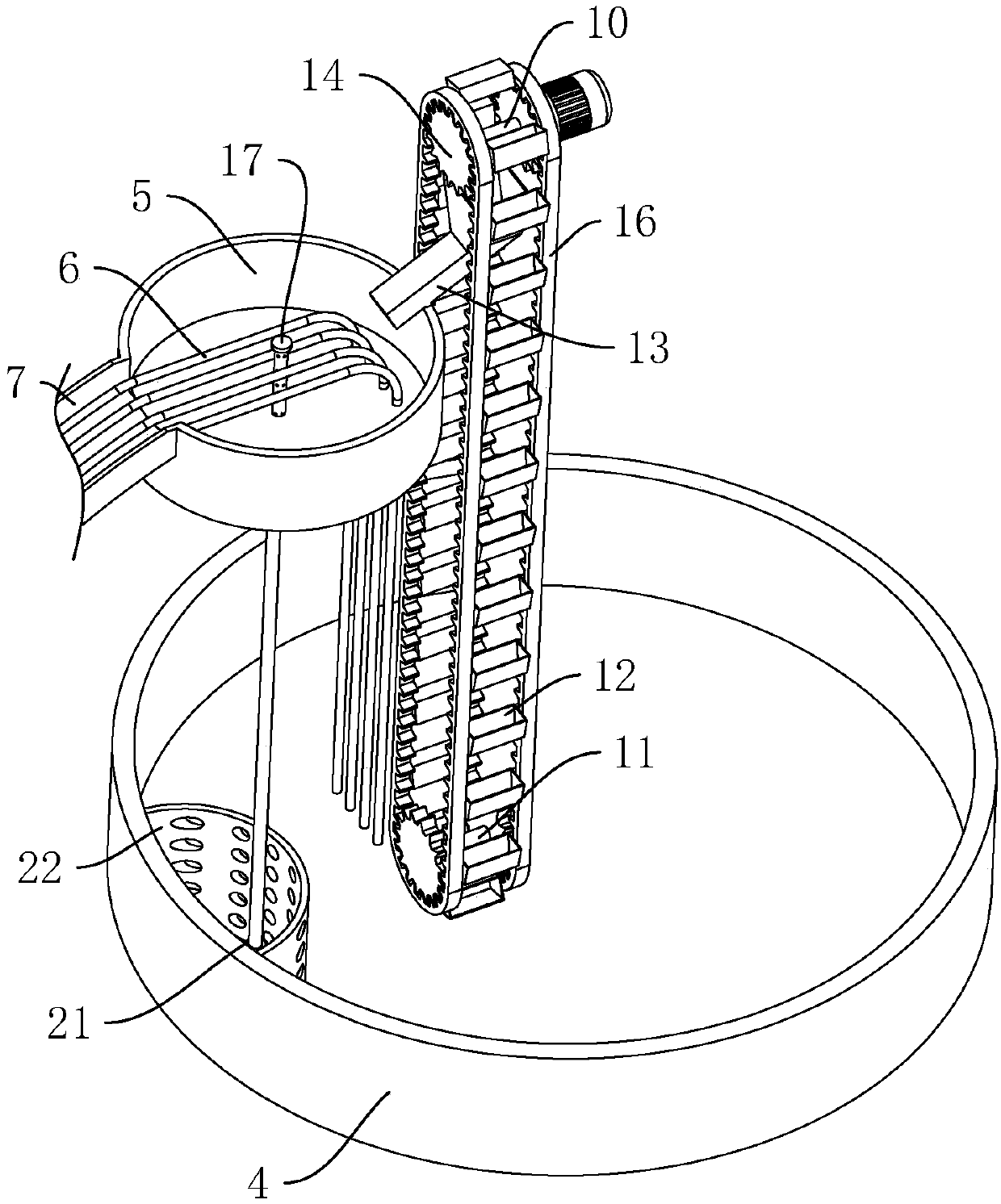

Artificial hill in garden

The invention discloses an artificial hill in a garden, and belongs to the field of garden decoration. According to the technical scheme, the artificial hill is characterized in that the artificial hill comprises an outer water pond, an artificial hill body and a circulation structure; the interior of the artificial hill body is hollow, an inner water pond is arranged in the artificial hill body,and the liquid level of the inner water pond is lower than that of the outer water pond; the circulation structure comprises an arched transparent siphon, one end of the siphon extends into the outerwater pond and is located below the liquid level of the outer water pond, the other end of the siphon penetrates through the artificial hill body to extend into the inner water pond, and the end faceof the end, located in the artificial hill body, of the siphon is lower than the water face of the outer water pond; and fishes with the width smaller than the diameter of the siphon are bred in the outer water pond. The artificial hill has the effect of being better in ornamental value.

Owner:ZHEJIANG WANCHUAN DECORATIVE DESIGN ENG CO LTD

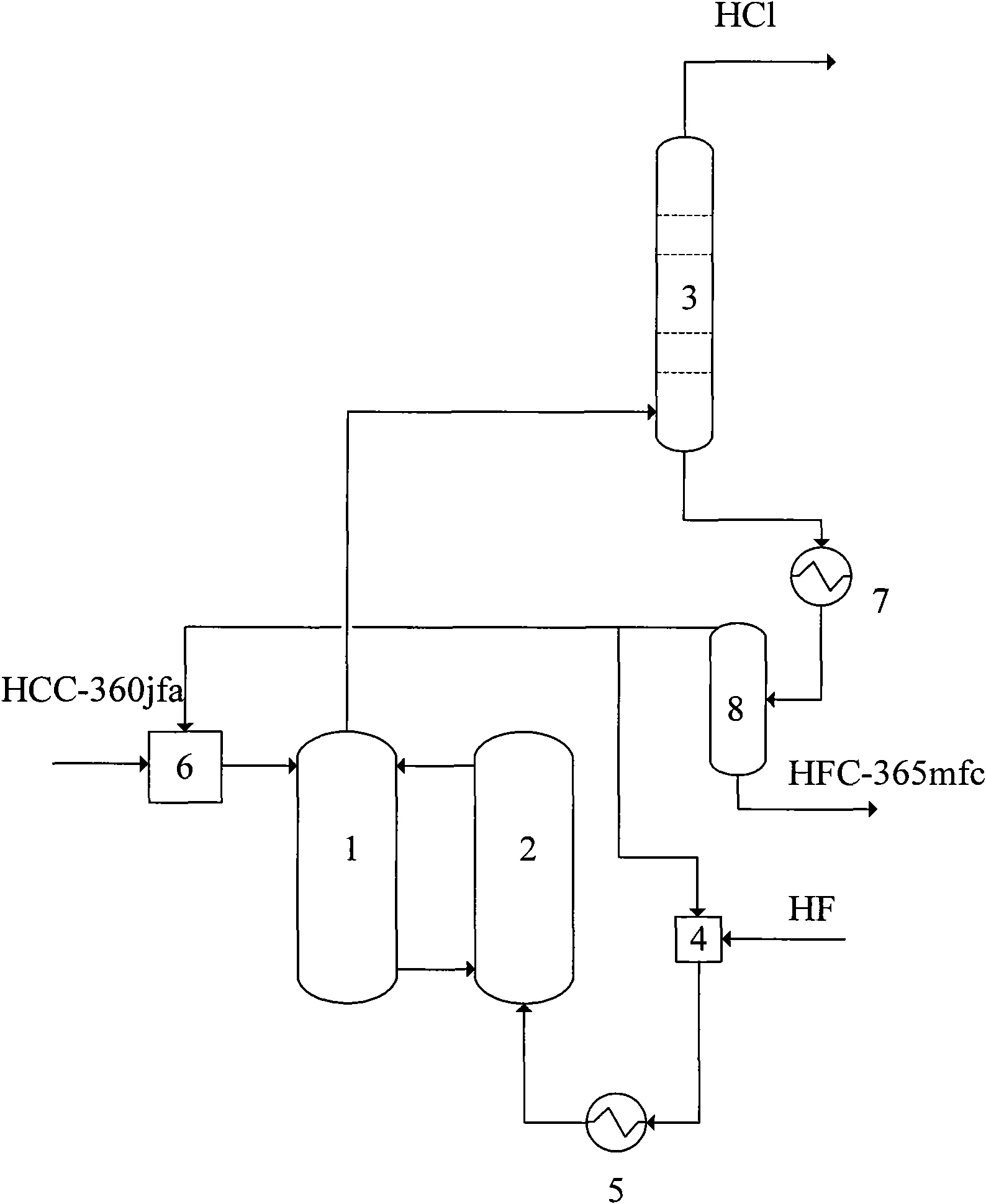

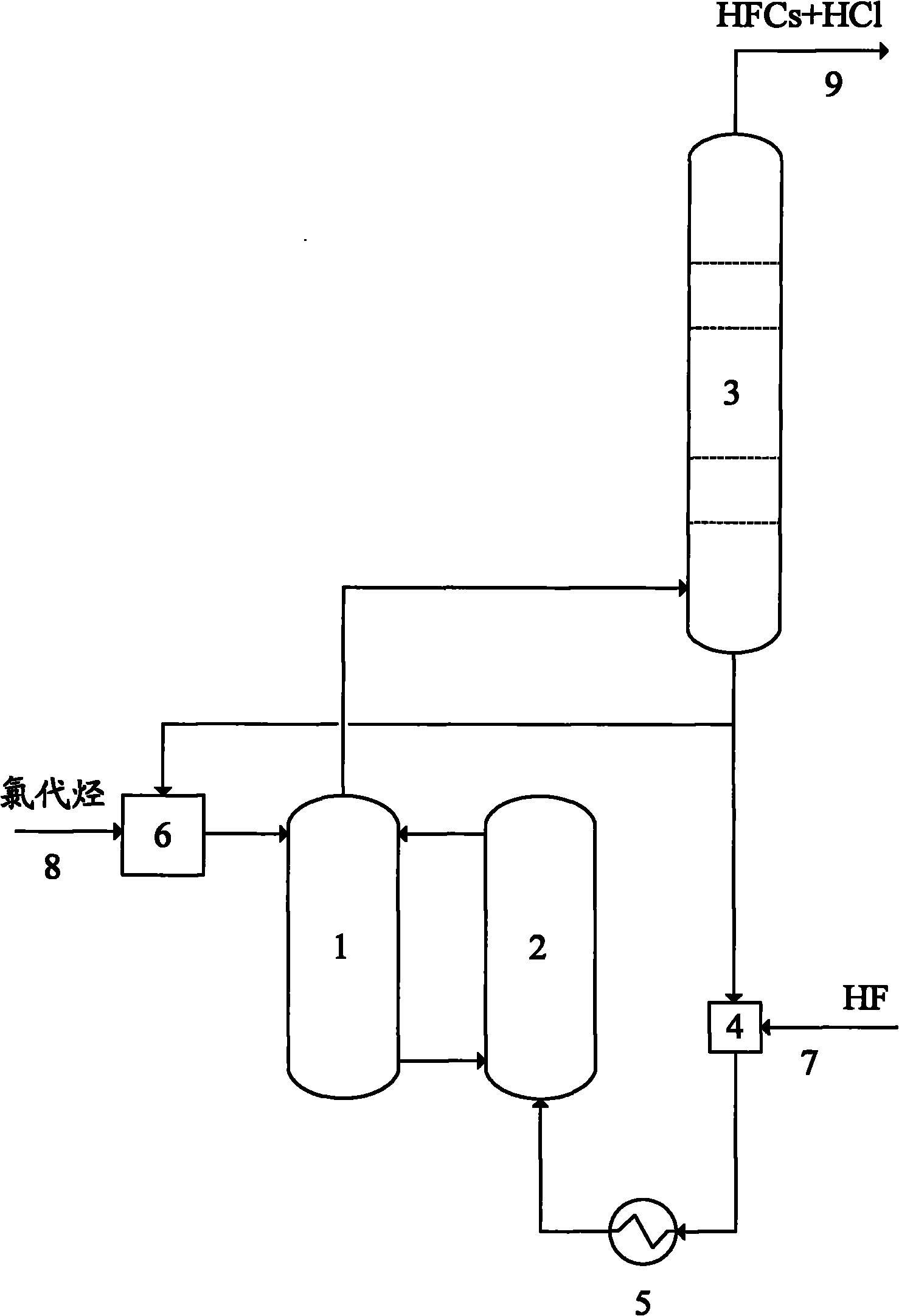

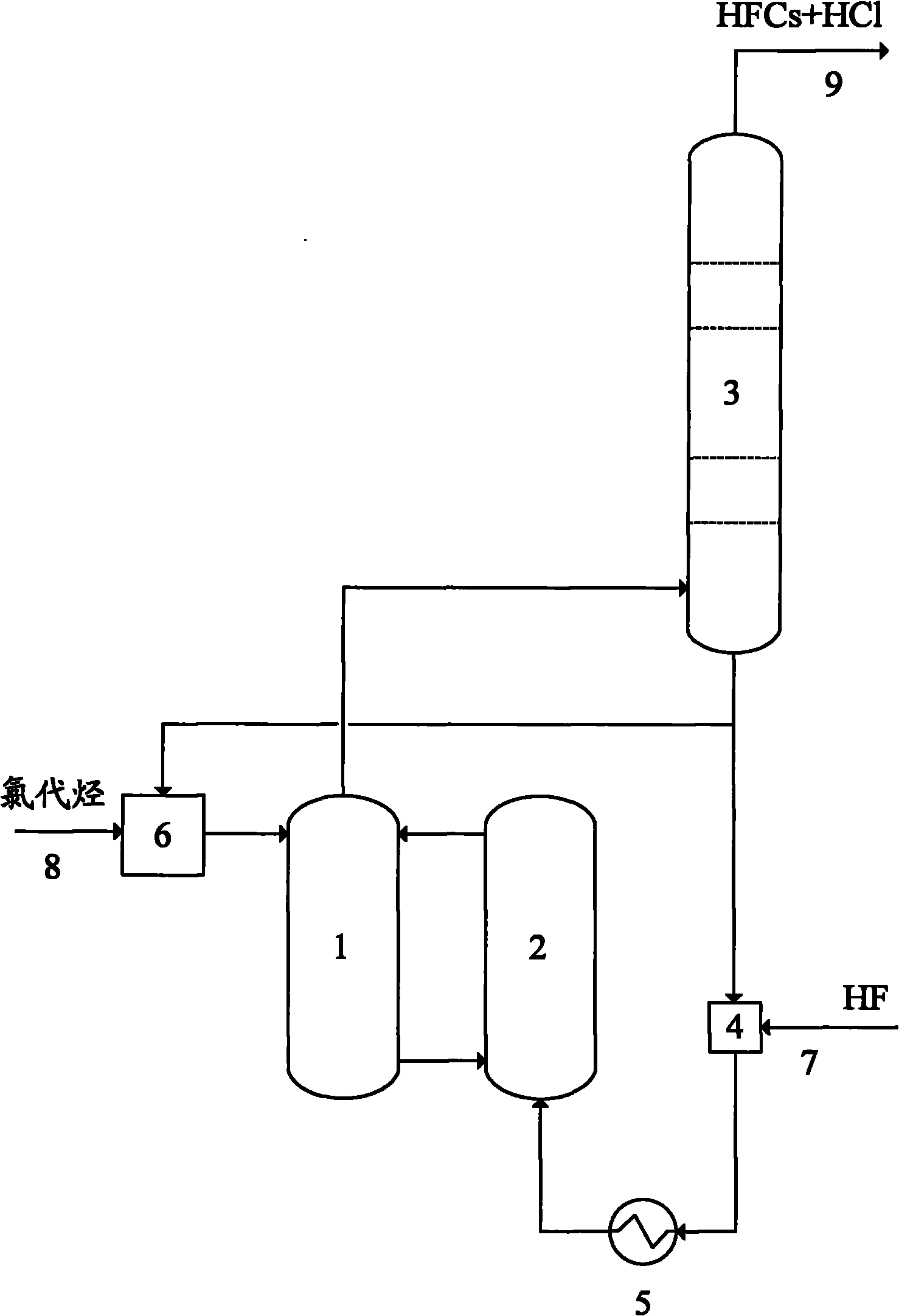

Preparation method of 1,1,1,3,3-pentafluorobutane

ActiveCN101913982BAchieve cycleRealize circular motionPreparation by halogen replacementHydrogen fluorideTetrachloride

The invention provides a preparation method of 1,1,1,3,3-pentafluorobutane, which comprises the following step of reacting 1,1,1,3,3,-pentachlorobutane with HF (Hydrogen Fluoride) in a liquid-phase fluorination reactor provided with a low-temperature reaction zone (1) and a high-temperature reaction zone (2) in the presence of a liquid-phase fluorination catalyst. The reaction conditions are as follows: the mol ratio of the HF to the 1,1,1,3,3,-pentachlorobutane is 6-15:1, the reaction pressure is 1.0-1.5 MPa, the reaction temperature of the low-temperature reaction zone is 60-90 DEG C, the reaction temperature of the high-temperature reaction zone is 90-140 DEG C, wherein the liquid-phase fluorination catalyst is antimony pentachloride or tin tetrachloride; the 1,1,1,3,3,-pentachlorobutane enters the low-temperature reaction zone (1) of the liquid-phase fluorination reactor; the fresh HF enters the high-temperature reaction zone (2) of the liquid-phase fluorination reactor and then enters a reaction system; and the circulating HF enters the low temperature reaction zone (1) and the high-temperature reaction zone (2) of the liquid-phase fluorination reactor simultaneously. The invention is used for the preparation of the 1,1,1,3,3-pentafluorobutane.

Owner:XIAN MODERN CHEM RES INST

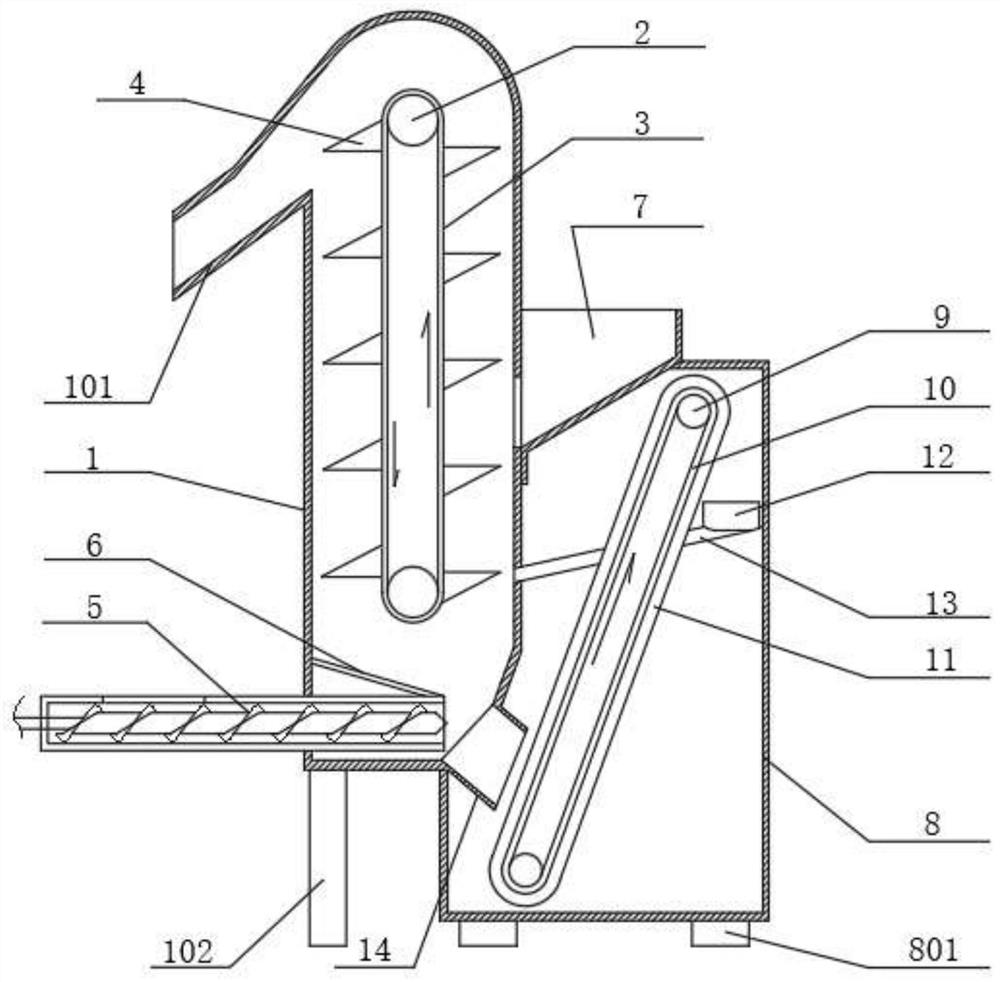

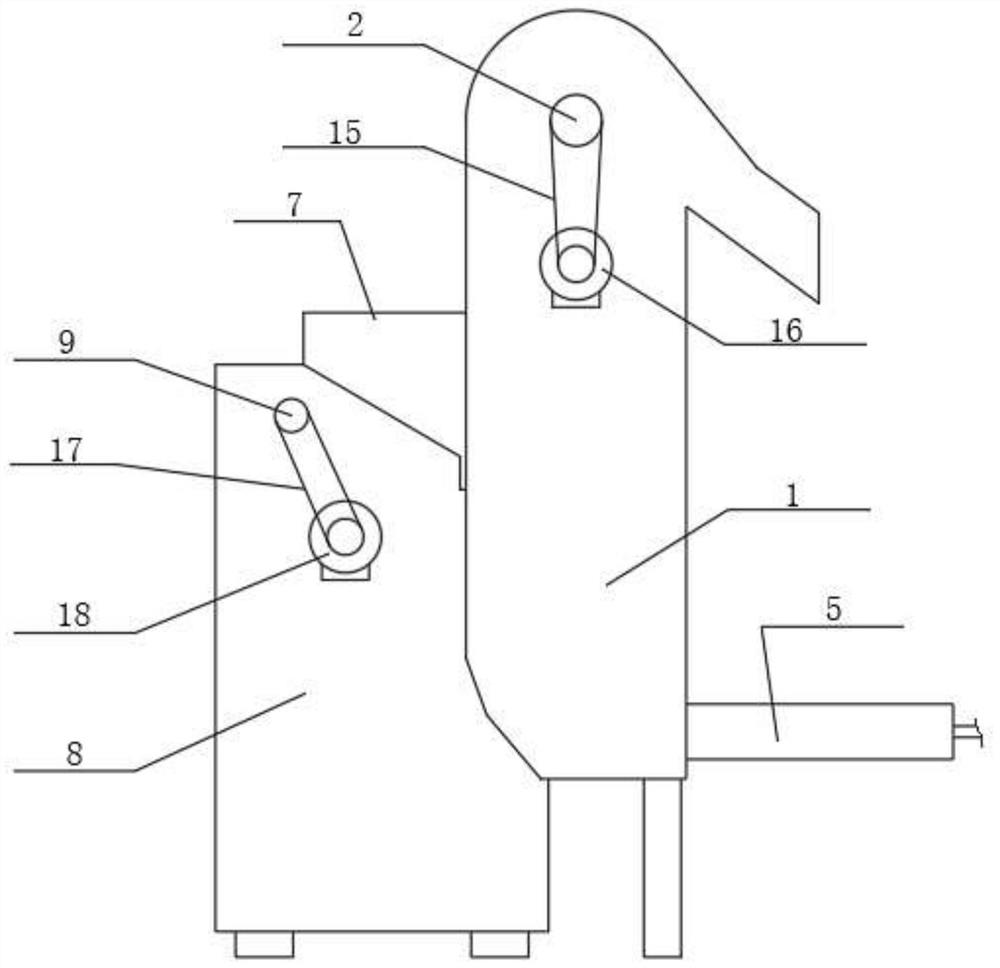

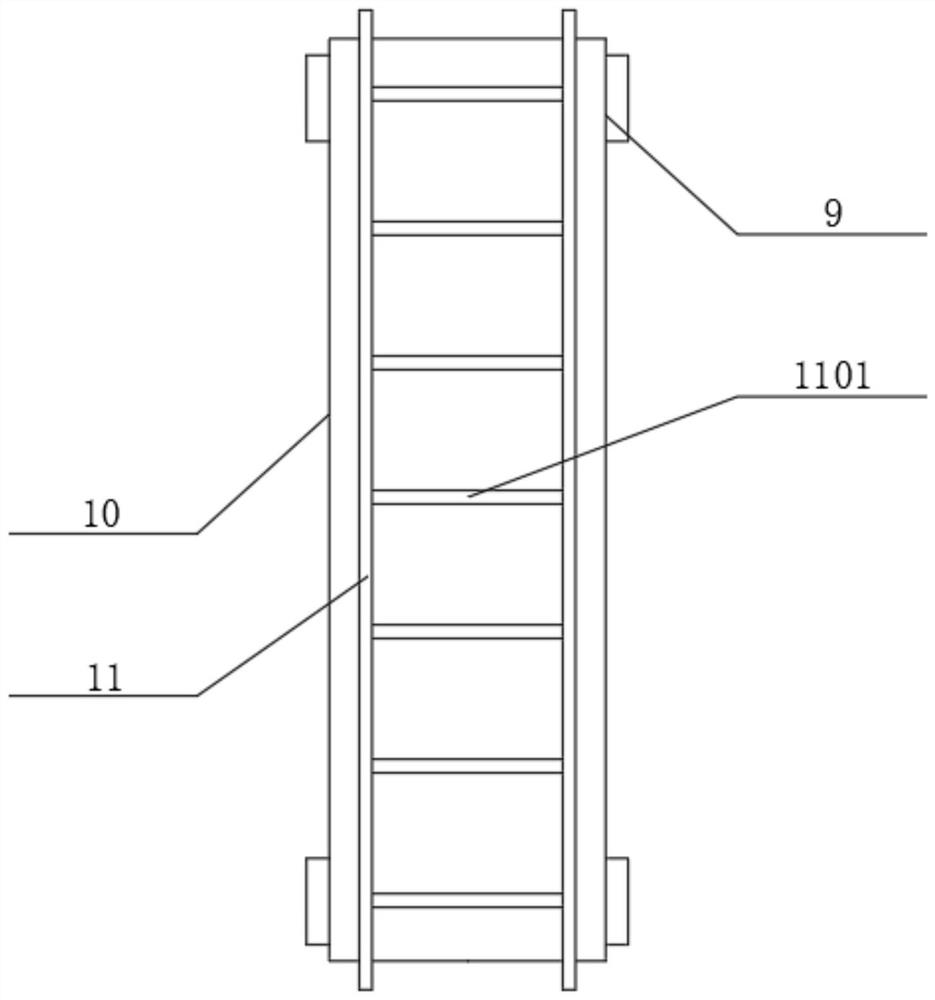

Lifting device for circulating grain dryer

ActiveCN111747056ARealize circular motionAvoid storage cornersDrying solid materialsPackagingThermodynamicsEngineering

The invention relates to the technical field of grain drying, in particular to a lifting device for a circulating grain dryer. The lifting device comprises a body shell and a lower screw conveyor structure, wherein the lower screw conveyor structure is embedded into the side wall of the body shell, a feed inlet is formed in the body shell, an extension pipe is arranged at the upper end of the bodyshell, the inner wall of the body shell is rotationally connected with two first rollers, and the two first rollers are located on the same vertical line. According to the lifting device, grains falling from a winnowing pan moving on the right side and grains conveyed by the lower screw conveyor structure enter the winnowing pan through a material collecting pipe, a second transmission belt, a collecting frame and a conveying pipe, storage dead corners at the bottom of an elevator are avoided, meanwhile, the lifting device is matched with the lower screw conveyor structure, circulation movement of the grains is achieved, when grains are located in the collecting frame and the conveying pipe, the grains slide down by means of self gravity, a power source is saved, the falling grains are stored through a rubber annular plate and a partition plate, and the grains are prevented from sliding down on the second conveying belt.

Owner:合肥麦稻之星机械有限公司

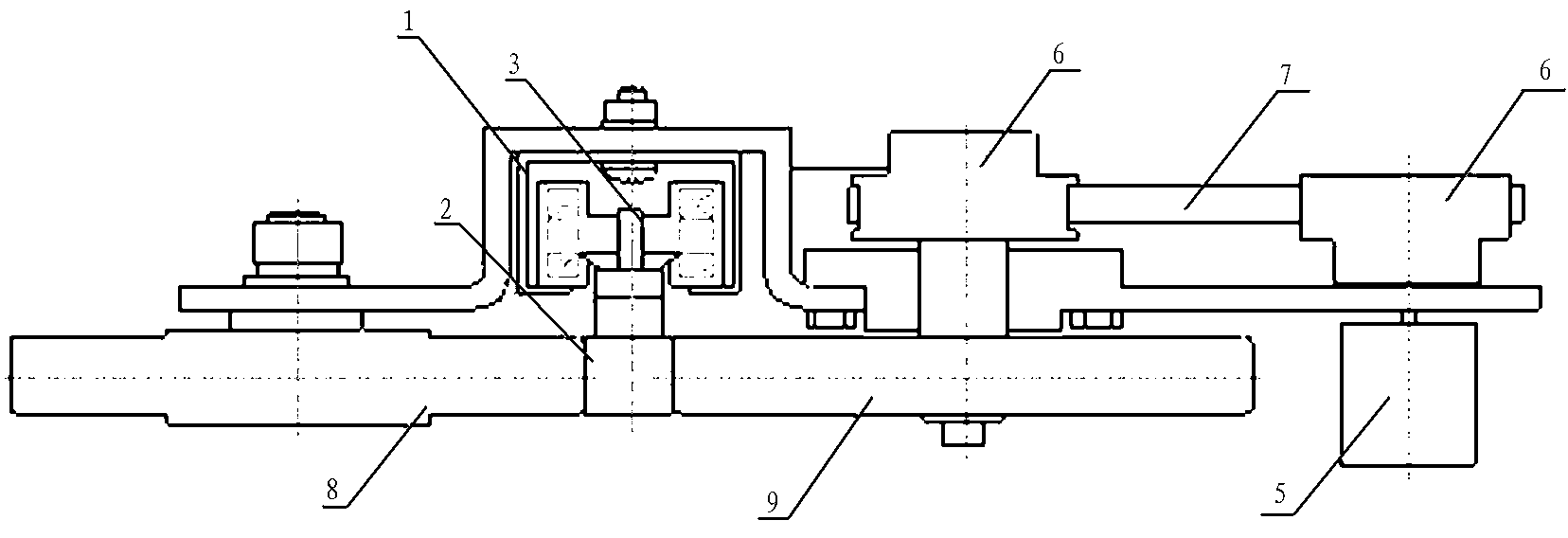

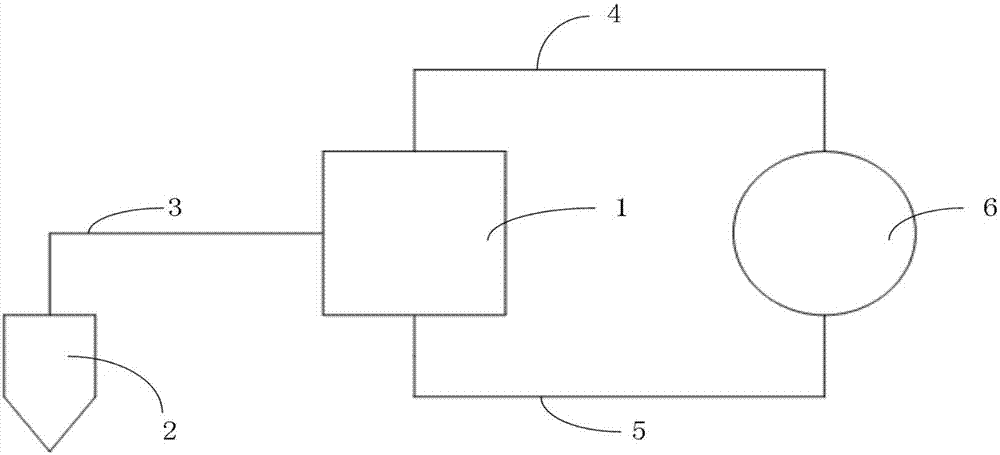

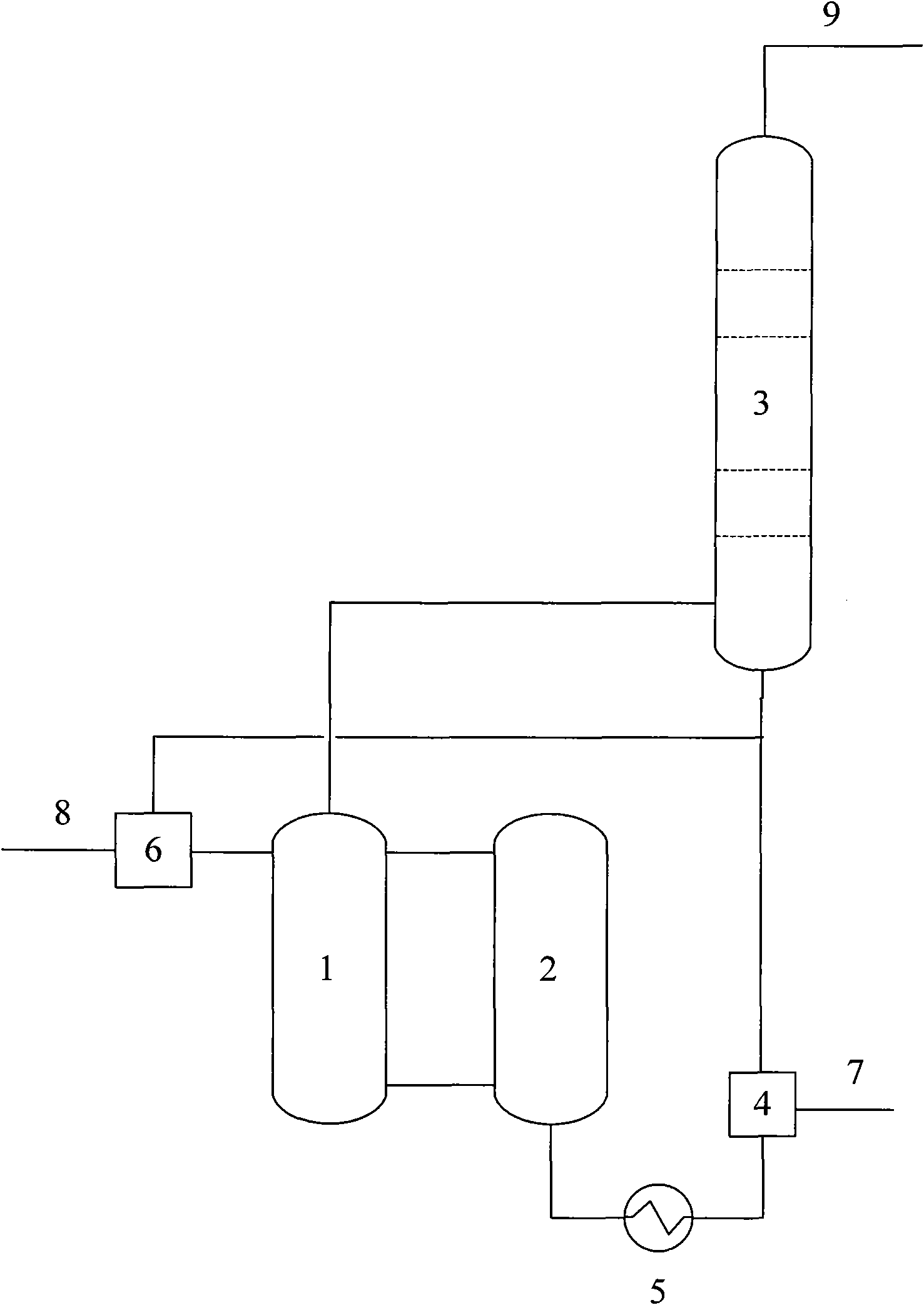

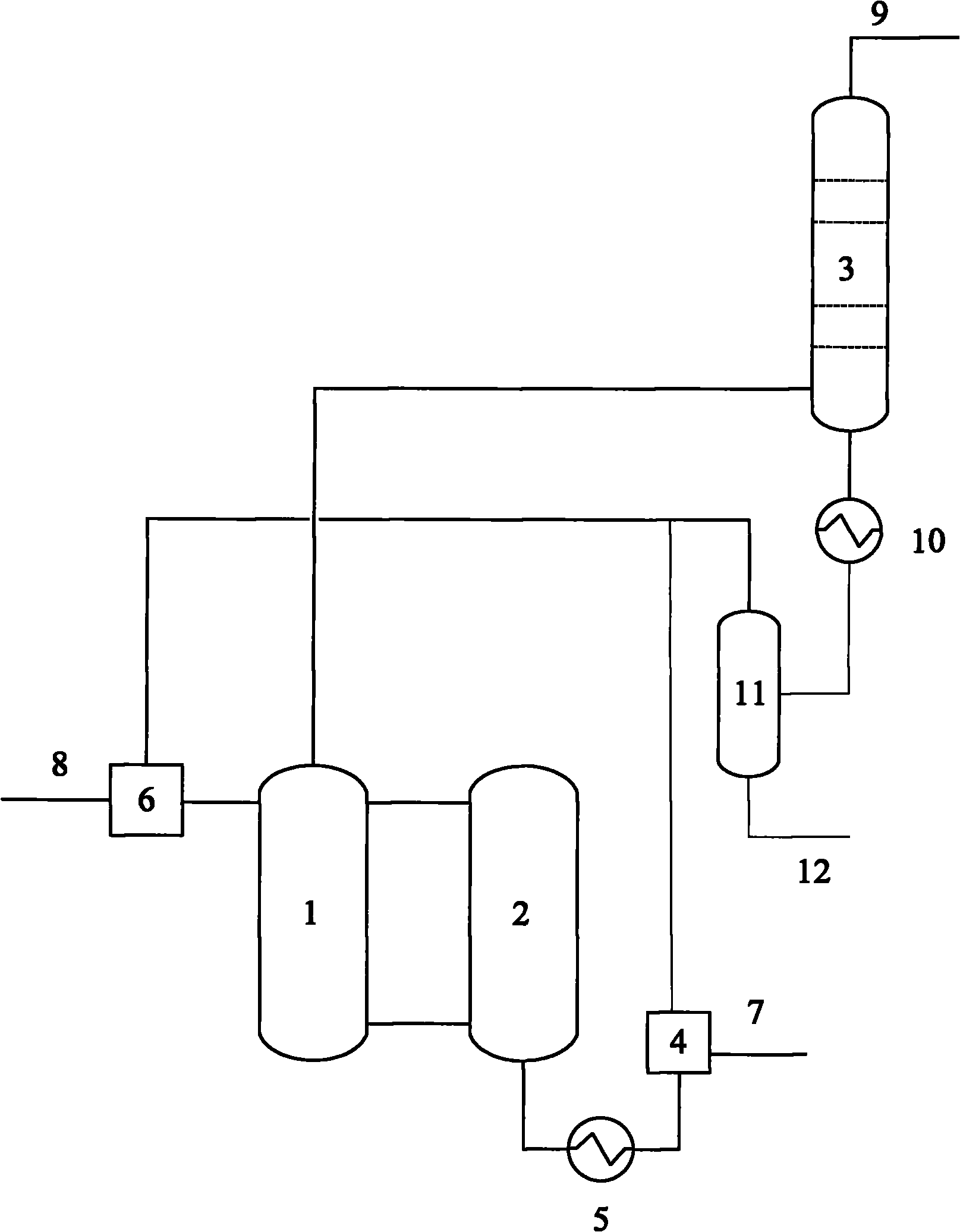

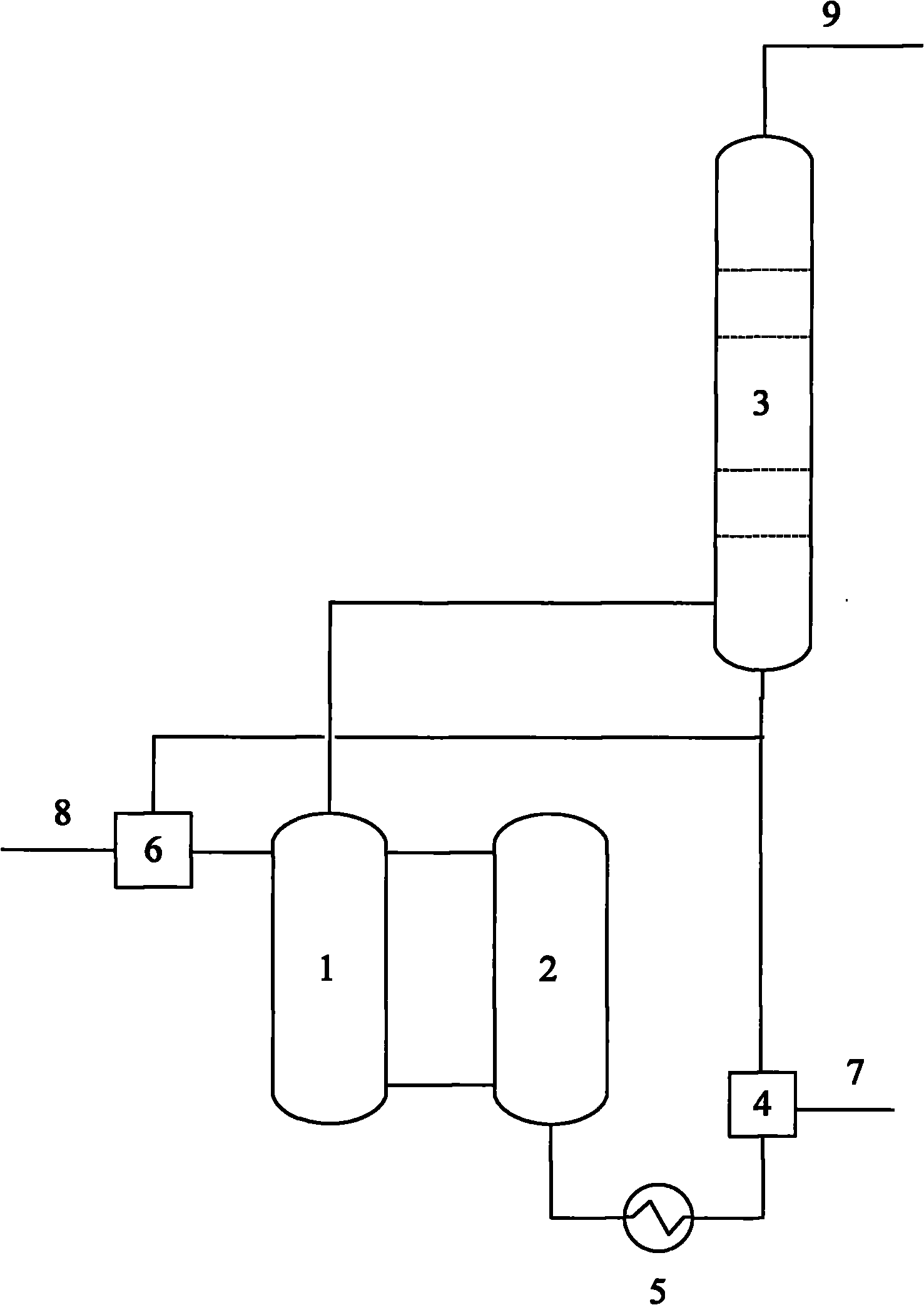

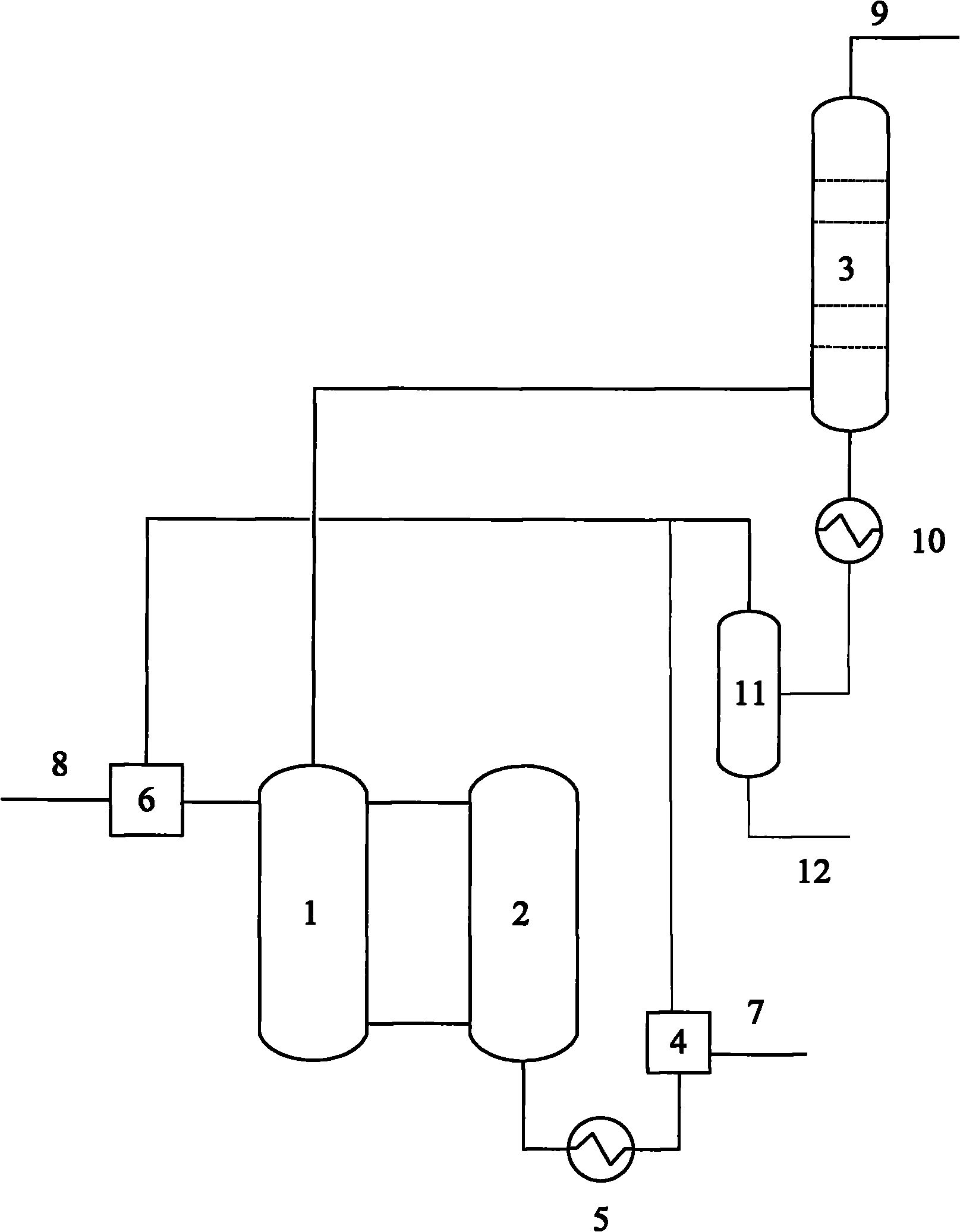

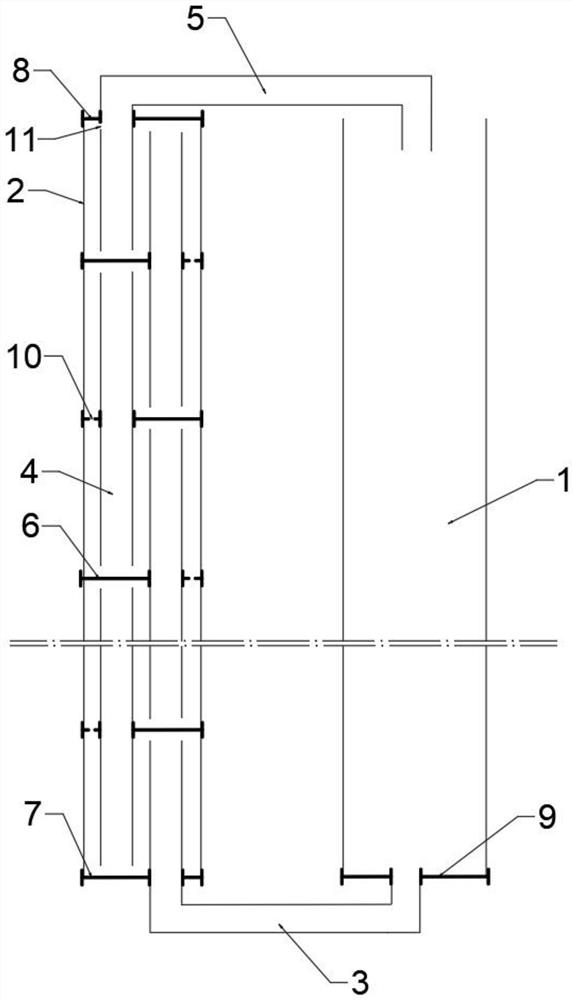

Liquid phase fluorination reaction device

InactiveCN101941884AReduce the temperatureHigh densityPreparation by halogen replacementProcess engineeringTower

The invention provides a liquid phase fluorination reaction device, which comprises a low-temperature reaction area (1), a high-temperature reaction area (2), a backflow tower (3), an HF feed mixer (4), an FH pre-heater (5), a chlorohydrocarbon feed mixer (6), an HF feeding pipe (7), a chlorohydrocarbon feeding pipe (8) and a discharge pipe (9) at the top of the backflow tower, wherein both the upper and lower parts of the low-temperature reaction area (1) are communicated with the high-temperature reaction area (2), a top outlet is communicated with a lower gas feeding inlet of the backflow tower (3); a top discharge port of the backflow tower is connected with the product discharge pipe (9), while a bottom discharge port is communicated with the HF feed mixer (4) and the chlorohydrocarbon feed mixer (6); the HF feed mixer (4) is communicated with the bottom feeding port of the high-temperature reaction area (2) through the FH pre-heater (5); the HF feed pipe (7) is connected with the feeding port of the HF feeding mixer (4); and the chlorohydrocarbon feeding pipe (8) is connected with the low-temperature reaction area (1) through the chlorohydrocarbon feed mixer (6). The liquid phase fluorination reaction device is mainly applied to a twp-step liquid phase fluorination reaction process for synthesizing hydrofluorocarbon.

Owner:XIAN MODERN CHEM RES INST

Supercritical composite electroplating drill bit machining device based on swept cathodes and use method

ActiveCN110257882AReduce wasteRealize circular motionCellsElectrolytic coatingsElectricityHigh volume manufacturing

The invention discloses a supercritical composite electroplating drill bit machining device based on swept cathodes and a use method and belongs to the technical field of electroplating machining of the drill bits. A transmission mechanism is arranged in the axial direction of an anode assembly in a reaction pool, the transmission mechanism is located below the anode assembly, and the transmission mechanism is provided with a clamping assembly and a cathode electric brush assembly matched with the transmission mechanism. The anode assembly comprises an insulated disk body located on one side of the reaction pool and an electricity conducting disk body located on one side of the corresponding face, to the insulated disk body, of the reaction pool. Multiple groups of anode electricity conducting posts are installed along the axis formed by the insulated disk body and the electricity conducting disk body between the insulated disk body and the electricity conducting disk body. The supercritical composite electroplating drill bit machining device based on the swept cathode and the use method achieve that in batch production, only one group of anode contact tube bodies are needed to correspond to multiple groups of machined drill bits, so that batch efficient production is achieved, the production cost greatly lowered, the electroplated drill bits are promoted to be widely popularized, and electricity waste caused by adopting an extra mechanical stirrer to conduct stirring is saved.

Owner:高国有

Pulp box and paper-form wet base forming equipment

PendingCN108193566AUniform concentrationSmall weight deviationTextiles and paperHigh volume manufacturingSlurry

Owner:FOSHAN BESURE TECH

Fabric winding frame device for textile workshop

The invention discloses a fabric winding frame device for a textile workshop. The fabric winding frame device comprises a supporting base, a drive mechanism, transverse supporting columns and a conveying mechanism. First buffer blocks and a second buffer block are arranged on the top of the supporting base. The two first buffer blocks are symmetrically distributed on the top of the supporting base, the second buffer block is located between the two first buffer blocks, supporting blocks are fixed to the tops of the first buffer blocks, one ends of the transverse supporting columns are rotationally connected with one sides of the tops of the portions, on one side of the second buffer block, of the supporting blocks through bearings, and the other ends of the supporting columns penetrate through the top of the conveying mechanism to be movably connected with one sides of the tops of the portions, on the other side of the second buffer block, of the supporting blocks through bearings. According to the fabric winding frame device for the textile workshop, winding fabric can be automatically wound around a winding barrel, the winding fabric is stored perpendicularly, thus, the storage space of the fabric can be reduced, and the occupied area of the fabric winding frame in a textile room is reduced.

Owner:徐州苏豪服装有限公司

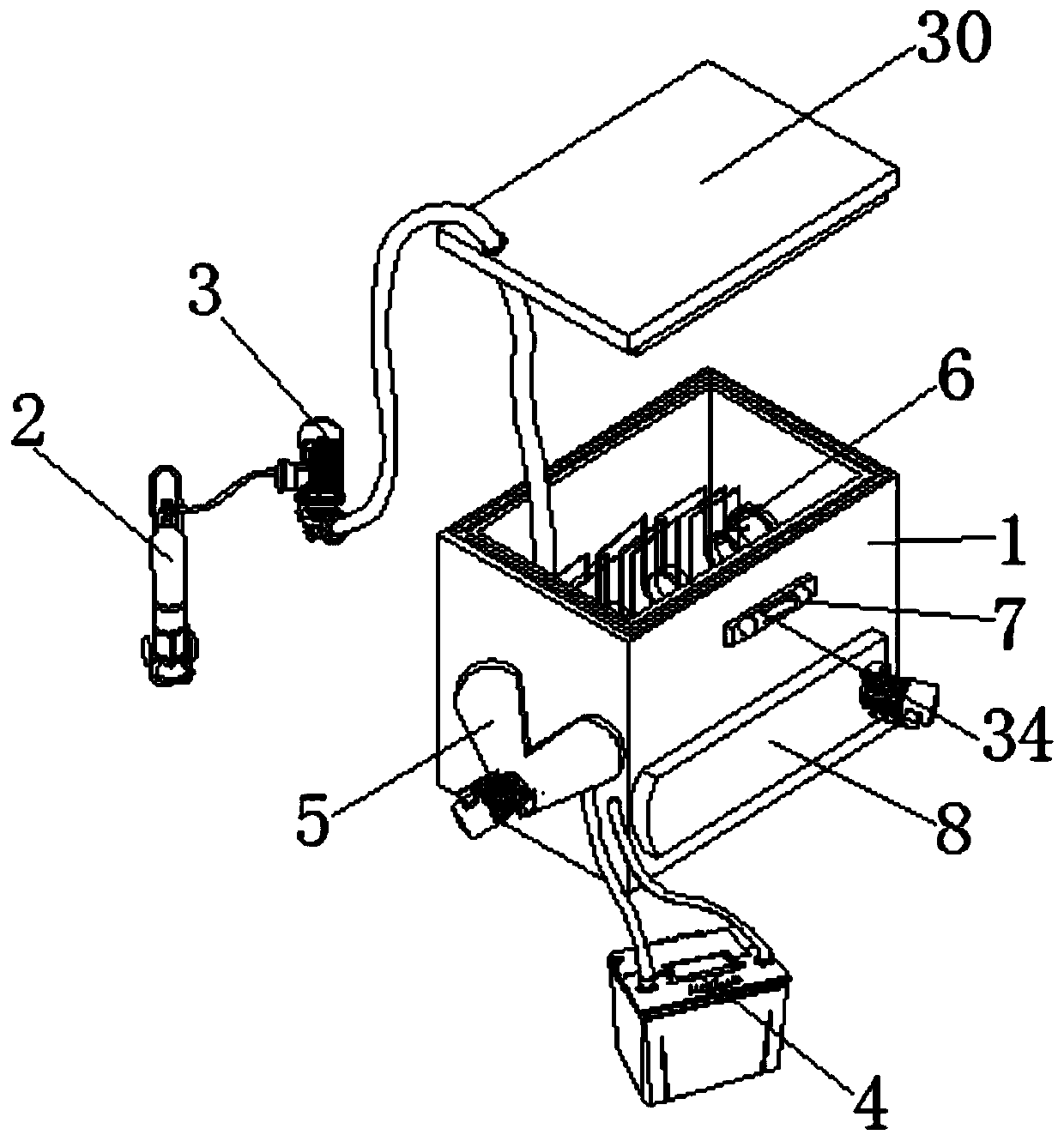

Health scrubbing and washing instrument

ActiveCN109567656ARealize up and down movementRealize circular motionBathroom accessoriesEngineeringFlange

The invention discloses a health scrubbing and washing instrument. The health scrubbing and washing instrument comprises four flanges, a scrubbing and washing support plate, four side baffles, a firstguiderail, a first support plate, four drive scrubbing and washing roller brackets, two second motors and two drive scrubbing and washing rollers, an upper water fender is fixedly installed on the upper side of the lower part of the scrubbing and washing support plate, a lower baffle is fixedly installed on the lower side of the lower part of the scrubbing and washing support plate, and the fourside baffles are respectively fixedly installed at four corners of the four side surfaces at the lower part of the scrubbing and washing support plate. The four flanges are firstly respectively installed on a wall of a bathroom or a bathhouse fixedly, and a first motor and a third motor are combined to act, so that the whole scrubbing and washing instrument moves up and down, and the stretching and the shrinking of a first telescopic electric cylinder and four third telescopic electric cylinders are regulated, so that a scrubbing and washing towel is fitted on the human body with certain pressure, and the scrubbing and washing towel is driven by the two second motors to circularly move so as to scrub and wash the human body.

Owner:张国添

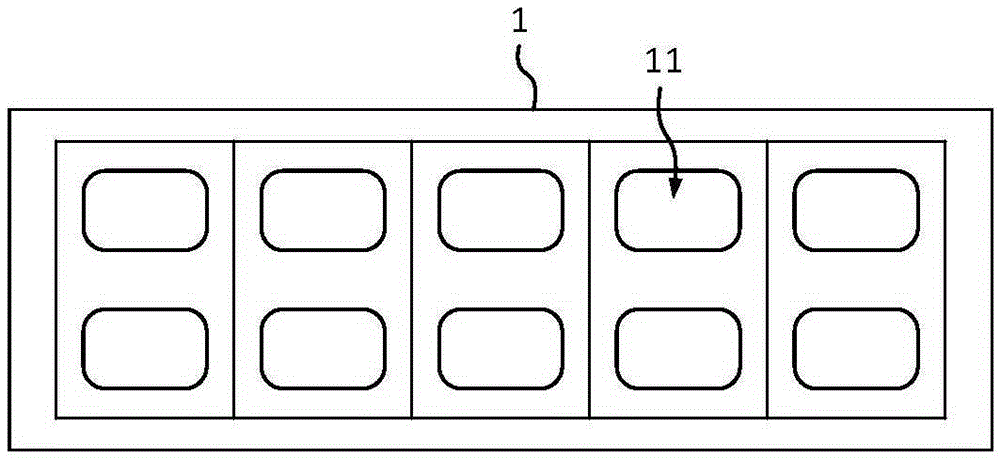

Camera movement control method

InactiveCN105334867AEasy to detectRealize detectionControl without using feedbackComputer graphics (images)Maximum efficiency

The invention provides a camera movement control method. Due to the fact that the maximum speed is set for camera movement, it is guaranteed that a camera can do uniform movement, and the accuracy of image acquisition is provided; in addition, a circulation path is formed by the first preset position, the second preset position, the third preset position and the fourth preset position, chip image acquisition can be achieved on a back-and-forth path of the camera movement, and the maximum efficiency is achieved. According to the camera movement control method, movement photographing of a chip can be completed in a 2*5 chip frame within 10 s, and the detection efficiency is four times higher than the manual detection efficiency.

Owner:CHONGQING YUANCHUANG PHOTOELECTRIC TECH CO LTD

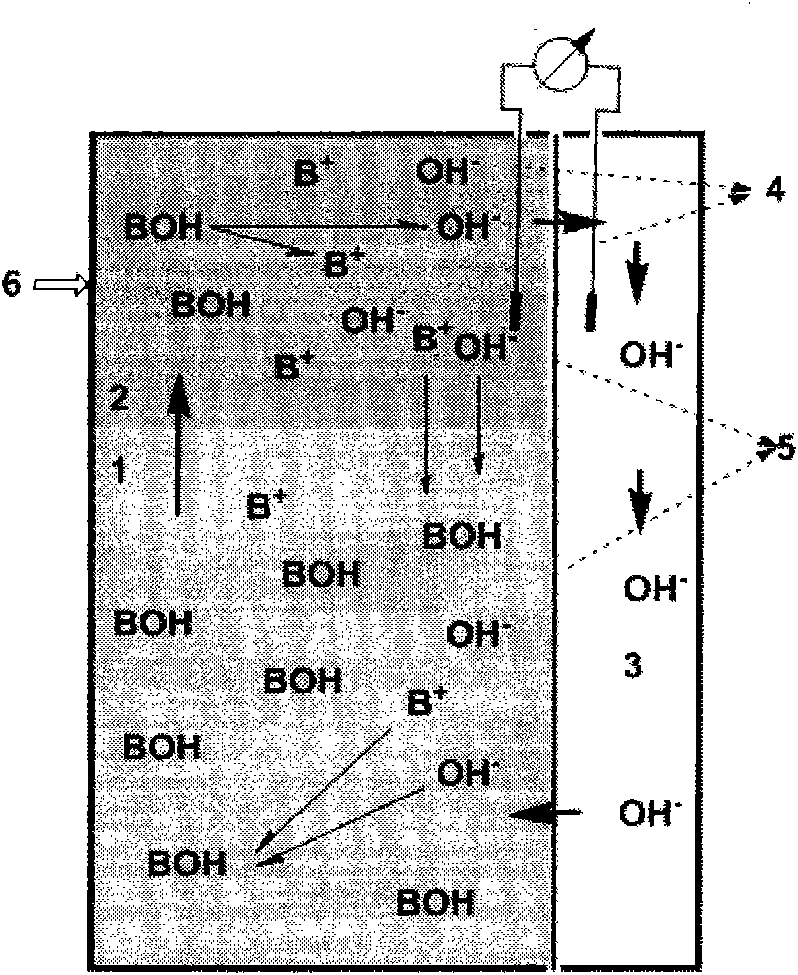

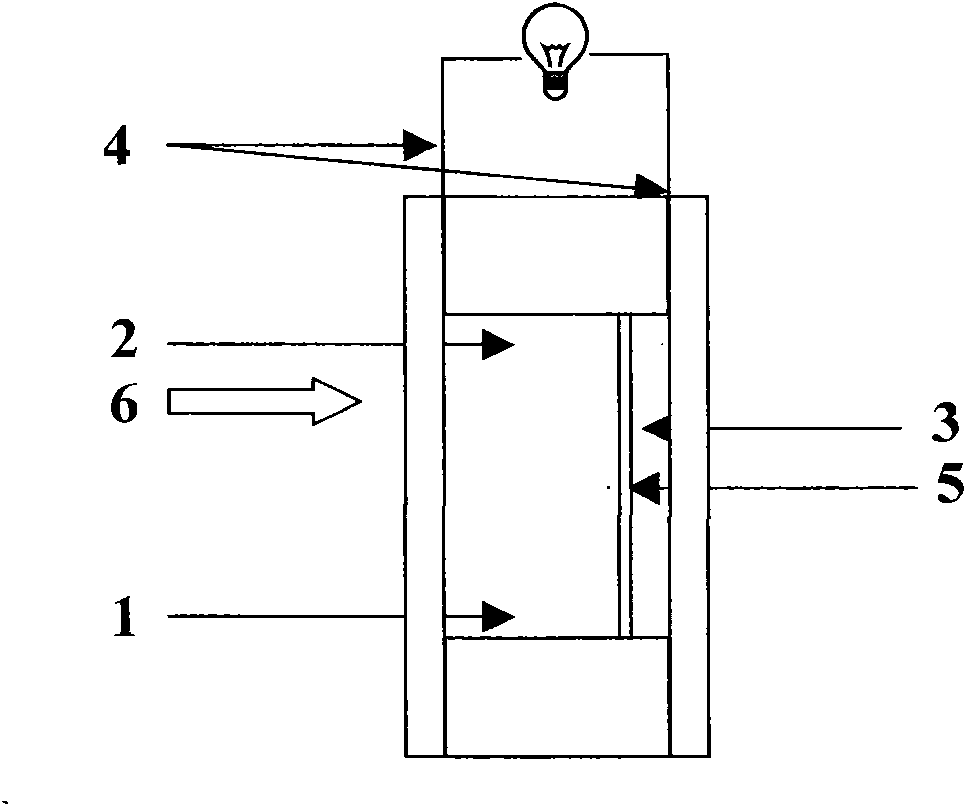

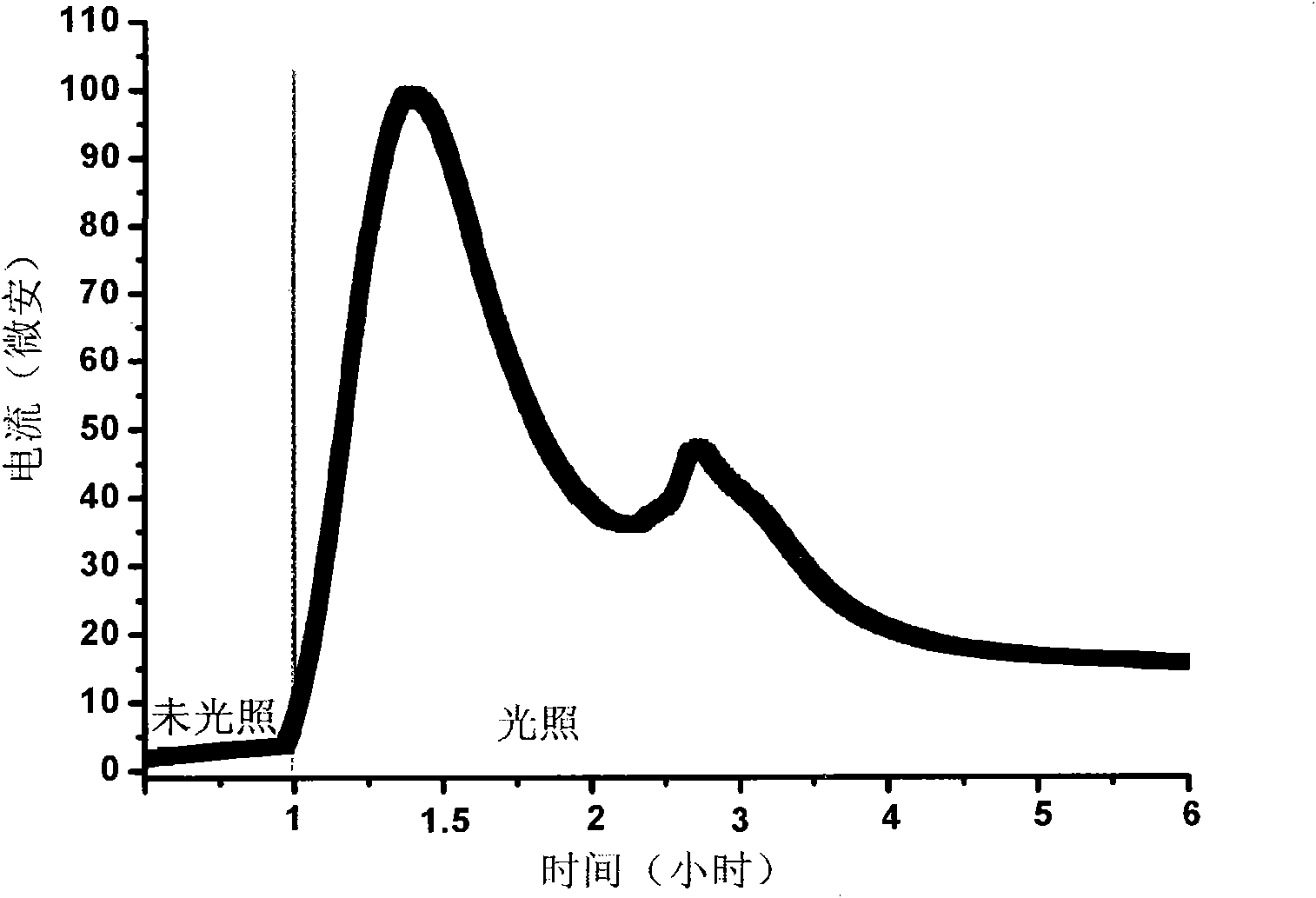

Photo-induced hydroxyl ionized solar battery

InactiveCN101872865ALow costPromote environmental protectionDeferred-action cellsPotassiumConcentration gradient

The invention relates to a photo-induced hydroxyl ionized solar battery for the combination of the solar energy and the light alkali molecules. In the invention, an enclosed container used as a photo-electrochemical pool is internally provided with an anion-exchange membrane, and the anion-exchange membrane divides the enclosed container into a first container and a second container which have different volumes; the first container contains the aqueous solution of the light alkali molecules or the aqueous solution of the light alkali molecules containing surfactant and sodium chloride or potassium chloride; the second container correspondingly contains water or the aqueous solution containing sodium chloride or potassium chloride and surfactant; one side wall of the first container is partially light-transmitted, and the transmitted light and the anion-exchange membrane form an incident angle of 90 degrees; the rest walls of the enclosed container are lightproof. In the invention, the light alkali molecules are photo-decomposed under the action of the light; the generated hydroxyl ions concentration gradient can be used for hydroxyl ion exchange by the anion-exchange membrane to generate electric current and potential; the persistency and the constancy of the electric current are realized by the inner circulations of the light alkali molecules and the generated ions generated after the light alkali molecules are photo-decomposed.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Liquid phase fluorination reaction device

InactiveCN101941884BReduce volumeAchieve cyclePreparation by halogen replacementProcess engineeringTower

The invention provides a liquid phase fluorination reaction device, which comprises a low-temperature reaction area (1), a high-temperature reaction area (2), a backflow tower (3), an HF feed mixer (4), an FH pre-heater (5), a chlorohydrocarbon feed mixer (6), an HF feeding pipe (7), a chlorohydrocarbon feeding pipe (8) and a discharge pipe (9) at the top of the backflow tower, wherein both the upper and lower parts of the low-temperature reaction area (1) are communicated with the high-temperature reaction area (2), a top outlet is communicated with a lower gas feeding inlet of the backflow tower (3); a top discharge port of the backflow tower is connected with the product discharge pipe (9), while a bottom discharge port is communicated with the HF feed mixer (4) and the chlorohydrocarbon feed mixer (6); the HF feed mixer (4) is communicated with the bottom feeding port of the high-temperature reaction area (2) through the FH pre-heater (5); the HF feed pipe (7) is connected with the feeding port of the HF feeding mixer (4); and the chlorohydrocarbon feeding pipe (8) is connected with the low-temperature reaction area (1) through the chlorohydrocarbon feed mixer (6). The liquid phase fluorination reaction device is mainly applied to a twp-step liquid phase fluorination reaction process for synthesizing hydrofluorocarbon.

Owner:XIAN MODERN CHEM RES INST

Water circulation device

The invention discloses a water circulation device. The water circulation device comprises a pipe A, 33 pipes B, a pipe C1, 32 pipes C2 and a pipe C3, wherein the adjacent pipes B are connected in a sealed mode through an adapter B2, so that the 33 pipes B are connected into an integral straight pipe; the lower end of the integral straight pipe is provided with an adapter B1; the upper end of the integral straight pipe is provided with an adapter B3; the lower end of the pipe A is provided with an adapter A1; the pipe C1 is communicated with the pipe A through the adapter A1 and communicated with the lower end of the integral straight pipe through the adapter B1; the pipe C3 is communicated with the integral straight pipe through the adapter B3; the other end of the pipe C3 is arranged at the upper end of the pipe A; the pipes C2 are arranged in the integral straight pipe; the middles of the pipes C2 are connected to the adapters B2 in a sealed mode; first through holes are arranged in the adapters B2 and located in the inner sides of the pipes B and the outer sides of the pipes C2; and second through holes are arranged in the pipe C3 and located in the pipes B and close to the adapter B3. According to the water circulation device, less energy is required during water circulation operation, more resources are saved, and the structure is compact.

Owner:黄守超

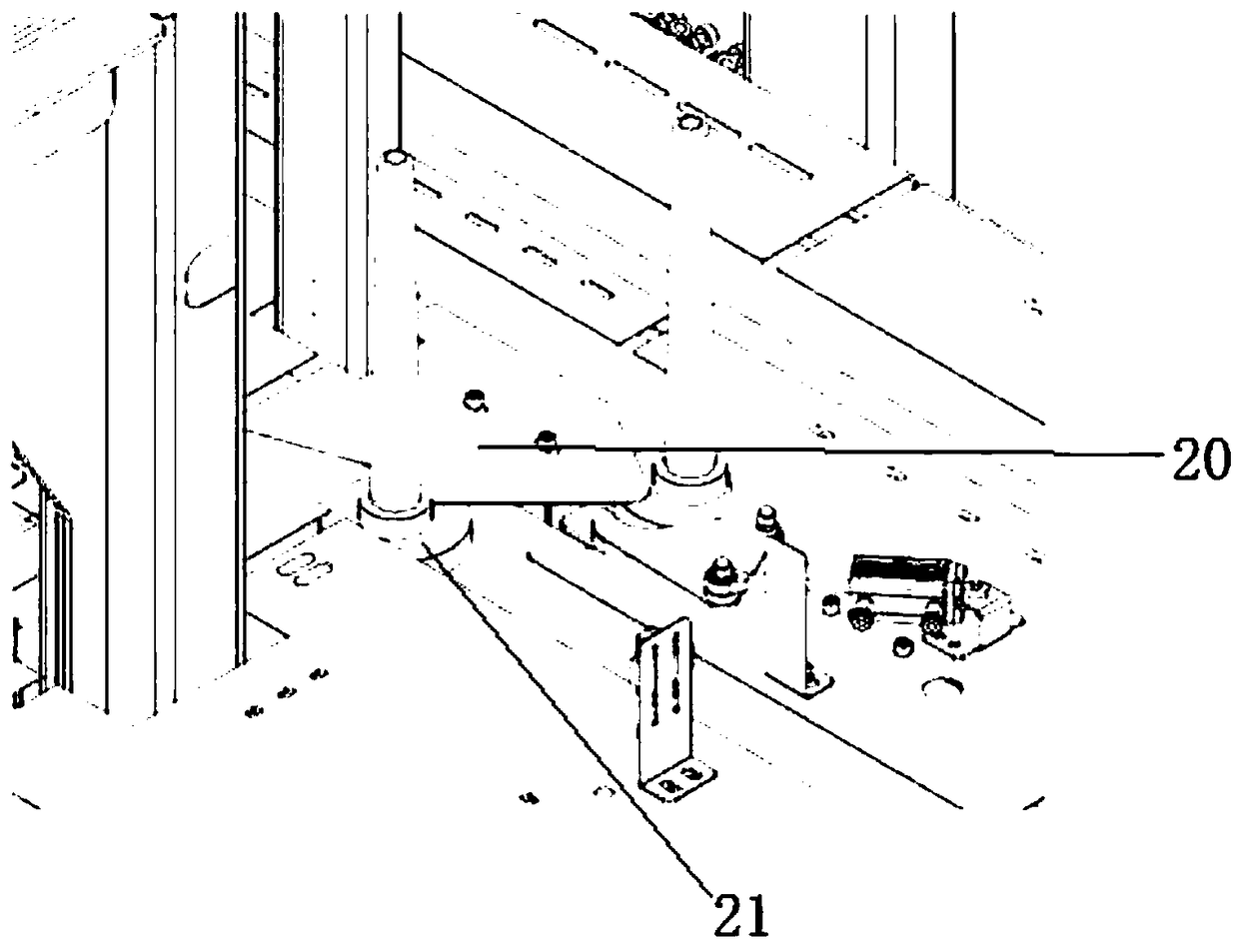

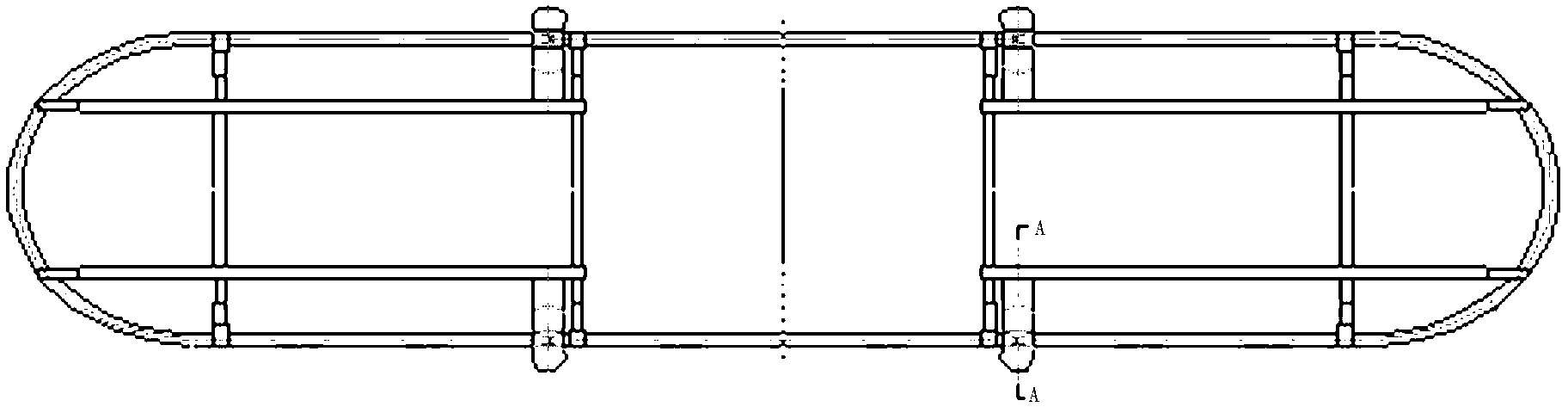

A fast-cycle atomic layer deposition device for micro-nanoparticles

ActiveCN109881180BImpact distributionSmooth transmissionChemical vapor deposition coatingLinear motionElectric machine

The invention belongs to the field of coating equipment manufacturing, and discloses rapidly circulating atomic layer deposition equipment for micro-nano particles. The rapidly circulating atomic layer deposition equipment for the micro-nano particles is formed by connecting two linear motion devices and two rotational motion devices end to end, and a sealed oval is formed. The linear motion devices comprise linear vibration motors, first cooling plates, first supporting plates, first heating pieces and material grooves which are sequentially connected from bottom to top in the vertical direction, atomic layer deposition reaction areas are arranged at one ends of the material grooves, and precursor spraying heads are mounted above the atomic layer deposition reaction areas. The rotationalmotion devices comprise rotational vibration motors, second cooling plates, second supporting plates, second heating pieces and rotational motion material grooves which are sequentially connected frombottom to top in the vertical direction. According to the rapidly circulating atomic layer deposition equipment for the micro-nano particles, the particles can circularly move in the material groovesat a stable motion speed, and the thicknesses of surface films of the micro-nano particle are controlled by controlling the times of the micro-nano particle passing through the atomic layer deposition reaction areas.

Owner:HUAZHONG UNIV OF SCI & TECH

A household material mixing device

ActiveCN109499442BRealize circular motionIncrease the lengthShaking/oscillating/vibrating mixersTransportation and packagingGear driveGear wheel

The invention belongs to the technical field of household electrical appliances, and specifically discloses a household material stirring device, which includes a mixing bucket, a rotating shaft is arranged in the mixing bucket, a cavity is arranged inside the rotating shaft, and chutes are provided at both ends of the cavity, and two chutes Sliding boards are installed inside, two racks are fixedly connected between the two sliding boards, first sprockets are installed on both ends of the cavity, and the two first sprockets are connected by a transmission chain, and two racks are slidingly installed on the rotating shaft. A second stirring rod; the second stirring rod is provided with a movable chamber, and the middle part of the movable chamber is provided with a transmission wheel meshing with the transmission chain. Extension rods are movably installed at both ends, and the drive wheel is connected with a transmission mechanism that drives the extension rod to extend repeatedly. This scheme can carry out all-round stirring and mixing of materials in the vertical and horizontal directions, the stirring is thorough, and the mixing effect is good.

Owner:宁波市弘露电子商务有限公司

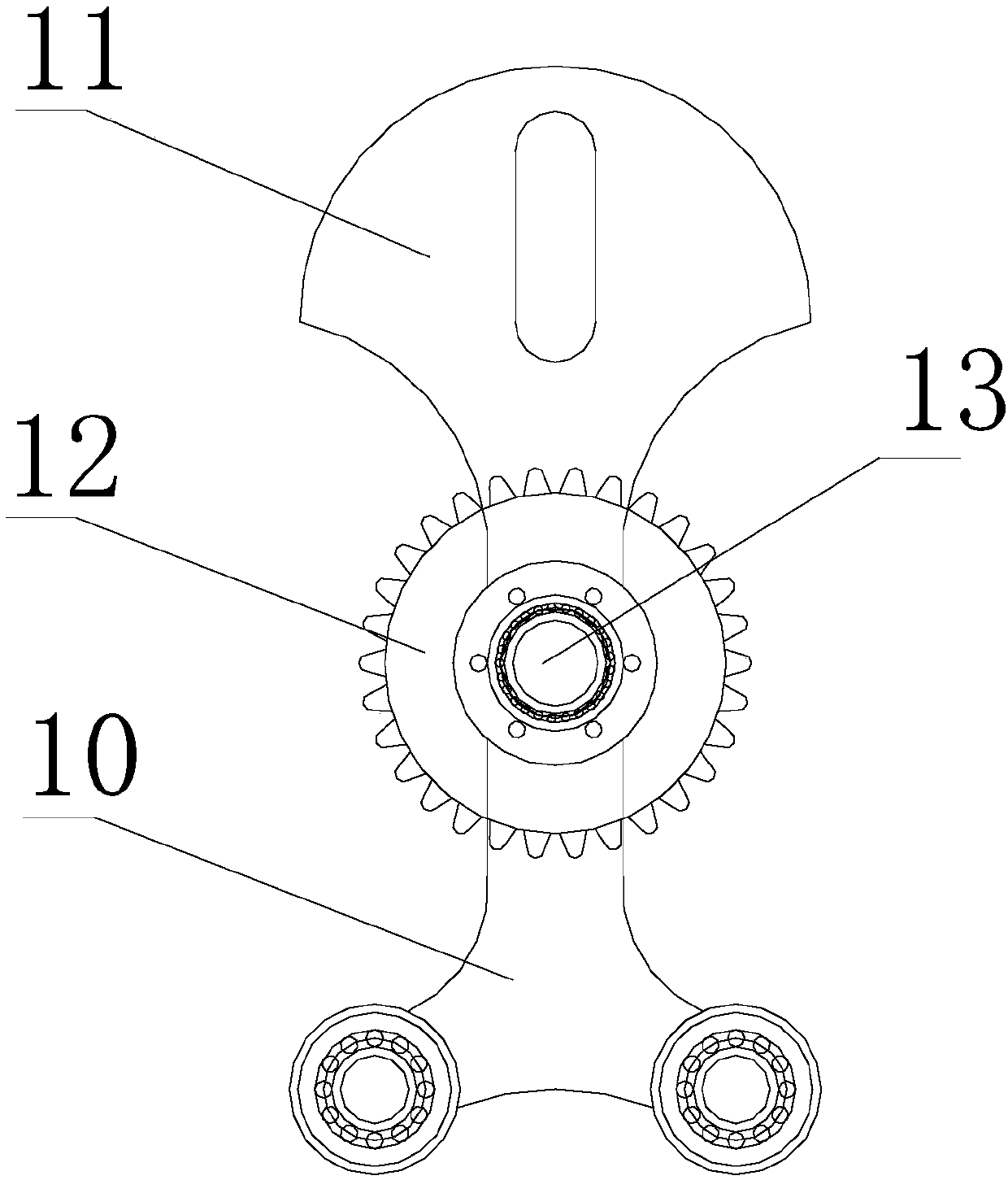

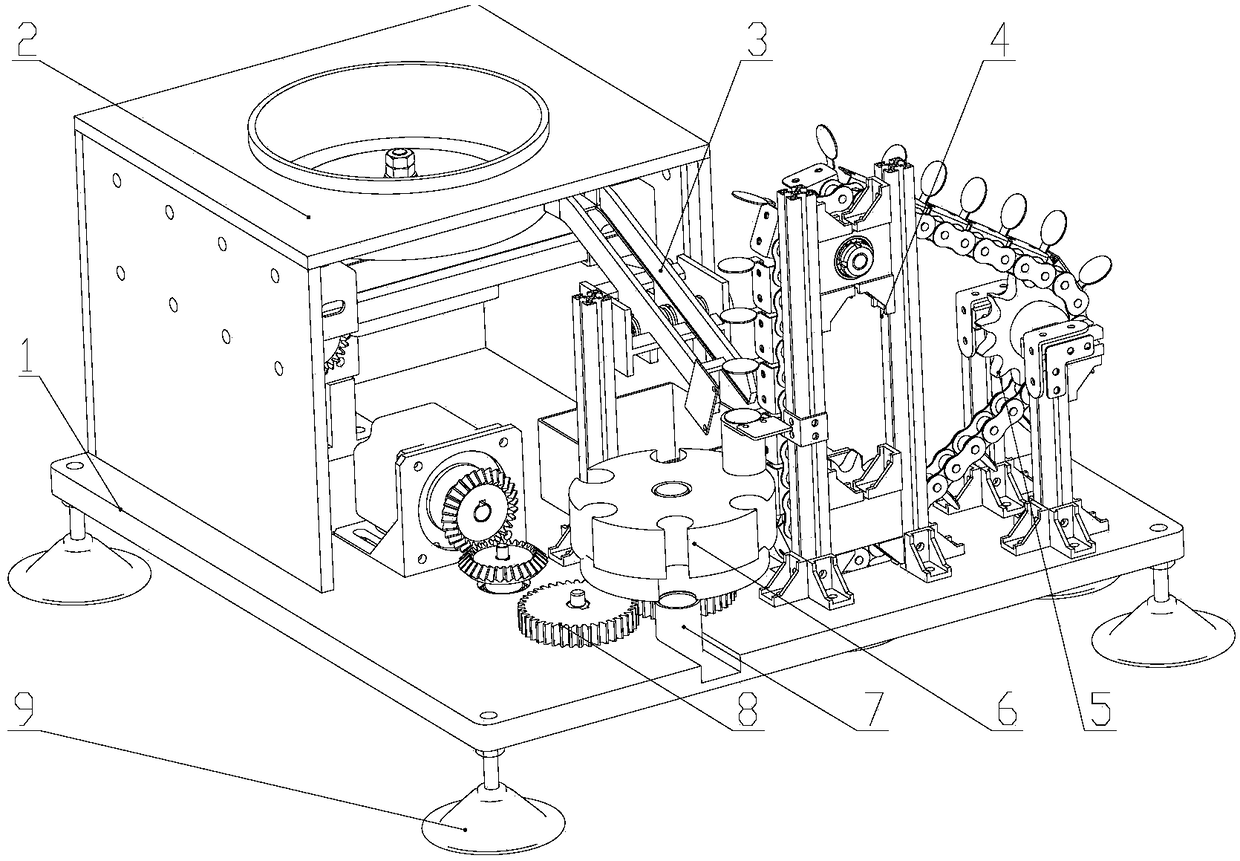

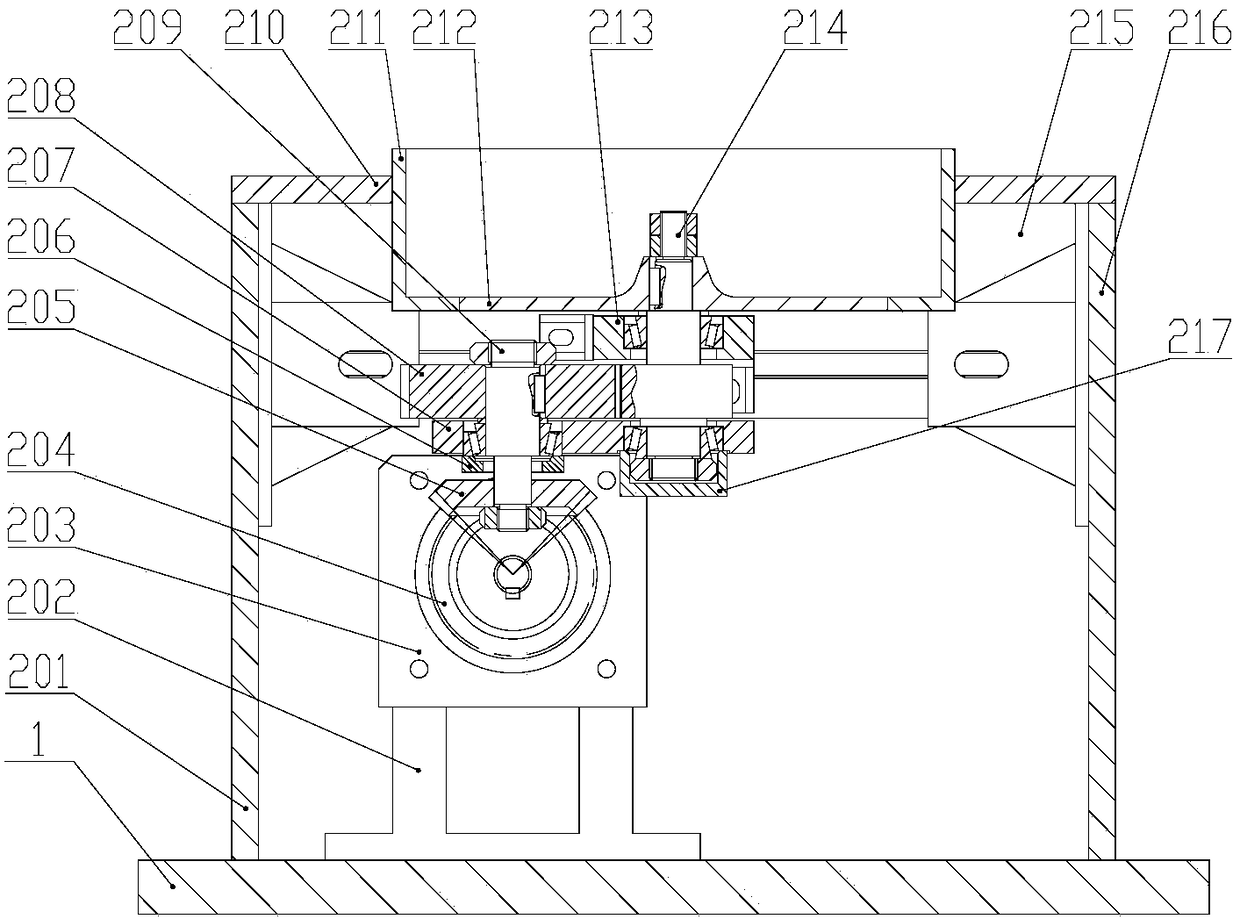

coin sorting machine

ActiveCN105869268BImprove separation efficiencyRealize circular motionCoin countersEngineeringPulley

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com