Coarse yarn circulating device in spinning frame

A circulation device and spinning frame technology, applied in textiles and papermaking, etc., can solve the problems of low work efficiency of roving workers, high labor intensity of roving workers, affecting the work of roving workers, etc., to achieve convenient transportation of roving, compact structure and simple design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

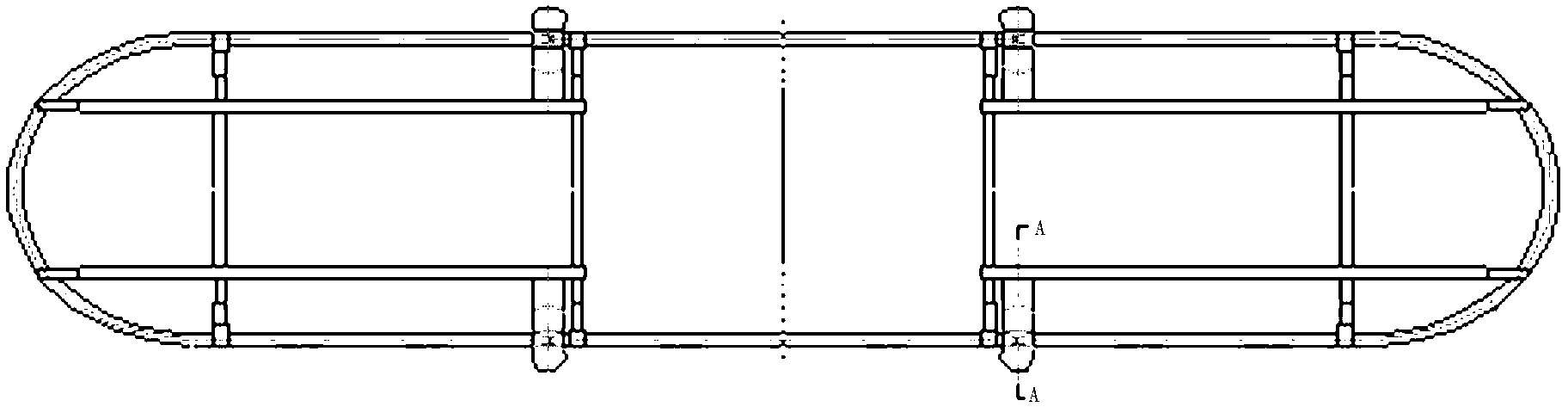

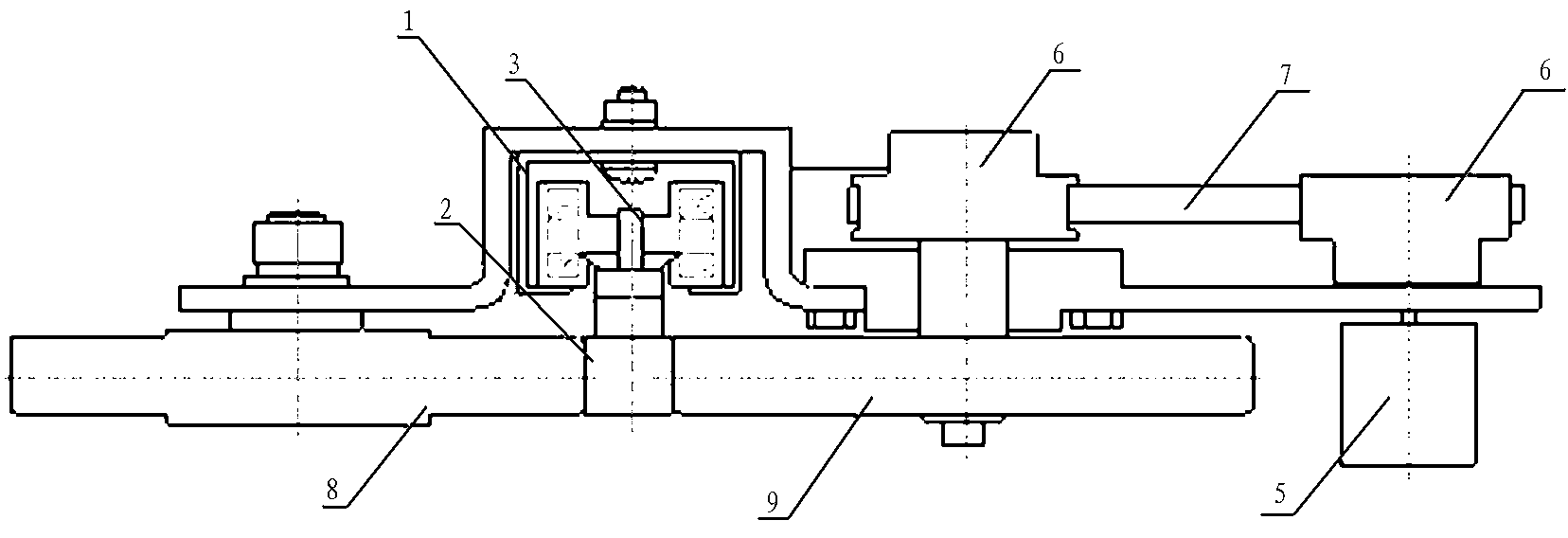

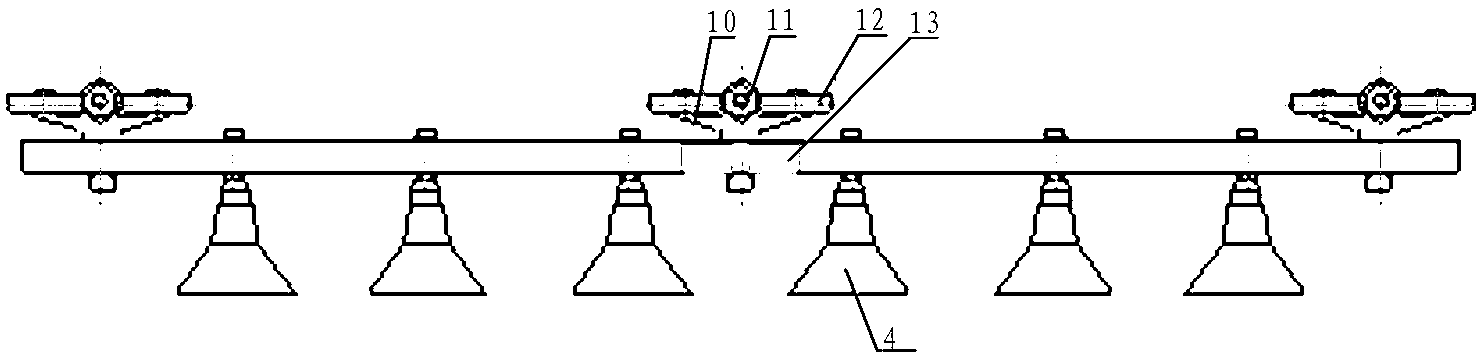

[0019] The roving circulation device in the spinning frame, which includes track 1, conveying rod 2, conveying rod guide device 3, hanging spindle 4, motor 5, gear 6, synchronous belt 7, first friction wheel 8 and second friction wheel 9, motor 5 is set under the track 1, the gear 6 is set on the output shaft of the motor 5, the first friction wheel 8 and the second friction wheel 9 are set on the track 1, the first friction wheel 8 is connected with the gear 6 through the synchronous belt 7, The conveying rod 2 is set in the groove of the track 1 through the conveying guide device 3, the hanging spindle 4 is arranged under the conveying rod 2, the two ends of the conveying rod 2 are respectively provided with hinges 13, and the adjacent hinges 13 pass through the conveying rod guiding device 3 on the shaft connection, the delivery rod 2 is located between the first friction wheel 8 and the second friction wheel 9, the first friction wheel 8, the second friction wheel 9 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com